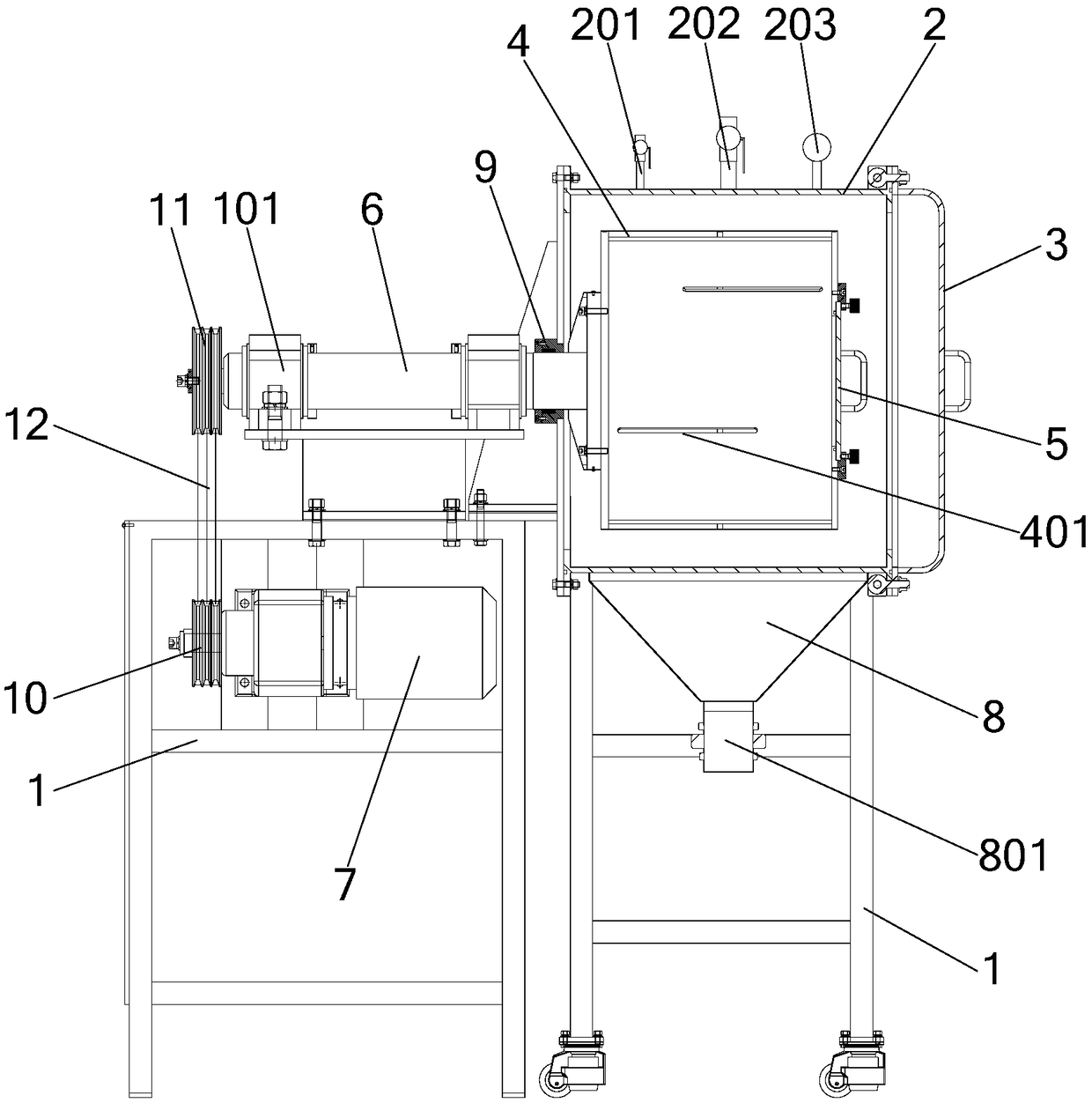

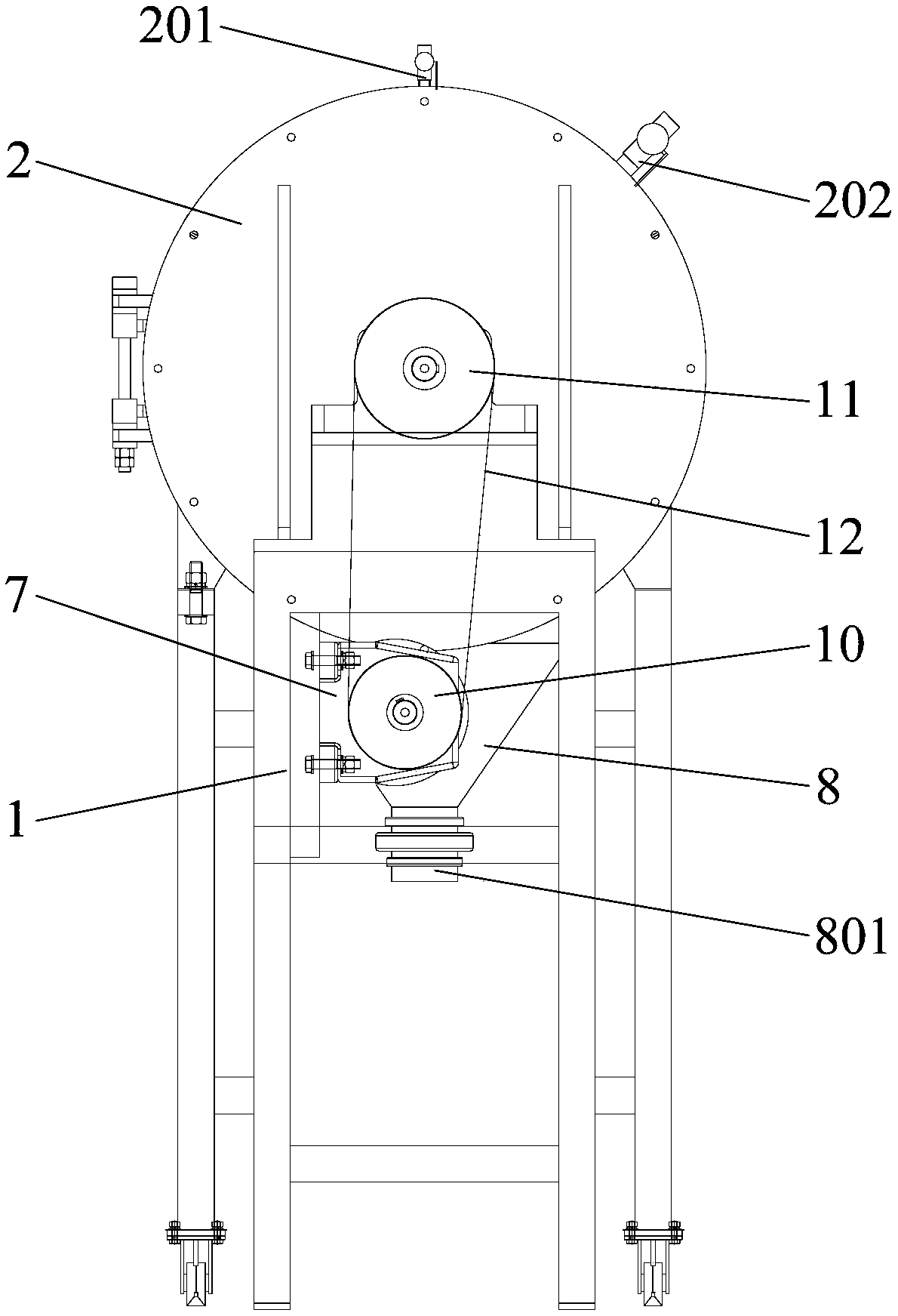

A kind of low oxidation metal powder and its preparation method and sealed ball mill for preparation

A metal powder, low-oxidation technology, applied in the field of metal powder processing, can solve the problems of failing to meet process requirements and reducing the purity of metal powder, and achieve the effect of reducing sealing requirements and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A titanium suboxide powder, the particle size is 100 mesh, the oxygen content is less than 0.15%, the nitrogen content is less than 0.02%, and the hydrogen content is less than 0.03%. It is ground into 100-mesh powder, and the powder is subjected to dehydrogenation and oxygen reduction treatment to obtain agglomerated metal suboxidation powder with an oxygen content of less than 0.15%, and then the agglomerated metal suboxidation powder is ground into powder under inert gas conditions , That is, titanium suboxide powder with a particle size of 100 mesh. Among them, the dehydrogenation and oxygen reduction treatment is carried out by conventional technology.

Embodiment 2

[0037] A low-oxidation Ti6Al4V powder, the particle size is 200 mesh, the oxygen content is less than 0.15%, the nitrogen content is less than 0.02%, and the hydrogen content is less than 0.03%. Grinding into 100-mesh powder, dehydrogenating and deoxidizing the powder to obtain agglomerated low-oxidized Ti6Al4V powder with an oxygen content of less than 0.15%, and then pulverizing the agglomerated low-oxidized Ti6Al4V powder into powder under inert gas conditions, That is, the low-oxidation Ti6Al4V powder with a particle size of 200 meshes was obtained. Among them, the dehydrogenation and oxygen reduction treatment is carried out by conventional technology.

[0038] The low-oxidation metal powder prepared in the above examples 1-2 has low oxygen content and high purity, and the preparation process does not affect its purity. The powder particle size is uniform, high in quality, and low in cost. It can be used as a spherical powder raw material for 3D printing, and powder cold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com