Heat-resistant alloy steel powder for MIM, preparation method and equipment thereof

A powder preparation and alloy steel technology, applied in the field of alloy steel powder, can solve problems such as intergranular corrosion, and achieve the effects of good sphericity, controllable oxygen content, and high high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A heat-resistant alloy steel powder for MIM, comprising the following mass percentages: Si0.7-1.2%, Cr24-27%, Mn0.2-1.2%, Nb1.0-1.5%, Ni19-22%, C0.3- 0.7%, Ti0.2-0.6%, the balance is Fe; and the laser particle size is between 7.0-9.0μm, the oxygen content is less than 0.4%, and the tap density is ≥4.8g / cm 3 .

[0020] According to the mass ratio of the above components, the heat-resistant alloy steel powder for MIM is prepared, which specifically includes the following steps:

[0021] S1. Mix 9 kinds of raw materials such as monocrystalline silicon, micro-carbon ferrochrome, high-carbon ferrochrome, ferromanganese, electrolytic nickel, carbon sheet, ferro-niobium, sponge titanium, and industrial pure iron in proportion, and put them into a 250Kg intermediate frequency furnace for smelting. The raw materials are melted in the intermediate frequency furnace, and then the molten steel is heated to 1600-1650°C and poured into the tundish. The molten steel enters the atomiz...

Embodiment 2

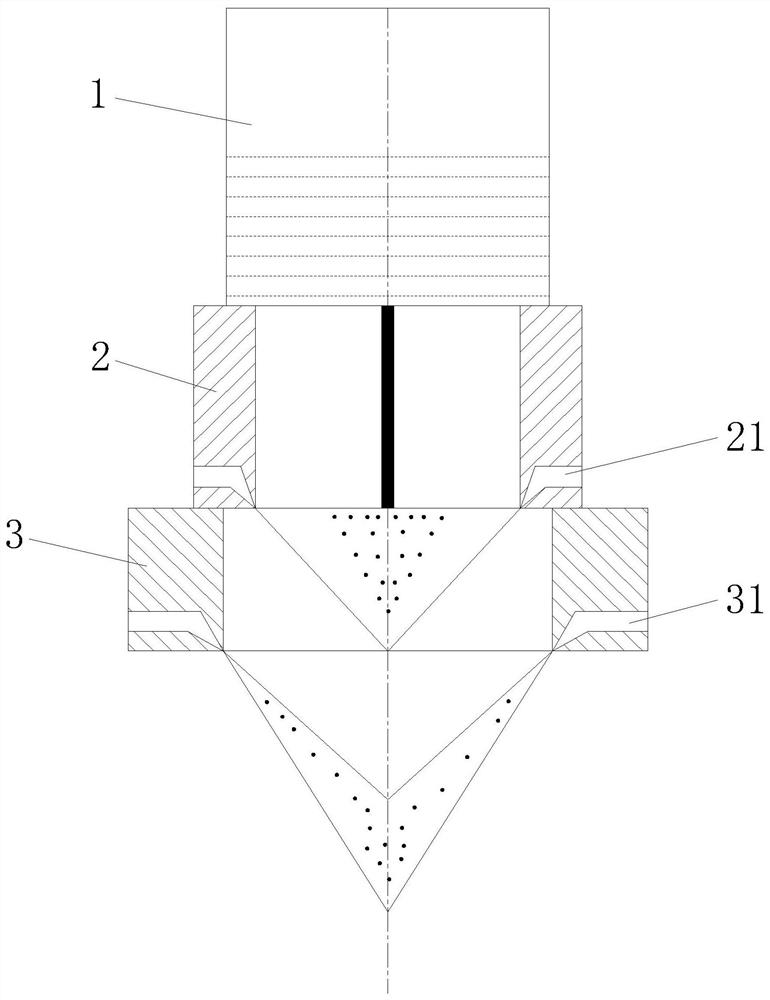

[0024] A heat-resistant alloy steel powder equipment for MIM. The equipment is an atomizer, which includes a tundish 1, a nitrogen gas furnace 2 and a high-pressure water furnace 3 from top to bottom. The top of the tundish is open and used for pouring molten steel; The outer ring of furnace 2 is provided with several nitrogen gas inlets 21, and the nitrogen gas inlets are at an angle of 10-20 degrees; the outer ring of high-pressure water furnace 3 is provided with a plurality of high-pressure water inlets 31, and the high-pressure water inlets are in two An included angle, the upper angle is 35-60 degrees, and the lower angle is 20-35 degrees. Melt the raw materials in an intermediate frequency furnace, then heat the molten steel to 1600-1650°C, pour it into the tundish 1, the molten steel enters the atomizer from the tundish 1, and the low-pressure nitrogen enters from the nitrogen gas inlet 21, and the molten steel first It is torn into a brush shape by 1Mpa-5Mpa low-press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com