Chemical raw material drying device

A drying device and technology for chemical raw materials, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as incomplete drying, achieve the effects of improving drying effect, increasing uncertainty, and reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

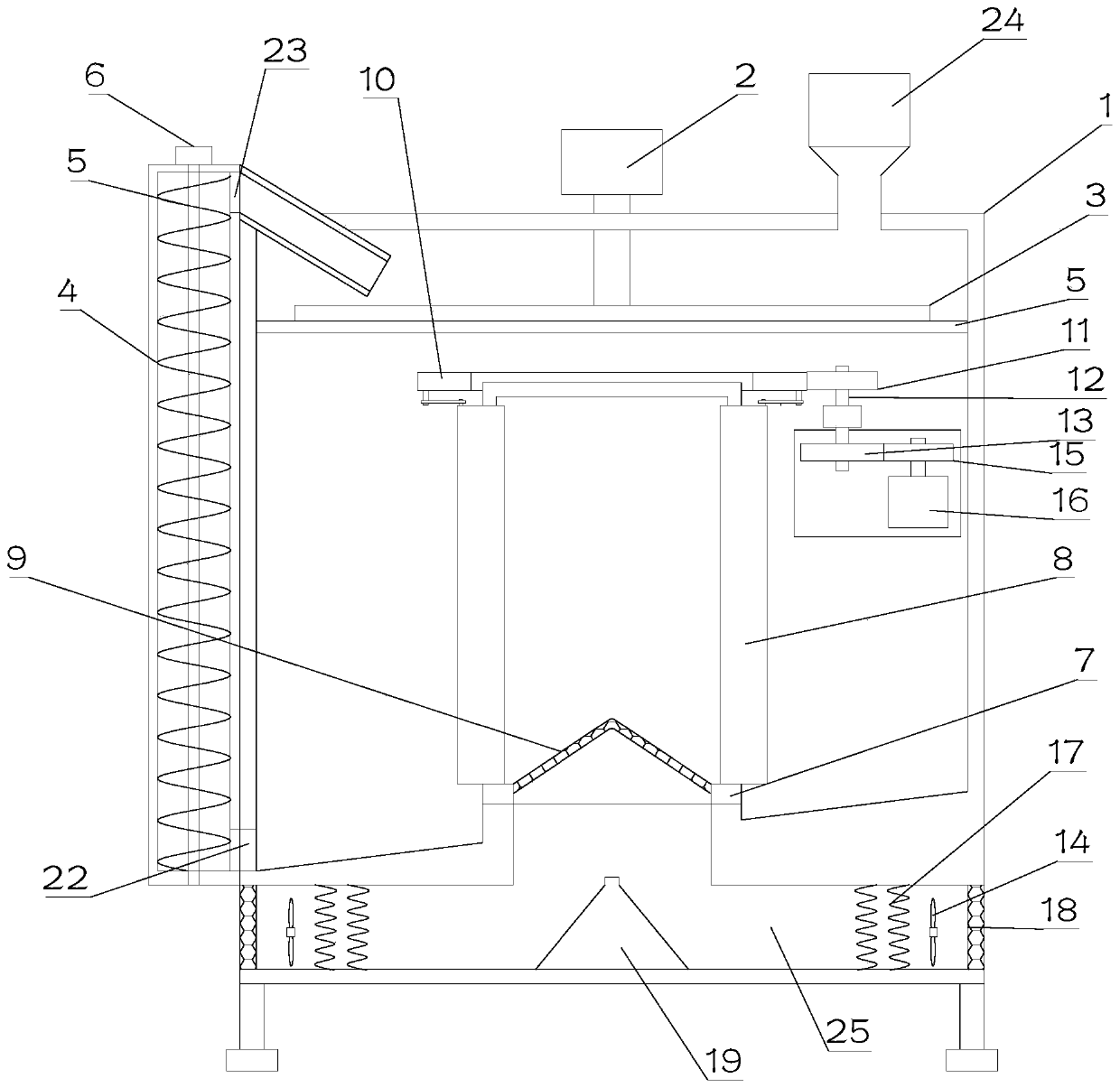

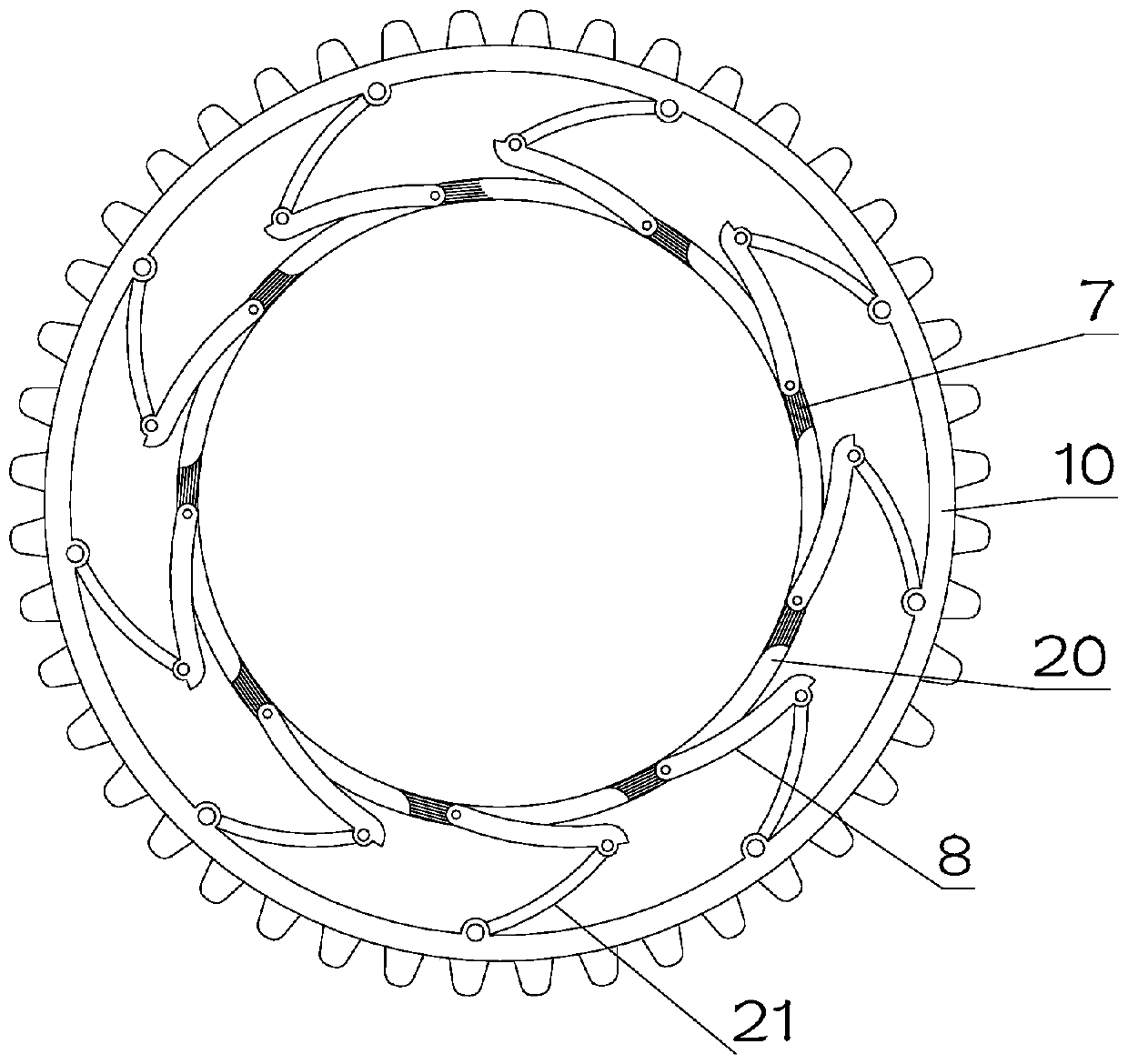

[0021] see Figure 1~3 , in Embodiment 1 of the present invention, a chemical raw material drying device includes a drying main body 1, a material distribution plate 26 is arranged on the drying main body 1, and a scraper plate 3 is attached to the material distribution plate 26, and is rotated and installed On the drying main body 1; the bottom of the material distribution plate 26 is provided with a gas distribution mechanism; the gas distribution mechanism includes a gas distribution cylinder 7 fixedly installed in the center of the drying body 1, and the gas distribution cylinder 7 is cylindrical, and The upper end is airtight; the air distributor 7 is provided with a plurality of air outlets 20 in an array, and the air outlet 20 is provided with an arc-shaped plate 8. One end of the arc-shaped plate 8 is hinged on the air outlet 20, and the other end is connected to the air outlet 20 through a connecting rod. 21 is connected on the ring 10, and the two ends of the connect...

Embodiment 2

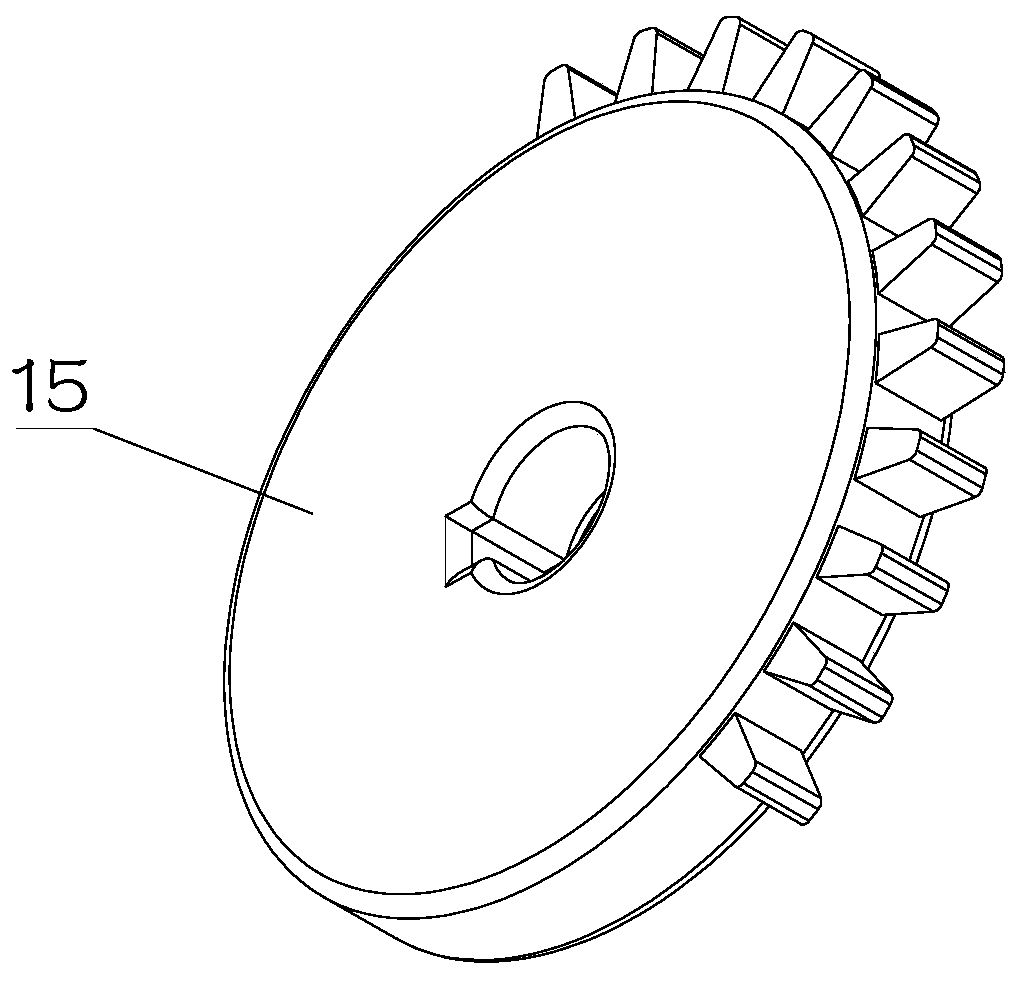

[0025] see Figure 1~3 The main difference between the present embodiment 2 and the embodiment 1 is that the rotating mechanism includes an A gear 11, a B gear 13, an incomplete gear 15 and a B motor 16, and the ring 10 is provided with a gear meshed with the A gear 11, The A gear 11 is installed inside the drying main body 1 through the rotating shaft 12, and the other end of the rotating shaft 12 is fixedly equipped with a B gear 13, and the B gear 13 meshes with the incomplete gear 15 installed on the B motor 16, The B motor 16 is fixedly installed inside the drying body 1 through a support; the B motor 16 drives the ring 10 to rotate intermittently through the incomplete gear 15, the B gear 13 and the A gear 11; when the incomplete gear 15 meshes with the B gear 13 , under the action of A gear 11 and B gear 13, the ring 10 drives the arc-shaped plate 8 to rotate inwardly so as to reduce the opening of the air outlet 20 and change the angle of the air outlet rotation; when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com