Direct synthesis of large-area graphene oxide based on plasma chemically enhanced vapor deposition

A plasma and vapor deposition technology, applied in the field of material science, can solve the problems of destroying the integrity of graphene oxide film and long reaction time, and achieve the effects of controllable oxygen content, short reaction time and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

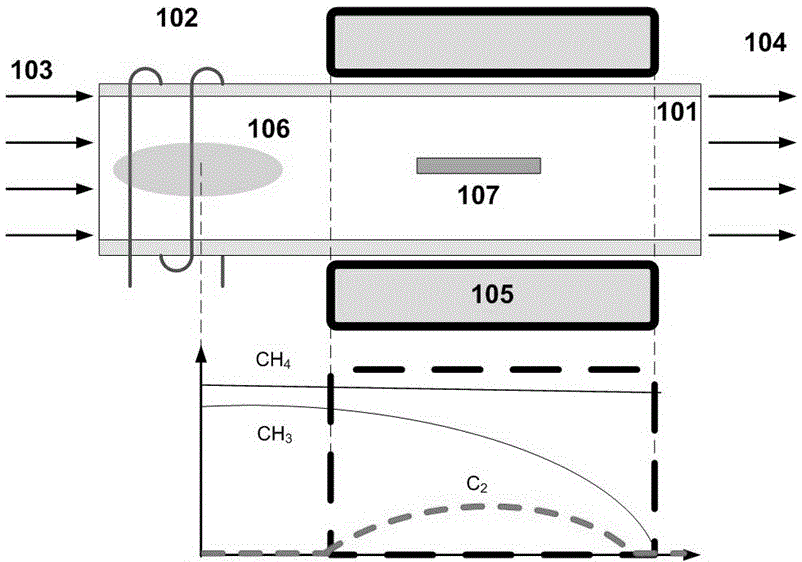

[0026] figure 1 Shown is a schematic of the plasma-enhanced chemical vapor deposition system used to synthesize graphene oxide. In this example, we use 99.998% pure copper foil with a thickness of 25 μm as the substrate.

[0027] First, put the cut copper foil into acetone and ultrasonically clean it for 10 minutes. After taking it out, rinse it with deionized water, and then soak it in dilute hydrochloric acid (5% mass concentration) for 10 minutes to remove the oxide on the surface of the copper foil. Then rinse the copper foil in deionized water, dry it with 99% nitrogen and put it in an incubator at 70°C to further remove the moisture on the surface. The copper foil after the above treatment can be used as the copper foil substrate 107 for graphene oxide synthesis.

[0028] The plasma enhanced chemical vapor deposition system used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com