Air conditioning system and defrosting control method thereof

An air-conditioning system and control method technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low evaporation temperature of working medium, room heat loss, energy consumption, etc., and achieve slow down and slow down. , the effect of slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

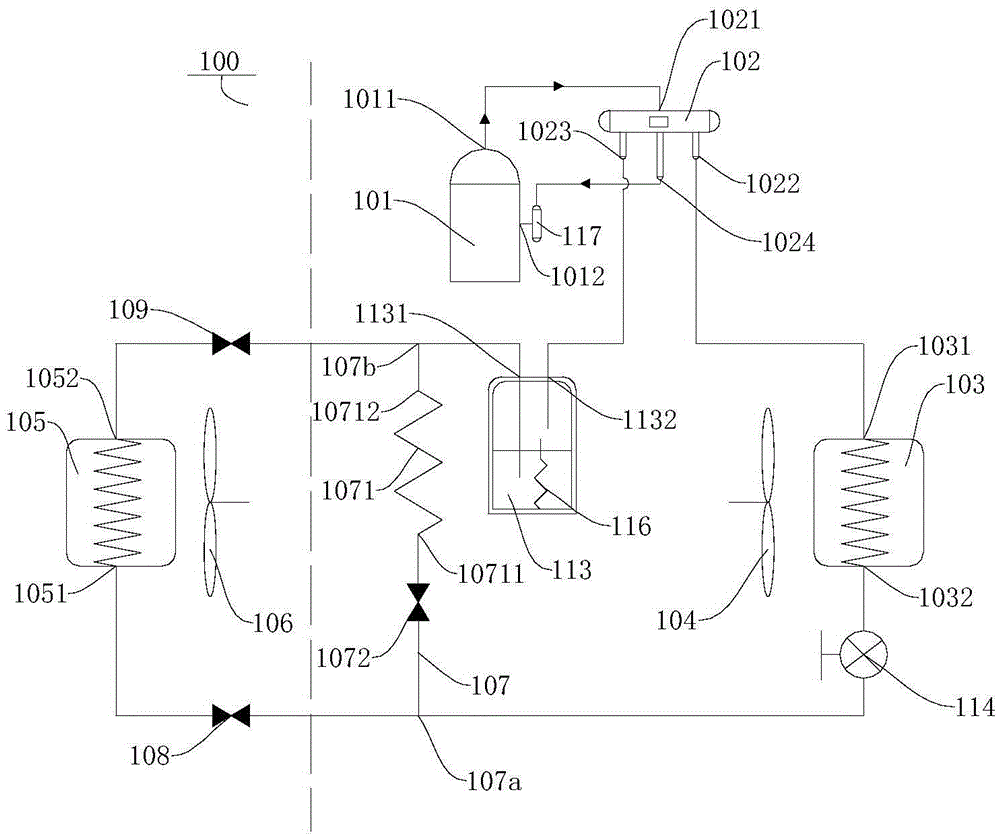

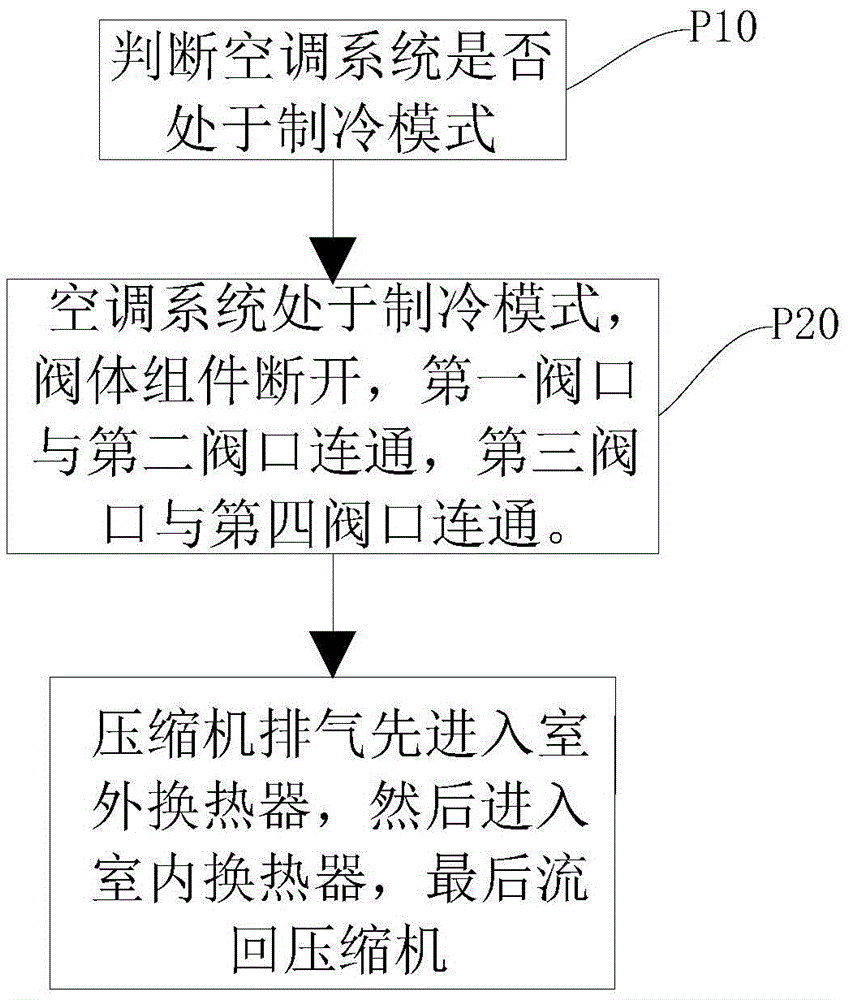

[0084] Such as figure 1 As shown, the air conditioning system 100 according to the embodiment of the present invention includes a compressor 101 (for example, a scroll compressor), a reversing assembly 102, a defrosting branch 107, an outdoor heat exchanger 103 (the ribs of the outdoor heat exchanger fins can be low-pressure loss ribs), outdoor fan assembly 104 (such as high static pressure fan), indoor heat exchanger 105, indoor fan assembly 106, first control valve 108, second control valve 109, throttling device, gas-liquid Separator 117 , reservoir 113 and heating assembly 116 .

[0085] Specifically, the compressor 101 has an exhaust port 1011 and an air return port 1012, and the reversing assembly 102 (such as a four-way valve) includes a first valve port 1021, a second valve port 1022, a third valve port 1023 and a fourth valve port 1024 , the first valve port 1021 is connected to the exhaust port 1011 of the compressor 101, the fourth valve port 1024 is connected to t...

Embodiment 2

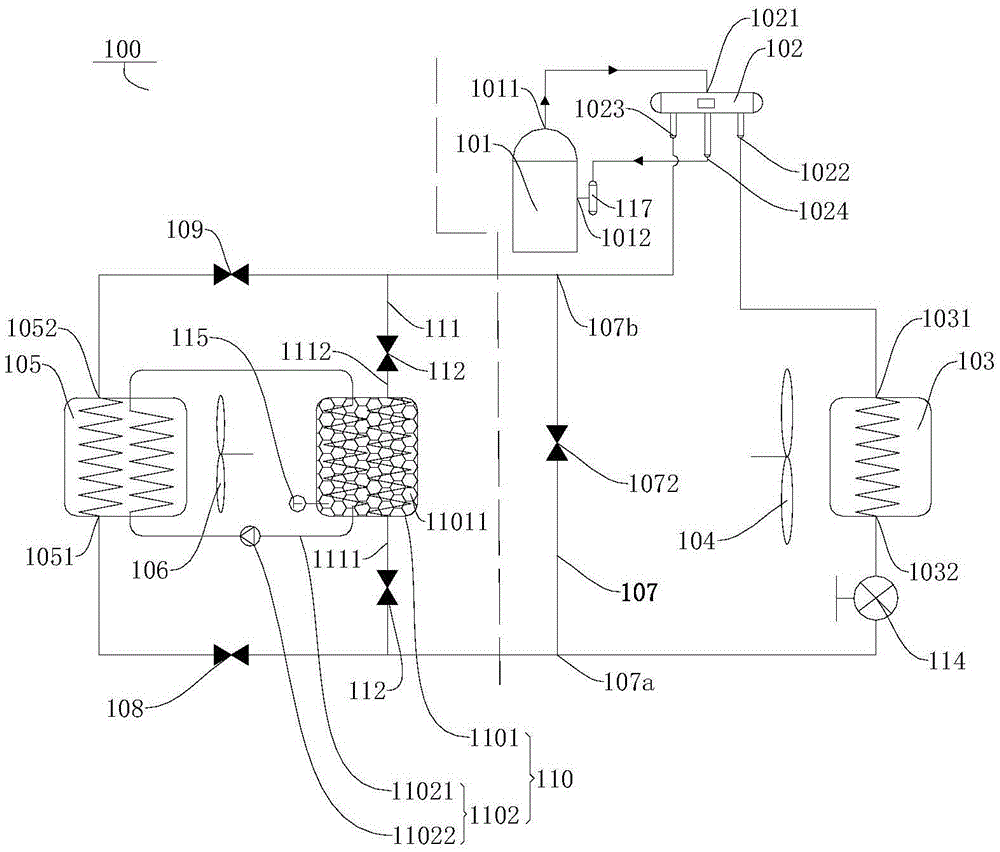

[0094] Such as figure 2 As shown, the difference from the first embodiment is that in this embodiment, the air conditioning system 100 further includes a heat storage assembly 110 , a heat storage branch 111 and a heat storage control valve 112 . The heat storage component 110 includes a phase change heat storage tank 1101 and a circulation component 1102. The circulation component 1102 can transfer the heat in the phase change heat storage tank 1101 to the room. Circulation pump 11022 on the top, circulation medium is provided in the circulation pipeline 11021, the circulation pump 11022 drives the circulation medium to flow in the circulation pipeline 11021, a part of the circulation pipeline 11021 is set in the phase change heat storage tank 1101, and a part is set in the near At the position of the indoor fan assembly 106, under the action of the circulation pump 11022, the medium in the circulation pipeline 11021 circulates to transfer the heat in the phase change heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com