Dust recycling system

A dust recovery and dust absorption technology, applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of diffuse dust in the workshop, waste, and impact on the health of workers, so as to improve the workshop environment and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

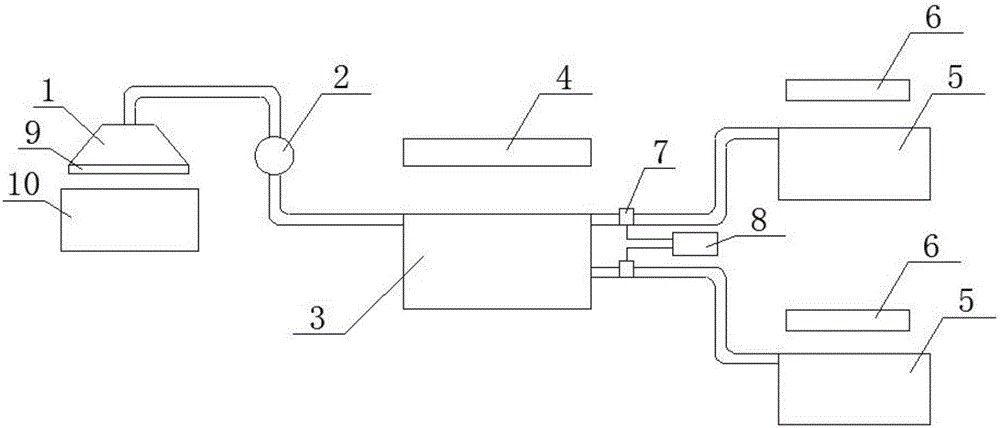

[0015] Such as figure 1 As shown, a dust recycling system includes a powder suction hood 1, an exhaust fan 2, a dust absorption pool 3, a spray device 4 and a plurality of sedimentation tanks 5, and the powder suction hood 1 is placed above the PVC production equipment, The powder suction cover 1 communicates with the air inlet of the exhaust fan 2 through a first pipeline; the air outlet of the exhaust fan 2 communicates with one end of the dust absorption pool 3 through a second pipeline, and the dust absorption pool 3 The other end of the other end communicates with a plurality of said sedimentation tanks 5 respectively through a plurality of third pipes; said spraying device 4 is placed above said dust absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com