Production line for low-oxygen-content hard alloy mixture and production technology thereof

A technology of cemented carbide and low oxygen content, which is applied in the field of powder metallurgy to prepare cemented carbide to achieve the effect of improving stability and controllability and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

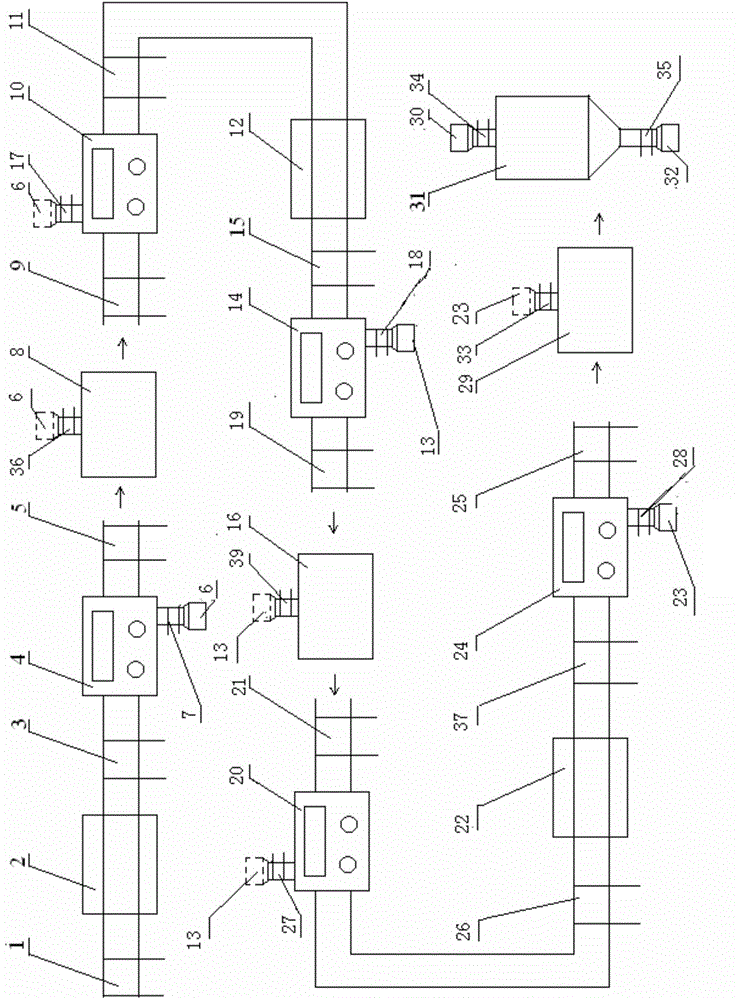

[0023] The production line of the present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is a schematic diagram of the production line of the nano-hard alloy mixture of the present invention.

[0024] like Figure 1-2 As shown, this method invents a production line of a low-oxygen cemented carbide mixture, which is composed of a reduction part for preparing blue tungsten powder, a reduction part for preparing tungsten powder, a carbonization part and a granulation part to form a closed system;

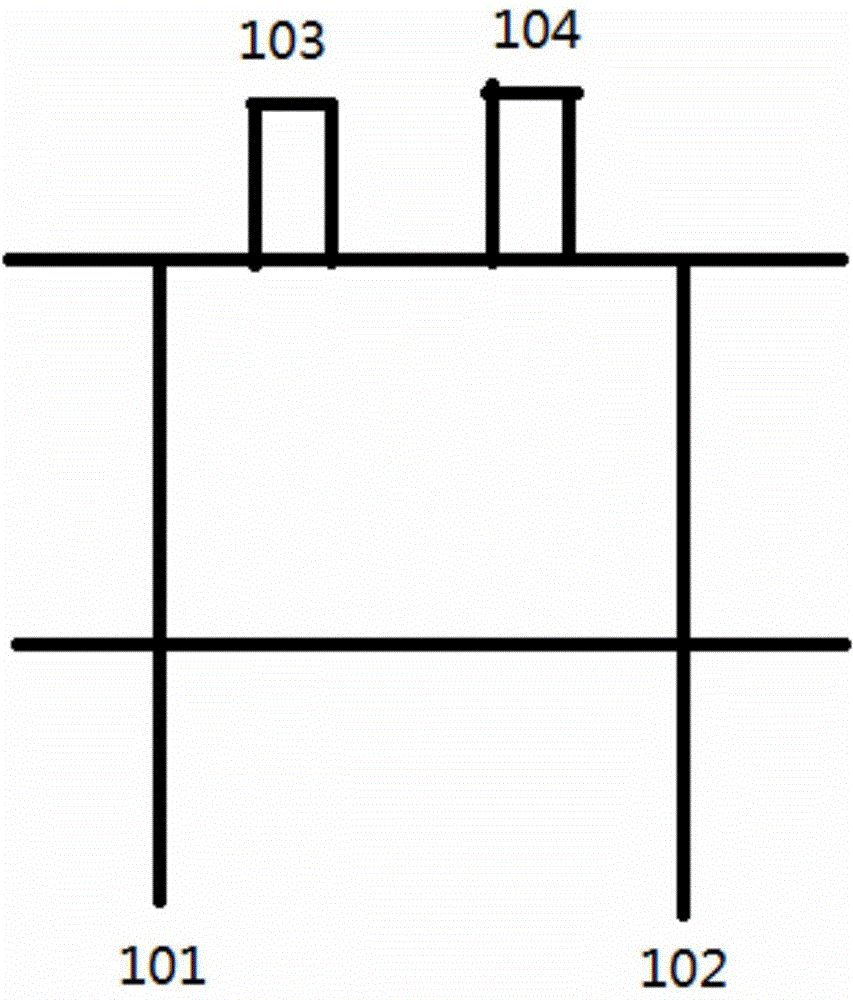

[0025] Wherein, the blue tungsten powder reduction part includes a first transition chamber 1, a rotary reduction furnace 2, a second transition chamber 3, a first glove box 4, a first closed bucket 6, a third transition chamber 5 and a first ball mill 7 ; The first transition chamber 1, the rotary reduction furnace 2, the second transition chamber 3, the first glove box 4 and the third transition chamber 5 are sequentially seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com