Low-tap-density 316 powder and preparation method thereof

A technology of tap density and powder, which is applied in the field of low tap density 316 powder and its preparation, can solve the problems of high impurity content of 316 powder, small mass fraction of C element, poor air permeability, etc., and achieve a wide range of filtration accuracy and low oxygen content Controllable, mechanically robust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A kind of preparation method of low tap density 316 powder, concrete steps are as follows:

[0013] (1) Mix Si0.3%, Cr16%, Mn0.3%, Ni12%, and Fe5 raw materials in proportion, put them into a 250Kg intermediate frequency furnace for smelting, and melt for about 1 hour. After the steel is liquefied and cleared, the temperature is raised to 1600°C and passed through 100Mpa. High-pressure water atomization into powder;

[0014] (2) After atomization, the powder is dried, sieved, and batched together to obtain the finished product.

Embodiment 2

[0016] A kind of preparation method of low tap density 316 powder, concrete steps are as follows:

[0017] (1) Mix Si1.0%, Cr18%, Mn1.2%, Ni14%, and Fe5 raw materials in proportion, put them into a 250Kg intermediate frequency furnace for smelting, melt for about 1 hour, and heat up to 1650°C after the steel is liquefied and cleared, passing through 110Mpa High-pressure water atomization into powder;

[0018] (2) After atomization, the powder is dried, sieved, and batched together to obtain the finished product.

Embodiment 3

[0020] A kind of preparation method of low tap density 316 powder, concrete steps are as follows:

[0021] (1) Mix Si0.7%, Cr17%, Mn0.9%, Ni13%, and Fe5 raw materials in proportion, put them into a 250Kg intermediate frequency furnace for smelting, melt for about 1 hour, and heat up to 1625°C after the steel is liquefied and cleared, passing through 105Mpa High-pressure water atomization into powder;

[0022] (2) After atomization, the powder is dried, sieved, and batched together to obtain the finished product.

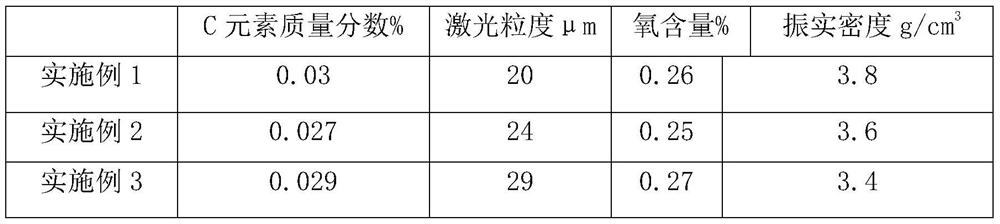

[0023] Table I

[0024]

[0025] It can be seen from the above table that the low tap density 316 powder C element mass fraction produced by the present invention is less than or equal to 0.03%, and the powder has an irregular shape. After pressing and sintering, the finished product has high mechanical strength, good air permeability, and high temperature resistance. Wide range of filtration accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com