Pulverizer special for lithium battery cathode material and closed-loop cyclic pulverizing system of pulverizer

A positive electrode material and closed-circuit cycle technology, applied in the field of material crushing, can solve the problems of low crushing efficiency, high energy consumption of airflow crushing, and high water intake, etc., to achieve good crushing effect, controllable oxygen content, and low water intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

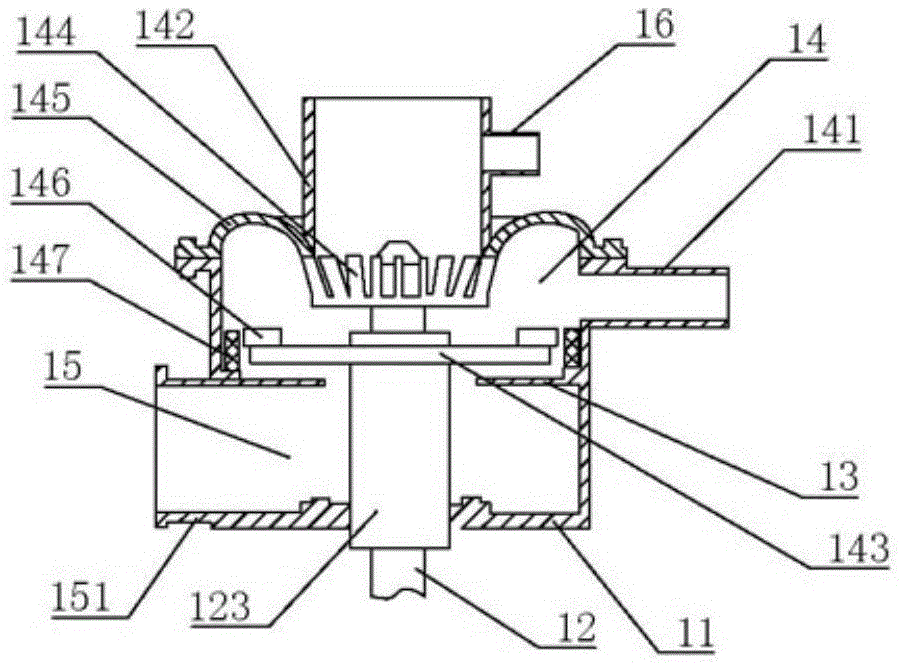

[0022] Such as figure 1 As shown, the special pulverizer for lithium battery positive electrode materials includes a pulverizer casing 11 installed on the frame. A rotating shaft 12 is arranged inside the pulverizer casing 11. A shaft sleeve 123 is set on the lower part of the shaft 12, and a pulverizing disc 143 is installed on the shaft sleeve. On 123; Grading impeller 144 installs rotating shaft 12 tops. The rotating shaft 12 is connected to the main shaft of the motor, and the motor is electrically connected to a frequency converter, and the speed of the motor is adjusted by the frequency converter to achieve the purpose of adjusting the size of the crushed particles.

[0023] The interior of the pulverizer shell 11 is provided with a partition 13, which divides the inside of the casing into a pulverization chamber 14 and an air intake chamber 15. The center of the partition 13 is provided with a communicating hole for air intake and the passage of the rotating shaft 12; ...

Embodiment 2

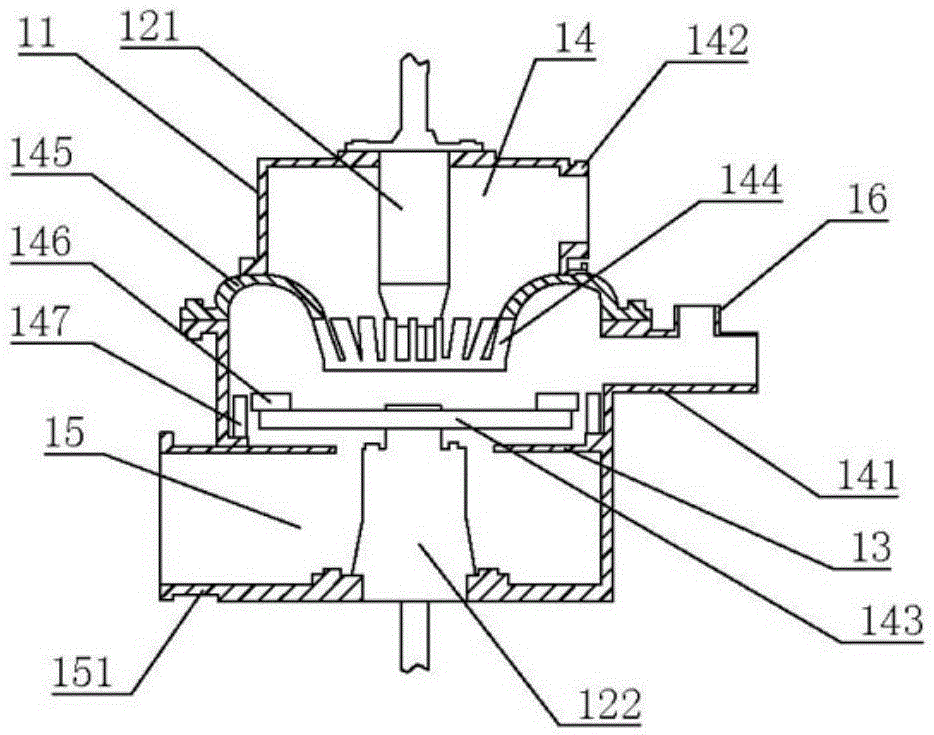

[0035] Such as image 3 As shown, in this embodiment, different from Embodiment 1, there are two rotating shafts, an upper rotating shaft 121 and a lower rotating shaft 122, in the crushing chamber 14, the crushing disc 143 is installed on the lower rotating shaft 122, and the classifying impeller 144 is installed on the upper rotating shaft 121. The upper shaft 121 is connected to the main shaft of the pulverizing motor, and the lower shaft 122 is connected to the grading motor. The pulverizing motor and the grading motor are each electrically connected to a frequency converter, and the speed of the motor is changed by the frequency converter to realize the adjustment of the particle size of the crushed material and the particle size of the classifier. Purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com