Equal-temperature homogenizing drier

A dryer and drying box technology, which is applied to local stirring dryers, dryers for static materials, dryers, etc., can solve the problems of uneven heating of materials, unfavorable drying of materials, affecting drying effects of materials, etc., and achieve uniform heating. , the effect of temperature homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The following "up" and "down" are consistent with the up and down directions of the drawings themselves.

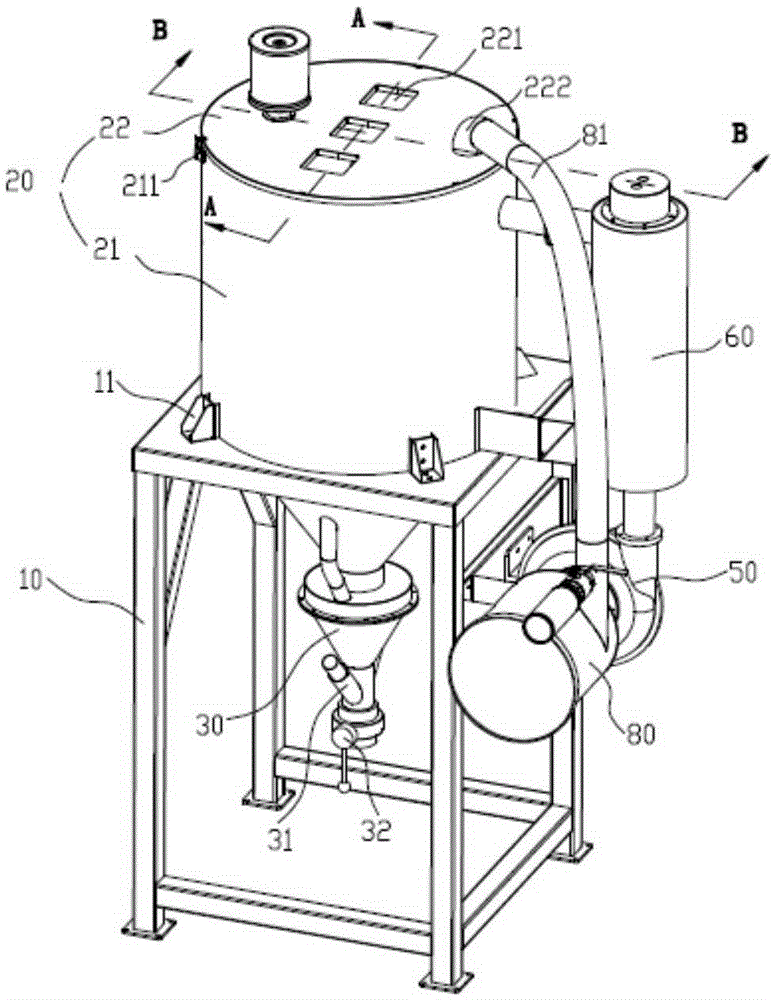

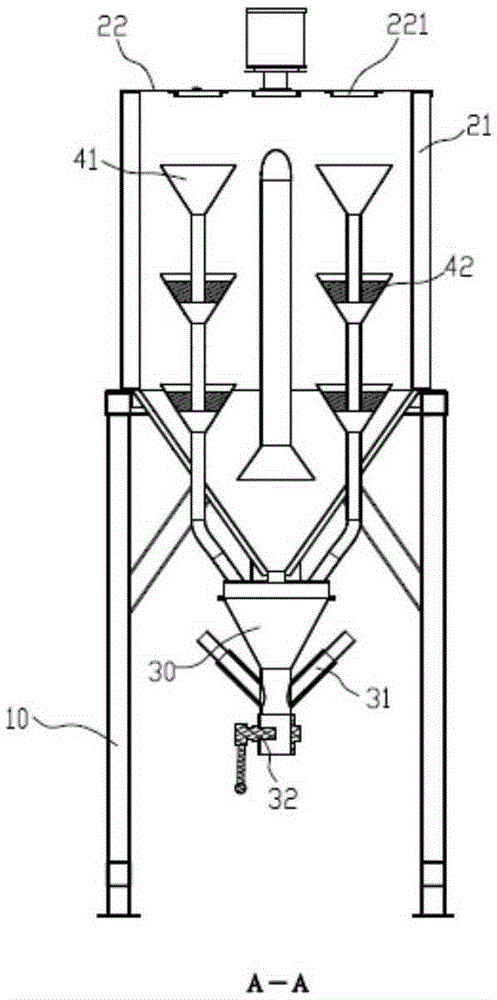

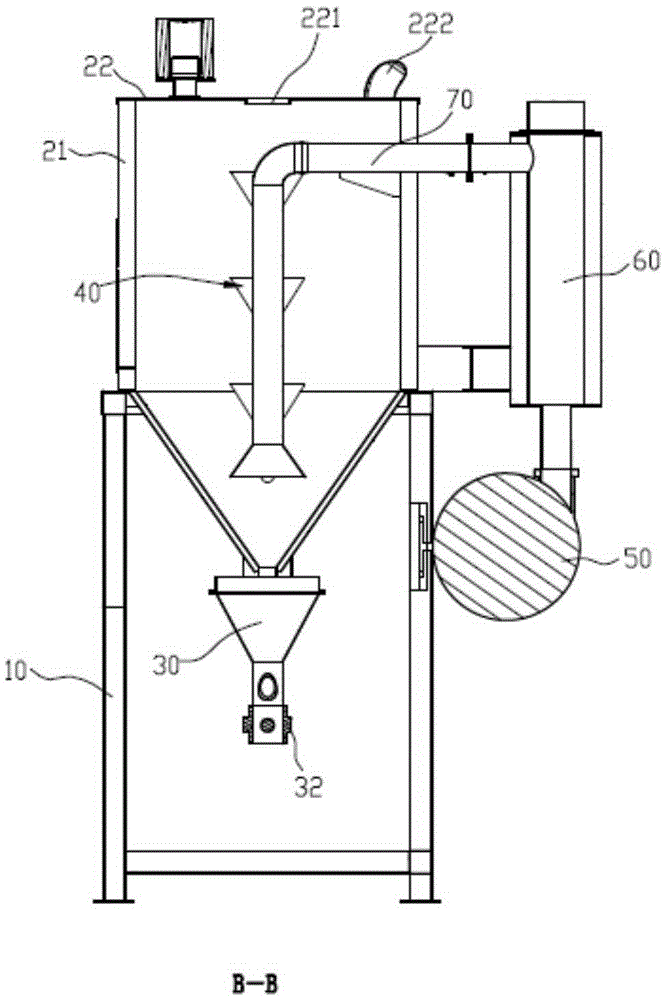

[0024] See figure 1 As shown, a uniform temperature and homogeneous dryer includes: a support frame 10, a drying box 20, a receiving box 30, a funnel unit 40 and a hot air circulation device. The drying box 20 includes a box body 21 having an accommodating cavity and an end cover 22 matched with the box body 21 , and at least one feeding port 221 and one port 222 are provided on the end cover 22 . The end cover 22 is fastened on the top of the box body 21 through a lock 211 , and the lock 211 is fixedly arranged on the outer wall of the upper part of the box body 21 . The support frame 10 is configured as a frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com