Wastewater recycling process and device

A waste water recycling and waste water technology, applied in natural water body treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of water waste, troublesome operation, high production cost, and reduce the discharge of waste water. , the effect of saving resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

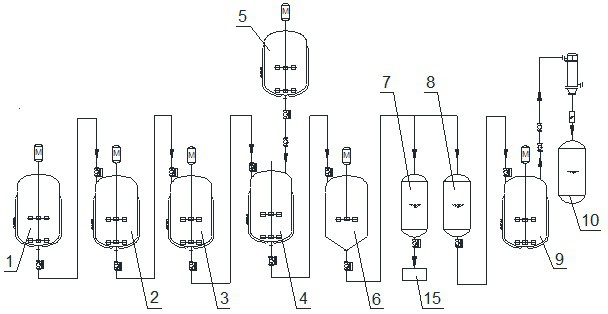

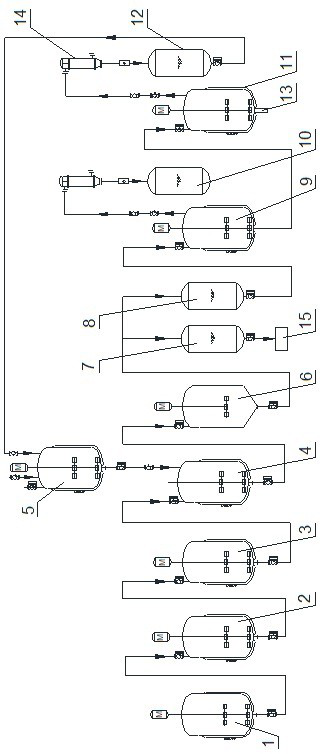

[0020] Such as figure 1 and 2 Shown, the present invention comprises a kind of waste water recycling technology, comprises the steps:

[0021] A. Perform single-effect distillation on the high-salt, high-COD and dark-color waste water obtained in the existing cytosine synthesis process, that is, carry out negative pressure distillation on the waste water, and undergo gas phase condensation treatment to obtain still residue and inorganic salt-free waste water Single-effect waste water, the main component of the still residue is solid waste salt;

[0022] B. Carry out solid waste treatment to the kettle residue to obtain the remaining single-effect wastewater;

[0023] C. Replace purified water with single-effect waste water, dilute 30% liquid alkali used in industrial production to obtain 10% dilute alkali, and add 10% dilute alkali to the neutralization process of cytosine synthesis process for neutralization reaction.

[0024] A device for realizing the waste water recove...

Embodiment 2

[0041] Such as figure 1 and 2 Shown, the present invention comprises a kind of waste water recycling technology, comprises the steps:

[0042] A. Perform single-effect distillation on the high-salt, high-COD and dark-color waste water obtained in the existing cytosine synthesis process, that is, carry out negative pressure distillation on the waste water, and undergo gas phase condensation treatment to obtain still residue and inorganic salt-free waste water Single-effect waste water, the main component of the still residue is solid waste salt;

[0043] B. Carry out solid waste treatment to the kettle residue to obtain the remaining single-effect wastewater;

[0044] C. Replace purified water with single-effect waste water, dilute 30% liquid alkali used in industrial production to obtain 10% dilute alkali, and add 10% dilute alkali to the neutralization process of cytosine synthesis process for neutralization reaction.

[0045] A device for realizing the waste water recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com