Production line and production process of a low-oxygen cemented carbide mixture

A technology of cemented carbide and low oxygen content, which is applied in the field of powder metallurgy to prepare cemented carbide to achieve the effect of avoiding oxidation, improving stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

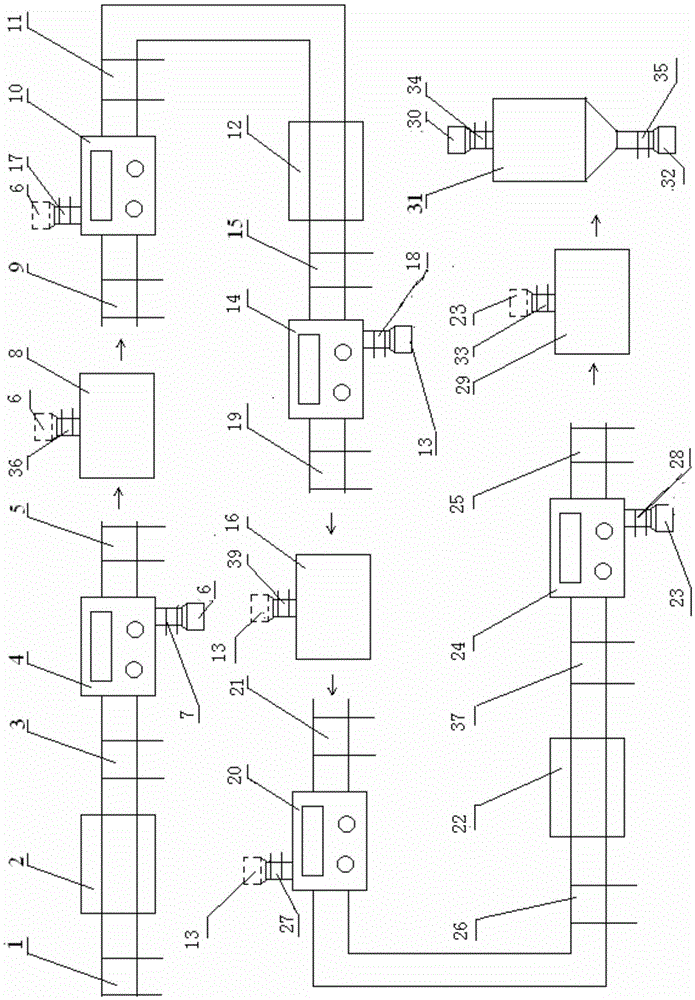

[0022] Cemented carbide with a WC grain size of less than 0.2 microns has very high strength and toughness. Due to the growth of WC during sintering, the particle size of WC powder needs to be less than 100 nm. This requires first obtaining nanoscale WO through nanotechnology 3 . Then, nanoscale WC is obtained through reduction carbonization.

[0023] Nanoscale WC is very active and can spontaneously ignite in air. If not spontaneously combustible, it has a high oxygen content. This has a great influence on the control of the carbon content and the properties of the final alloy.

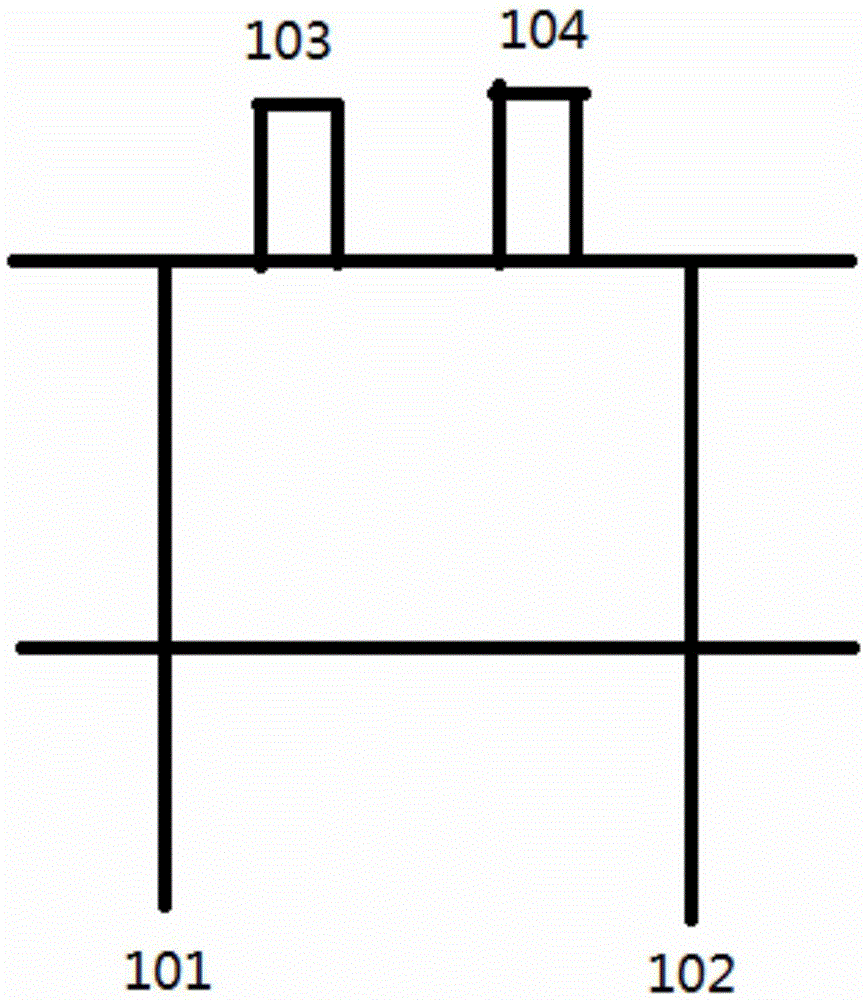

[0024] Nano WO 3 The preparation of nano-WC needs to go through the reduction and carbonization stages, and these two high-temperature stages will make the nanoparticles grow up. In order to inhibit the growth, the nano-WO 3 It is reduced to nano-blue tungsten, then reduced to nano-tungsten powder, then carbonized, and finally carbonized to obtain nano-tungsten carbide. The next step is to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com