Hot air circulation drying device for capacitor production

A technology of hot air circulation and drying equipment, which is applied in drying, drying machines, drying chambers/containers, etc., can solve the problem of uneven heating of capacitors, and achieve the effects of reducing drying dead angle, uniform heating, and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

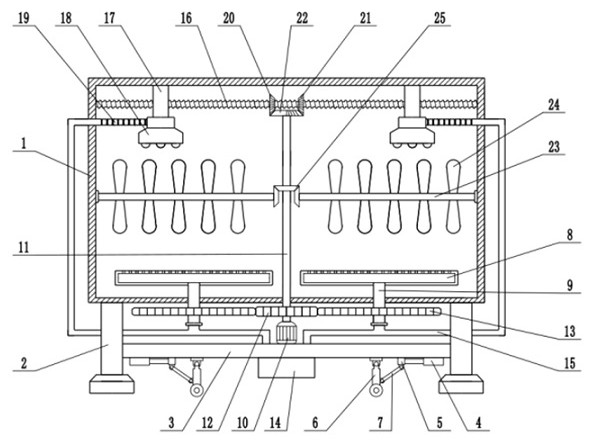

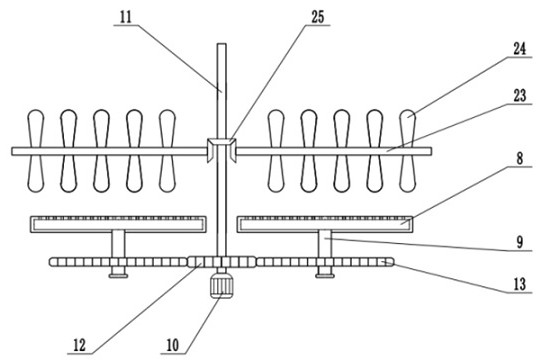

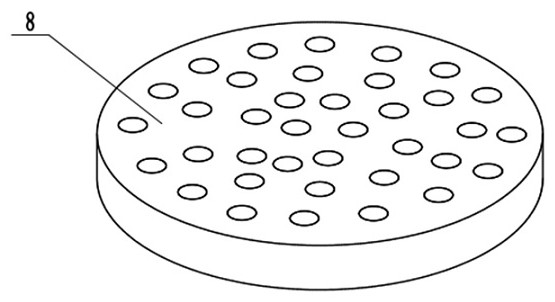

[0023] see Figure 1-3 , in an embodiment of the present invention, a hot air circulation drying device for capacitor production, including a box body 1, a leg 2, a hot air blower 14 and an air outlet 18, the bottom of the box body 1 is fixedly connected with a leg 2, and the bottom of the leg 2 is provided with There is a fixed plate 3, the edge of the fixed plate 3 is fixedly connected with the feet 2, and the inside of the box body 1 is equipped with a turntable 8. There are two turntables 8, which are arranged symmetrically. The inside of the turntable 8 is hollow, and the surface of the turntable 8 is distributed with air outlet , the bottom of the turntable 8 is equipped with a hollow shaft 9, the hollow shaft 9 communicates with the turntable 8, the lower end of the hollow shaft 9 extends through the box 1 to the bottom of the box 1, the hollow shaft 9 is connected to the box 1 in rotation, and the fixed plate 3 The upper surface of the motor 10 is fixedly connected wit...

Embodiment 2

[0025] On the basis of Embodiment 1, a moving mechanism is installed on the bottom of the fixed plate 3, and the moving mechanism includes a telescopic mechanism 4, a slide block 5, a movable rod 6 and a connecting rod 7, and the bottom of the fixed plate 3 is fixedly connected with a telescopic mechanism 4. The mechanism 4 is an electro-hydraulic telescopic cylinder. The extended end of the telescopic mechanism 4 is fixedly connected with a slider 5, and the slider 5 is slidably connected with the bottom of the fixed plate 3 to control the expansion and contraction of the telescopic mechanism 4, which can drive the slider 5 to move left and right. The lower surface of the plate 3 is hinged with a movable rod 6, the lower end of the movable rod 6 is equipped with universal wheels, the lower surface of the slide block 5 is hinged with a connecting rod 7, and the lower end of the connecting rod 7 is hinged with the middle part of the movable rod 6. During this device, control the...

Embodiment 1、 Embodiment 2

[0026]In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: place the capacitor to be dried on the turntable 8, start the hot air blower 14, and the hot air generated by the hot air blower 14 is transported to the turntable 8 through the air pipe 15, and then Exhausted through the air outlet on the surface of the turntable 8, at the same time, the hot air generated by the hot air blower 14 is transported to the air outlet 18 through the air pipe 15 and sprayed out to dry the capacitor, start the motor 10, and drive the driving shaft 11 to rotate, thereby driving the turntable 8 rotate synchronously, so that the capacitor is more fully in contact with the hot air, and the heat is more uniform. At the same time, when the motor 10 is running, it drives the driving shaft 11 to rotate. When the half bevel gear 22 meshes with the left bevel gear 20, it drives the screw rod 16 to rotate. When The half bevel gear 22 is separated from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com