Cyclic tea leaf drying device

A drying device and tea technology, applied in drying, drying machine, heating device and other directions, can solve the problems of tea accumulation, tea yellowing, affecting the quality of finished tea products, etc., and achieve the effect of uniform heating and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

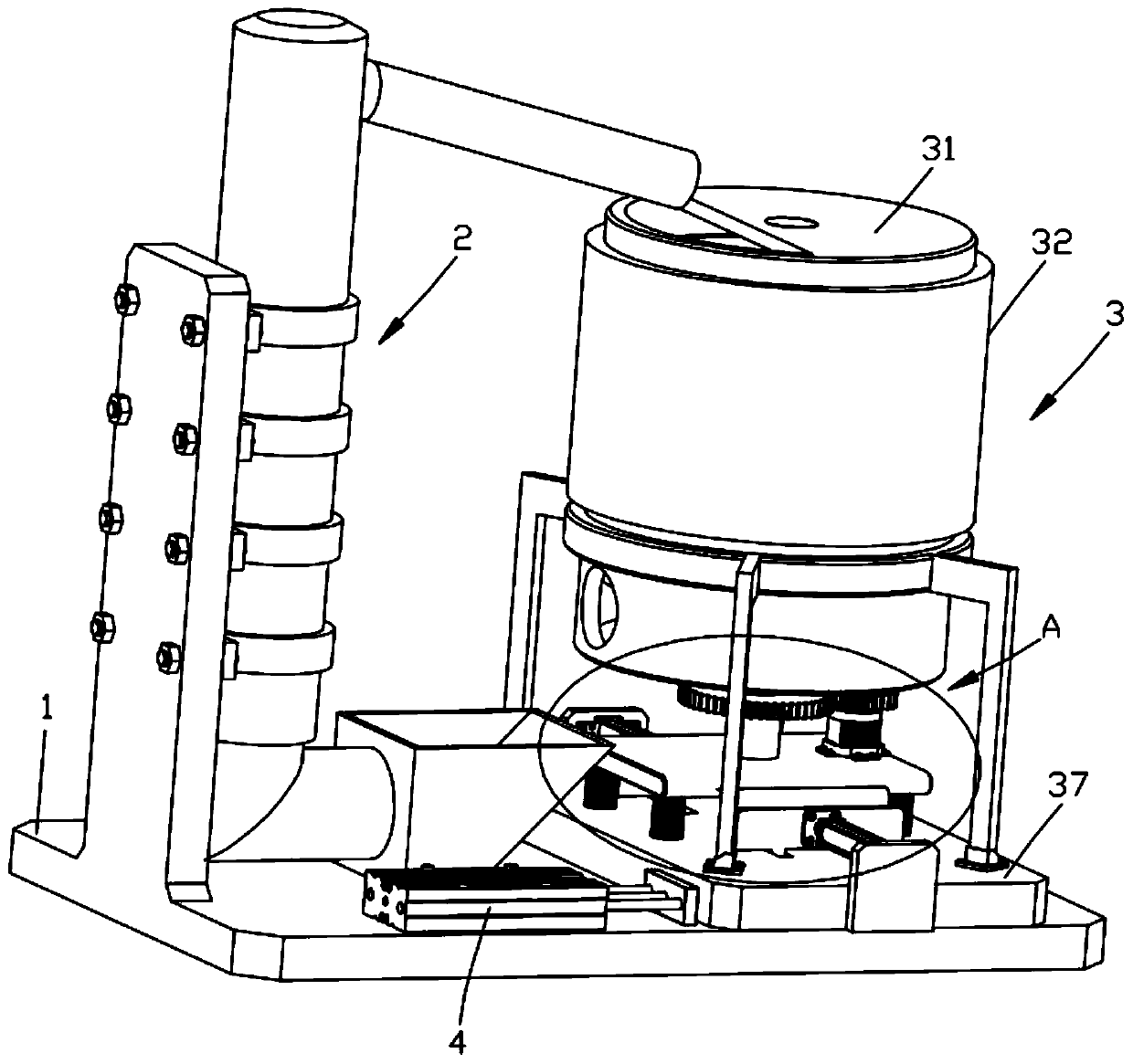

[0026] See Figure 1 to Figure 6 , The present invention provides a technical solution:

[0027] A circulating drying device for tea, comprising a support frame 1, a hoist 2, a drying mechanism 3 and a double-shaft cylinder 4, wherein:

[0028] The elevator 2 is installed on the support frame 1. The feed inlet of the elevator 2 is located on the lower side of the outlet of the drying barrel 31, and the outlet of the elevator 2 is located on the upper side of the inlet of the drying barrel 31, and the tea leaves It can be cyclically transported to the drying barrel 31 by the elevator 2;

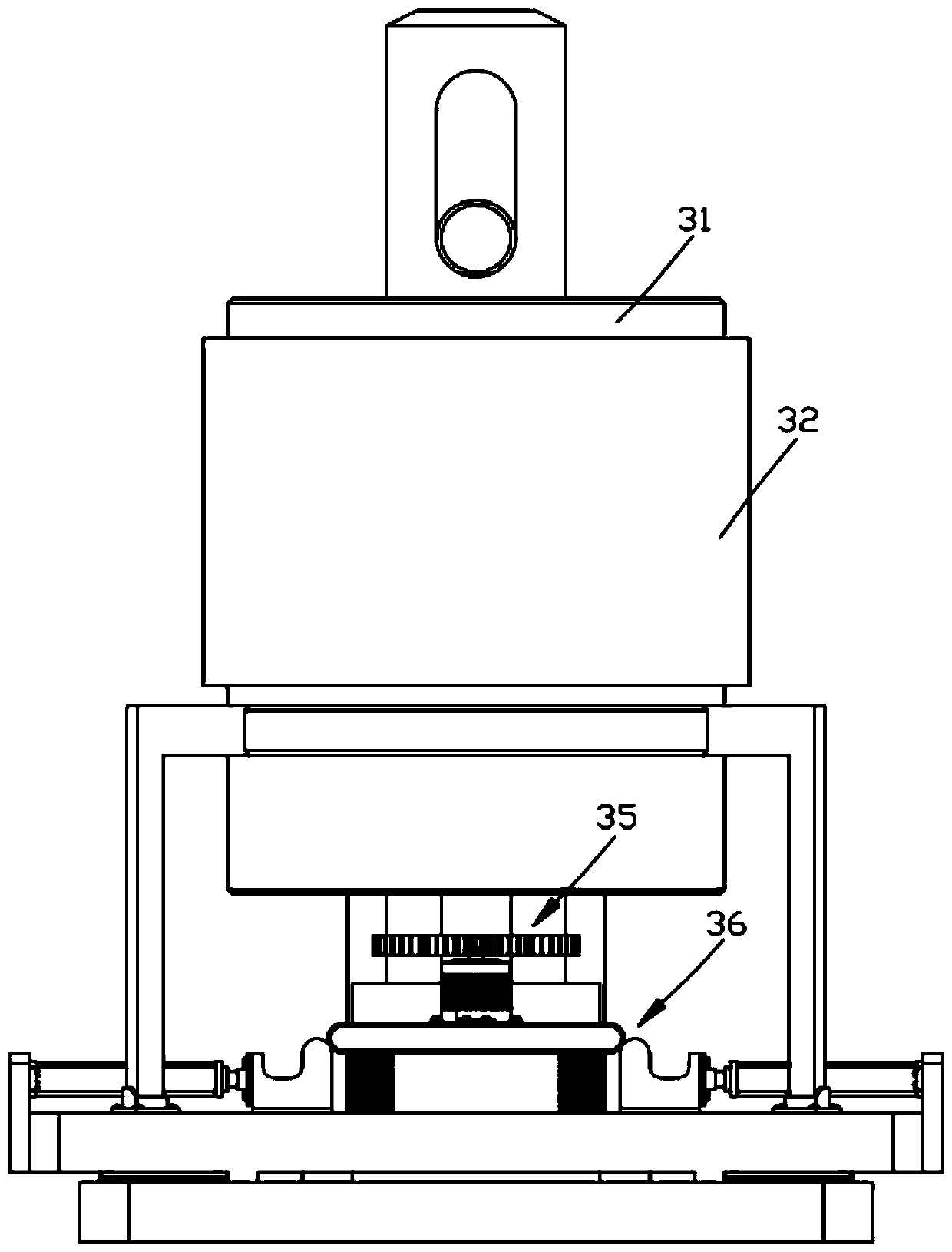

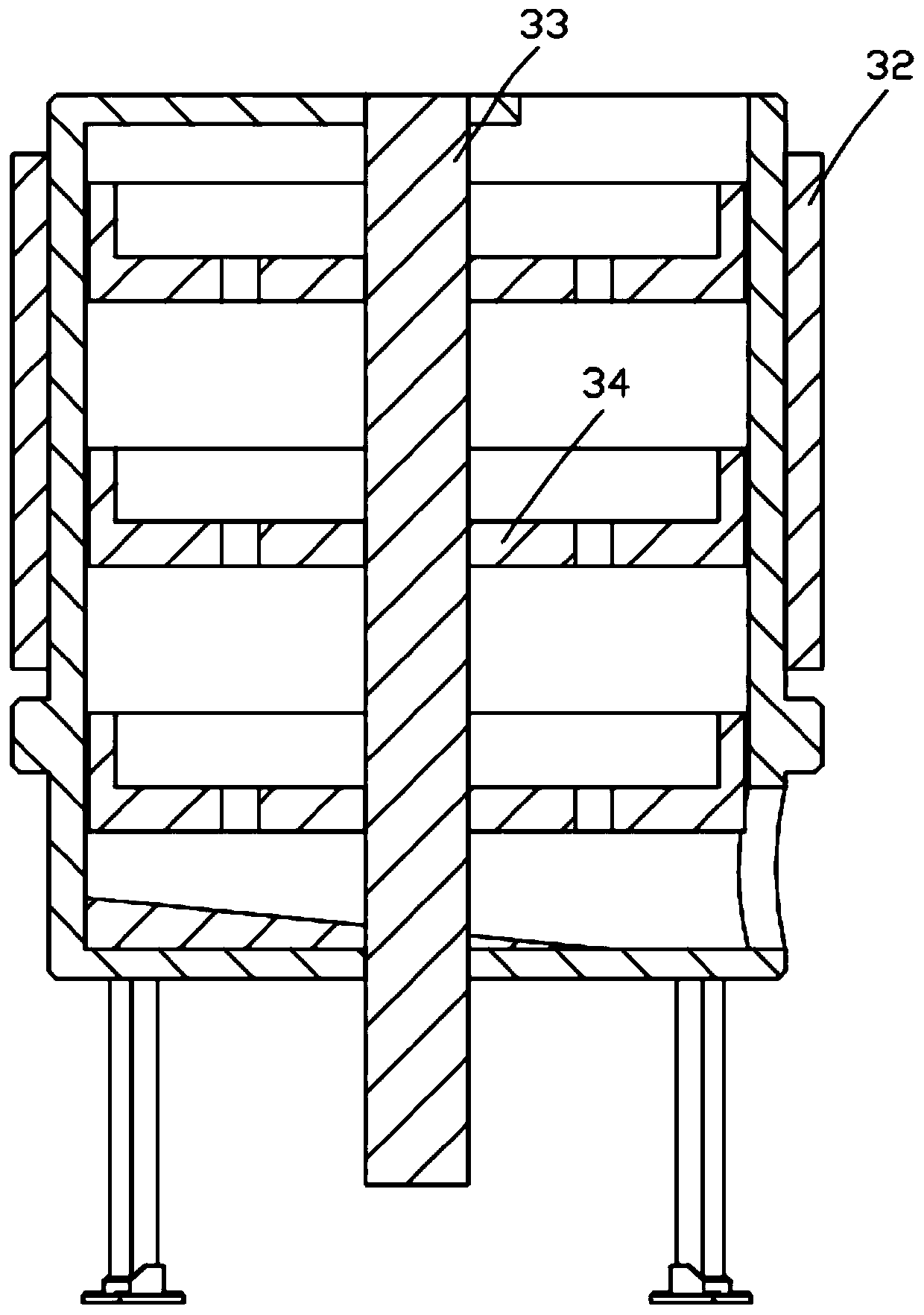

[0029] The drying mechanism 3 includes a drying barrel 31, an electric heating plate 32, a rotating shaft 33, a drying tray 34, a driving mechanism 35, a reciprocating motion mechanism 36 and a bottom plate 37. The drying tub 31 is fixedly installed on the bottom plate 37 by bolts, and the drying An electric heating plate 32 is provided on the outside of the barrel 31, and the electric heating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com