Patents

Literature

42results about How to "Realize cycle drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

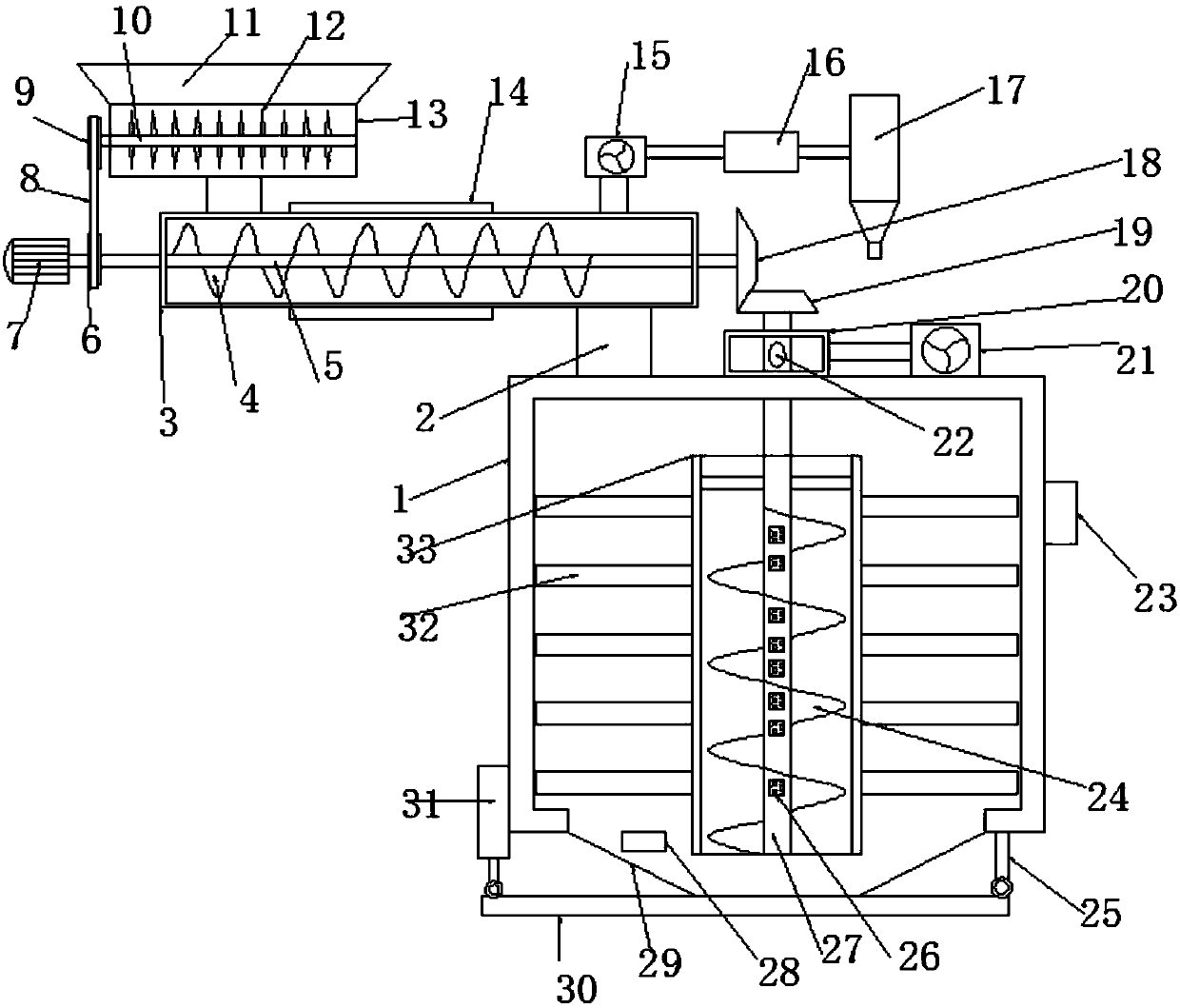

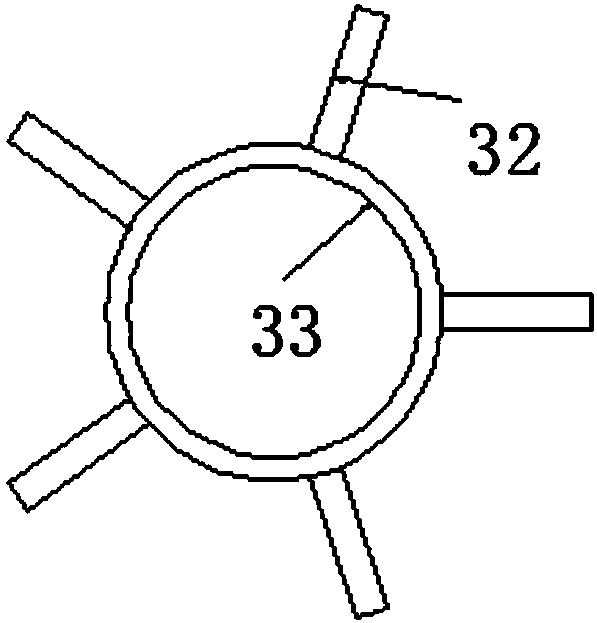

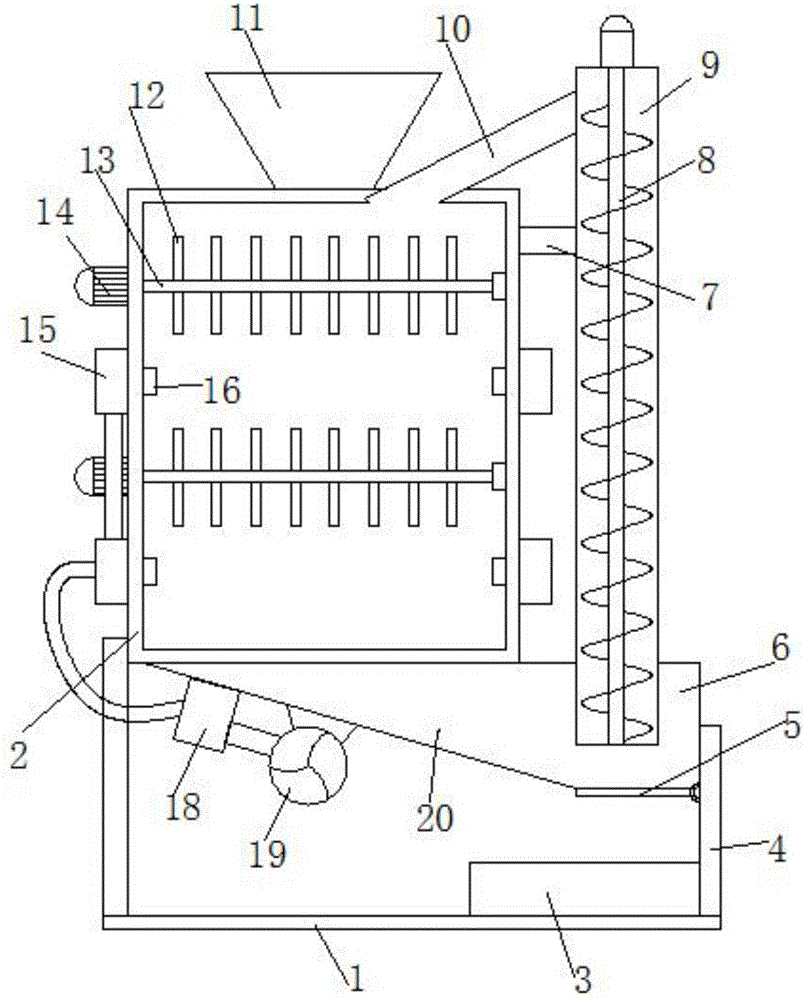

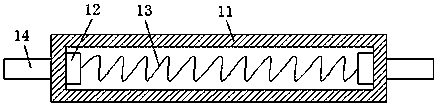

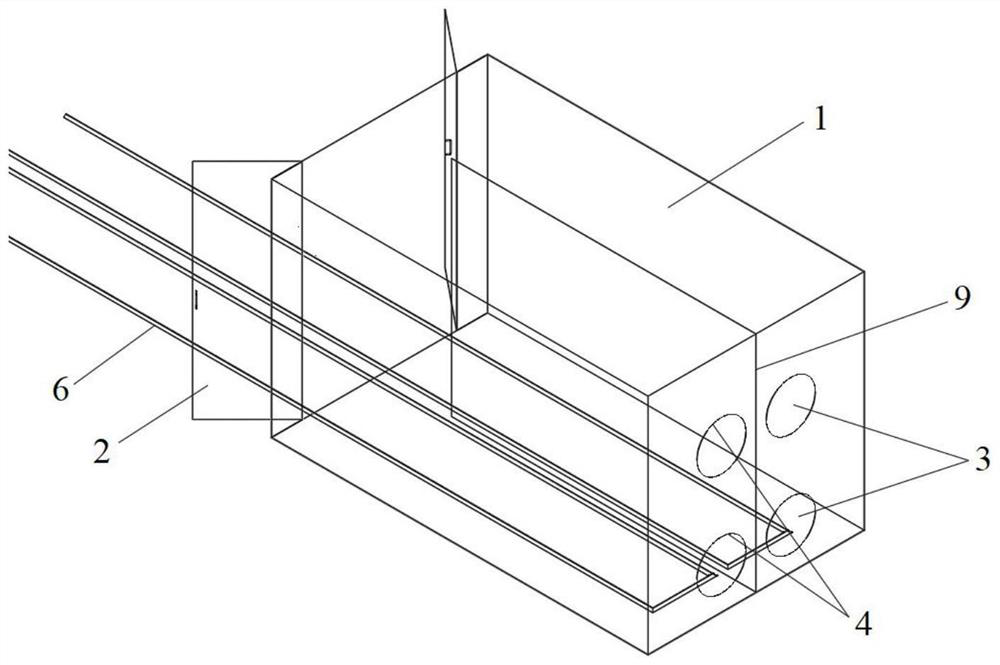

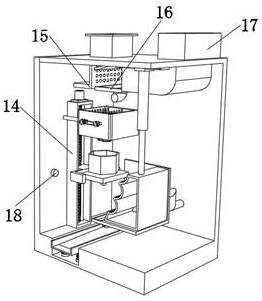

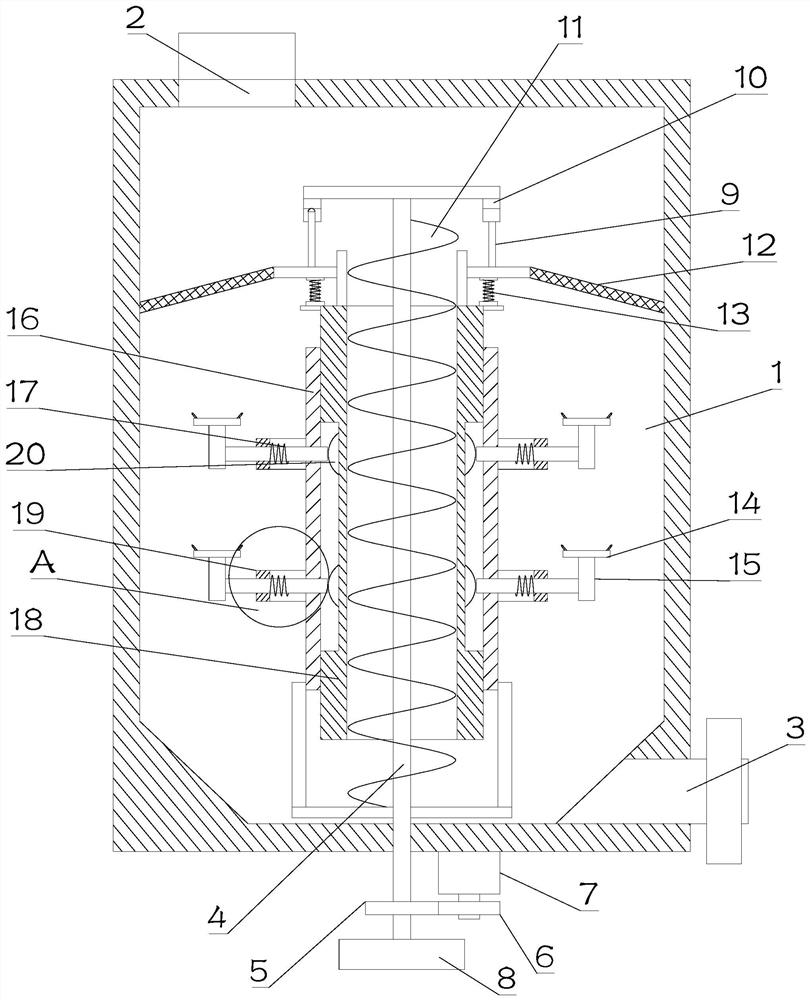

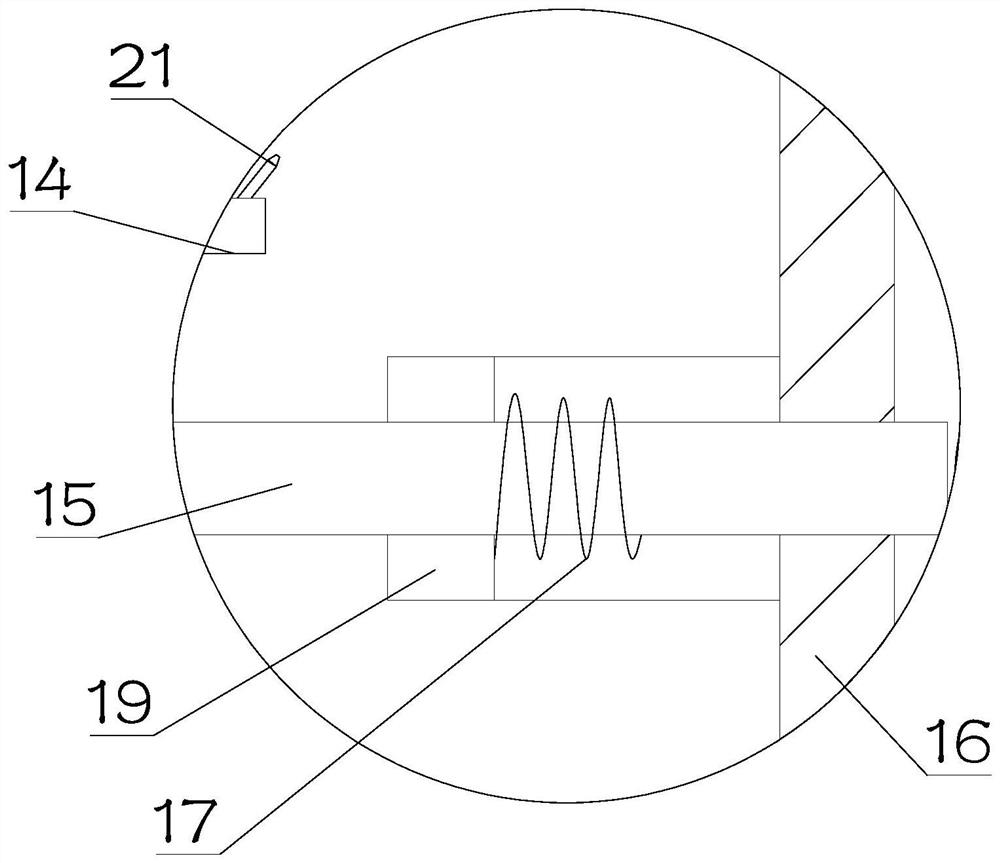

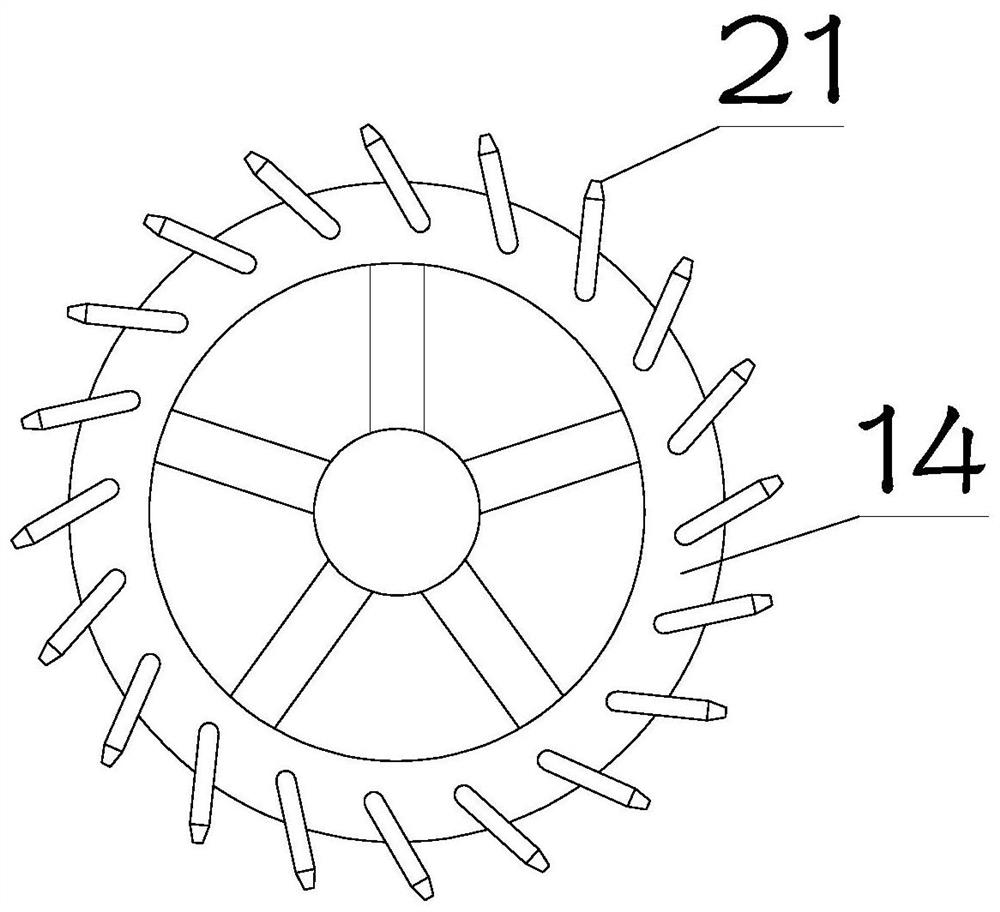

Internal circulation type traditional Chinese medicine drying equipment

InactiveCN107940974AReduce volumeFully dryDrying machine combinationsDrying gas arrangementsSpiral bladeBiochemical engineering

The invention discloses internal circulation type traditional Chinese medicine drying equipment. The equipment comprises a processing box, a connecting channel and a feeding cylinder; the connecting channel is formed in the left upper end of the processing box, and the upper end of the connecting channel is connected with and fixed to the feeding cylinder, a pushing shaft is arranged in the feeding cylinder in a penetrating mode, and a spiral blade is arranged on the pushing shaft; a heating block sleeves the outer side of the feeding cylinder and is used for heating materials in the feeding cylinder, the two ends of the pushing shaft penetrate through the feeding cylinder, the left end of the pushing shaft is fixedly connected with the output end of a driving motor, and a driving gear isarranged at the right end of the pushing shaft; and a driving belt wheel is arranged on the part, close to the driving motor, of the pushing shaft, a feeding pipe is arranged on the upper left side ofthe feeding cylinder, and a crushing box is arranged at the upper end of the feeding pipe. According to the equipment, the structure is simple and reasonable; the materials are crushed in advance sothat the size of the materials can be reduced, and later drying can be facilitated; and meanwhile, circulation drying of the materials in the processing box can be realized through the equipment so that the materials can be fully dried, and the equipment is high in practicability.

Owner:马良彬

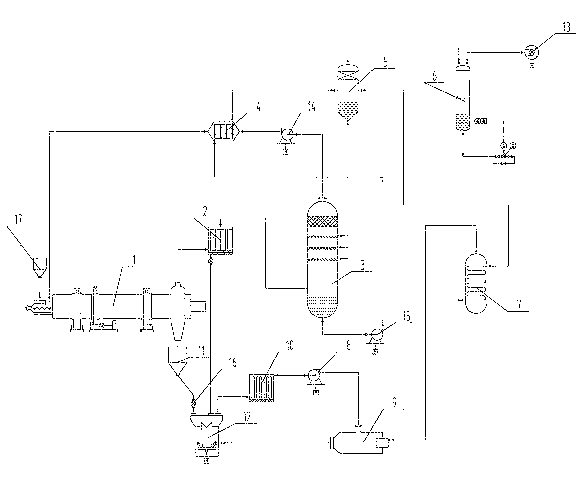

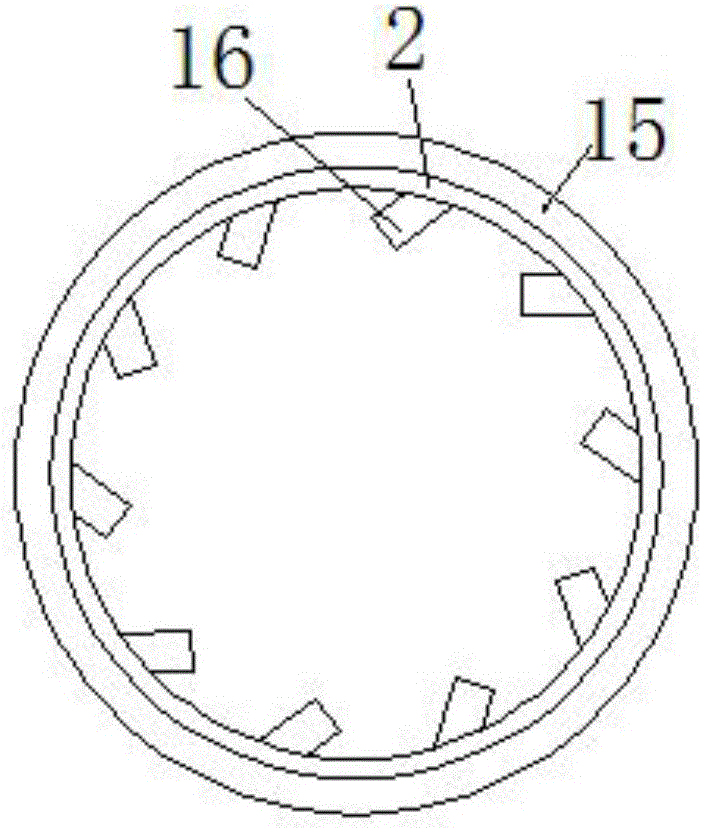

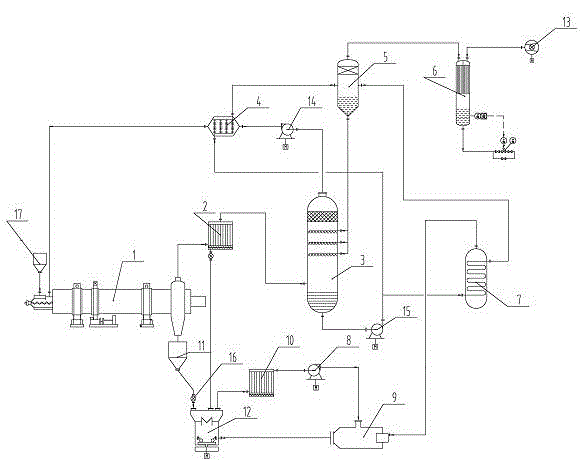

Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

ActiveCN103234214AReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationMoistureVacuum pump

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

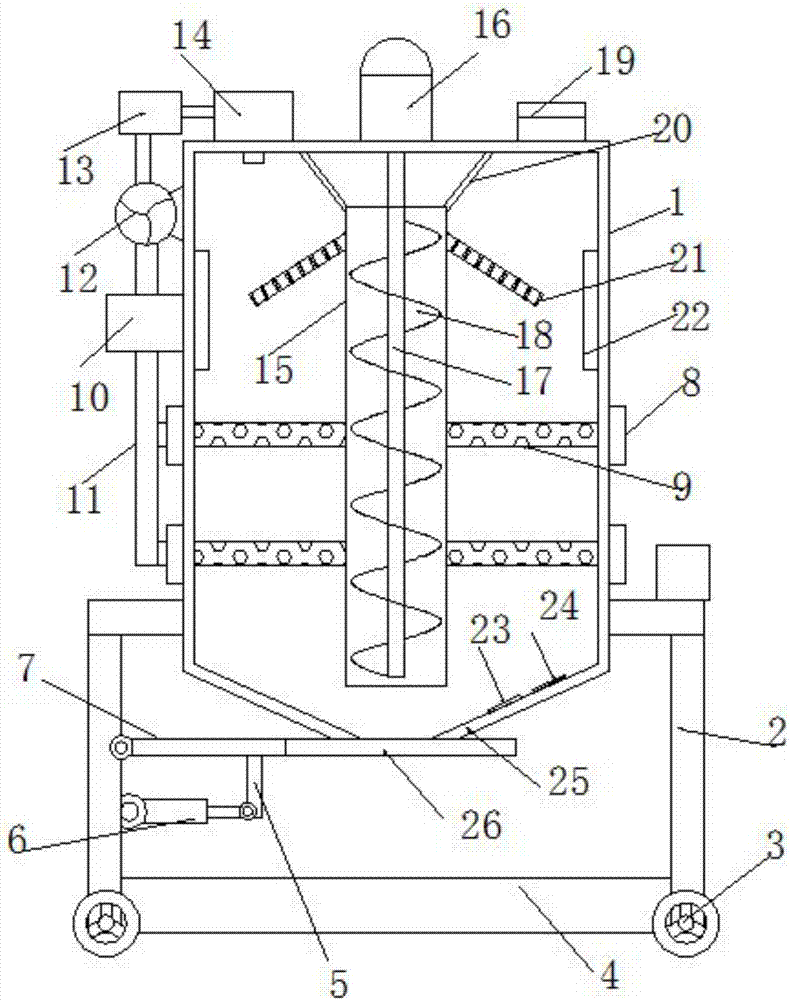

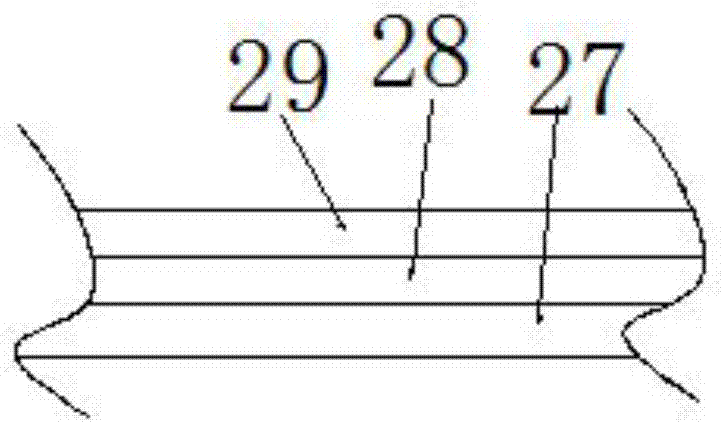

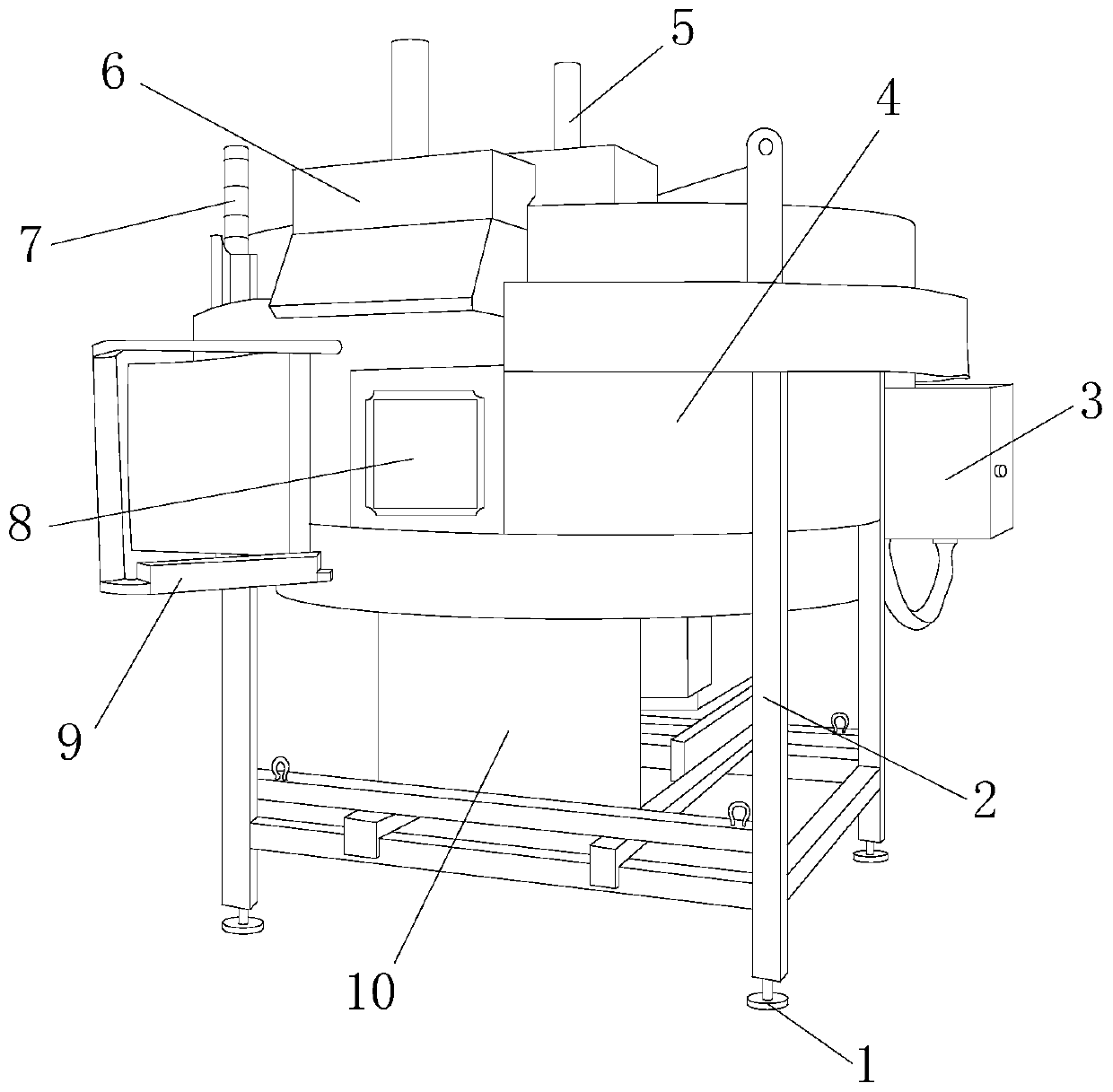

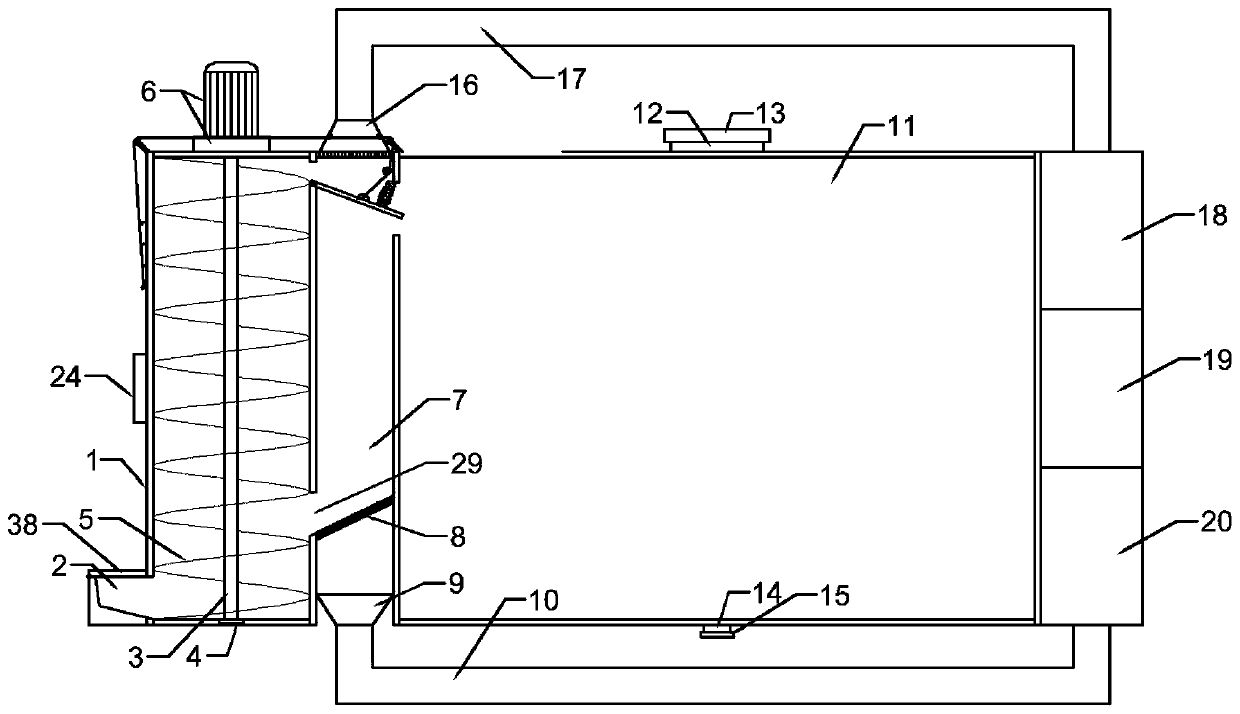

Mixing type fructus lycii drying device

InactiveCN106959002AAvoid passingReduce pollutionDrying gas arrangementsDrying solid materialsHelical bladeEngineering

The invention discloses a mixing-type wolfberry drying device, which comprises a drying box. Outriggers are arranged symmetrically on both sides of the lower end of the drying box. The position is vertically provided with a lifting tube, and a rotating shaft is arranged inside the lifting tube, and a spiral blade is arranged on the outside of the rotating shaft in the lifting tube. Suspenders are provided between the two sides and the inner wall of the top of the drying box, and a leveling grid is provided on the outside of the lifting tube near the suspenders. Environmental pollution, this drying method not only avoids the problem of insufficient drying of the existing device, but also removes the dust in the material. It has the disadvantage of being inconvenient for the device to discharge the material, and has strong practicability.

Owner:合肥图腾龙企业管理事务所(有限合伙)

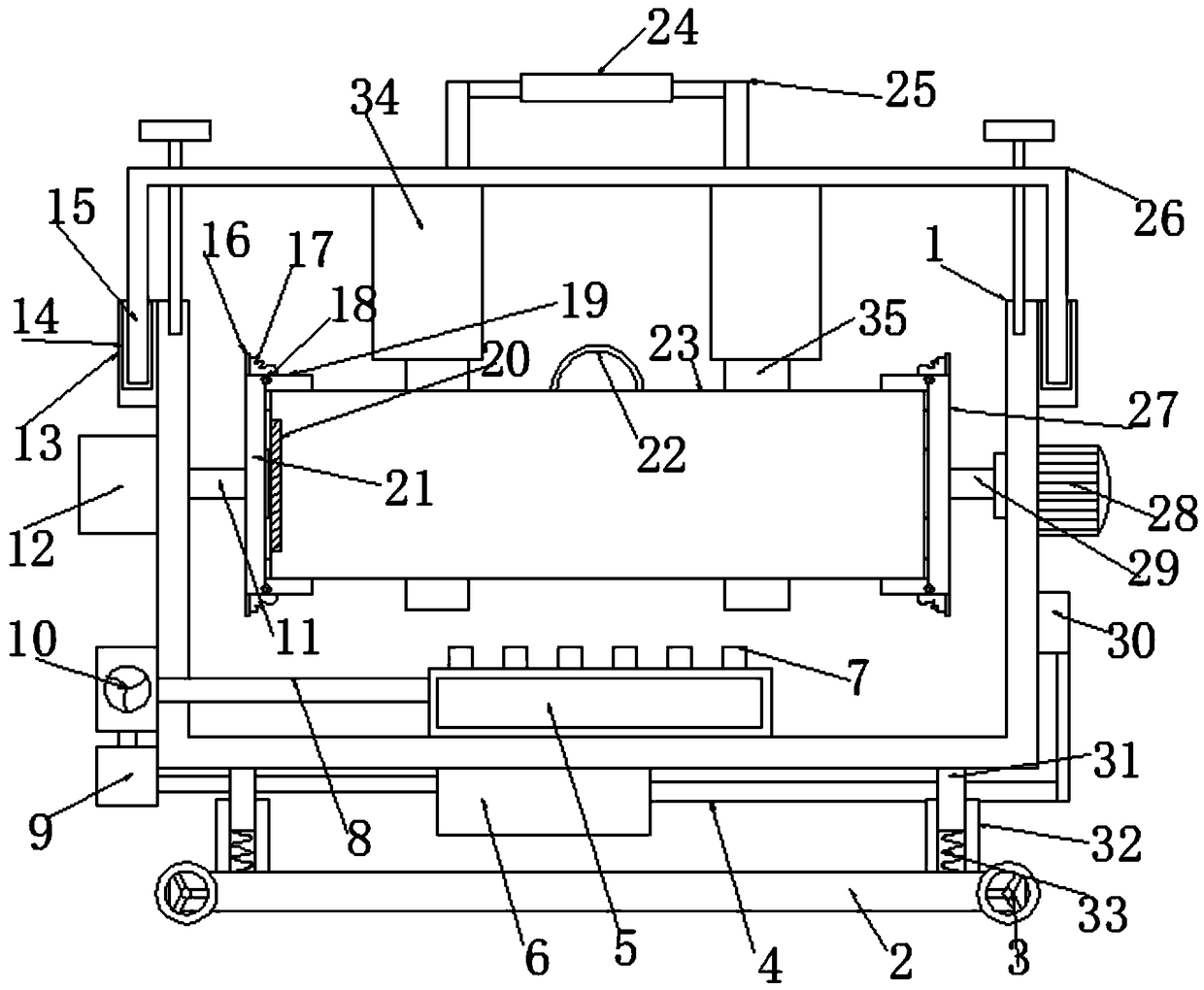

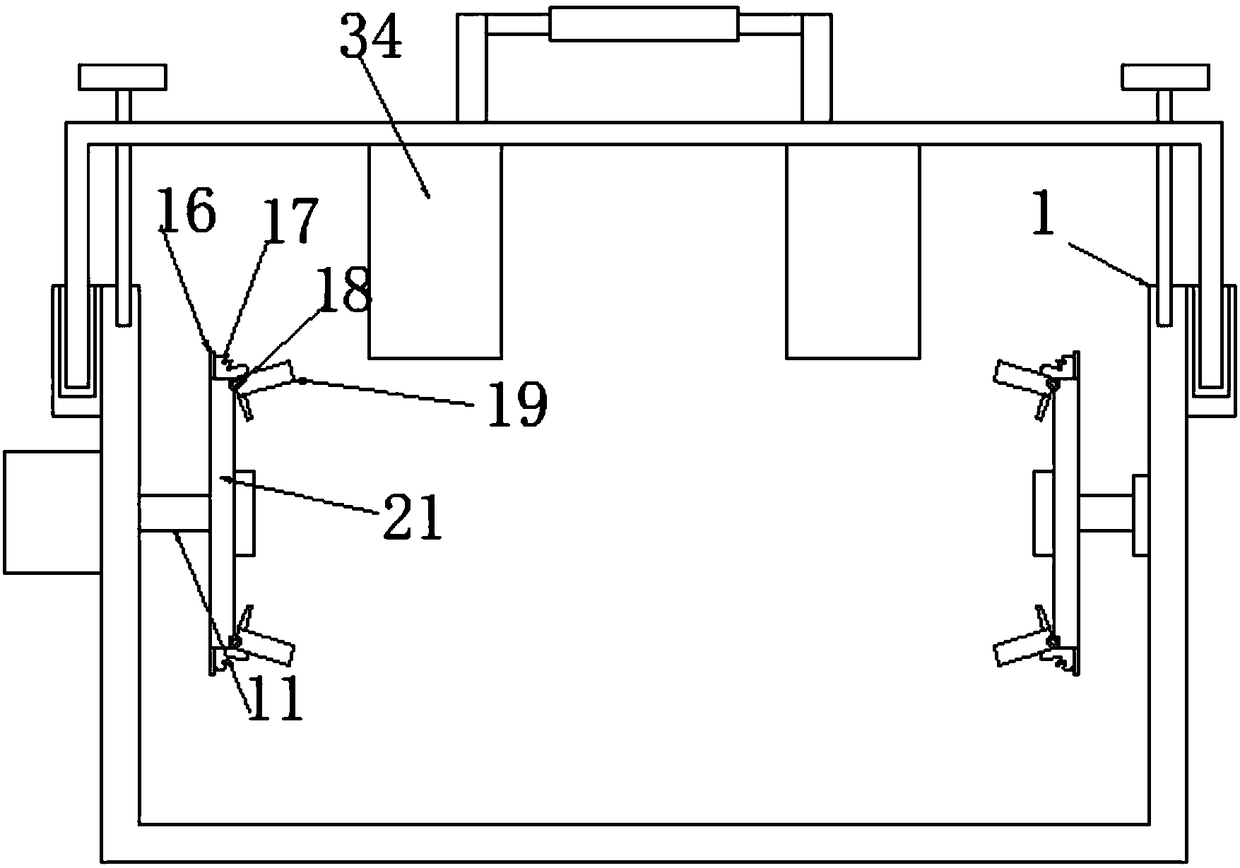

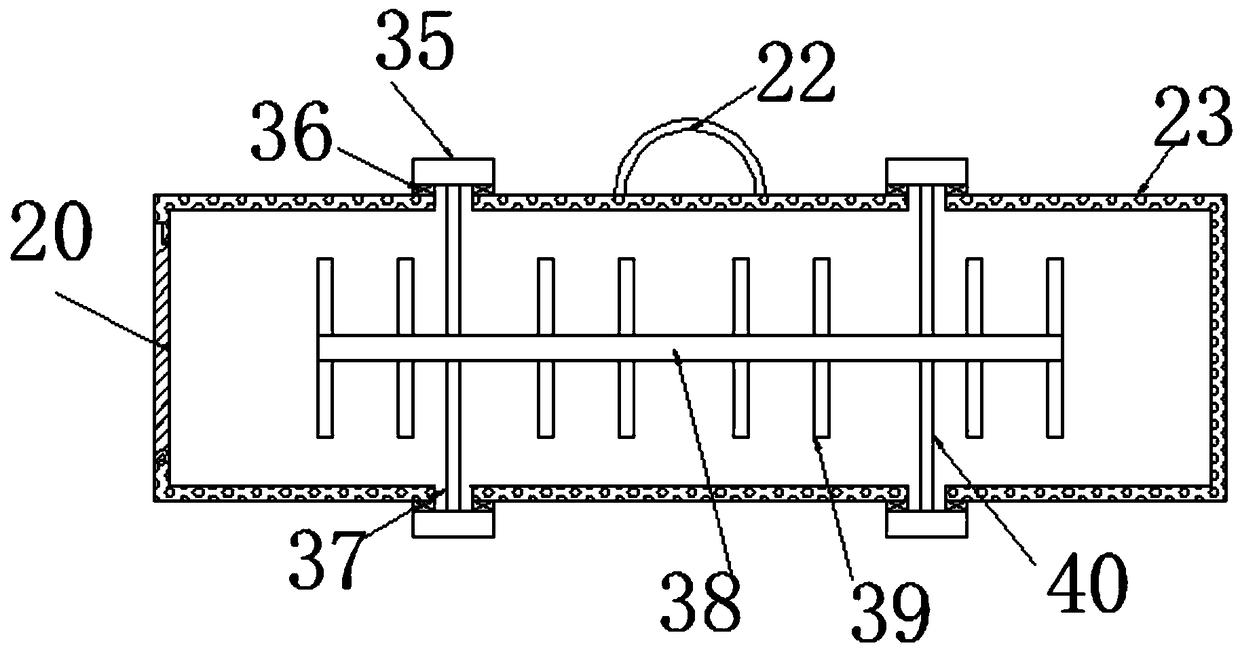

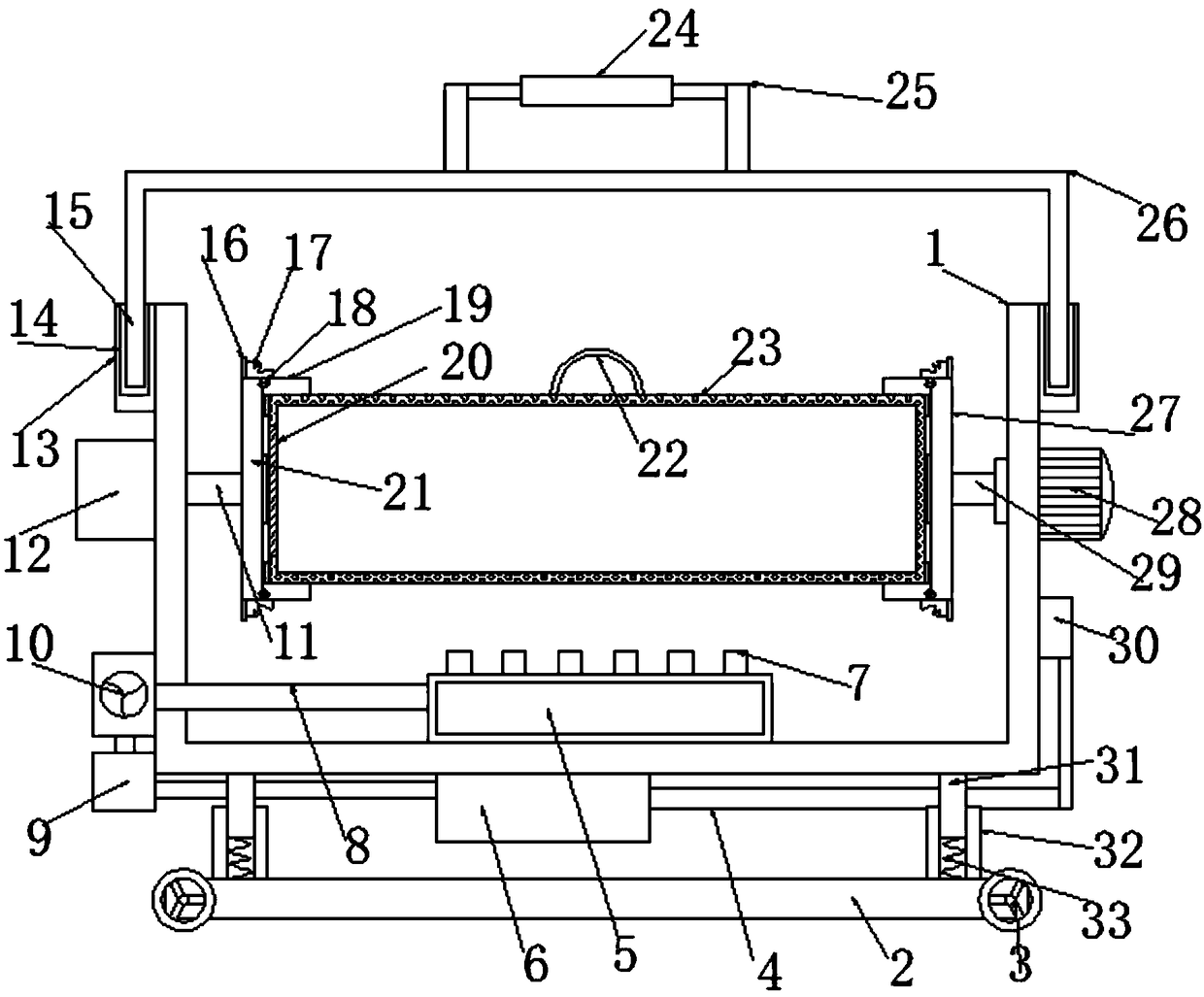

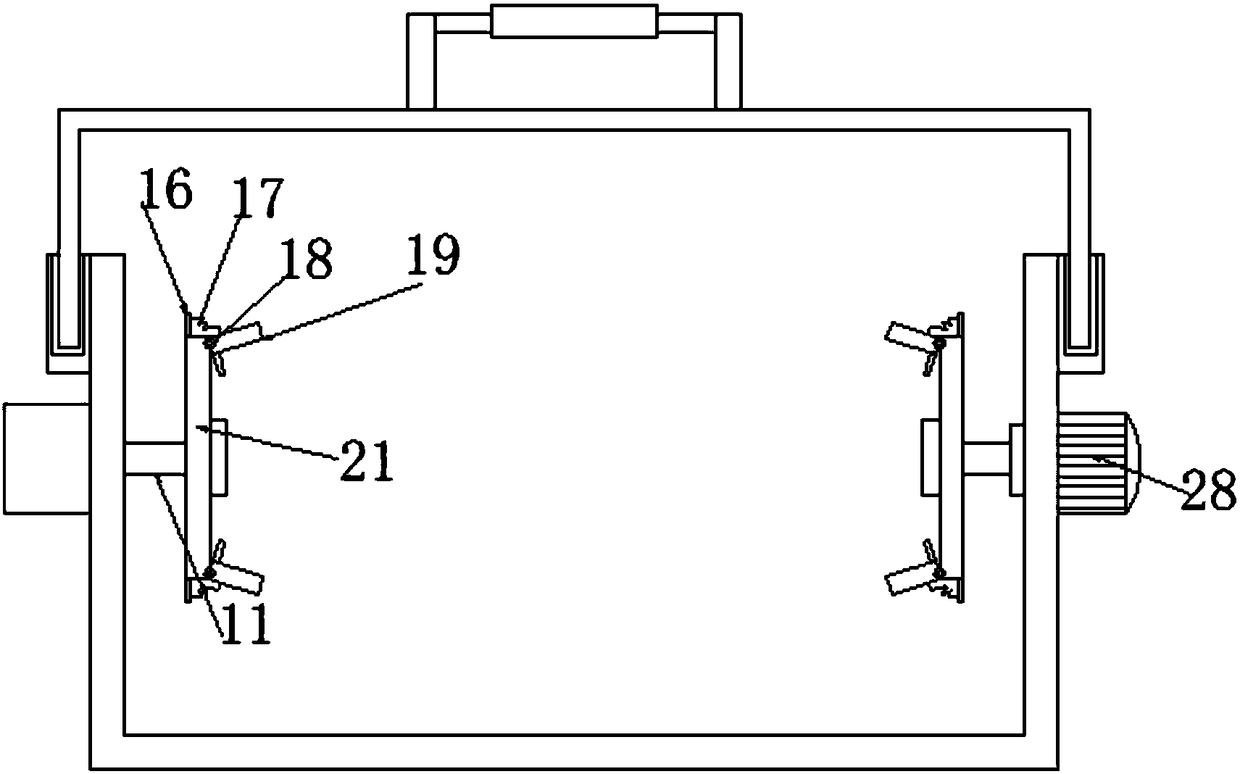

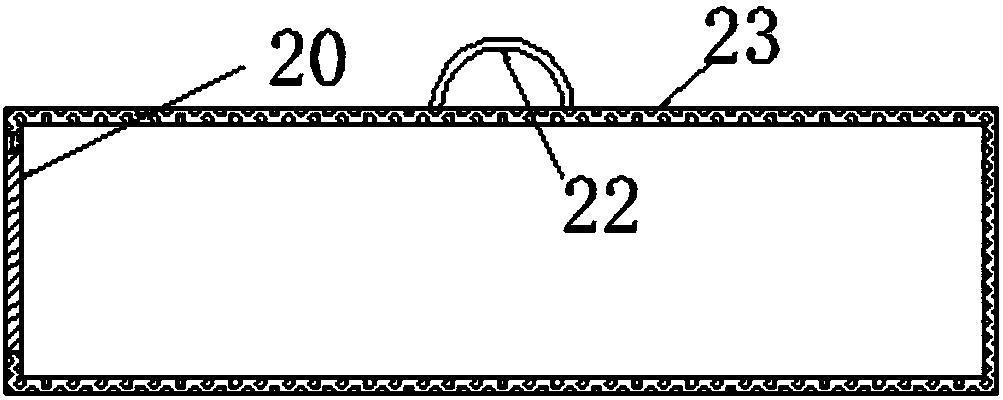

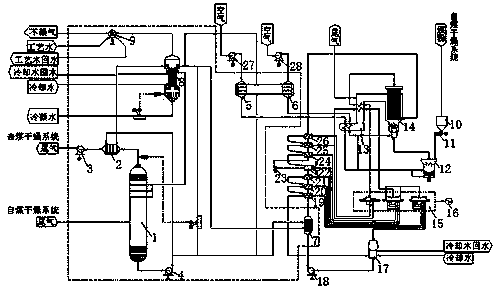

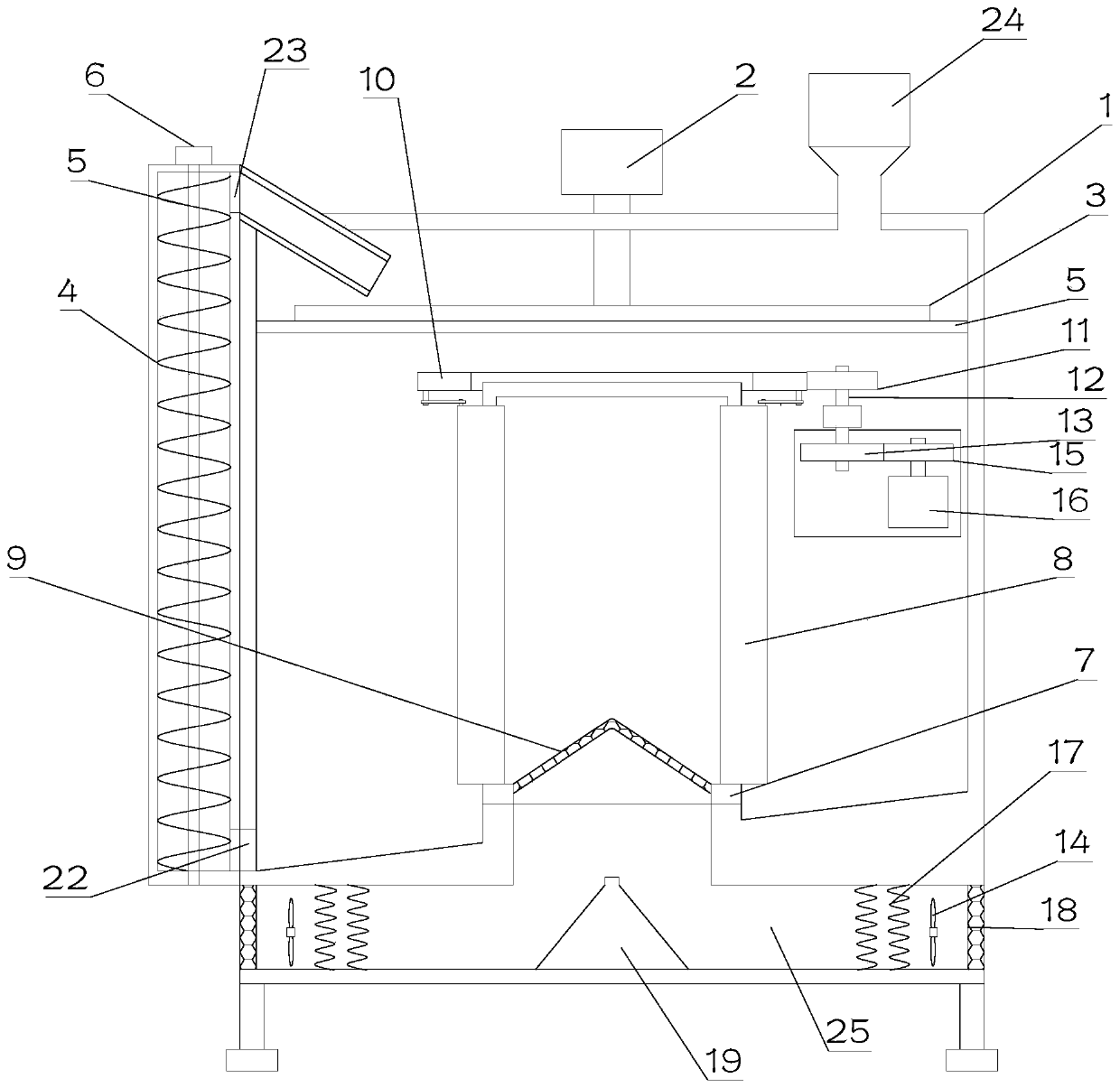

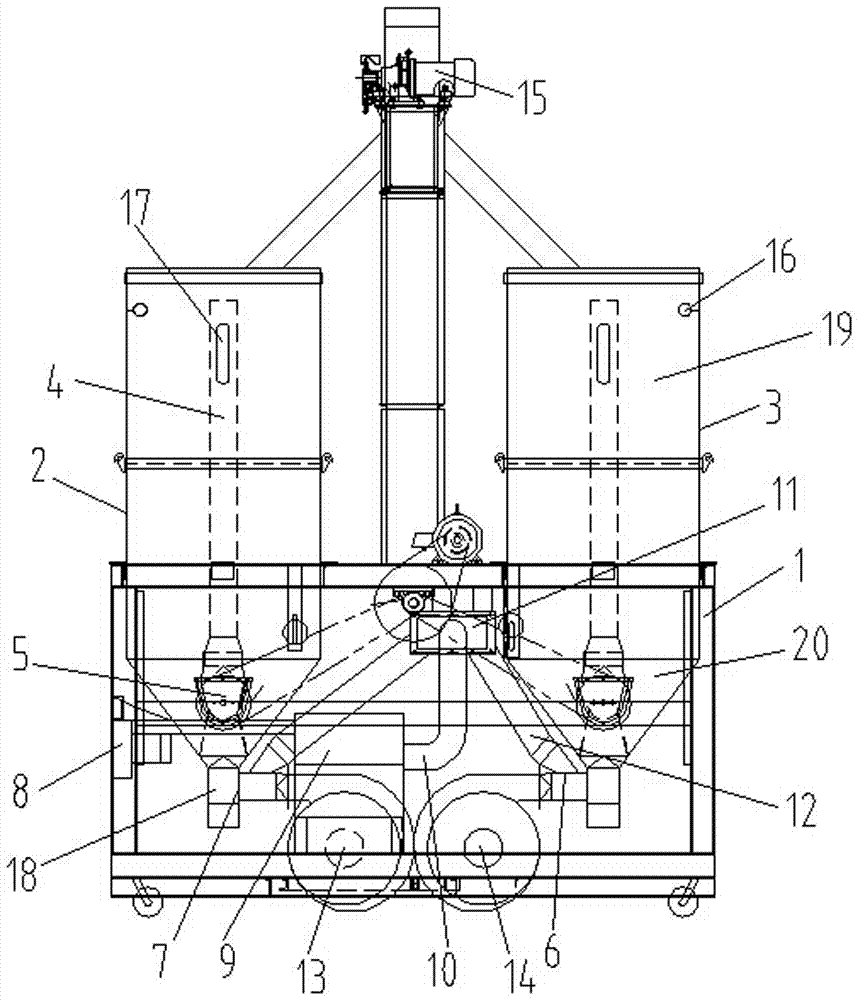

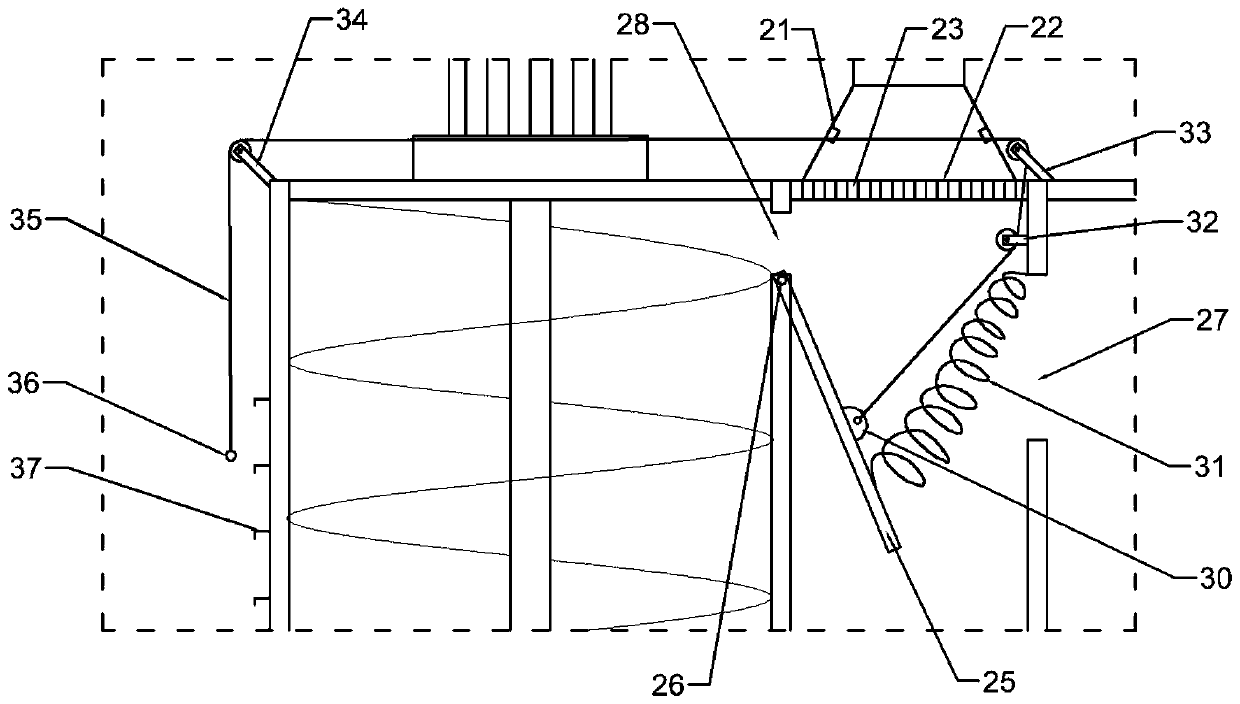

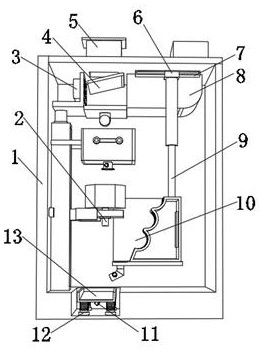

Traditional Chinese medicine processing and drying device capable of automatically stirring

InactiveCN108626989AEasy to take outSimple structureDrying gas arrangementsDrying chambers/containersBiochemical engineeringSeismic resistance

The invention discloses a traditional Chinese medicine processing and drying device capable of automatically stirring. The traditional Chinese medicine processing and drying device comprises a box body, wherein a base is arranged under the box body; rolling wheels used for conveniently carrying the device are arranged on the left side and the right side of the base; an opening and a box cover located at the opening are arranged at the upper end of the box body; insertion plates are arranged at the lower end of the box cover; insertion grooves matched with the insertion plates are formed in theouter sides of the upper end of the box body; a sealing pad is arranged in each insertion groove; through cooperation of the insertion grooves and the insertion plates, the box cover can be movably arranged on the box body. The traditional Chinese medicine processing and drying device is simple and reasonable in structure, convenient to carry and excellent in seismic resistance, so that a dryingcylinder can be conveniently taken out in the later period, and materials can be conveniently taken and replaced in the later period; the drying efficiency can be improved; the cyclic drying is achieved, so that the energy-saving effect is achieved; the materials in the drying cylinder can be turned and stirred; the drying effect is improved; and the device is high in practicality.

Owner:康泽波

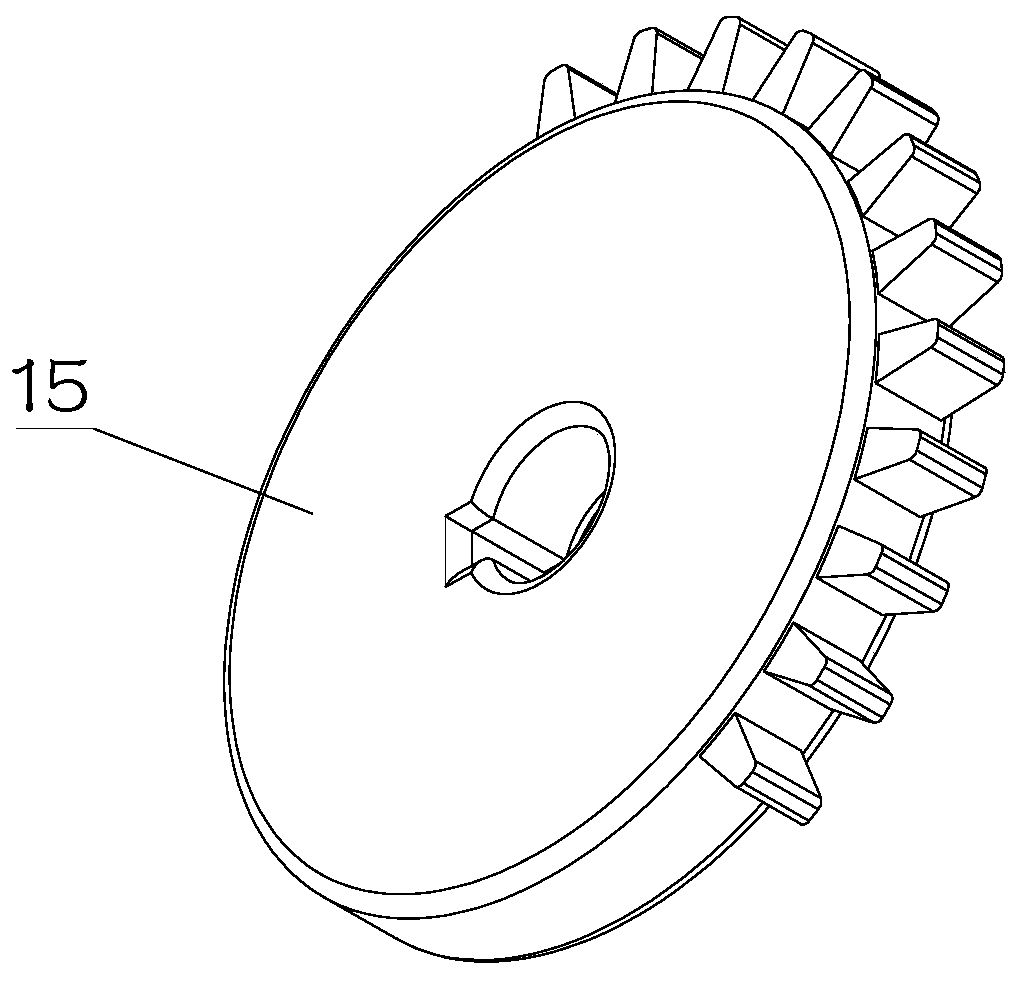

Traditional Chinese medicine machining and drying device based on self-locking function

InactiveCN108592622ASimple structureEasy to carryDrying gas arrangementsDrying chambers/containersDrive motorTelescopic cylinder

The invention discloses a traditional Chinese medicine machining and drying device based on a self-locking function. The traditional Chinese medicine machining and drying device based on the self-locking function comprises a box. A base is arranged on the lower side of the base. The left side and the right side of the base are provided with rolling wheels enabling the device to be convenient to carry. A hydraulic telescopic cylinder is fixed to the left side of the box. The output end of the hydraulic telescopic cylinder is provided with a telescopic squeezing rod. The right end of the telescopic squeezing rod is fixedly provided with a moving press disk. A drive motor is fixed to the right end face of the box. The output end of the drive motor is provided with a drive shaft. The left endof the drive shaft is fixedly provided with a fixed press disk. The fixed press disk and the movable press disk are both provided with self-locking fixing mechanisms. The traditional Chinese medicinemachining and drying device based on the self-locking function is simple and reasonable in structure, convenient to carry and good in anti-seismic performance; a drying drum can be conveniently takenout as a whole in a later period, so that material fetching and replacing are facilitated in the later period, and the drying efficiency is improved beneficially; and circular drying is achieved, so that the energy-saving effect is achieved, and high practicability is achieved.

Owner:康泽波

Efficient drying device for biofuels

InactiveCN106440718AImprove discretenessKeep dryGranular material dryingDrying gas arrangementsBiofuelDrive motor

The invention discloses an efficient drying device for biofuels. The efficient drying device comprises a base and a drying box, wherein the drying box is arranged above the base; the drying box is a cylindrical barrel; a collection box is arranged at the lower end of the drying box; the left side surface of the collection box is a guide oblique surface; supporting legs are arranged among the drying box, the collection box and the base; a discharge baffle plate is arranged at the bottom of the collection box; a lifting barrel is embedded on the upper end face of the collection box where the discharge baffle plate is positioned; a fixed rod is arranged between the left upper side of the lifting barrel and the drying box; a screw conveyer is arranged inside the lifting barrel; a material return pipeline is arranged between the left upper side of the lifting barrel and the top of the drying box; a feeding pipe is arranged on the upper end face of the lifting barrel; a feed hopper is arranged in the middle position of the top of the drying box; stirring shafts are horizontally arranged inside the drying box under the feed hopper; a plurality of stirring rods are arranged on the stirring shafts; and the left ends of the stirring shafts penetrate through the left side wall of the drying box, and are connected with driving motors. According to the efficient drying device, the structure is simple and reasonable, circular drying of materials is achieved, the drying effect is good, and the practicability is high.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Method of utilizing coal drying exhaust steam to reduce coal consumption of coal-fired power generator set and recovering water

ActiveCN103968659AReduce coal consumption for power supplyIncrease temperatureDrying solid materialsProcess engineeringThermal water

The invention relates to a method of utilizing coal drying exhaust steam to reduce coal consumption of a coal-fired power generator set and recovering water. The method is to add a heat and water recovery system between a coal drying system and the coal-fired power generator set, wherein the heat and water recovery system can convert heat and water vapor carried by the dry tail gas to heat and water carried by hot water, and then the hot water carrying a lot of heat is used for preheating carrier gas entering the coal drying system, air entering a coal-fired boiler system and condensed water after condensing steam by a steam turbine in order to realize efficient transfer of the heat carried by the dry tail gas to the coal-fired power generator set, reduce the coal consumption for the coal-fired power generator set and recover water. The method is characterized by completely recovering and utilizing heat and water vapor carried by the dry tail gas, so as to obviously reduce the coal consumption of a power plant, and conform to the national industry policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Stirring blowing-type traditional Chinese medicine airing device

InactiveCN108387102AAids in dryingImprove drying effectDrying machine combinationsDrying gas arrangementsEngineeringOpen structure

The invention discloses a stirring blowing-type traditional Chinese medicine airing device. The stirring blowing-type traditional Chinese medicine airing device comprises a base and a charging box, wherein rollers are symmetrically arranged on the left and right sides of the base, so that the device is convenient to move, the charging box is arranged above the base, the charging box is a cylindrical barrel of which the upper end is open, the upper open structure facilitates feeding later, a hydraulic telescopic rod is rotatably connected to the left upper end of the base, the output end of thehydraulic telescopic rod is hinged to the bottom of the charging box, a rotating support rod is hinged to the right lower side of the charging box, the lower end of the rotating support rod is fixedly connected with the base, and a lifting barrel is arranged in the middle position above the charging box. The stirring blowing-type traditional Chinese medicine airing device has the advantages of the simple and reasonable structure, convenience in movement and high practicability, the material airing effect is greatly increased, and additionally, circular airing of materials is realized by the scheme, so that the limitation to an airing area is eliminated.

Owner:丁小标

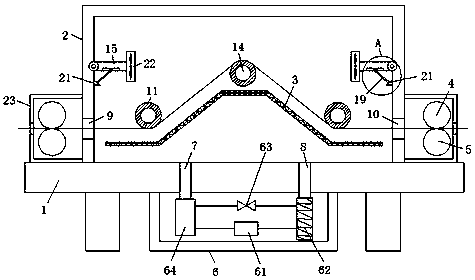

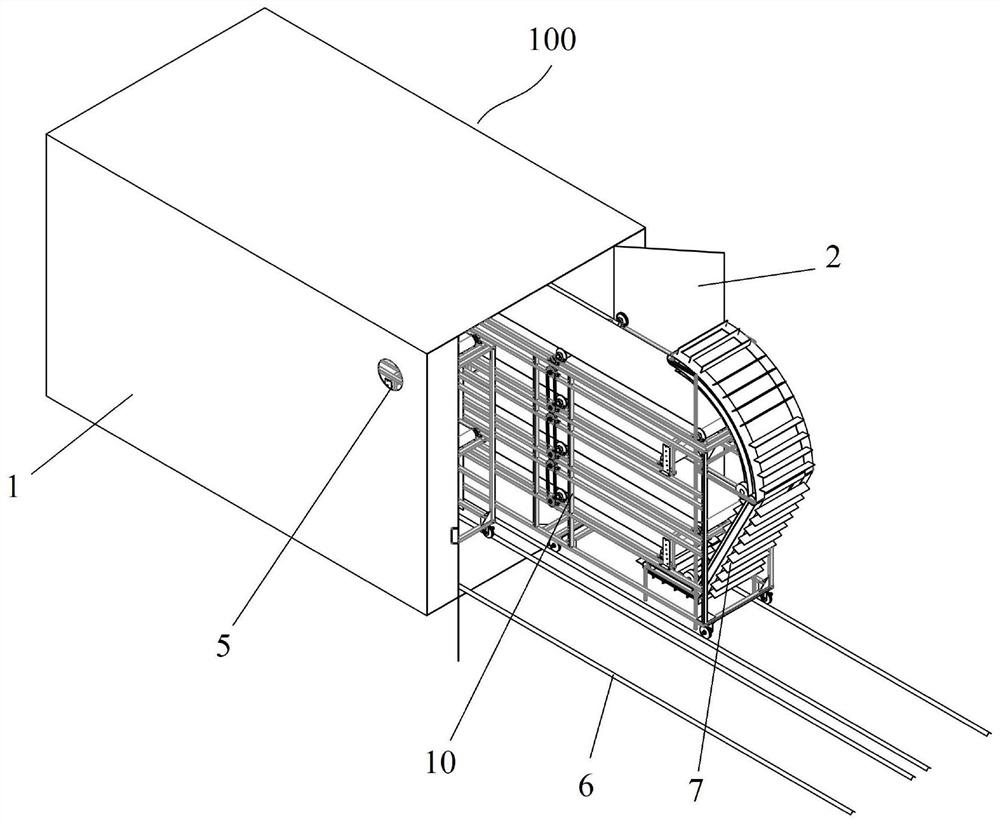

Multifunctional drying device for textile fabric

InactiveCN107702495AFull sweepRealize cycle dryingDrying gas arrangementsDrying machines with progressive movementsEngineeringTextile

The invention discloses a multifunctional drying device for textile fabric. The multifunctional drying device for the textile fabric comprises a workbench. The upper end of the workbench is fixedly connected with a machine body shell. An upper traction roller and a lower traction roller are installed on the inner wall of a mounting frame. A plurality of rotating rollers are evenly distributed on the inner wall of the machine body shell in a staggered mode. The two sides of the inner wall of the machine body shell are symmetrically and rotationally connected with motion bars, and a fan is arranged at the end, away from the machine body shell, of each motion bar. Each inclined block is fixed to one side of the inner wall of the machine body shell. The textile fabric is arranged inside the machine body shell. The textile fabric enters the machine body shell from a feeding inlet, sequentially passes through the multiple rotating rollers and is discharged from a discharging outlet. A dryingbox is installed at the bottom of the workbench. The multifunctional drying device for the textile fabric is simple in structure and easy to operate, achieves circular drying of the textile fabric, improves drying efficiency, meanwhile, does not damage the textile fabric, and improves the quality of products.

Owner:湖州佳伟纺织品有限公司

Circulating type chemical raw material drying device

InactiveCN108489243ARealize cycle dryingImprove drying efficiencyDrying gas arrangementsDrying chambers/containersPulp and paper industryRaw material

The invention discloses a circulating type chemical raw material drying device. A body is included; a feeding hopper is arranged at the upper end of the body; a conveying belt is arranged at the bottom of the feeding hopper, and is arranged in the body; a material scraping wheel used for scraping materials is arranged below the conveying belt; a circulating air duct is arranged on the right side of the body; an air guiding plate for guiding air is arranged at the upper end of the circulating air duct; the bottom of the left side of the circulating air duct is provided with an air outlet in which a draught fan is arranged; a material guiding plate is arranged on the left side of the bottom of the body; a circulating device is arranged on the left side of the body; the material guiding plateis arranged on the right side of the circulating device; a first material port is formed in the bottom of the right end of the circulating device; an outlet of a second material port is formed in theupper end of the portion, at the uppermost end, of the conveying belt; and supporting legs are arranged at the bottom of the body. The circulating type chemical raw material drying device is good indrying effect, high in drying efficiency, convenient to move and convenient to use.

Owner:陈璐滨

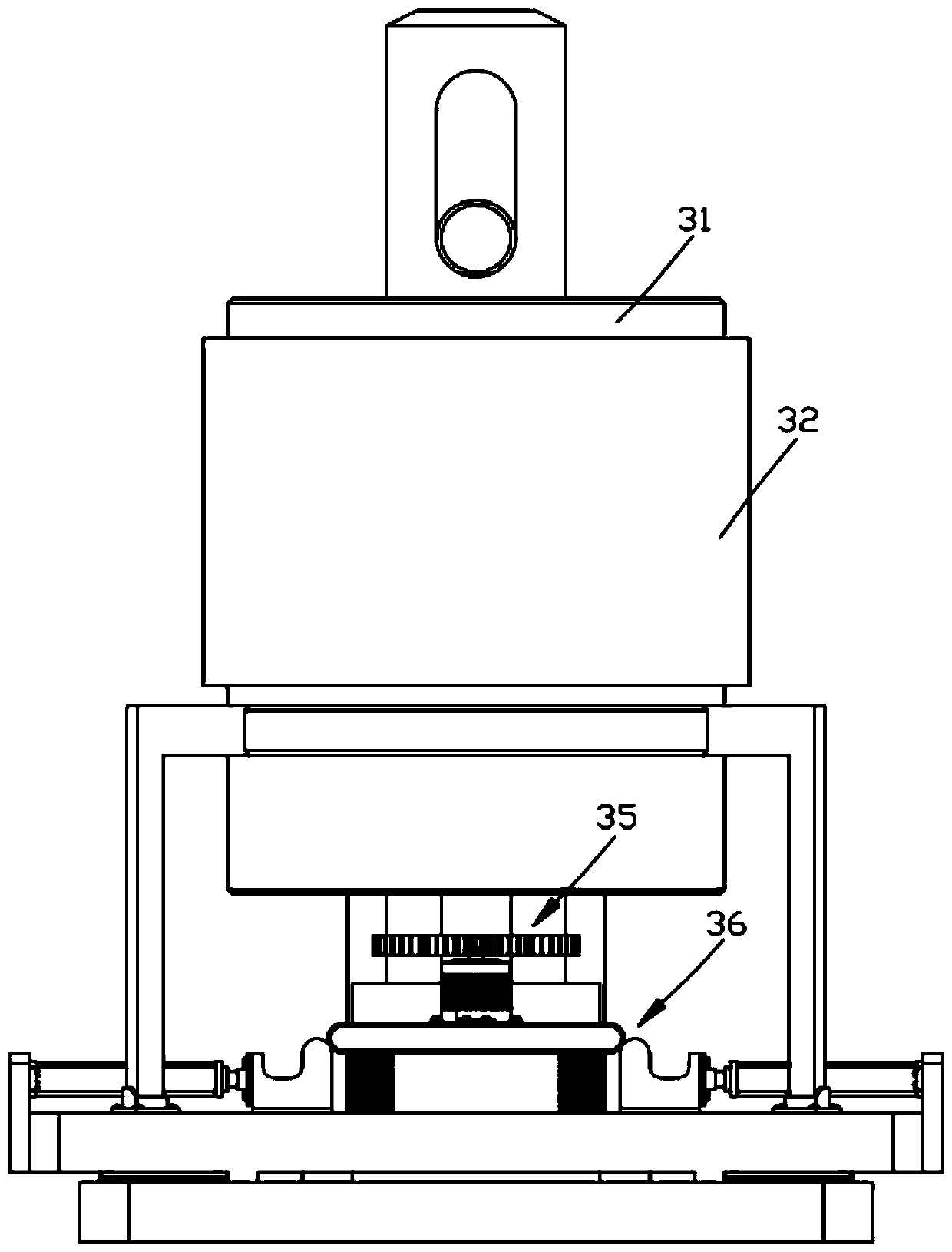

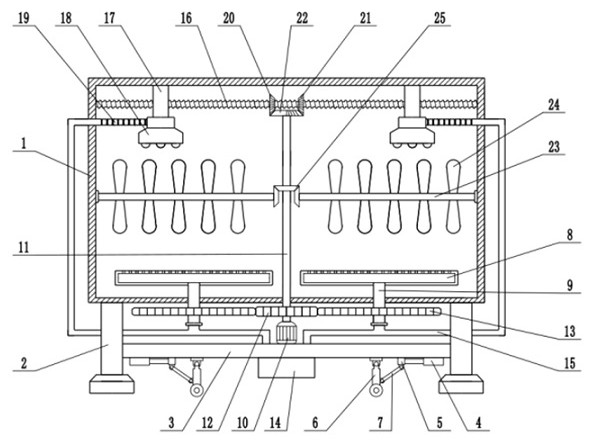

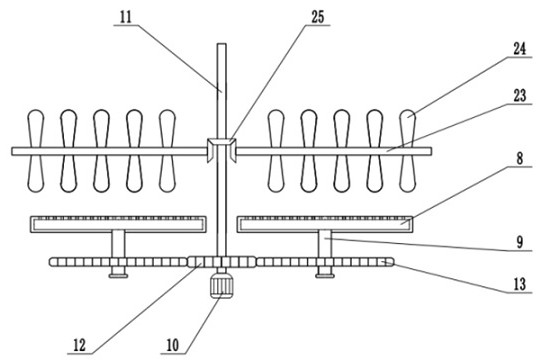

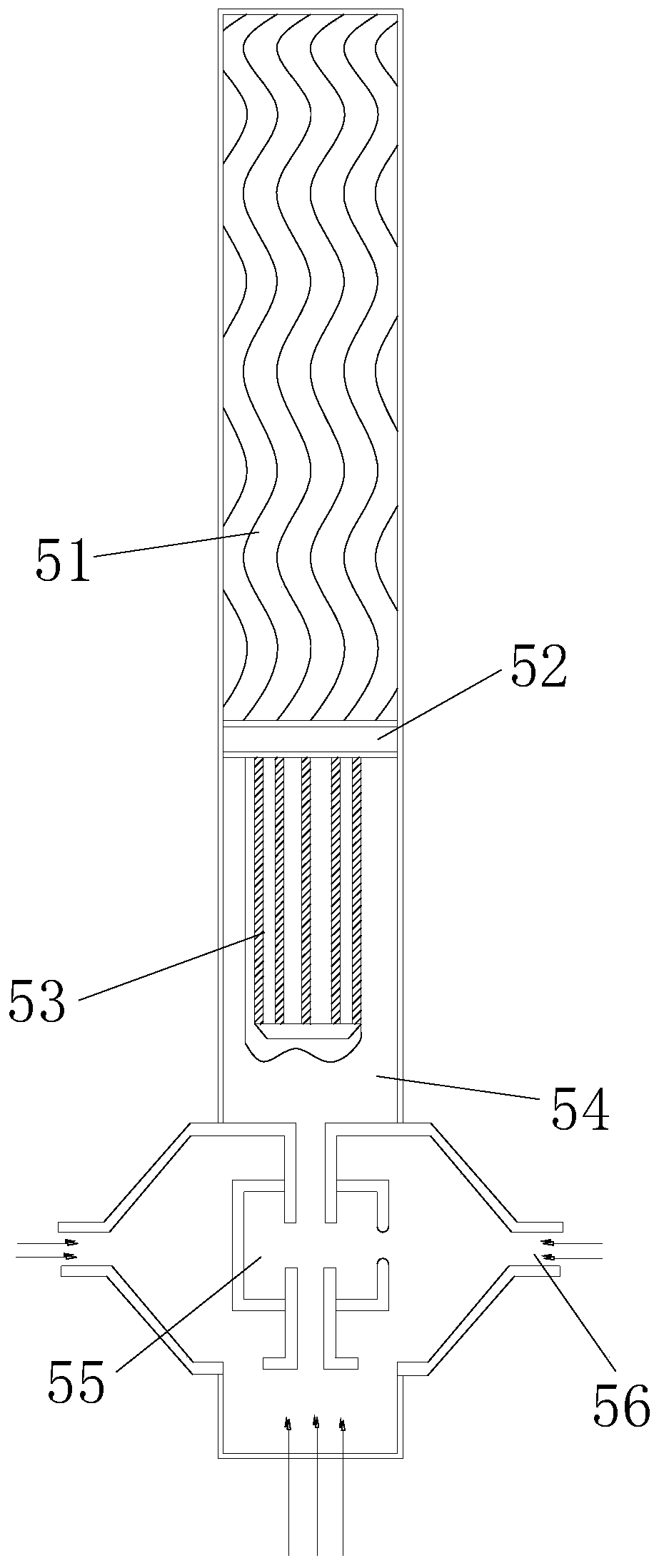

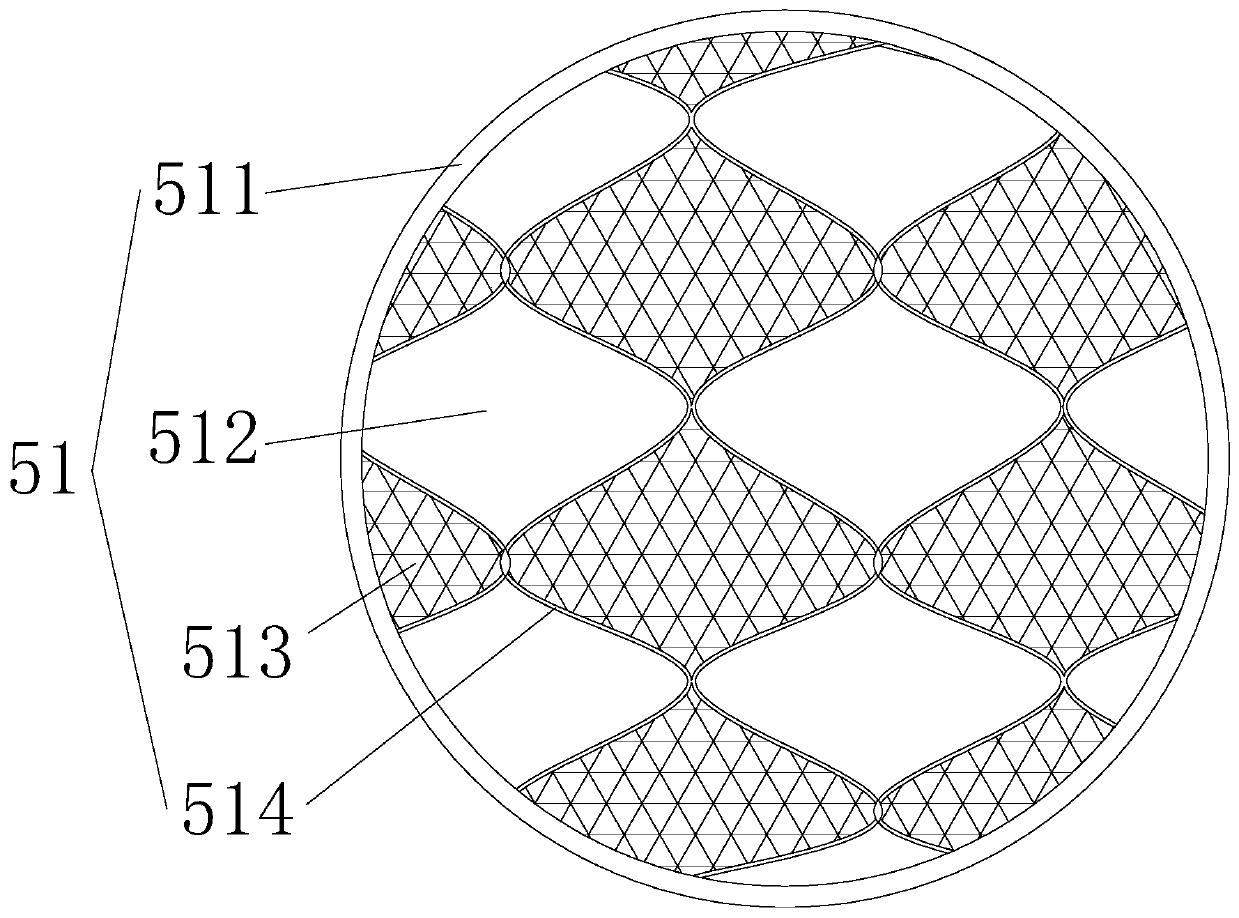

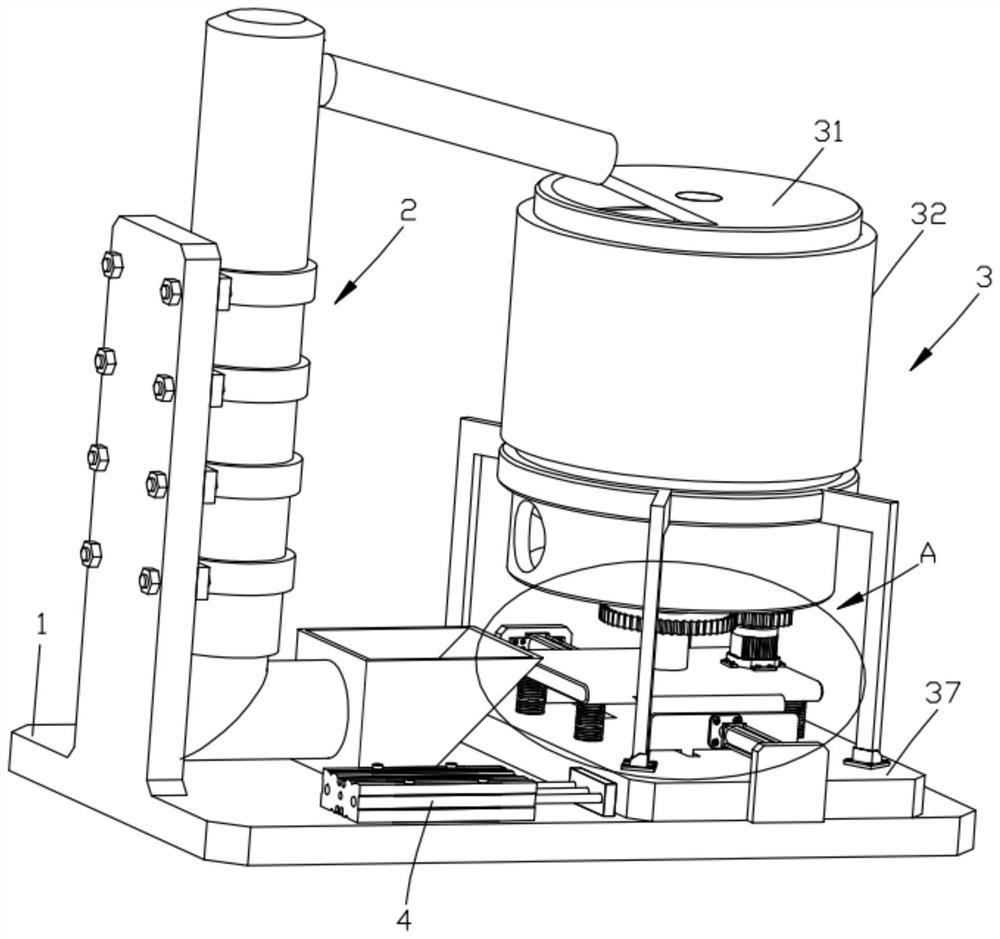

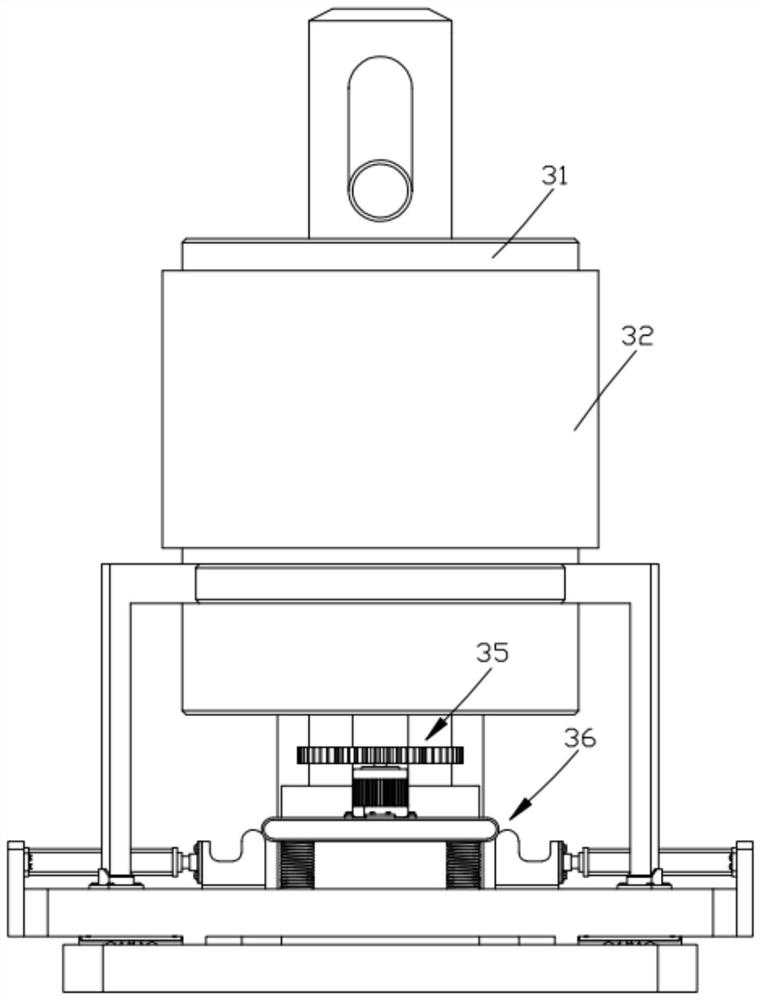

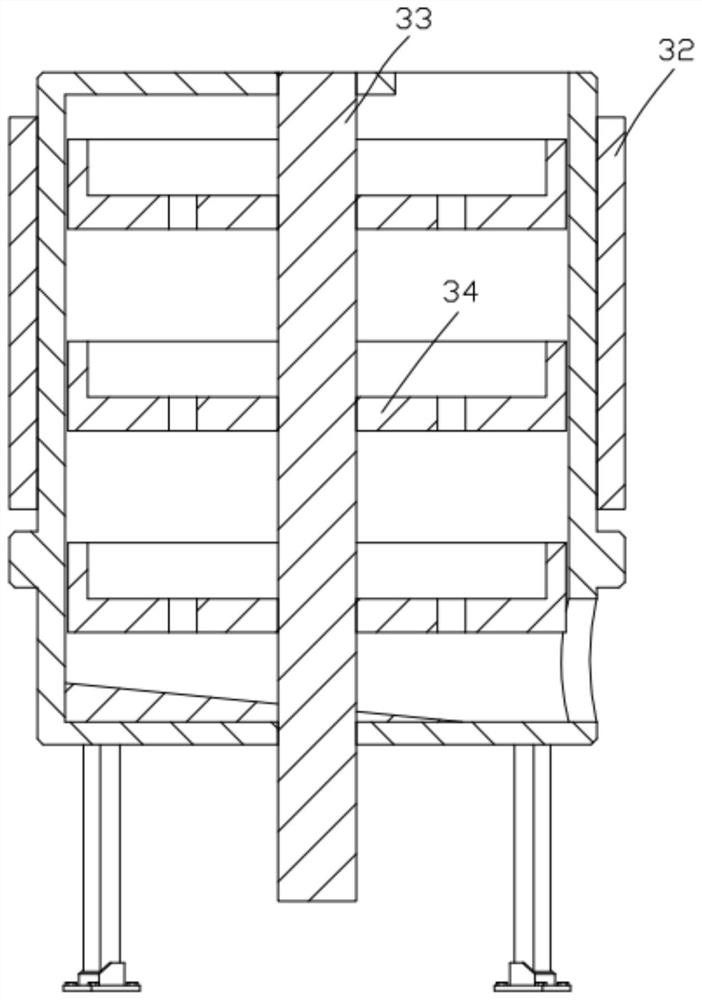

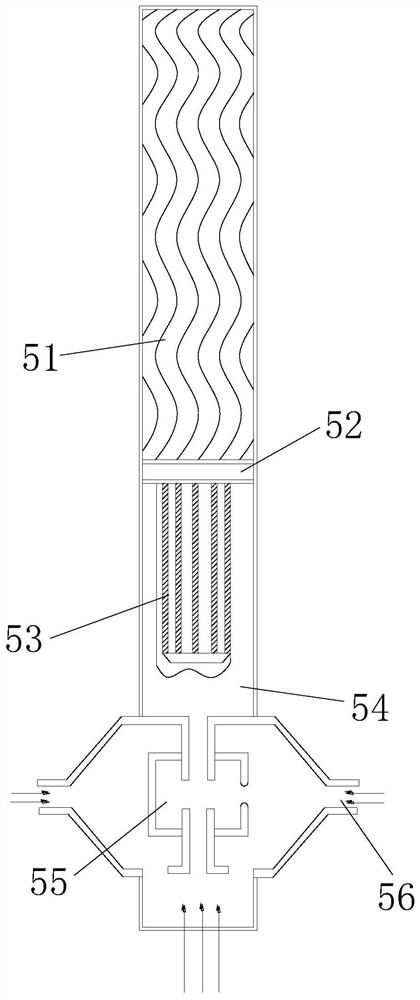

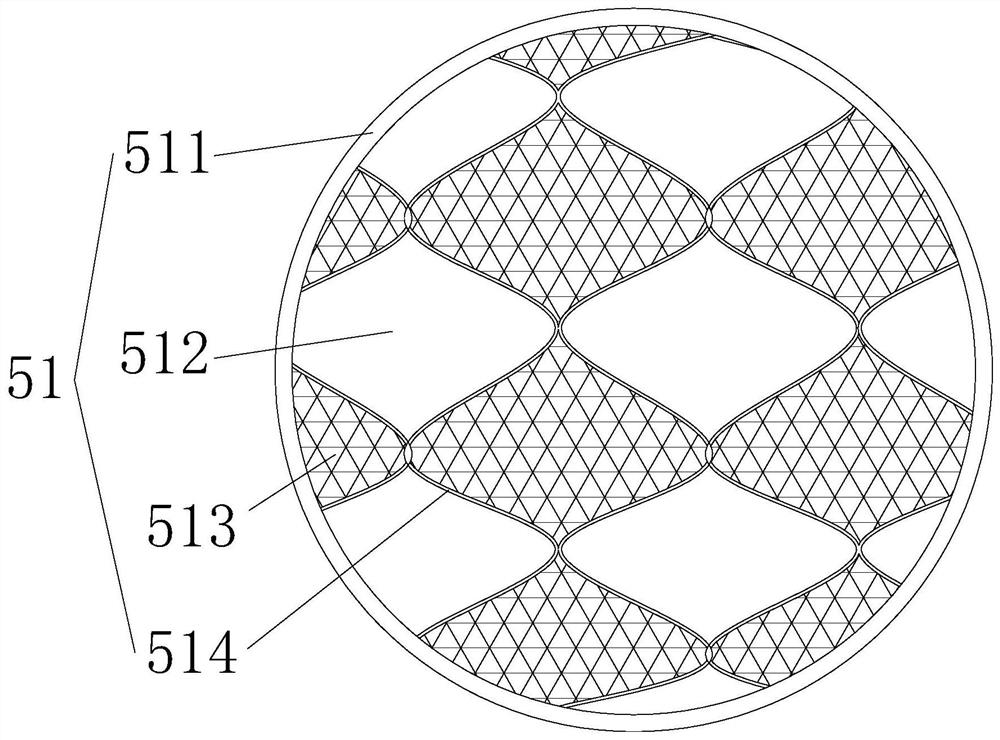

Cyclic tea leaf drying device

ActiveCN109855413AGuaranteed qualityEvenly heatedPre-extraction tea treatmentDrying solid materialsElectric heatingTea leaf

The invention provides a cyclic tea leaf drying device. An elevator is arranged on a supporting frame. A drying mechanism comprises a drying barrel, an electric heating sheet, a rotation shaft, dryingdiscs, a drive mechanism, a reciprocating mechanism and a bottom plate. The drying barrel is arranged on the bottom plate, the outer side of the drying barrel is provided with the electric heating sheet, the bottom plate is movably arranged on the supporting frame through a double-shaft air cylinder, and the reciprocating mechanism is arranged on the bottom plate. One end of the rotation shaft isrotationally arranged on the reciprocating mechanism, and the other end of the rotation shaft penetrates through the drying barrel and forms a moving pair with the drying barrel. The multiple dryingdiscs fixedly sleeve the rotation shaft at equal intervals. The drive mechanism is arranged on the reciprocating mechanism and is in transmission connection with the rotation shaft. The elevator is used for conveying tea leaves dried in the drying barrel into the drying barrel again, and cyclic tea leaf drying is achieved; during conveying, the tea leaves are overturned, and accordingly the dryingquality is guaranteed; and the reciprocating mechanism drives the drying discs to move up and down, so that the tea leaves are boiled in the drying barrel, and the tea leaves are evenly heated.

Owner:婺源县万和茶业有限公司

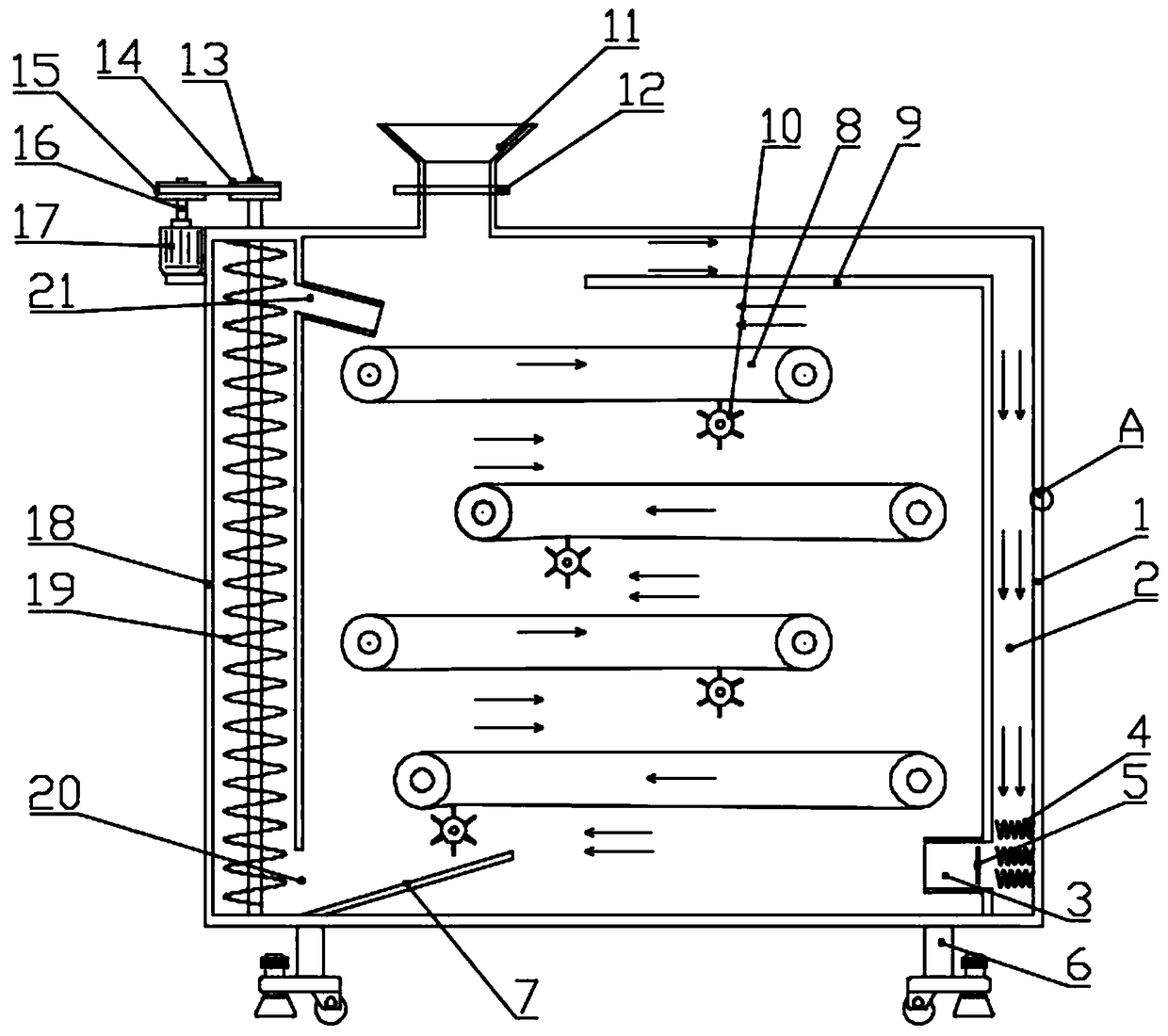

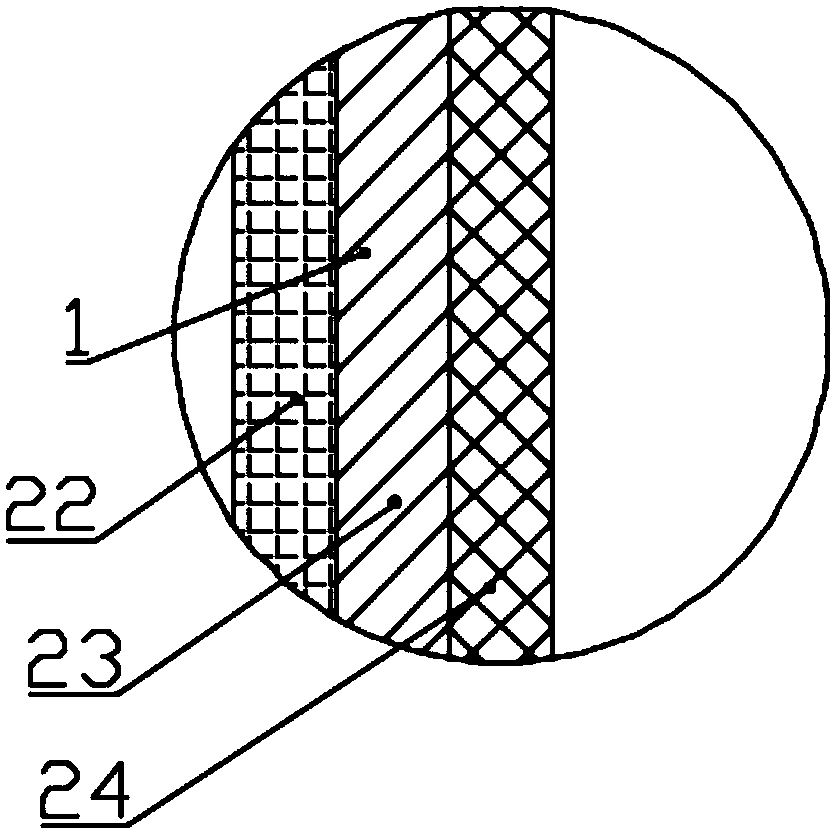

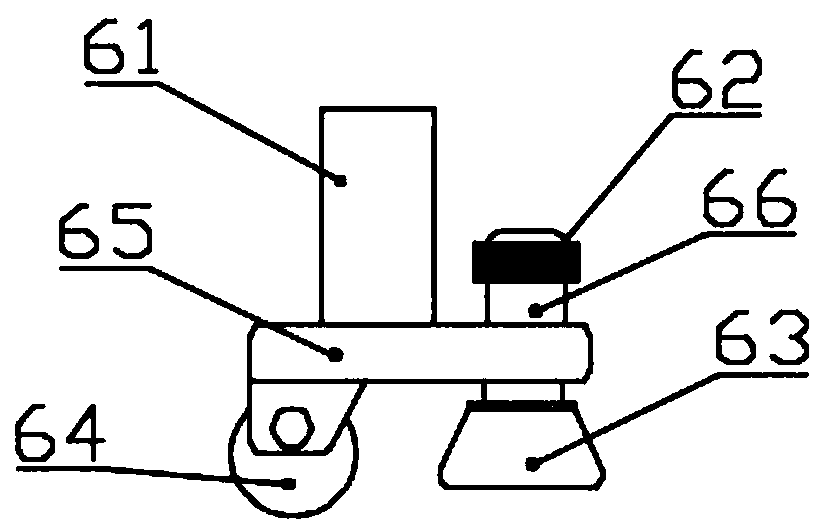

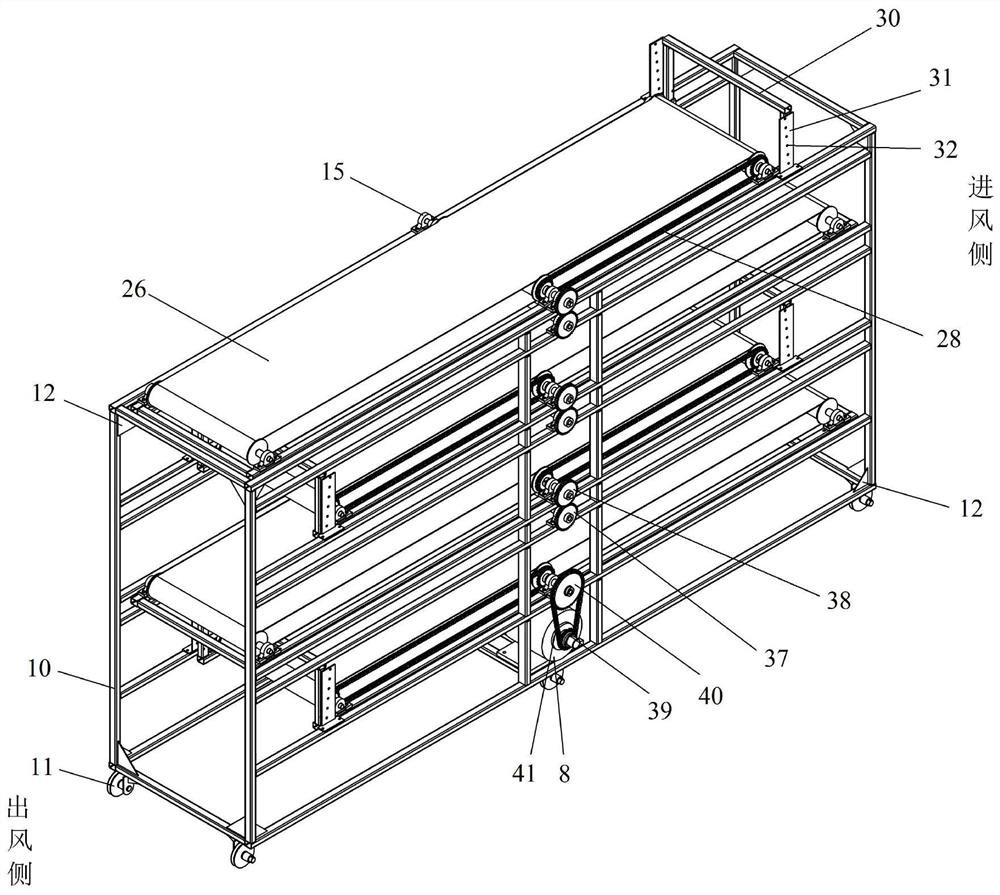

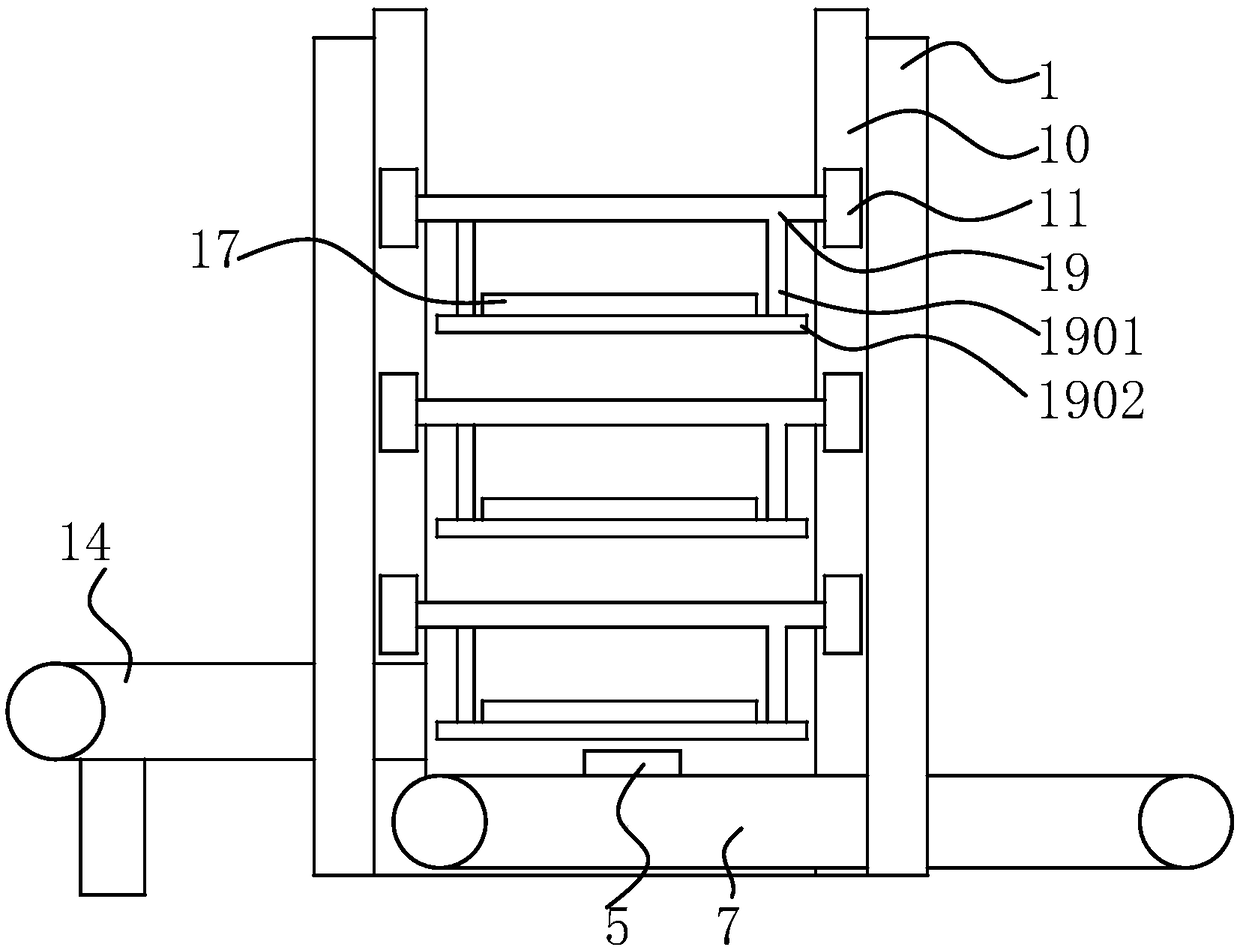

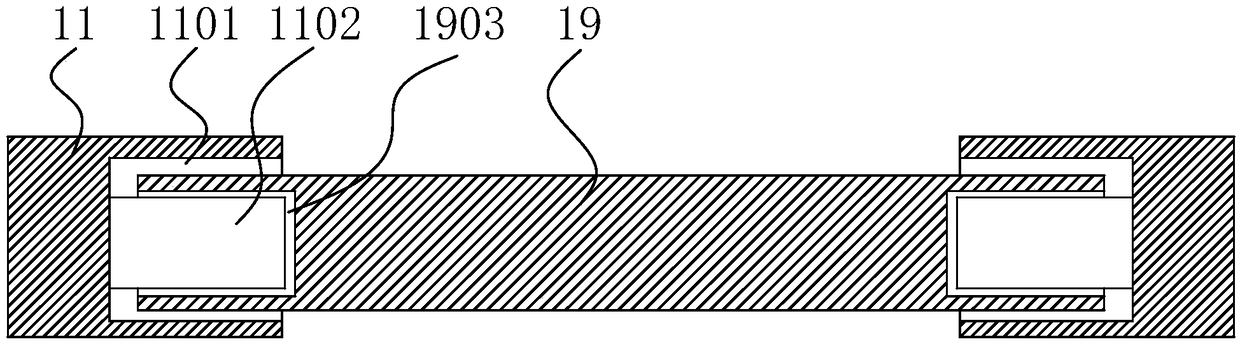

Hot air drying room

PendingCN113432406ADry evenly and fullyFully automatedDrying gas arrangementsDrying machines with progressive movementsHot blastMechanical engineering

The invention discloses a hot air drying room, and relates to the field of drying equipment. The hot air drying room comprises a box body, a guide mechanism, a dynamic conveying device and a circulating conveying device, wherein the dynamic conveying device comprises a frame body, a sliding mechanism, a driving mechanism, a plurality of material conveying mechanisms, a plurality of locking adjusting assemblies and a plurality of transmission mechanisms; and the plurality of material conveying mechanisms are sequentially installed on the frame body from top to bottom, the middle of each material conveying mechanism is rotationally installed on the frame body, one end of each material conveying mechanism is installed on the frame body through one locking adjusting assembly, every two adjacent material conveying mechanisms are connected through one transmission mechanism, the material conveying directions of every two adjacent material conveying mechanisms are opposite, and the feeding end of the lower material conveying mechanism in every two adjacent material conveying mechanisms is located at the outer side of the discharging end of the upper material conveying mechanism. According to the hot air drying room, the influence of a non-uniform flow field on material drying is reduced, the automation of material drying is realized, and the working efficiency is improved.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Hot air circulation drying device for capacitor production

InactiveCN112361763ARealize cycle dryingSolve uneven heatingDrying gas arrangementsDrying chambers/containersReciprocating motionElectric machine

The invention relates to the technical field of drying, in particular to a hot air circulation drying device for capacitor production. The hot air circulation drying device comprises a box body, supporting legs, a hot air blower and an air outlet, wherein the supporting legs are fixedly connected to the bottom of the box body, a fixing plate is arranged below the supporting legs, a rotating disc is arranged inside the box body, a hollow rotating shaft is arranged at the bottom of the rotating disc, a motor is fixedly connected to the upper surface of the fixing plate, a driving shaft is fixedly connected to the shaft extension end of the motor, a driving gear sleeves the driving shaft, a driven gear sleeves the hollow rotating shaft, the hot air blower is fixedly connected to the bottom ofthe fixing plate, an air delivering pipe is arranged at an exhaust port of the hot air blower, a lead screw is further arranged inside the box body, a moving block sleeves the lead screw, and the airoutlet is fixedly connected to the lower surface of the moving block. In the drying process, the rotating disc rotates synchronously, so that a capacitor is in more sufficient contact with hot air, and the capacitor is heated more uniformly; and meanwhile, the motor drives the moving block to do transverse reciprocating motion, so that the hot air is discharged more uniformly, and drying dead angles are reduced.

Owner:益阳市鹏程科技发展有限公司 +1

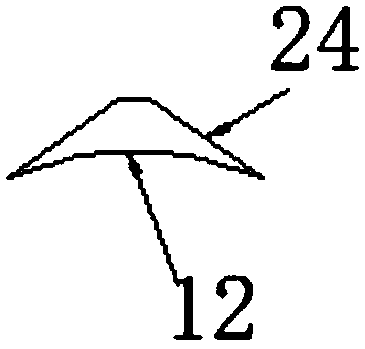

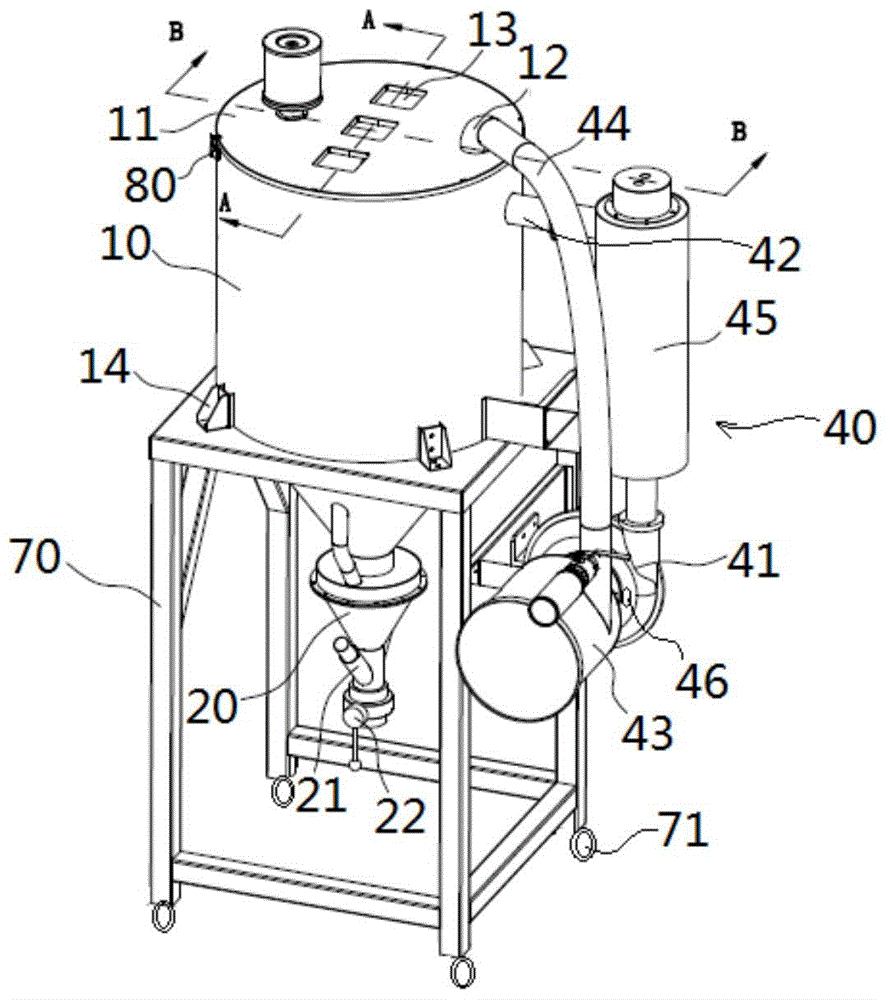

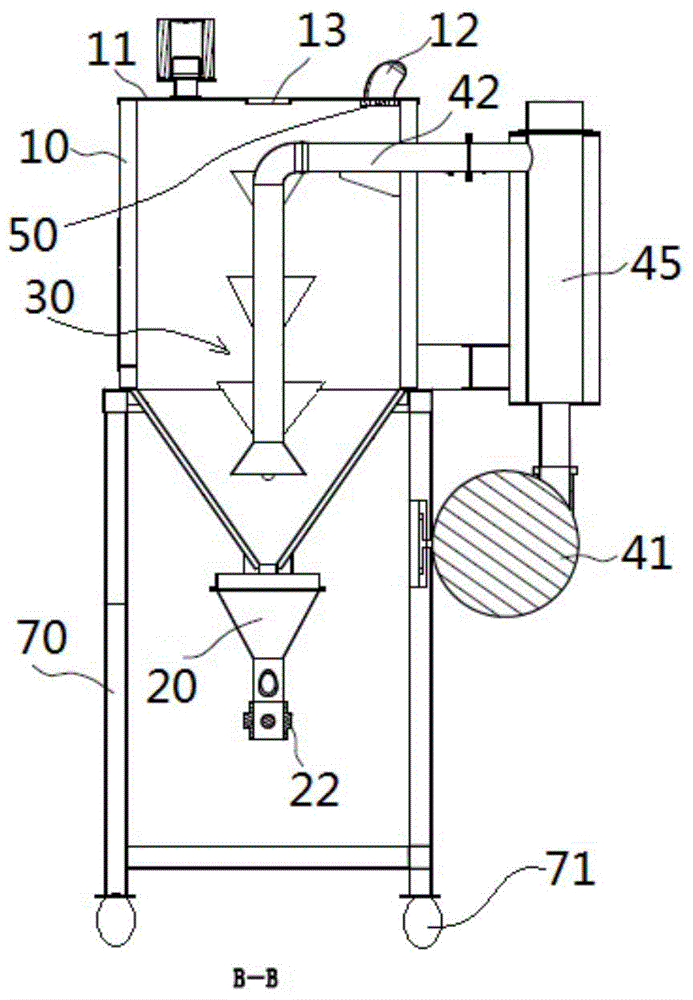

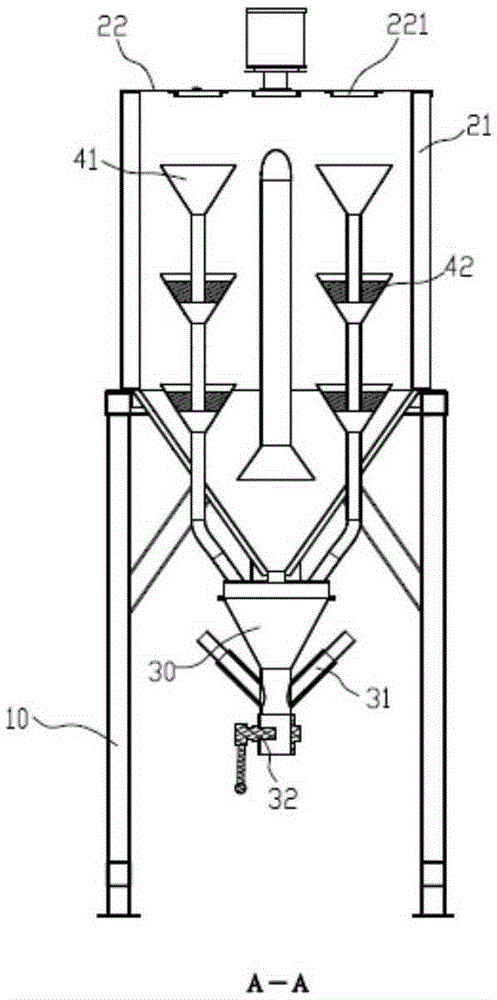

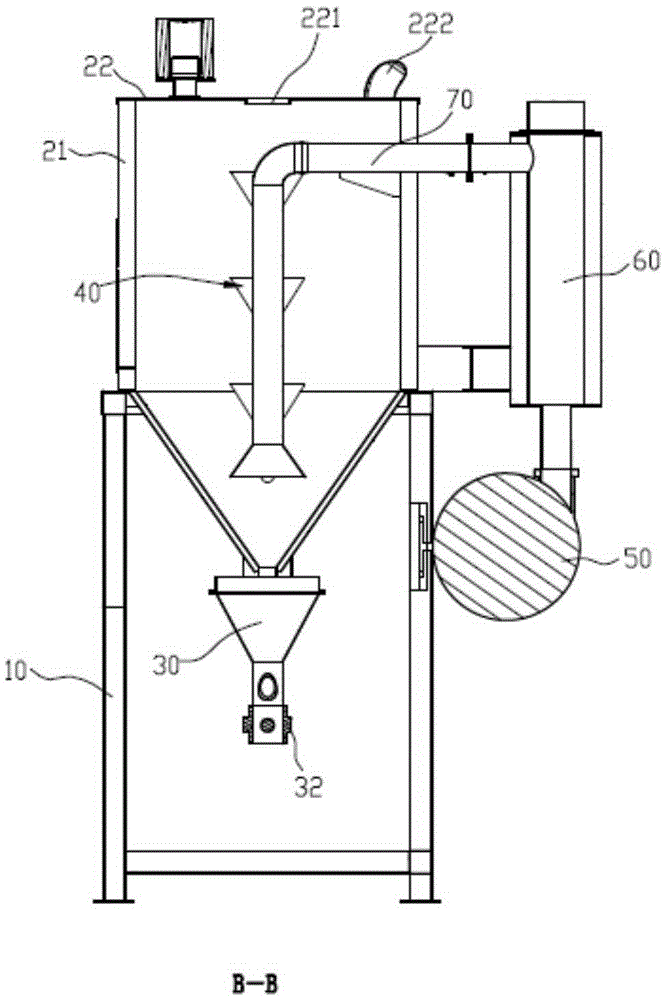

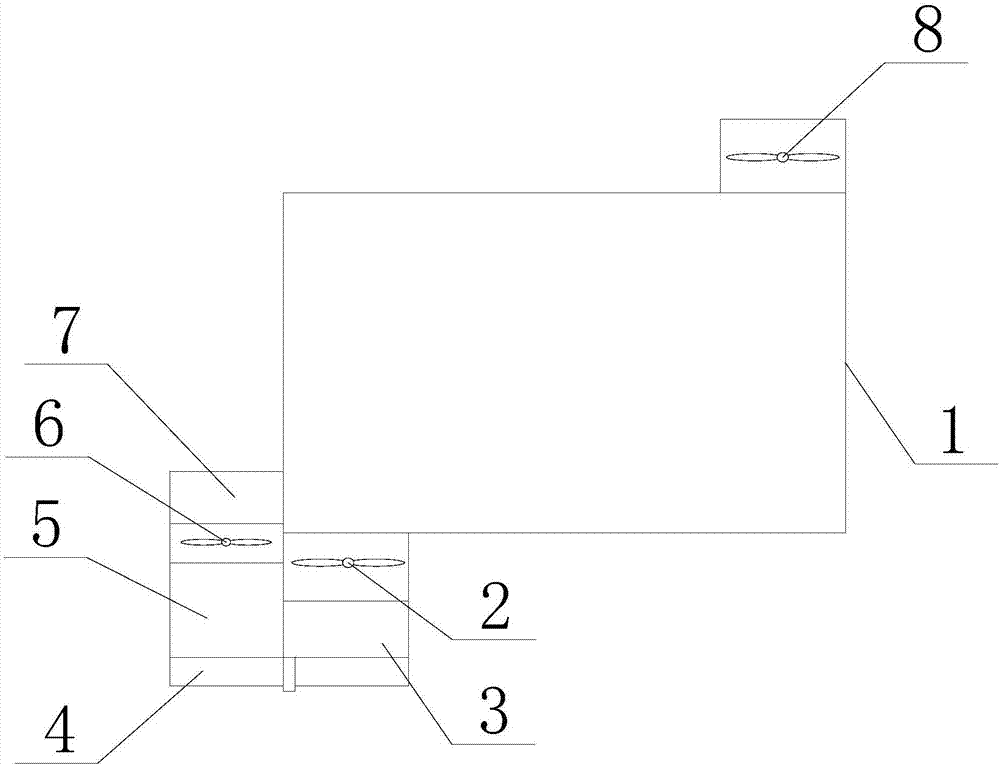

Hot air circulating drying machine

InactiveCN104964544ATemperature homogenizationEvenly heatedDrying gas arrangementsDrying chambers/containersEngineeringAir blower

The invention discloses a hot air circulating drying machine. The hot air circulating drying machine comprises a drying oven provided with a containing cavity, an end cover and a collection tank, wherein the drying oven is airtightly covered with the end cover; the collection tank is communicated with a discharge port of the drying oven; the end cover is provided with an air outlet and at least one feed port; a funnel unit is arranged under each feed port; each funnel unit comprises at least two funnels which are communicated; each funnel comprises an inverted conical part, the inverted conical part of the lower funnel is larger than that of the upper funnel; and the upper inverted conical parts are provided with a plurality of drying through holes; the drying oven is connected with a hot air circulating unit. The hot air circulating unit comprises a hot air blower, an air supply pipe, a filter and an air outlet pipe connected with the filter. A filter screen is fixed to the air outlet. At least one fan unit is fixedly arranged on the inner sidewall of the drying oven and located on one side of the funnel units. By adopting the hot air circulating drying machine, materials are heated evenly, the drying effect is good, and drying hot air can be cyclically utilized.

Owner:SUZHOU HONGHENG CHEM

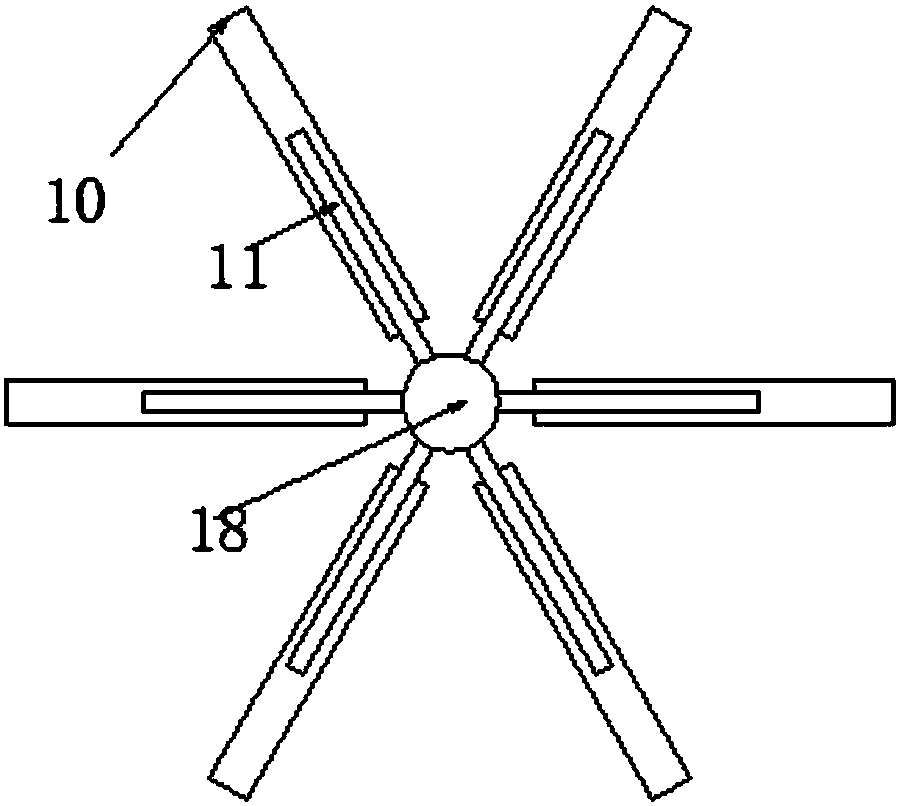

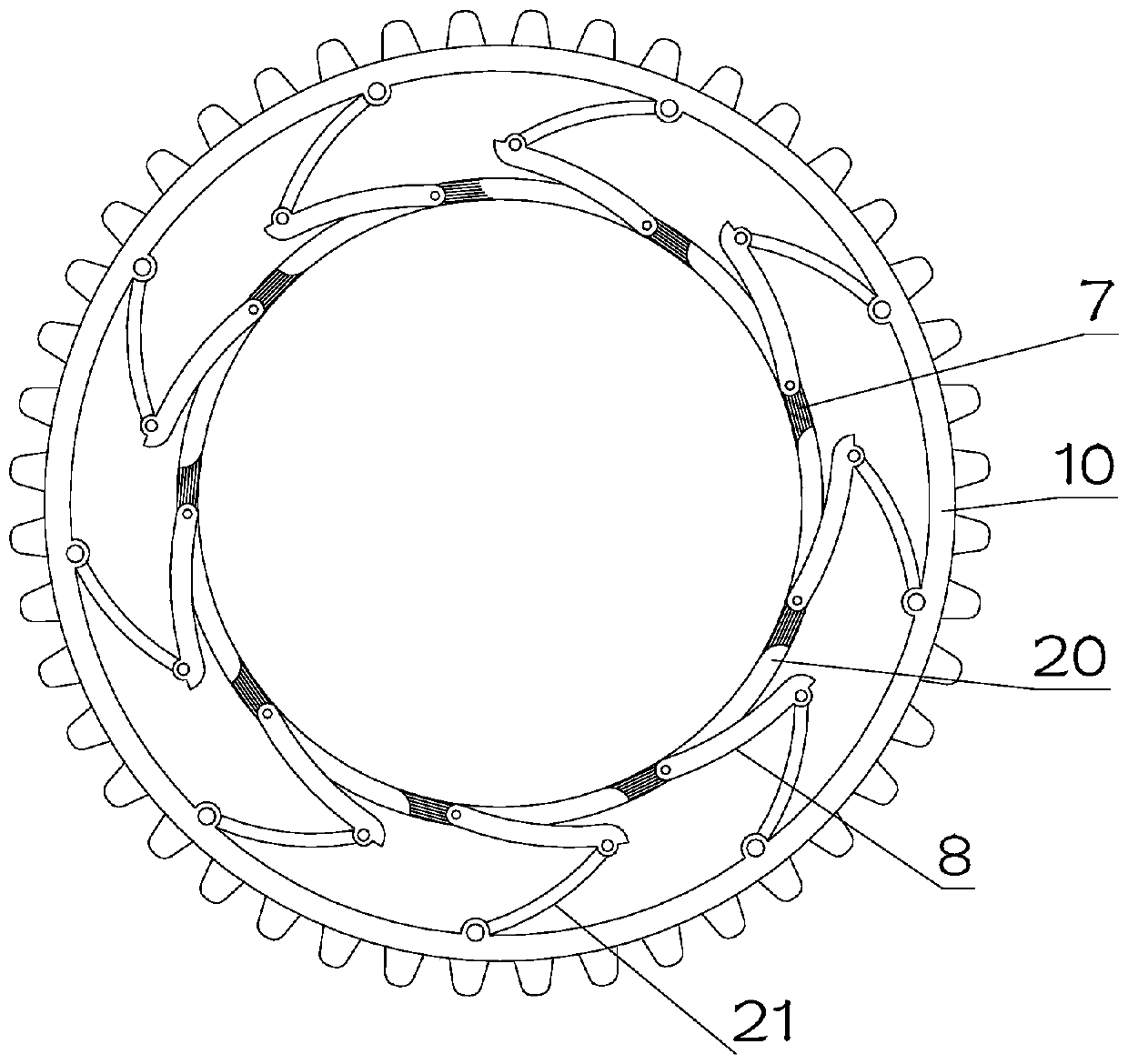

Chemical raw material drying device

ActiveCN110762997AEvenly dispersedAchieve dryingDrying gas arrangementsDrying solid materialsEngineeringMechanical engineering

The invention discloses a chemical raw material drying device, and relates to the technical field of chemical equipment. The drying device comprises a drying main body, wherein a material distributingplate is arranged on the drying main body, a scraping plate is attached to the material distributing plate, and is rotatably mounted on the drying main body; an air distributing mechanism is arrangedat the bottom of the material distributing plate; the air distributing mechanism comprises an air distributing cylinder fixedly arranged at the central position of the drying main body, the air distributing cylinder is cylindrical, and the upper end of the air distributing cylinder is sealed; a plurality of air outlet holes are formed in the air distributing cylinders in array, arc-shaped platesare arranged on the air outlet holes, one ends of the arc-shaped plate are hinged to the air outlet holes, the other ends of the arc-shaped plates is connected to a circular ring through connecting rods, and the two ends of the connecting rods are hinged to the arc-shaped plates and an inner ring of the circular ring correspondingly; the circular ring is provided with a rotating mechanism for driving the circular ring to rotate intermittently; the rotating mechanism is fixedly installed in the drying main body; and the bottom of the air distributing cylinder communicates with a heating pipeline on the drying main body, and the heating pipeline is arranged at the bottom of the drying main body. According to the device, the drying of raw materials is well realized.

Owner:营口兴福化工有限公司

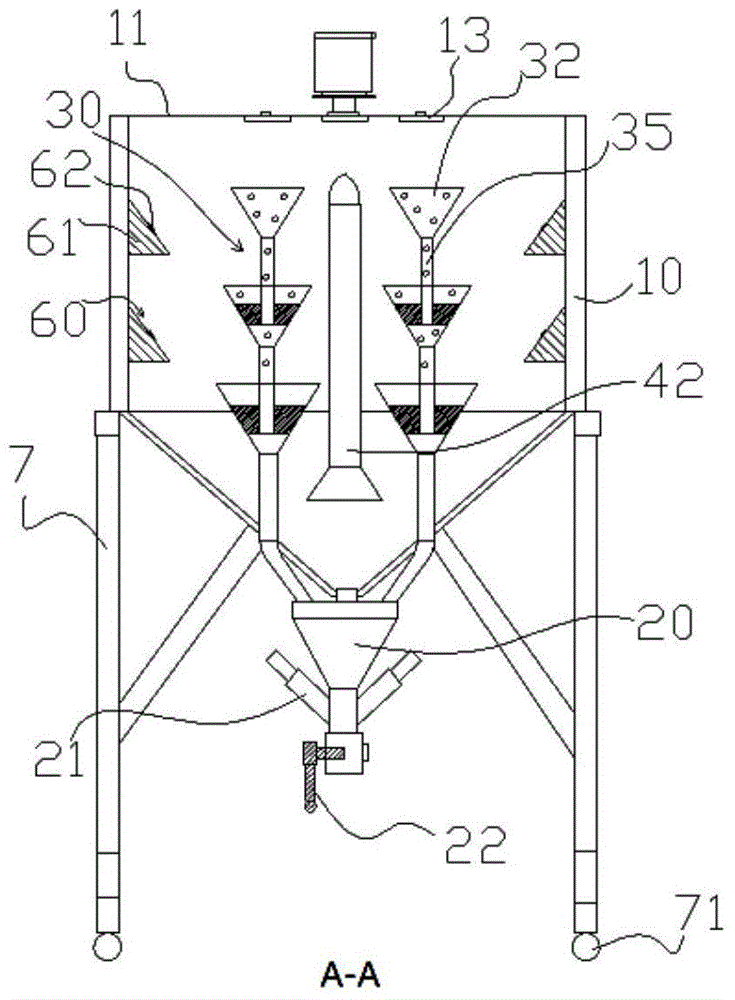

Equal-temperature homogenizing drier

InactiveCN105352276AReduce descent speedExtended drying timeDrying gas arrangementsDrying machines with local agitationEngineeringDry box

The invention discloses an equal-temperature homogenizing drier. The equal-temperature homogenizing drier comprises a drying box, a supporting frame, a material receiving box, a funnel unit and a hot air circulating device. The drying box comprises a box body with a containing cavity and an end cover matched with the box body. The end cover is provided with at least one feed port and an end port. The supporting frame is arranged into a frame body used for supporting the drying box. The material receiving box is arranged below the drying box and communicated with a material outlet of the drying box. The funnel unit is fixedly arranged in the containing cavity of the box body and communicated with the material receiving box through a pipeline. The funnel unit is located under the feed port. The hot air circulating device is arranged to provide circulating air to the drying box. The equal-temperature homogenizing drier has the beneficial effects that materials are evenly heated, and the material drying effect is good.

Owner:DONGGUAN NIASI PLASTICS MACHINERY CO LTD

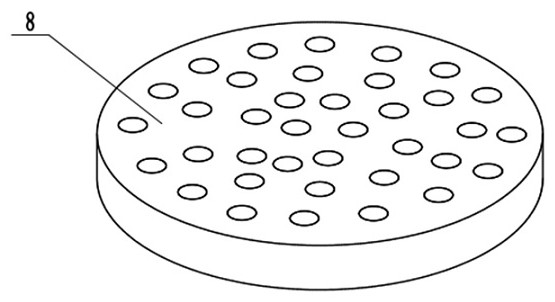

Dampproof device of electric vehicle lithium battery

InactiveCN106953046AImprove securityReduce humidityCell component detailsEngineeringElectric vehicle

The invention discloses a dampproof device of an electric vehicle lithium battery. The dampproof device comprises a lithium battery box, an air-intake fan and a drying disc, wherein the air-intake fan is arranged on the outer wall of the lithium battery box; an air-outlet end of the air-intake fan is communicated with the interior of the lithium battery box; the drying disc is arranged at an air-inlet end of the air-intake fan; and air is dried by the drying disc and then enters the lithium battery box through the air-intake fan. In the dampproof device of the electric vehicle lithium battery disclosed by the invention, as the air is dried by the drying disc and then enters the lithium battery box through the air-intake fan, the humidity in the lithium battery box is reduced, and the safety of a lithium battery in a wet environment is improved.

Owner:四川升能泰科技有限公司

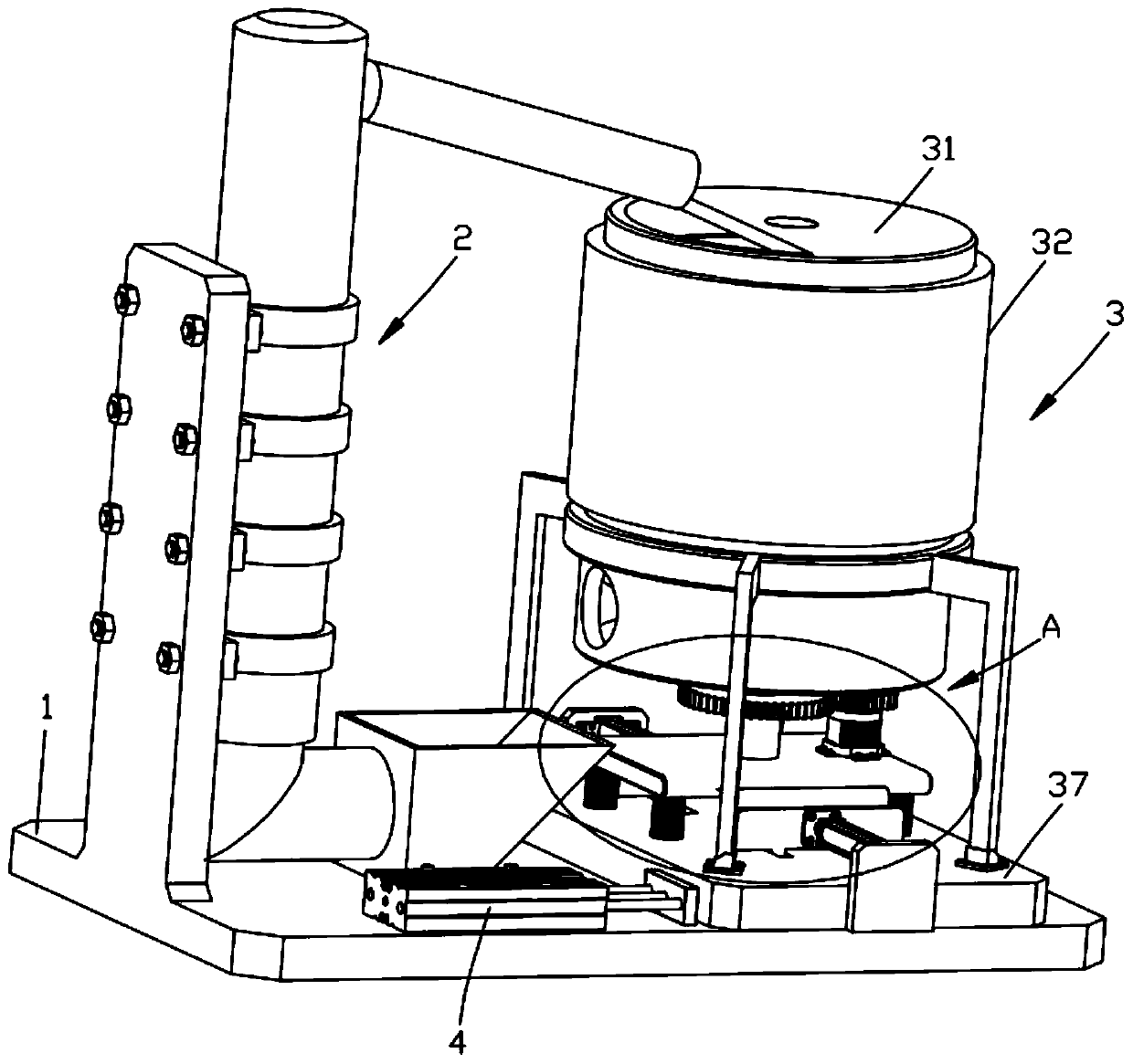

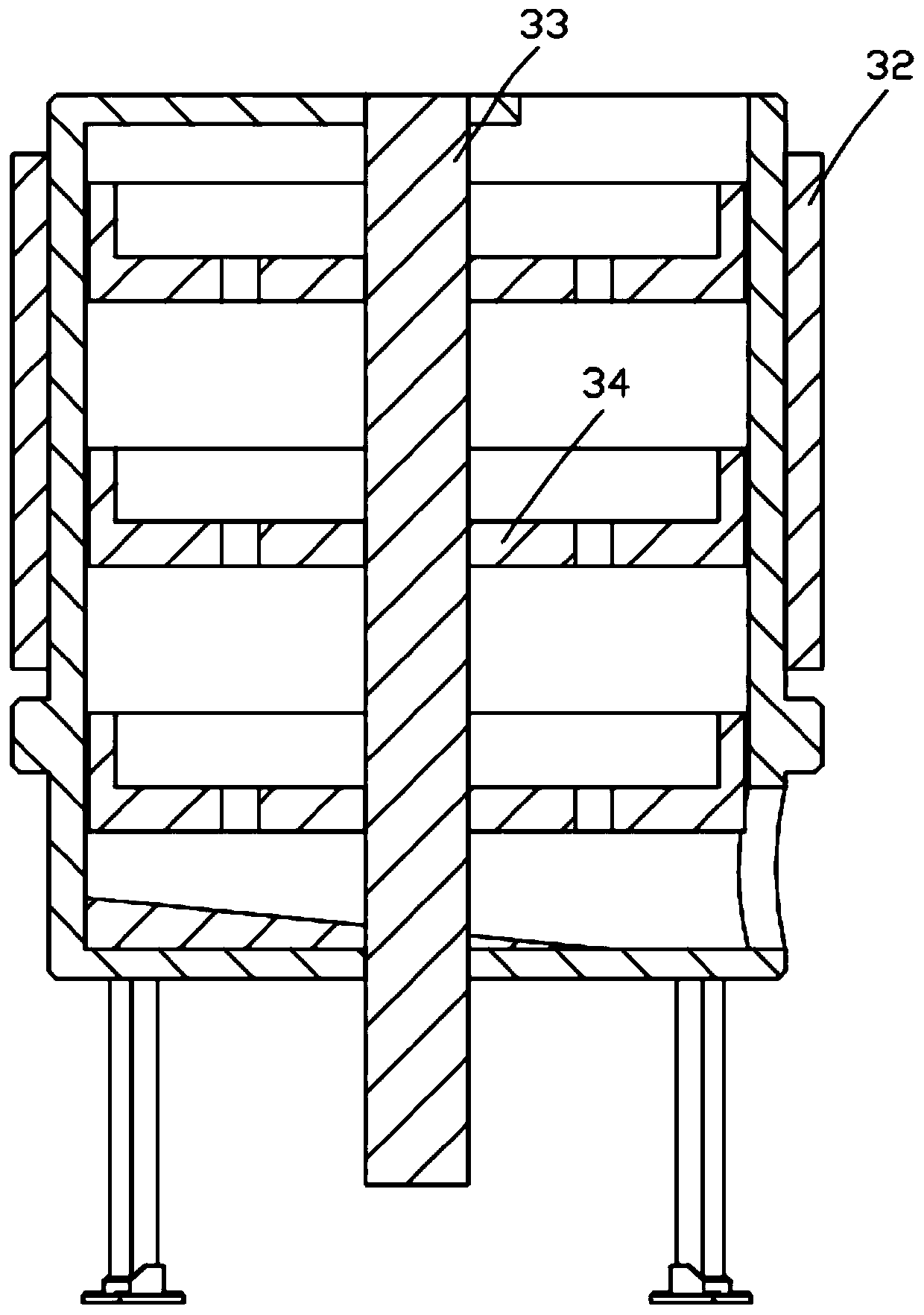

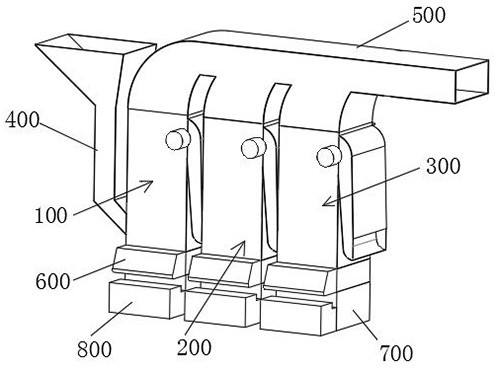

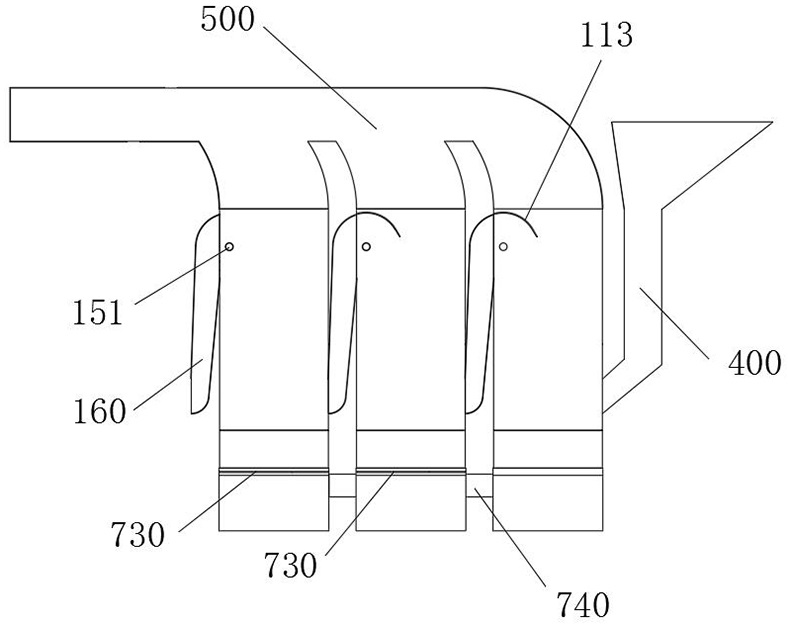

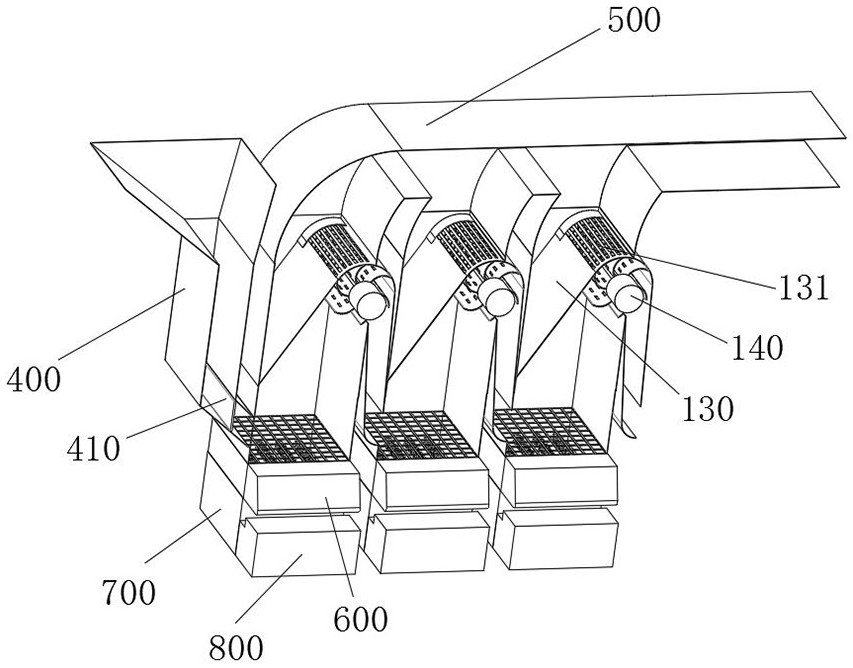

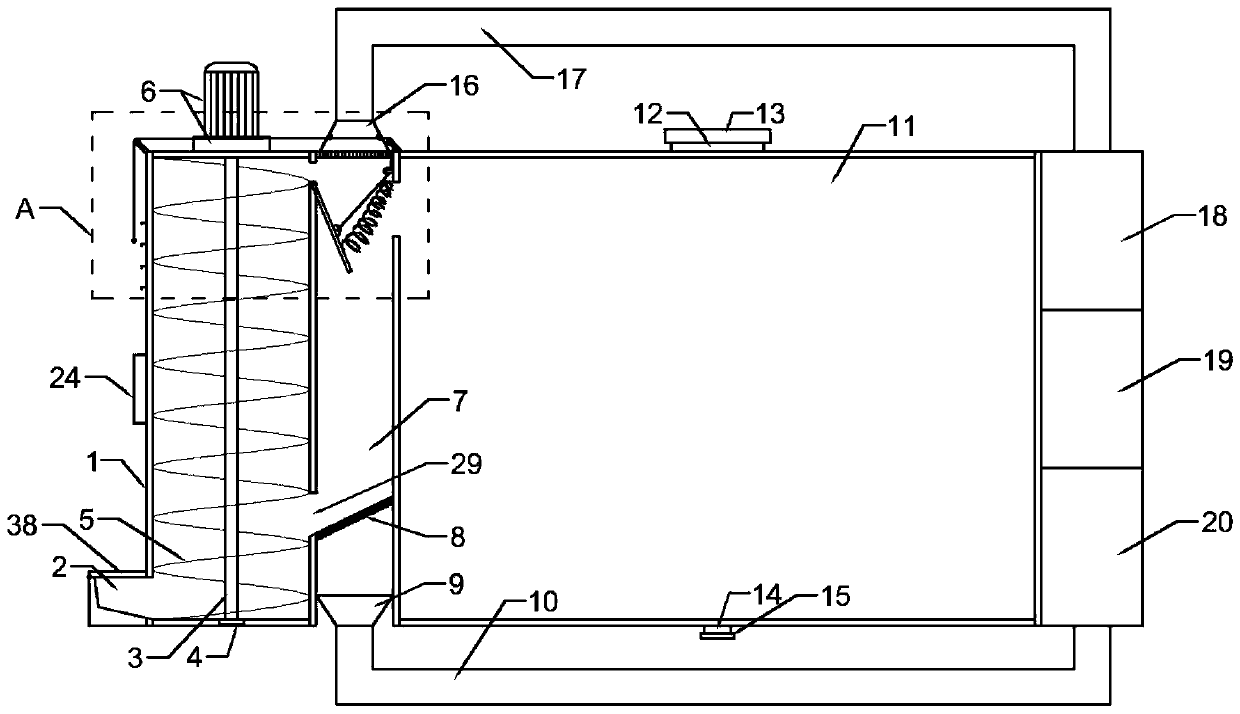

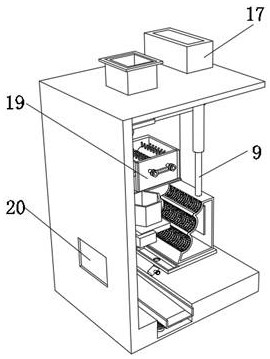

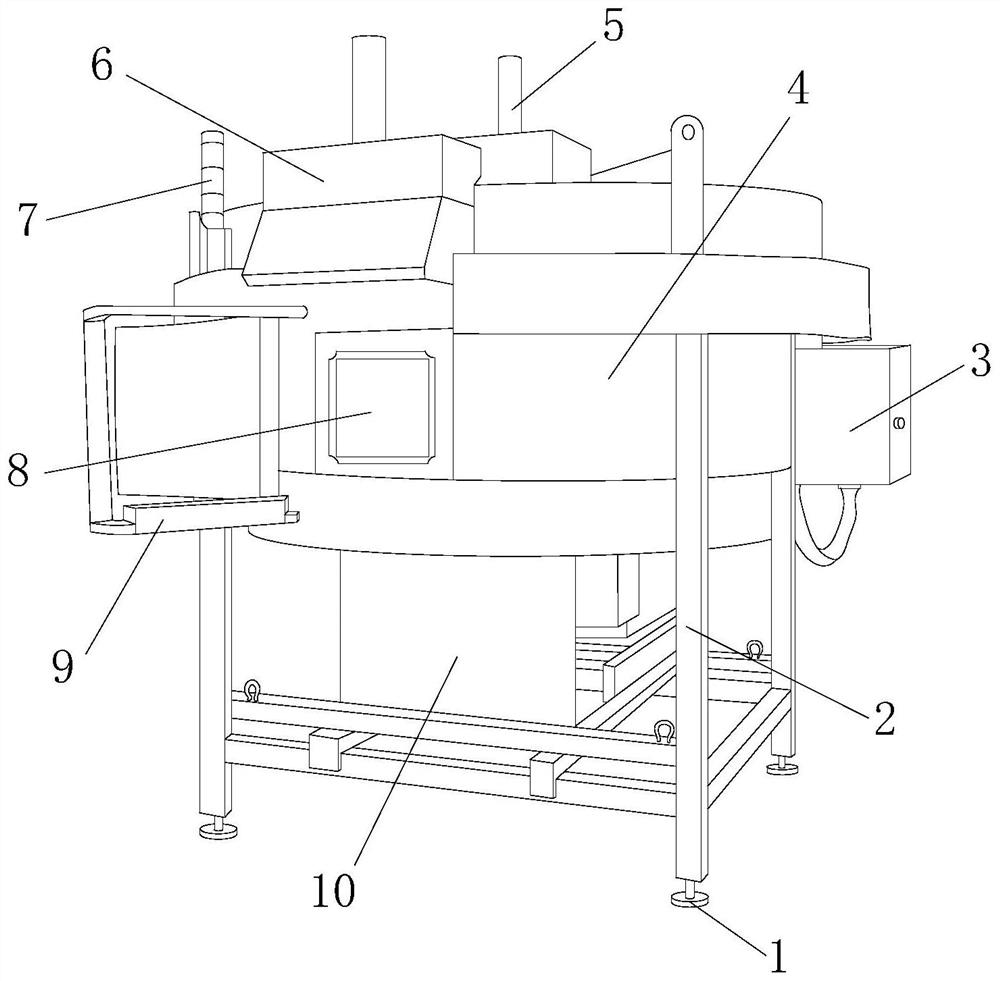

A circulating drying equipment for edible fungi

ActiveCN112369631BDry fastConvenient automatic separationFood treatmentProcess engineeringMicrobiology

The present invention relates to the technical field of edible fungus drying equipment, in particular to a circulation drying equipment for edible fungus, which includes a heating mechanism 1, a heating mechanism 2 and a heating mechanism 3 arranged in parallel, the heating mechanism 1 includes a heating chamber, the Both the bottom and the top of the heating chamber are provided with openings. Among the present invention, the object of the present invention is to provide a kind of circulating drying equipment for edible fungi, through the setting of the heating chamber, the fan blows air into the ventilation box, the air flow is heated when passing through the heater, and the raw materials are heated under the action of the hot air flow Toss in the heating chamber and fully contact with the hot air flow, so that the raw materials can be dried quickly. The dried raw materials will be blown up by the hot air flow due to their light weight and move to the feeding wheel along the guide plate. Rotate to send the dried raw materials to the connecting pipe, enter the next stage of drying or discharge, which is convenient for automatic separation of dried raw materials, avoiding excessive drying of some raw materials, and convenient for continuous production.

Owner:宜春职业技术学院

Grain drying machine

InactiveCN107024105ARealize cycle dryingDry evenlyDrying gas arrangementsDrying solid materialsCold airEngineering

The invention relates to a grain drying machine. The grain drying machine comprises a rack, a hot air device, a cold air device and a drying cavity set used for containing grains are arranged on the rack, a first drying cavity and a second drying cavity are symmetrically formed in the drying cavity set, the first drying cavity and the second drying cavity are internally provided with hollow drying pipes, the bottom ends of the drying pipes are connected to the hot air device, the top end of each drying pipe is lower than the top end of the corresponding drying cavity, feeding augers are arranged at the lower ends of the drying pipes in the drying cavity set, and a hot air inlet connected with the hot air device and a cold air inlet connected with the cold air device are formed in the lower portions of the feeding augers in the drying cavity set. Through cooperation of the drying pipes and the feeding augers, circular drying of grain is achieved, due to the fact that the hot air device alternatively achieves air inlet, and the cold air device achieves continuous air inlet, the temperature in the first drying cavity and the temperature in the second drying cavity are balanced, coking of grain is reduced, and uniform drying of grain is effectively achieved.

Owner:JIANGSU YIZHENG HUAYU MACHINERY

Energy-saving environment-friendly flue gas heat exchange device of metallurgic rotary hearth furnace

ActiveCN110038379AReduce energy consumptionRealize cycle dryingHuman health protectionCombination devicesFlue gasWorking environment

The invention provides an energy-saving environment-friendly flue gas heat exchange device of a metallurgic rotary hearth furnace and relates to the field of metal smelting in heavy industry. The invention aims to solve the problems of low recycling ratio and metallic chips and CO in flue gas directly discharged into air of the present flue gas heat exchange device of the metallurgic rotary hearthfurnace. The energy-saving environment-friendly flue gas heat exchange device of the metallurgic rotary hearth furnace comprises anti-sliding anchors, a bearing bracket, a controller, a metallurgic furnace chamber, a flue gas discharging mechanism and a feeding port. After the flue gas heat exchange device is improved, backflow of flue gas can be realized, so that waste can be recycled and the energy-saving purpose can be achieved; and meanwhile, the metallic chips flying along with flue gas can be separated by a centrifugal force generated by a centrifugal dedusting device and then fall intothe metallurgic furnace chamber, so as to guarantee the metallurgic rate of the rotary hearth furnace; due to the design of multilayer filtering of plate-fin clapboards, environment-friendly emissionof flue gas can be realized and improvement of working environment of workers can be benefited.

Owner:苏州因知成新能源有限公司

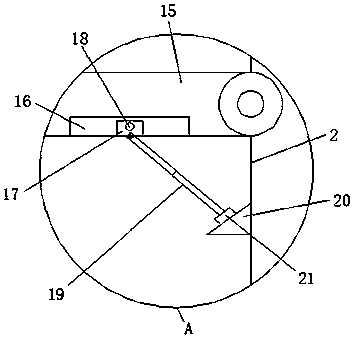

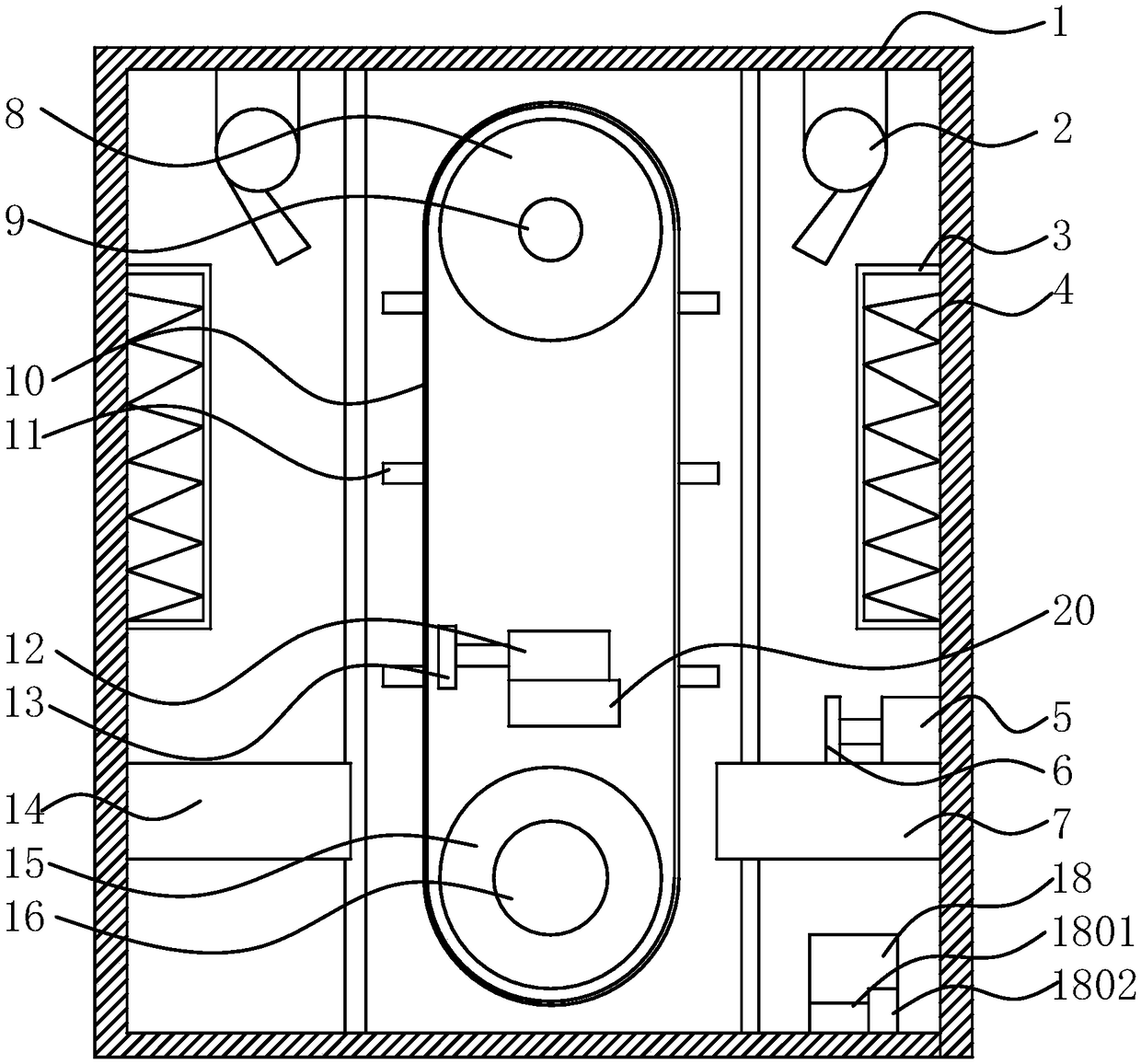

Storage battery pole plate circulation drying device

InactiveCN108955210ARealize cycle dryingSimple structureLead-acid accumulator electrodesDrying machines with progressive movementsDrive wheelEngineering

The invention discloses a storage battery pole plate circulation drying device. The storage battery pole plate circulation drying device comprises a shell, a conveying device and a control device, wherein the conveying device and the control device are arranged in the shell; the conveying device comprises a driving wheel and a driven wheel opposite to the driving wheel; the driven wheel is arranged on the upper portion of the inner wall of the shell through a rotary shaft; the driving wheel is arranged on the lower portion of the inner wall of the shell and is in transmission connection with amotor arranged on the inner wall of the shell; the driving wheel is in transmission connection with the driven wheel through a chain; the chain is oppositely provided with connection plates, and swing rods are movably arranged between the connection plates; the swing rods are connected with storage plates through fixing rods, and pole plates are placed on the storage plates; the two sides of theinner wall of the shell are provided with electric heating wires, and protective nets are arranged outside the electric heating wires; and the top of the shell is obliquely provided fans. According tothe storage battery pole plate circulation drying device, circulation drying of the storage battery pole plates is achieved, and the storage battery pole plates can be dried for a long time.

Owner:安徽迅启电源科技有限公司

Dust recycling system

InactiveCN106268134AImprove the environmentReduce manufacturing costCombination devicesThermal waterWaste management

The invention relates to a dust recycling system which comprises a dust absorbing cover, an exhaust fan, a dust absorbing pool, a spraying device and a plurality of settling ponds, wherein the dust absorbing cover is arranged above a PVC production device; the dust absorbing cover is communicated with an air inlet of the exhaust fan through a first pipeline; an air outlet of the exhaust fan is communicated with one end of the dust absorbing pool through a second pipeline; the other end of the dust absorbing pool is respectively communicated with the settling ponds through a plurality of third pipelines; the spraying device is arranged above the dust absorbing pool and is used for spraying hot water into the dust absorbing pool; an electric hot air device for blowing hot air for each settling pond is arranged above each settling pond. Compared with the prior art, the dust recycling system has the advantages that PVC dust can be recycled, the workshop environment can be improved and the production cost can be lowered.

Owner:广西聚成管道科技有限公司

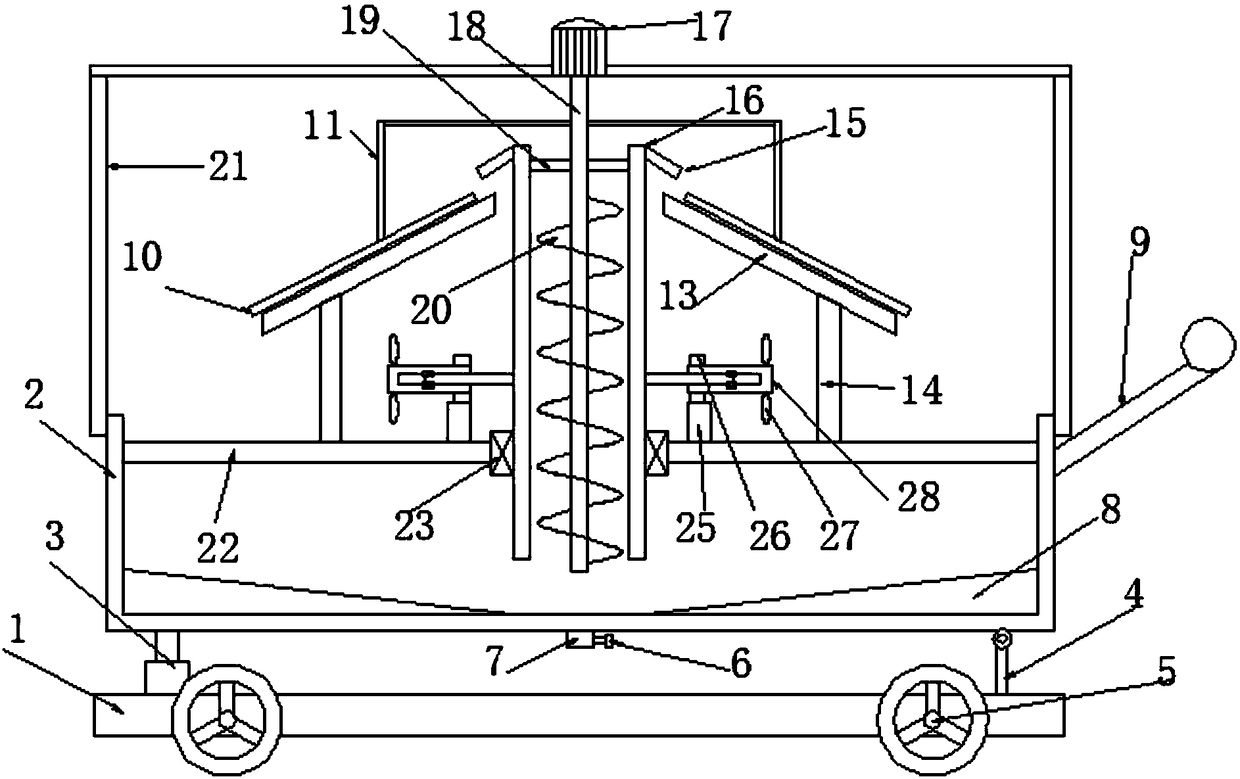

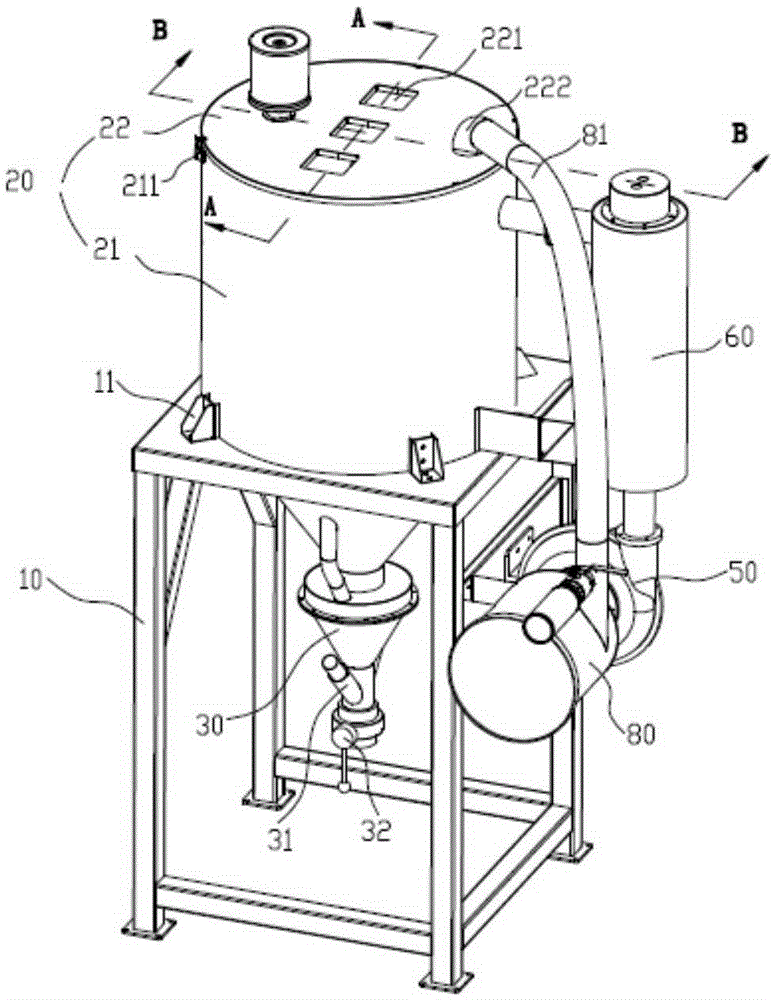

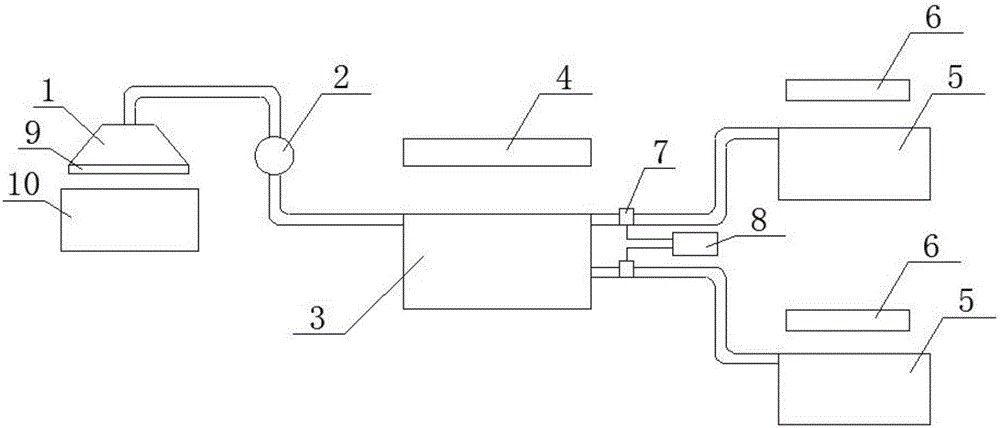

An integrated equipment for drying and storing soybeans

ActiveCN107927851BPrevent mildewPrevent malfunctionLarge containersTank wagonsEngineeringProduct gas

The invention discloses integrated soybean drying and storage equipment. The integrated soybean drying and storage equipment comprises a conveying barrel, a drying cylinder, a storage box and a dryingpower source, wherein the drying cylinder is positioned between the conveying barrel and the storage box, the drying power source comprises a dry gas delivery outlet, a dry gas delivery pipe, a gas recovery port, a gas recovery pipe, a drying device, a blower and a heating device, the conveying barrel comprises a feeding port mounted at the bottom of the conveying barrel, the bottom of the feeding port is communicated with the inside of the conveying barrel, a driving device is mounted at the top of the conveying barrel, an output end of the driving device is connected with a rotating shaft,and the rotating shaft extends into the conveying barrel and is rotationally connected with the bottom of the conveying barrel through a rotating bearing. The integrated soybean drying and storage equipment conducts drying on soybeans by virtue of the drying cylinder matched with the blower and the heating device, realizes cyclical drying by combination of the conveying barrel until the humidity of the dried soybeans meets an expected requirement, effectively avoids mildew of the soybeans and avoids the problem that the soybeans cannot be aired and dried in time due to bad weather.

Owner:桐城市建设投资发展有限责任公司

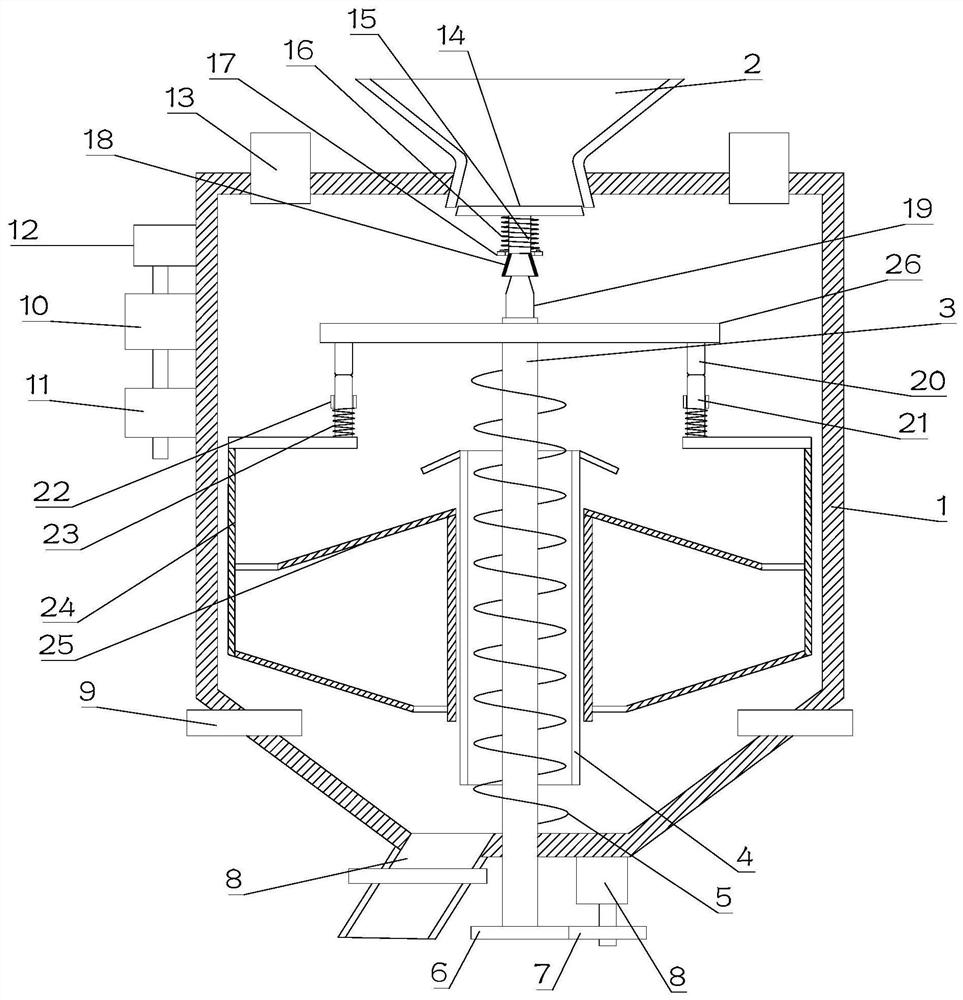

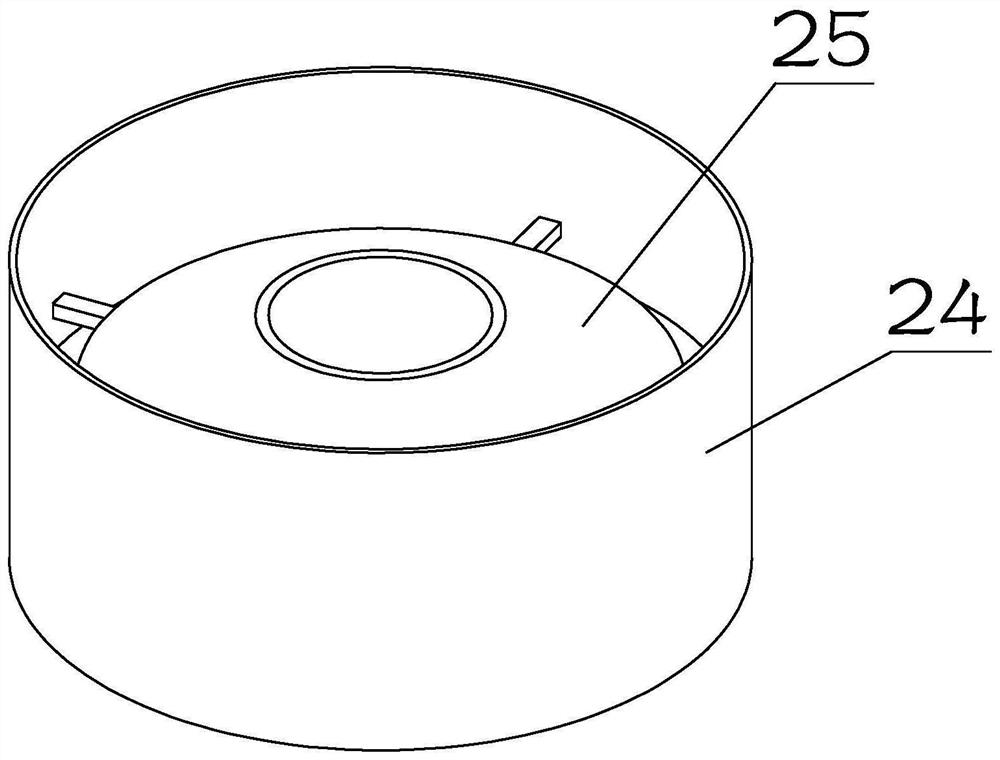

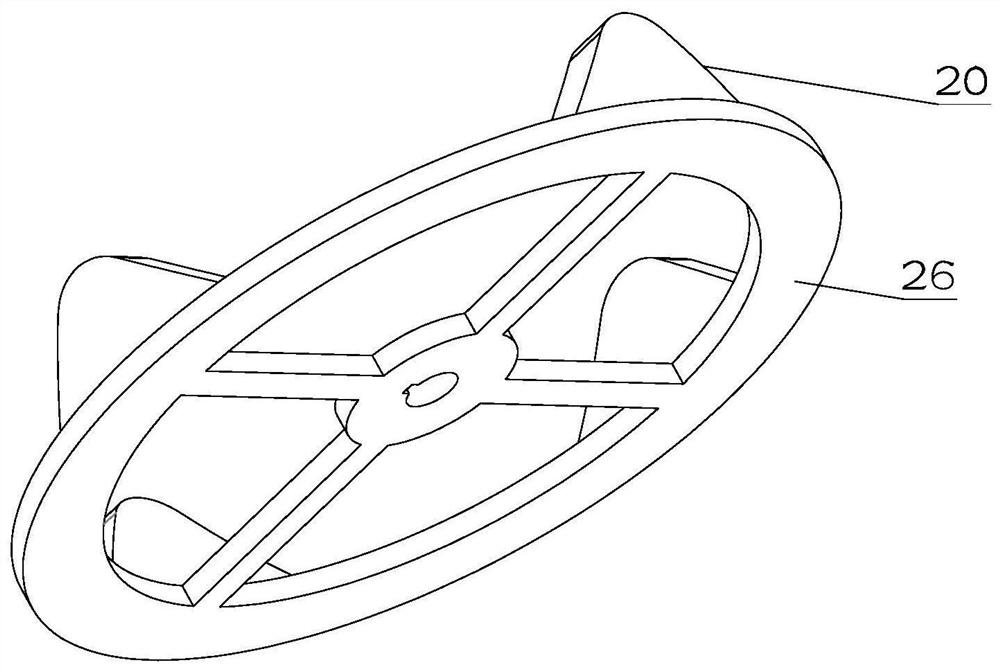

Circulating drying device for building materials

InactiveCN111623608AImprove drying effectRealize cycle dryingDrying gas arrangementsDrying machines with non-progressive movementsBuilding materialStructural engineering

The invention is suitable for the technical field of building material production equipment, and provides a circulating drying device for building materials. The drying device comprises a drying mainbody, a feeding hopper, a circulating assembly and a drying part, wherein the drying main body has the hollow interior and is used for drying; the feeding hopper is fixedly mounted on the drying mainbody and communicates with the interior of the drying main body; the circulating assembly is arranged in the center of the drying main body; the drying part sleeves the outer side of the circulating assembly in an up-and-down vibration manner, and is arranged in an up-and-down vibration manner; and inclined plates which are obliquely arranged are arranged on two sides of the interior of the dryingpart in a crossed mode, the circulating assembly comprises a rotating shaft which is rotationally arranged in the drying main body and performs autorotation, the rotating shaft is fixedly sleeved with a driving part 26, a plurality of protrusions are symmetrically arranged at the bottom of the driving part 26, the protrusions abut against connecting rods elastically arranged in the drying main body, and the bottoms of the connecting rods are fixedly mounted on the upper portion of the drying part. With the circulating drying device for the building materials, the materials bounce in the drying part to be dried, and then the drying effect is improved.

Owner:陈爱君

A circulating drying device for tea

ActiveCN109855413BRealize cycle dryingGuaranteed qualityPre-extraction tea treatmentDrying solid materialsReciprocating motionAgricultural engineering

The invention provides a tea circulation drying device. The hoist is installed on a support frame. The drying mechanism includes a drying barrel, an electric heating sheet, a rotating shaft, a drying disk, a driving mechanism, a reciprocating mechanism and a bottom plate. The barrel is installed on the bottom plate, and there is an electric heating plate on the outside. The bottom plate is movably installed on the support frame through a double-axis cylinder, and the reciprocating mechanism is installed on the bottom plate. The dry barrel forms a moving pair with the drying barrel, and several drying discs are equidistantly fixed on the rotating shaft, and the driving mechanism is installed on the reciprocating mechanism and connected with the rotating shaft. The tea leaves dried in the drying barrel are conveyed to the drying barrel through the elevator, which realizes the circular drying of the tea leaves. When conveying, the tea leaves are turned over to ensure the quality of the drying. The reciprocating motion mechanism drives the drying plate. The up and down movement makes the tea 'boil' in the drying barrel, so that the tea is heated evenly.

Owner:婺源县万和茶业有限公司

Anti-accumulation turning material drying device for rice processing

ActiveCN112044761BKeep dryFully contactedGas current separationDrying gas arrangementsAgricultural engineeringStructural engineering

The invention discloses an anti-accumulation turning and drying device for rice processing, which relates to the technical field of turning and drying devices; in order to fully improve the contact area between rice and hot air; it specifically includes a shell, the outer wall of the top of the shell is passed through bolts An electric slideway is fixed, and the output end of the electric slideway is slidably connected with a sliding seat, and the outer wall of the bottom of the sliding seat is fixed with an electric push rod through bolts, and the output end of the electric push rod is fixed with a wave-shaped drying box through bolts, The inner wall of one side of the wave-shaped drying box is provided with a heating plate; More than two leaks. The present invention can form a certain holding space with the wave-shaped drying box by being provided with a protective box, and can be used to hold the rice exported from the hexagonal turning box, and the heat can be transferred by being provided with a blower and a heating plate. The air is discharged through the leak hole.

Owner:湖北共发米业有限公司

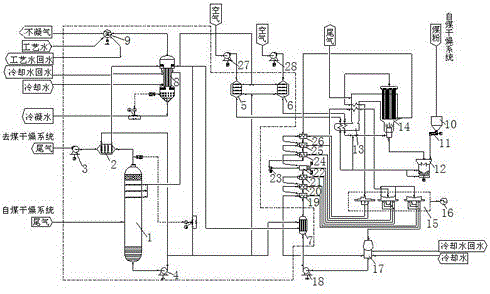

A method for reducing coal consumption and water recovery of coal-fired generating units by using coal drying and exhaust steam

ActiveCN103968659BReduce coal consumption for power supplyIncrease temperatureDrying solid materialsWater vaporProcess engineering

The invention relates to a method of utilizing coal drying exhaust steam to reduce coal consumption of a coal-fired power generator set and recovering water. The method is to add a heat and water recovery system between a coal drying system and the coal-fired power generator set, wherein the heat and water recovery system can convert heat and water vapor carried by the dry tail gas to heat and water carried by hot water, and then the hot water carrying a lot of heat is used for preheating carrier gas entering the coal drying system, air entering a coal-fired boiler system and condensed water after condensing steam by a steam turbine in order to realize efficient transfer of the heat carried by the dry tail gas to the coal-fired power generator set, reduce the coal consumption for the coal-fired power generator set and recover water. The method is characterized by completely recovering and utilizing heat and water vapor carried by the dry tail gas, so as to obviously reduce the coal consumption of a power plant, and conform to the national industry policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Pulverized coal gasification pulverization and water recovery integrated system and method for high-moisture coal

ActiveCN103234214BReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationVacuum pumpMoisture

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

An energy-saving and environment-friendly metallurgical rotary hearth furnace flue gas heat exchange device

ActiveCN110038379BReduce energy consumptionRealize cycle dryingHuman health protectionCombination devicesThermodynamicsFlue gas

The invention provides an energy-saving environment-friendly flue gas heat exchange device of a metallurgic rotary hearth furnace and relates to the field of metal smelting in heavy industry. The invention aims to solve the problems of low recycling ratio and metallic chips and CO in flue gas directly discharged into air of the present flue gas heat exchange device of the metallurgic rotary hearthfurnace. The energy-saving environment-friendly flue gas heat exchange device of the metallurgic rotary hearth furnace comprises anti-sliding anchors, a bearing bracket, a controller, a metallurgic furnace chamber, a flue gas discharging mechanism and a feeding port. After the flue gas heat exchange device is improved, backflow of flue gas can be realized, so that waste can be recycled and the energy-saving purpose can be achieved; and meanwhile, the metallic chips flying along with flue gas can be separated by a centrifugal force generated by a centrifugal dedusting device and then fall intothe metallurgic furnace chamber, so as to guarantee the metallurgic rate of the rotary hearth furnace; due to the design of multilayer filtering of plate-fin clapboards, environment-friendly emissionof flue gas can be realized and improvement of working environment of workers can be benefited.

Owner:苏州因知成新能源有限公司

Chemical raw material circulating drying device

InactiveCN112747583AEvenly dispersedRealize cycle dryingDrying gas arrangementsDrying solid materialsEngineeringMechanical engineering

The invention relates to the technical field of chemical production, and provides a chemical raw material circulating drying device. The device comprises a device body with the hollow interior, a material conveying barrel is arranged in the middle of the interior of the device body, the outer side of the material conveying barrel is sleeved with a sleeve arranged in a self-rotating mode, a plurality of supporting sleeves are arranged outside the sleeve in an array mode, connecting pieces sliding in a reciprocating mode are arranged in the supporting sleeves, and air spraying discs are arranged on the connecting pieces in a self-rotating mode; a rotating shaft is arranged in a through hole in the material conveying barrel in a self-rotating mode, a material conveying auger is fixedly arranged on the outer side of the rotating shaft, a material distributing piece is arranged at an outlet in the upper end of the material conveying barrel, and a vibrating mechanism used for driving the material distributing piece to vibrate up and down in a reciprocating mode is arranged between the material distributing piece and the material conveying auger. According to the device, circulating drying is achieved, raw materials can be evenly dispersed, meanwhile, the raw materials can make uniform contact with hot air, and drying is more sufficient.

Owner:王丽丽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com