Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

A high-moisture coal, integrated system technology, applied in combustion methods, block/powder fuel preparation, indirect carbon dioxide emission reduction, etc., can solve the problems of poor operating environment, economic infeasibility, fine coal ignition, etc. Heat consumption, gas consumption, oxygen content are completely controllable, and the effect of energy saving and emission reduction is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

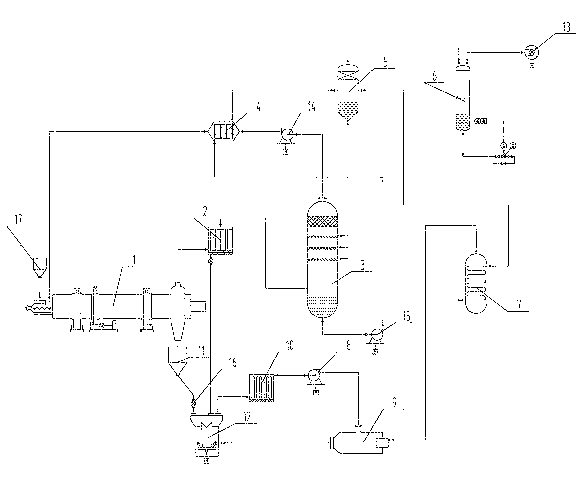

[0038] Such as figure 1 As shown, the pulverized coal gasification and water recovery integrated system for high-moisture coal includes a steam indirect heat exchange dryer 1, an absorption tower 3, a flash tower 5, a vacuum pump / venturi jet pump 13 and a raw coal bunker 17.

[0039] The input end of the steam indirect heat exchange dryer 1 is connected to the raw coal bunker 17, and the upper part of the other end is connected with a bag filter I2, and the lower part of the other end is provided with a buffer bin 11; the buffer bin 11 is connected with a coal mill through the conveying pipe I 12; One side of the coal mill 12 is connected with a hot blast stove 9, and its top is respectively equipped with a bag filter II10 and a conveying pipeline II, which is connected with the bag filter I2; The furnace 9 is connected; the bag filter I2 is connected with the absorption tower 3 and the buffer bin 11 respectively; the top of the absorption tower 3 is connected with the carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com