Nitrogen gas sealed circulating PVA powder processing method

A closed cycle, nitrogen technology, applied in grain processing, etc., can solve the problems of easy combustion, large temperature influence, dust pollution, etc., and achieve the effect of improving product quality, concentrating particle size distribution width, and controlling oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

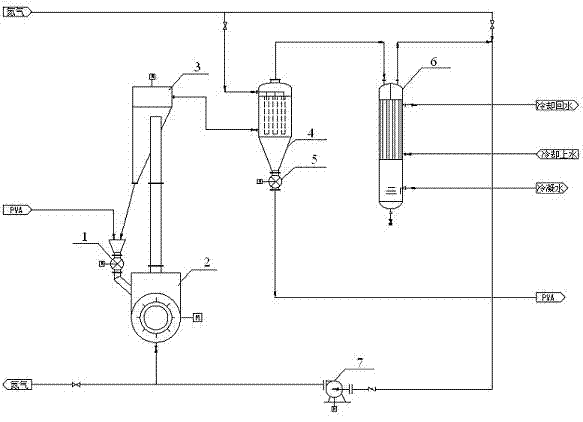

[0023] Such as figure 1 Shown, a kind of nitrogen airtight circulation PVA pulverization method comprises the following steps:

[0024] (1) The PVA polymer or resin with a length of 2-5mm, a width of 1-3mm, a thickness of 0.3-1.2mm and a temperature of 28-45°C is continuously and evenly added to the crusher 2 after passing through the rotary air locker I1 to obtain PVA particles.

[0025] Among them: Crusher 2 is provided by Tianhua Chemical Machinery and Automation Research and Design Institute Co., Ltd., and its patent number is ZL201220651933.3.

[0026] (2) Input nitrogen gas to the crusher 2, so that the PVA particles are transported to the classifier 3 for classification, and the blades set on the top of the classifier 3 are rotated to rotate the PVA particles and nitrogen gas to obtain large particles of PVA and particles with a particle size of 20-40 mesh, Nitrogen gas for qualified PVA particles with a temperature <45°C; large particles of PVA fall into the lower cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com