A kind of preparation method of high-performance sintered re-fe-b system

A re-fe-b, re-fe-b-m technology, applied in the field of preparation of high-performance sintered Re-Fe-B series, can solve the problems of metal mold heating, affecting work efficiency and product quality, etc., to achieve easy control, The effect of avoiding local or corner oxidation and improving the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

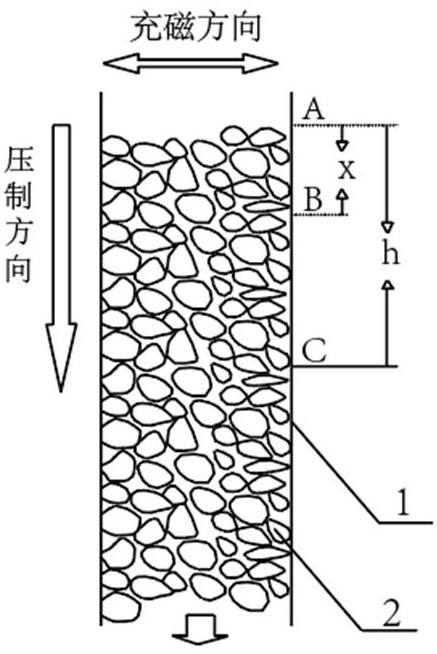

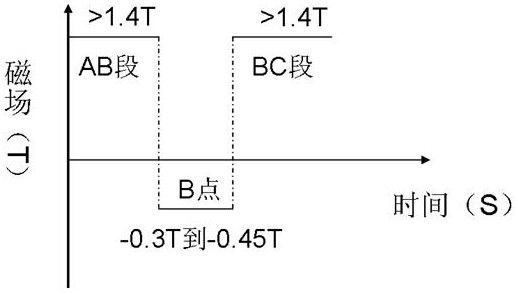

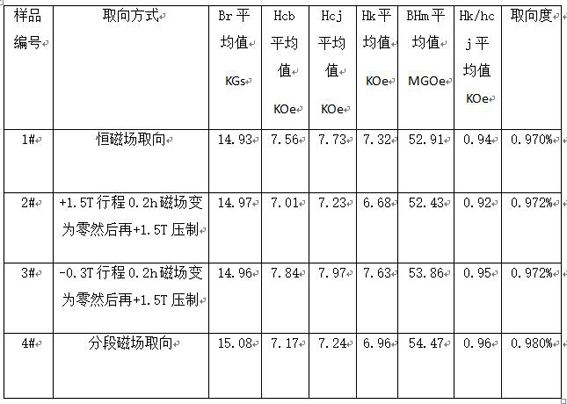

[0032] The invention provides a preparation method of high-performance sintered Re-Fe-B system, which adopts a quick-setting process to make Re-Fe-B-M alloy quick-setting sheets, wherein; in addition, the pouring temperature and rotation speed of the smelting alloy quick-setting sheets should be suitable , the narrower the columnar crystal width distribution of the quick-setting sheet, the better, wherein Re is Nd, and M includes Ga, Cu, Co and Zr; the alloy quick-setting sheet is hydrogenated and air-milled to make a micropowder with an average particle size of 5.1 μm; The obtained micropowder was added with 1.2ml / Kg of lubricant and mixed evenly; it was oriented under the protection of N2 gas, and the sample obtained in the forward magnetic field +1.5T orientation (referred to as constant magnetic field orientation) was recorded as the 1# sample; the powder started to be positive Magnetic field +1.5T orientation, after the upper punch is pressed down for 0.2h, the upper punch...

Embodiment 2

[0045] The invention provides a preparation method of high-performance sintered Re-Fe-B system, which adopts a rapid-setting process to prepare a Re-Fe-B-M alloy rapid-setting sheet, wherein R is one of Nd, Pr, Dy or Tb M is selected from a variety of Cr, Co, Ni, Ga, Cu, Al, Zr, Nb, Ti; the alloy quick-setting sheet is hydrogenated and air-flow milled to make micropowders with different particle sizes, and the particle size is 3.0 um~5.5um, the jet mill adopts N2 medium or other inert gas medium; the obtained micropowder is added with 1.2ml / Kg lubricant and then mixed; it is oriented under the protection of N2 gas, and it adopts segmented magnetization orientation, and the powder begins to contact the positive direction. Magnetic field +1.5T orientation, after 0.2h of upper punching stroke, reverse magnetic field -0.4T orientation, stay for 3s, and then forward magnetic field +1.5T, press into green compacts (h refers to the position where the upper punch contacts the powder to...

Embodiment 3

[0061] The present invention provides a preparation method of high-performance sintered Re-Fe-B system. The samples 19#, 21#, 22# and 23# in Example 2 are cut to a thickness of 3um in the direction of magnetization, and polished on six sides. , cleaned, and after Tb was expanded under certain conditions, the corresponding samples were recorded as 25# to 28#.

[0062] Table 7: Properties of some of the above samples after diffusion

[0063]

[0064] The Hcj of the samples in Example 2 are all below 15KOe. In order to improve the Hcj, some samples were subjected to Tb expansion treatment. After the diffusion, the Hcj of the samples increased significantly, and the increase was about: 10.45-12.82KOe, Br slightly decreased, 28# sample The Br can reach 15.04KGs while the Hcj can reach 18.24KOe, and the sum of BHm and Hcj of the 25# sample can reach 76.28.

[0065] The invention provides a preparation method of high-performance sintered Re-Fe-B system with Br greater than 14.5KG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com