Double-air supply airflow mill

A technology of jet mill and air supply pipeline, which is applied in grain processing and other directions, can solve the problems of insufficient particle size distribution of magnetic powder, increased production cost, and difficulty in controlling the oxygen content of magnetic powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

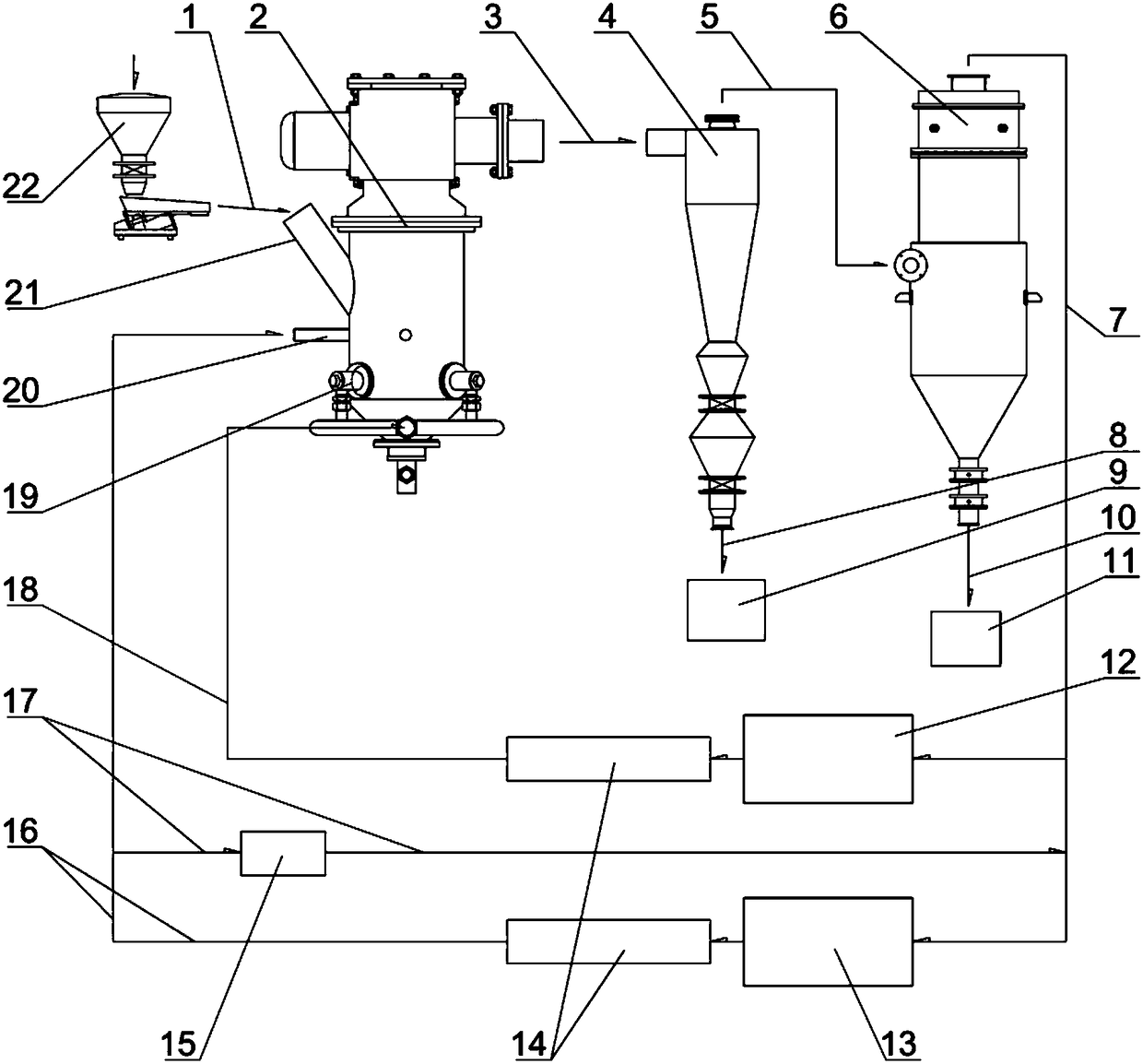

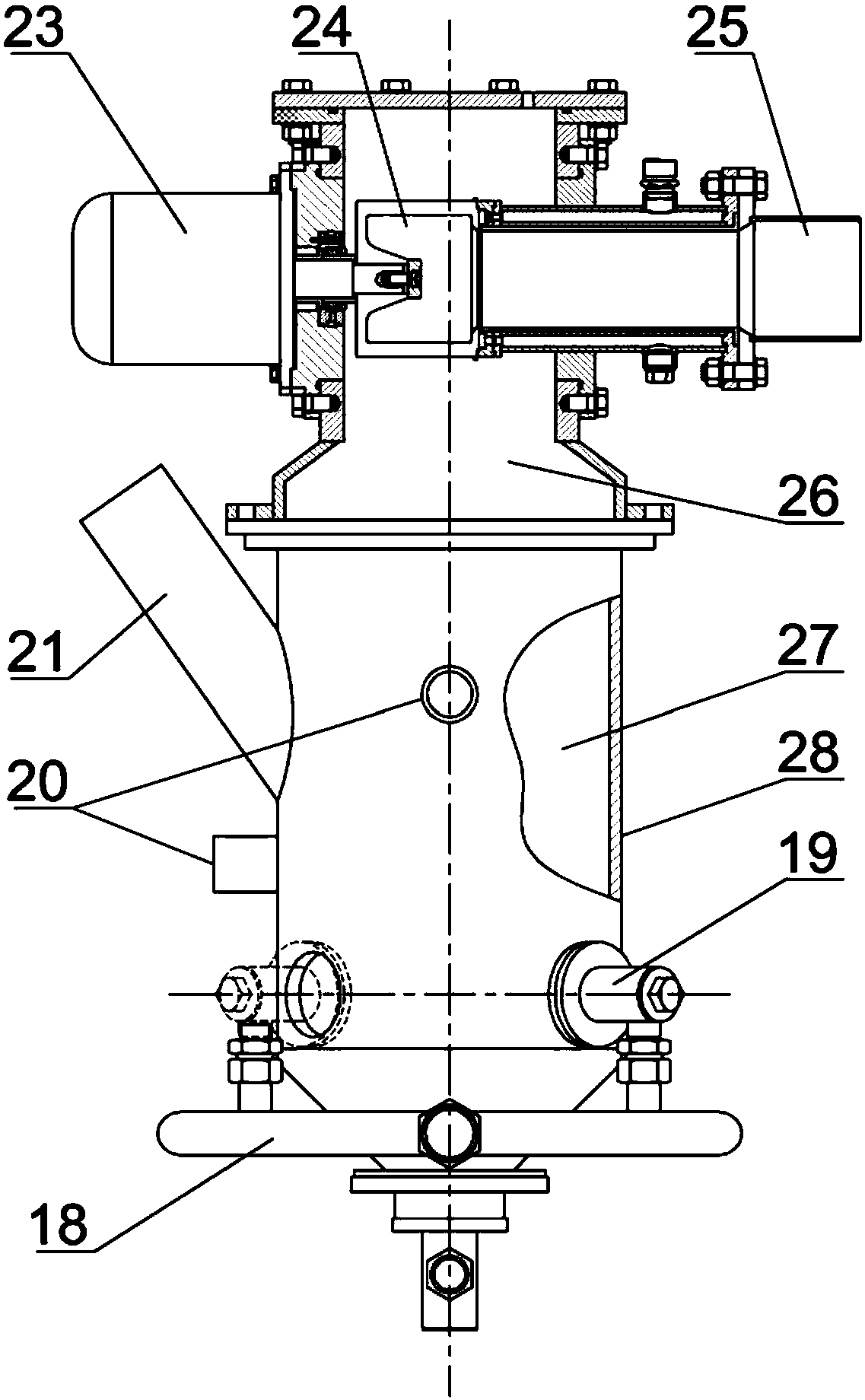

[0012] The double air-supply jet mill includes a main engine 2, a separator 4, a filter 6, and a compressor 12 that are arranged and connected in sequence. The air outlet of the filter is connected to the air inlet of the compressor through the return air pipeline 7, and the air outlet of the compressor It is connected with the air inlet 19 of the nozzle in the main engine through the high-pressure air supply pipeline 18, and is characterized in that: it also includes a fan 13, the main engine is provided with at least one low-pressure air inlet 20, and the low-pressure air inlet of the main engine passes through the low-pressure air supply pipeline 16. It is connected with the exhaust port of the fan, and the air inlet of the fan is connected with the return air pipe. A bypass pipeline 17 is connected between the low-pressure gas supply pipeline and the return gas pipeline, and a regulating valve 15 is arranged on the bypass pipeline.

[0013] The main machine is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com