Titanium carbide-based solid solution metal ceramic and preparation method thereof

A cermet and solid solution technology, applied in the field of cermet materials and powder metallurgy, can solve the problems of high energy consumption, long preparation period, difficult control of oxygen content, etc., and achieve low energy consumption, easy control of oxygen content, and low oxygen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, comprises the following steps successively:

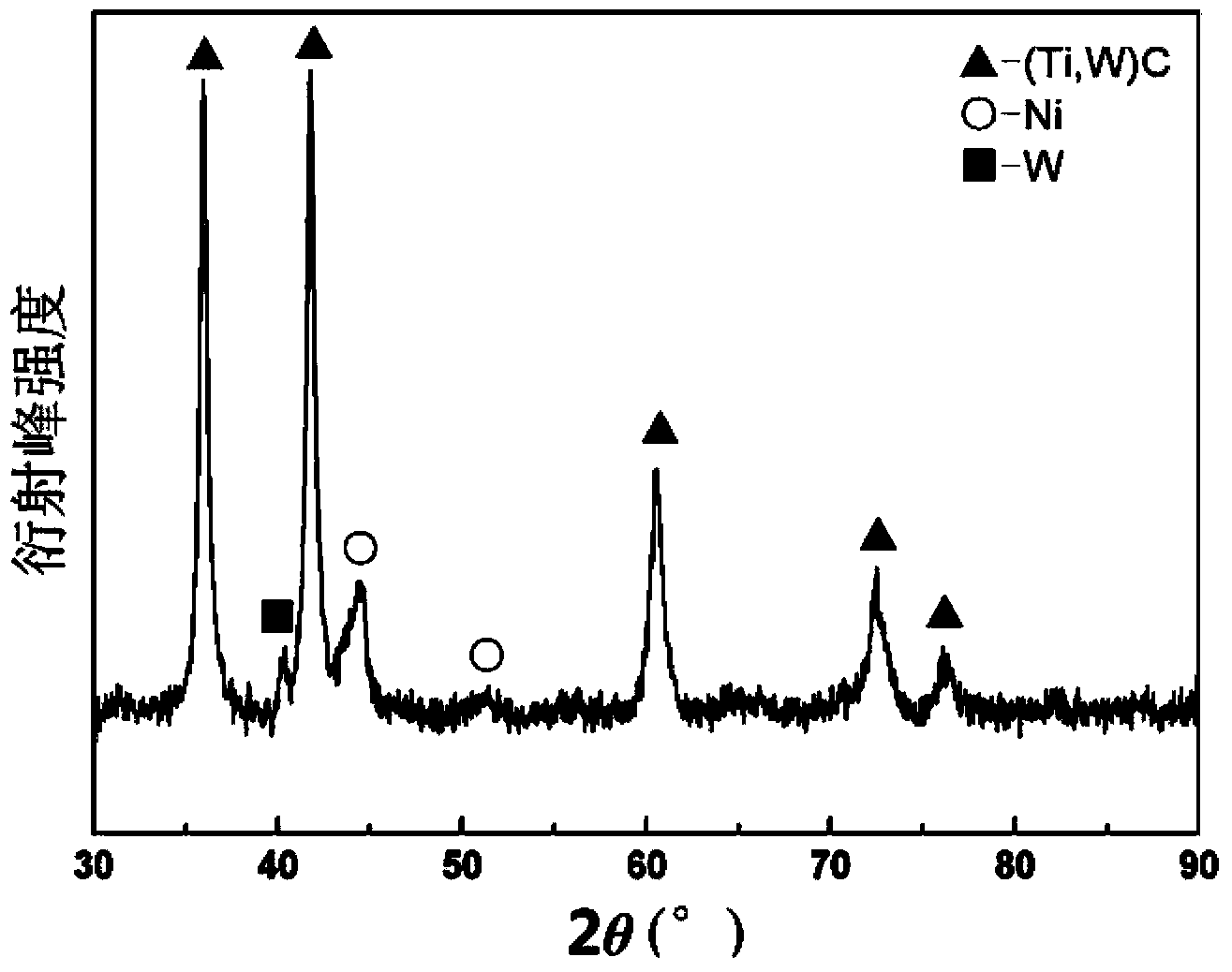

[0022] (1) Put Ti powder, W powder, Ni powder and graphite powder into the ball mill tank, fill it with argon, and perform high-energy ball milling on a planetary ball mill to induce a self-propagating reaction to obtain (Ti, W)C-Ni composite Raw material powder, its X-ray diffraction pattern sees figure 1 The mass percent of each component is: Ti powder 54.61%, W powder 11.02%, Ni powder 20.00%, graphite powder 14.37%;

[0023] Ti powder has a particle size of 45 μm and a purity of 99%, W powder has a particle size of 3.80 μm and a purity of 99.9%, Ni powder has a particle size of 2.25 μm and a purity of 99.8%, graphite powder has a particle size of 5.5 μm and a purity of 99.9%;

[0024] When performing high-energy ball milling, the ball-to-material ratio is 25:1, the rotational speed is 350rpm, and the ball-milling time is 6h;

[0025] (2) The obtained (Ti, W)C-Ni composite raw material powder is mixed with...

Embodiment 2

[0028] Embodiment 2, comprises the following steps successively:

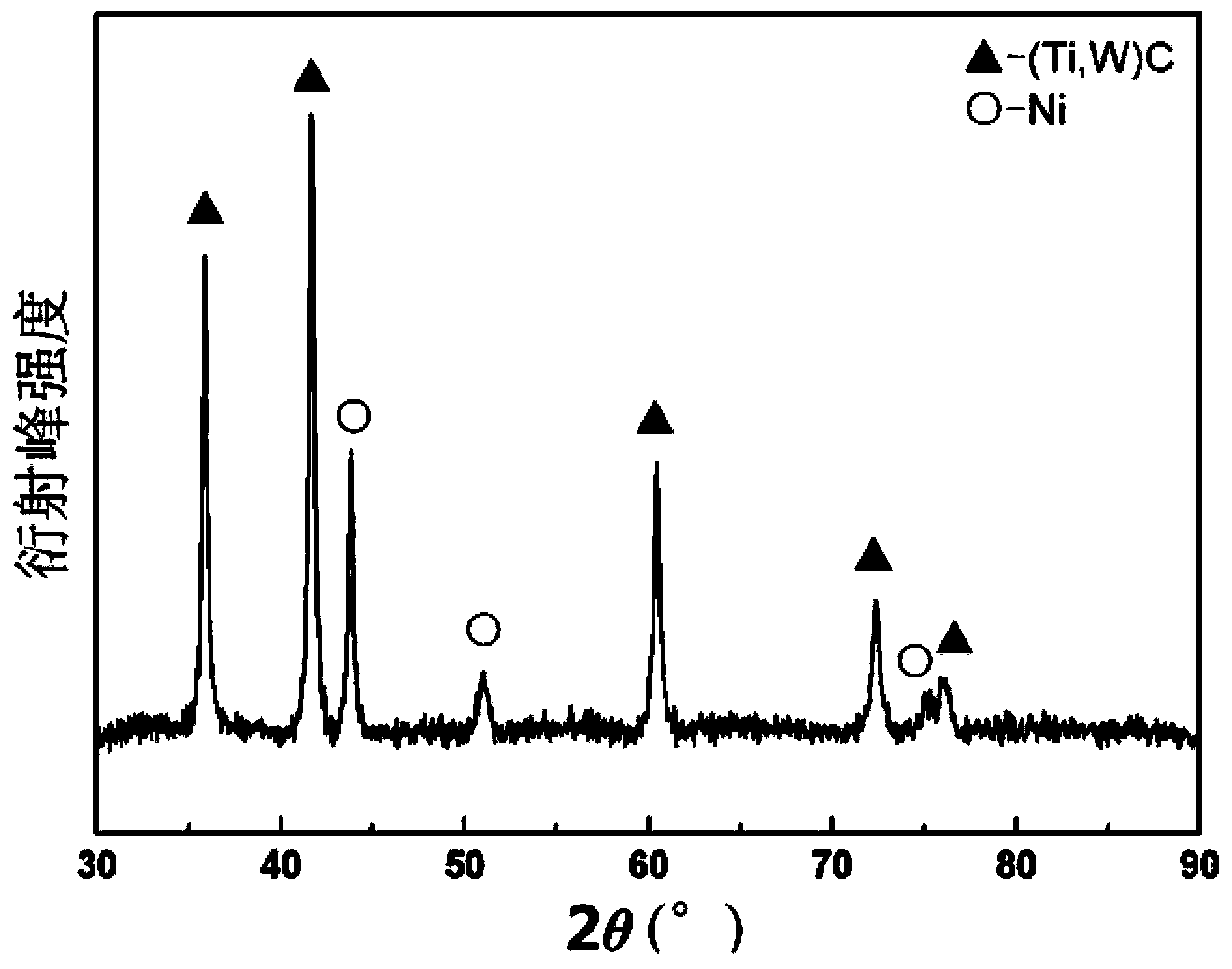

[0029] (1) Put Ti powder, W powder, Ni powder and graphite powder into the ball mill tank, fill it with argon, and perform high-energy ball milling on a planetary ball mill to induce a self-propagating reaction to obtain (Ti, W)C-Ni composite Raw material powder; the mass percent of each component is: Ti powder 40.60%, W powder 27.46%, Ni powder 20.00%, graphite powder 11.94%;

[0030] Ti powder has a particle size of 45 μm and a purity of 99%, W powder has a particle size of 3.80 μm and a purity of 99.9%, Ni powder has a particle size of 2.25 μm and a purity of 99.8%, graphite powder has a particle size of 5.5 μm and a purity of 99.9%;

[0031]When performing high-energy ball milling, the ball-to-material ratio is 30:1, the rotation speed is 400 rpm, and the ball milling time is 4 hours.

[0032] (2) The obtained (Ti, W)C-Ni composite raw material powder is mixed with 3wt% molding agent polyethylene glycol (P...

Embodiment 3

[0035] Embodiment 3, comprises the following steps successively:

[0036] (1) Put Ti powder, W powder, Ni powder and graphite powder into the ball mill tank, fill it with argon, and perform high-energy ball milling on a planetary ball mill to induce a self-propagating reaction to obtain (Ti, W)C-Ni composite Raw material powder; the mass percent of each component is: Ti powder 48.13%, W powder 20.50%, Ni powder 18.00%, graphite powder 13.37%;

[0037] Ti powder has a particle size of 45 μm and a purity of 99%, W powder has a particle size of 3.80 μm and a purity of 99.9%, Ni powder has a particle size of 2.25 μm and a purity of 99.8%, graphite powder has a particle size of 5.5 μm and a purity of 99.9%;

[0038] When performing high-energy ball milling, the ball-to-material ratio is 30:1, the rotational speed is 350 rpm, and the ball milling time is 5 hours.

[0039] (2) The obtained (Ti, W)C-Ni composite raw material powder is mixed with 2.5wt% molding agent polyethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com