Chemical raw material circulating drying device

A technology of drying device and chemical raw materials, applied in drying, drying machine, drying gas arrangement and other directions, can solve problems such as insufficient drying uniformity, and achieve the effect of sufficient drying and uniform drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

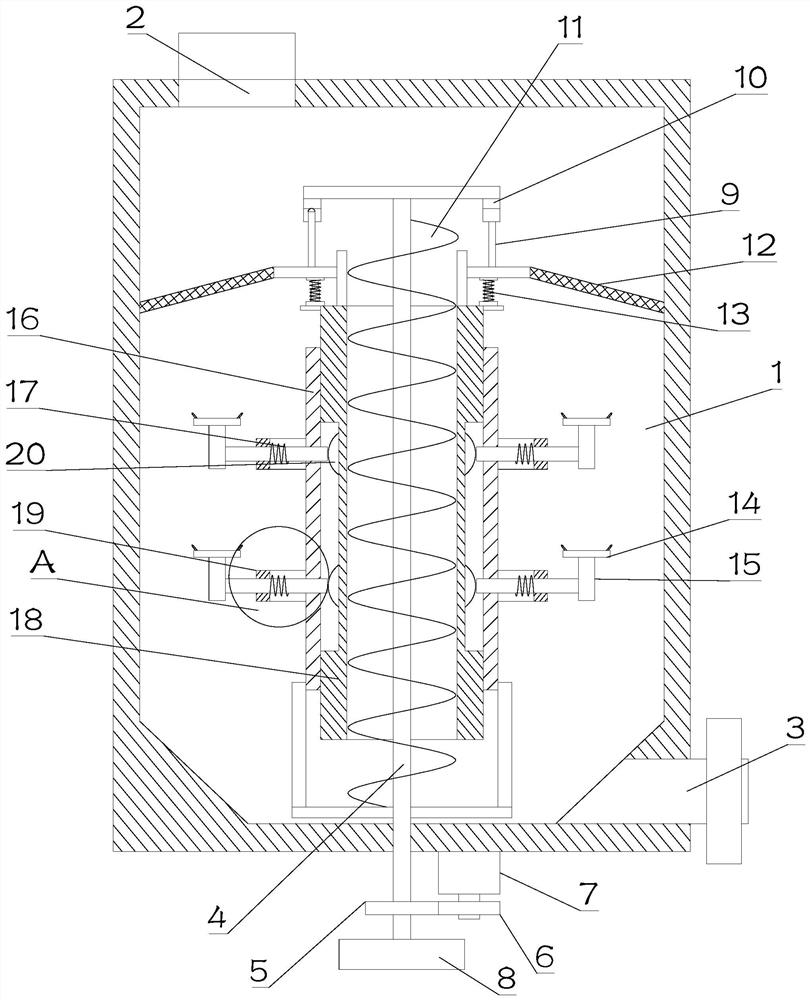

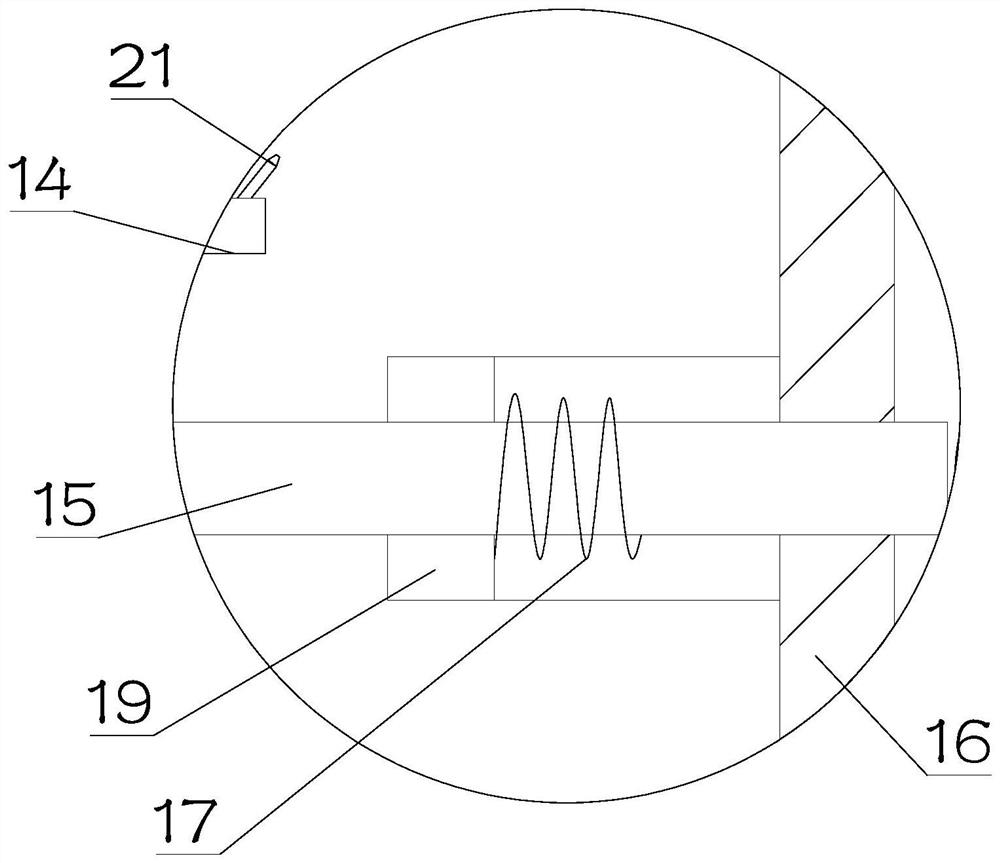

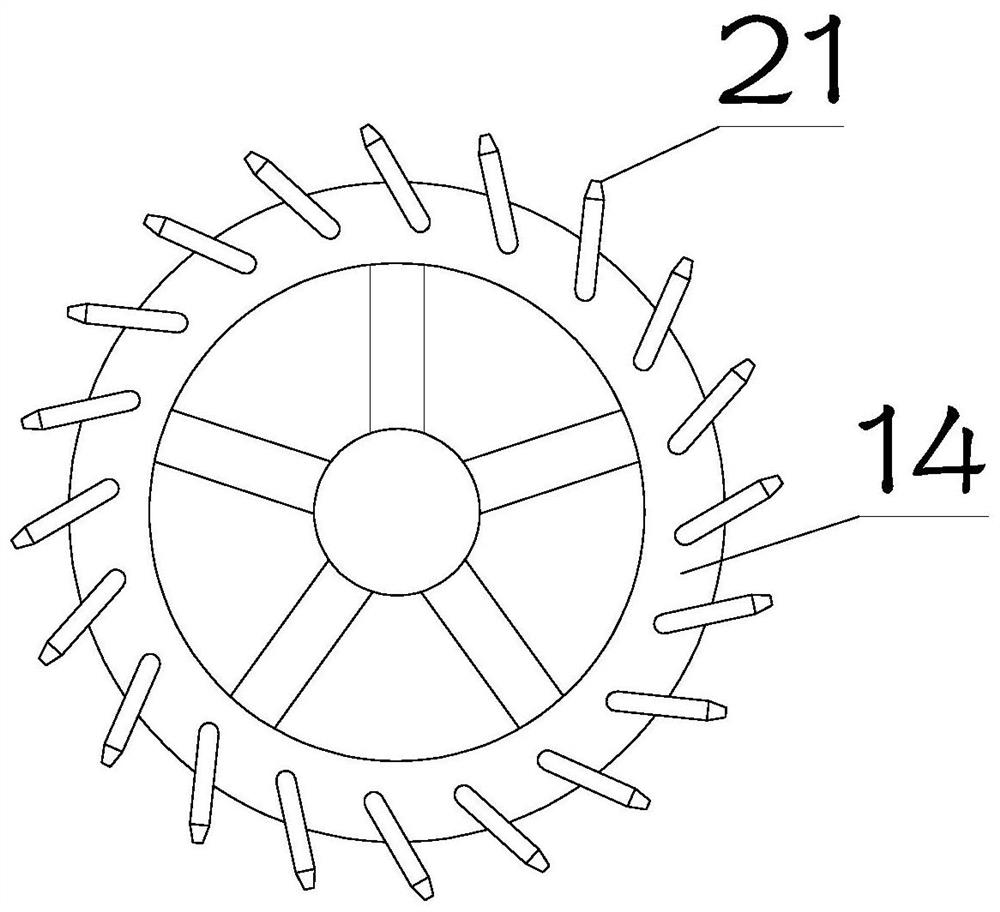

[0023] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a chemical raw material circulation drying device provided in the embodiment of the present invention, including: a device main body 1 provided in a hollow interior, and a feeding cylinder is provided in the middle of the device main body 1 18. A self-rotating sleeve 16 is sleeved on the outside of the feeding tube 18, and a plurality of support sleeves 19 are arranged in an array outside the sleeve 16, and a reciprocating sliding connector 15 is provided inside the support sleeve 19 , the connecting piece 15 is provided with an air jet disc 14 for self-rotation; the inner through hole of the said feeding cylinder 18 is provided with a rotating shaft 4 for self-rotating, and the outer side of the rotating shaft 4 is fixedly equipped with a feeding auger 11, and the feeding A distributing member 12 is provided at the outlet of the upper end of the barrel 18, and a vibrating mechanis...

Embodiment 2

[0026] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the vibrating mechanism includes the interference rods 9 symmetrically installed on both sides of the distribution part 12, the upper end of the interference rods 9 is in contact with the drive ring 10, and the drive ring 10 Fixedly installed on the rotating shaft 4, the drive ring 10 is symmetrically provided with an arc groove, and the arc groove intermittently slides over the conflicting rod 9 during rotation; superior. Specifically, when the rotating shaft 4 drives the drive ring 10 to rotate, during the rotation process of the drive ring 10, the arc-shaped groove intermittently slides over the conflicting rod 9, thereby causing the distributing member 12 to reciprocate intermittently, thereby making the cycle process uniform Sprinkle it into the inside of the main body 1 of the device, so that the raw materials can be evenly contacted with the hot air.

[0027] An elastic suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com