Storage battery pole plate circulation drying device

A cycle drying and storage battery technology, which is applied in the direction of lead-acid battery electrodes, dry solid materials, dry goods processing, etc., can solve the problems that the conveying device occupies a large area and cannot cycle dry the plates, and achieves good drying effect and simple structure , The effect of speeding up the production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

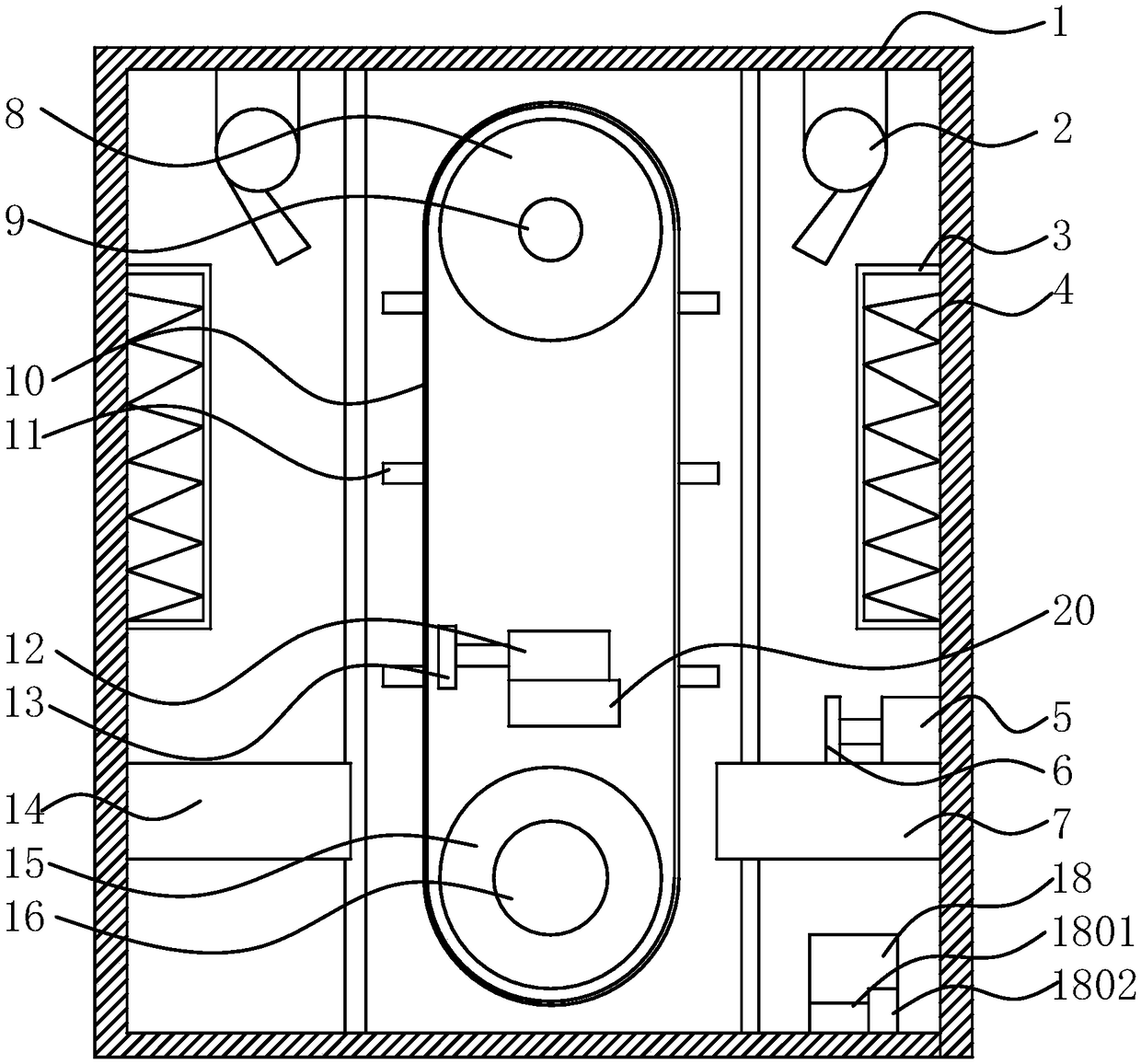

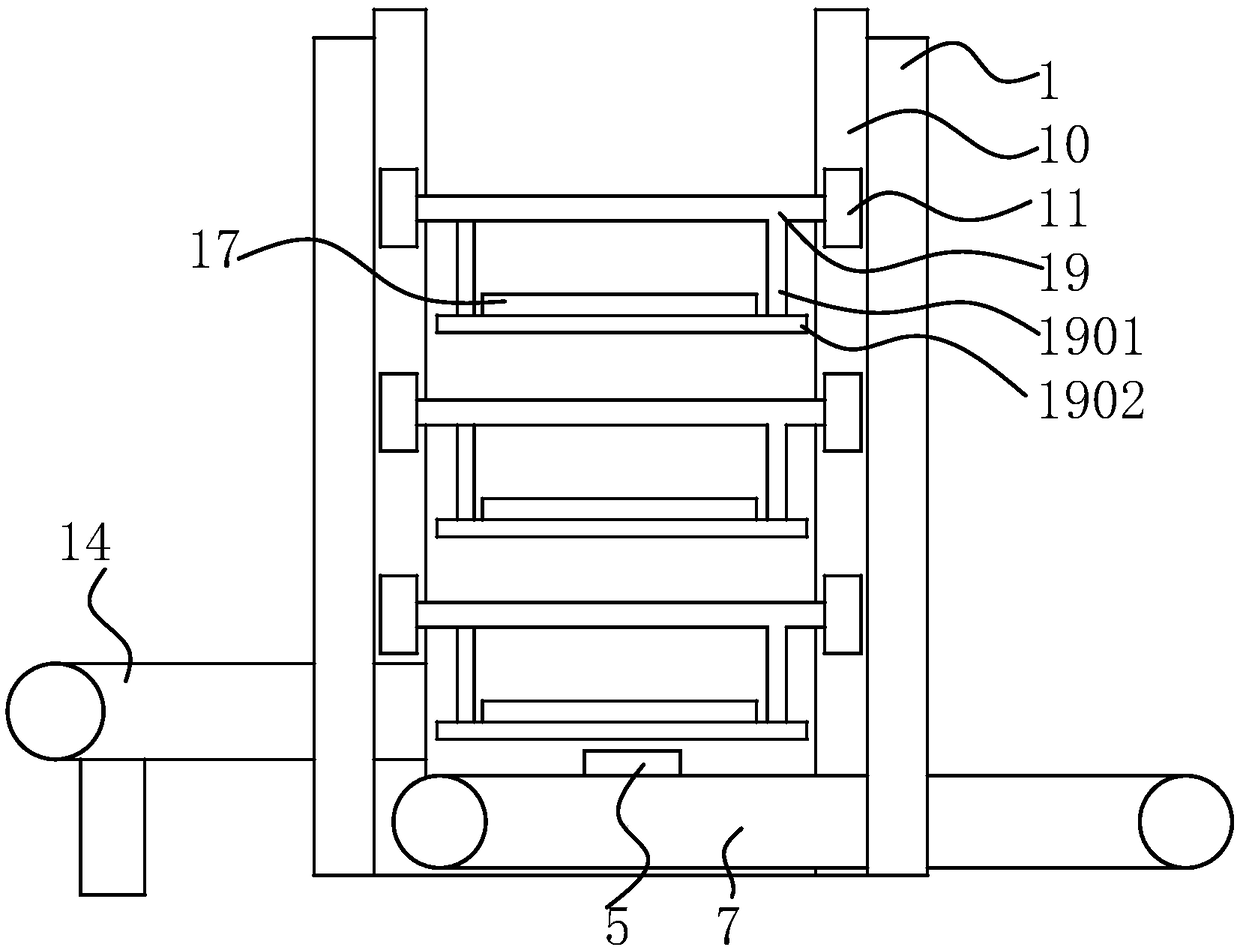

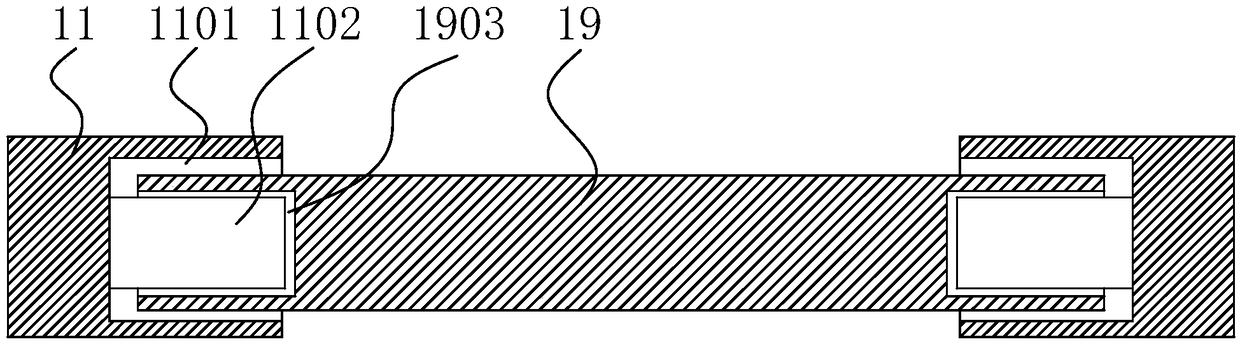

[0020] Such as figure 1 , figure 2 As shown, the present invention provides a battery plate circulation drying device, including a housing 1, a conveying device arranged in the housing 1, and a control device. The conveying device includes a driving wheel 15 and a driven wheel 8 oppositely arranged. The rotating shaft 9 is arranged on the upper part of the inner wall of the housing 1, and the driving wheel 15 is arranged on the lower part of the inner wall of the housing 1 and is in transmission connection with the motor 16 arranged on the inner wall of the housing 1. The driving wheel 15 is in transmission connection with the driven wheel 8 through the chain 10, and the chain 10 The connecting plate 11 is oppositely arranged on the top, and the swing rod 19 is movable between the connecting plates 11. The swing rod 19 is connected to the placement plate 1902 through the fixed rod 1901. The pole plate 17 is placed on the placement plate 1902. The two sides of the inner wall o...

Embodiment 2

[0025] Such as figure 1 , figure 2 As shown, the present invention provides a battery plate circulation drying device, including a housing 1, a conveying device arranged in the housing 1, and a control device. The conveying device includes a driving wheel 15 and a driven wheel 8 oppositely arranged. The rotating shaft 9 is arranged on the upper part of the inner wall of the housing 1, and the driving wheel 15 is arranged on the lower part of the inner wall of the housing 1 and is in transmission connection with the motor 16 arranged on the inner wall of the housing 1. The driving wheel 15 is in transmission connection with the driven wheel 8 through the chain 10, and the chain 10 The connecting plate 11 is oppositely arranged on the top, and the swing rod 19 is movable between the connecting plates 11. The swing rod 19 is connected to the placement plate 1902 through the fixed rod 1901. The pole plate 17 is placed on the placement plate 1902. The two sides of the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com