Gas atomization method for preparing oxygen supersaturated iron-based alloy powder

An iron-based alloy and gas atomization technology, which is applied in the gas atomization preparation of oxygen supersaturated iron-based alloy powder and the preparation of gas atomized iron-based alloy powder, can solve the long process cycle and the cost of high-purity metal bars High production efficiency, low production efficiency and other problems, to achieve the effect of simple preparation process, conducive to consolidation and forming, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of Fe-14.15Cr-0.50Ti-3.19W-0.25Y iron-based alloy powder with an oxygen content of 0.31%

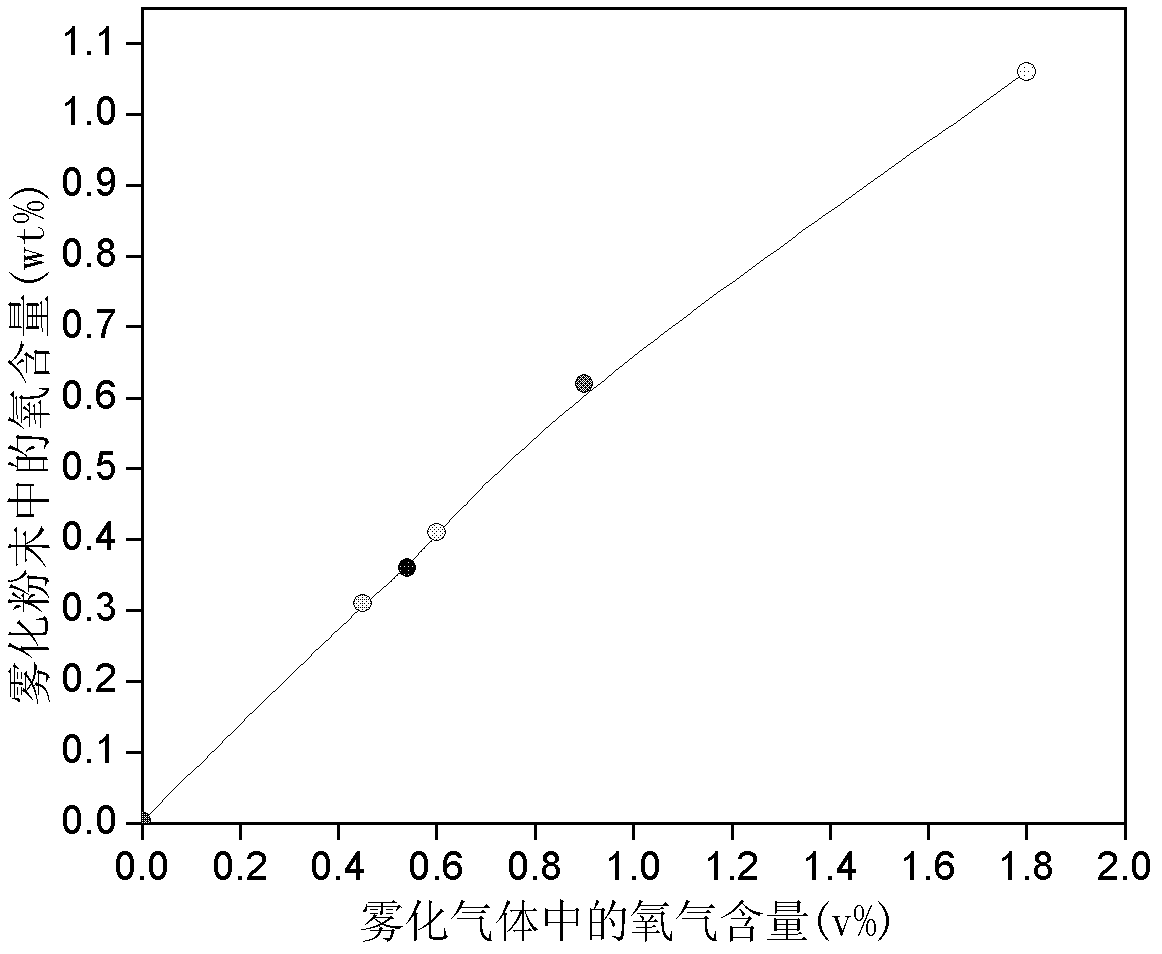

[0045] According to the alloy composition requirements, pure metals and intermediate alloys are used to prepare alloy raw materials; according to the alloy oxygen content requirements, according to the attached figure 1 Determine to adopt the argon gas that contains 0.45% (volume ratio) oxygen as atomization medium; The alloy raw material of preparation is placed in the smelting crucible of close-coupled atomization equipment, vacuum degree is drawn to 10 -1 Above Pa, then fill it with protective atmosphere, smelt, and heat the atomizing bag to 1600°C at the same time; when the alloy is completely alloyed, adjust the temperature of the alloy melt to 120°C-130°C above the melting point of the alloy and stabilize it, then put the melt Pour the body into the atomization bag, open the atomization gas valve for atomization; perform atomization in a tightly couple...

Embodiment 2

[0046] Example 2: Preparation of Fe-14.13Cr-0.48Ti-3.01W-0.36Y iron-based alloy powder with an oxygen content of 1.06%

[0047] According to the oxygen content requirements of the alloy, according to the attached figure 1 Determine to adopt the argon gas that contains 1.80% (volume ratio) oxygen as atomization medium, then according to the method and step of example 1, prepare the iron-based alloy powder that oxygen content is 1.06%, no oxide, used atomization gas pressure is 4.0 MPa.

Embodiment 3

[0048] Example 3: Preparation of Fe-12.35Cr-0.49Ti-2.5W-0.25Y iron-based alloy powder with an oxygen content of 0.41%

[0049] According to the oxygen content requirements of the alloy, according to the attached figure 1 Determine to adopt the argon gas that contains 0.60% (volume ratio) oxygen as atomization medium, then according to the method and step of example 1, prepare the iron-based alloy powder that oxygen content is 0.41%, no oxide, used atomization gas pressure is 5.5 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com