Method for fruits biological freezing point preservation and the storehouse

A fresh-keeping method and fresh-keeping storage technology, applied in the fields of fruit and vegetable fresh-keeping, food preservation, food science, etc., can solve problems such as difficult control and slow development, and achieve the effect of improving quality, excellent performance, and optimizing combined refrigeration system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

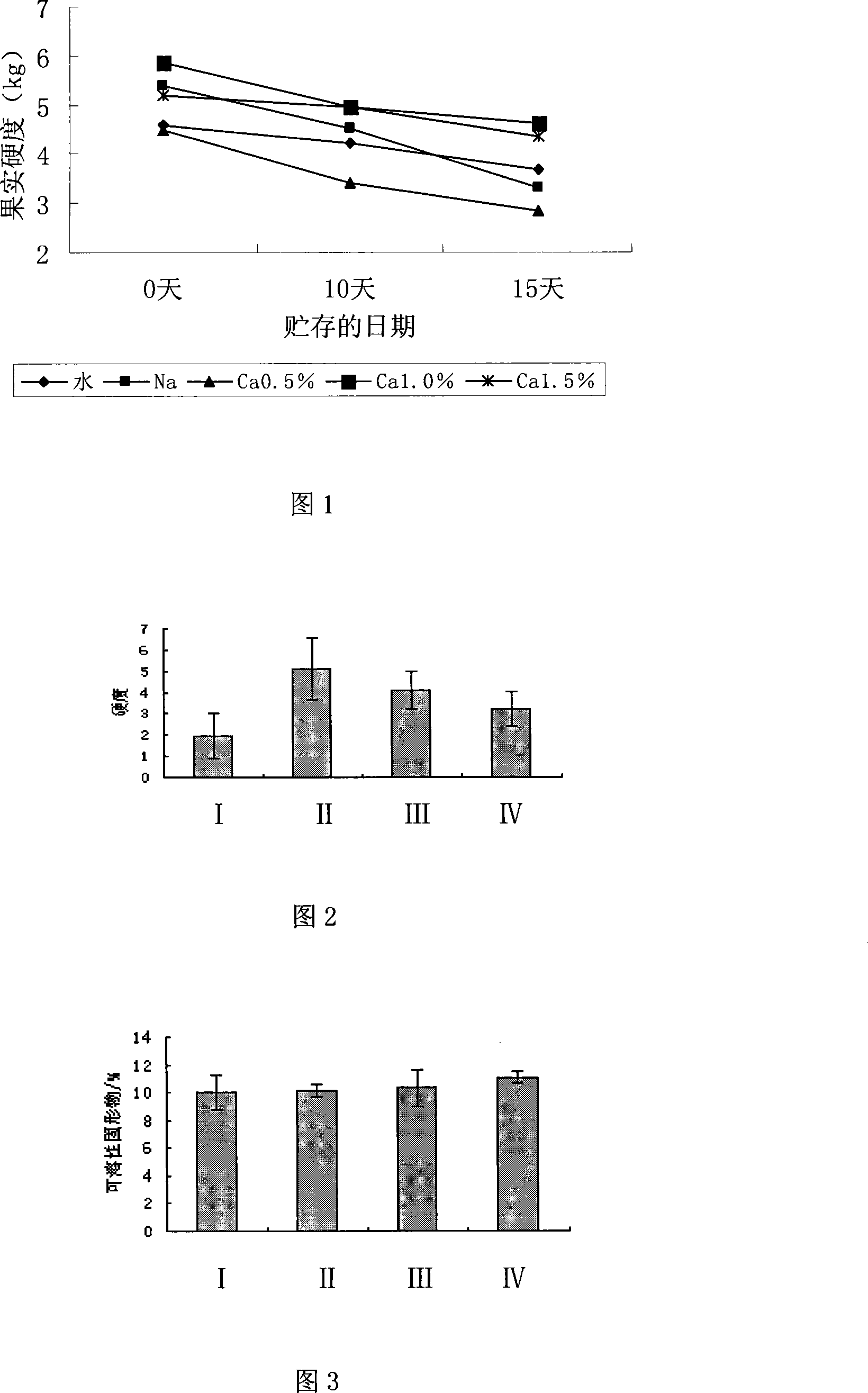

[0037] Embodiment 1: The impact of spraying calcium on fruit firmness

[0038] In 2006, the late-maturing peach Jingyan from the Huaijia orchard in Xinli Village, Nandulehe Township, Pinggu District was used as the test material, and 15 Jingyan plants with moderate growth and moderate fruiting were selected. On July 4th, July 10th, July 26th, August 1st, August 8th, and August 16th, the concentration of 0, 0.5%, 1%, and 1.5% nitric acid was sprayed on the tree respectively. Calcium solution, contrast is water and sodium nitrate, and the spray dose to every tree is 2.5 liters / tree, and each treatment is repeated 3 times. The fruit harvest date is September 11 (normal production and harvest date). After harvesting, the fruit was stored in a refrigerator at 0°C, and samples were taken on day 0, day 5, and day 10, and the hardness, soluble solids, etc. were measured.

[0039] As shown in Figure 1, the fruits after calcium spraying had no significant difference in firmness betwee...

Embodiment 2

[0040] Embodiment 2: the impact of different bagging on fruit quality

[0041] In this experiment, Jingyan (11-year-old, rootstock is peach) was used as the test material. The fruit bags used are conventional bags and sulfuric acid paper bags, the conventional bags are basically opaque, and the light transmittance of the sulfuric acid paper bags is about 50%. The sulfuric acid paper bag is homemade, made of sulfuric acid paper for ordinary drawing, and the size is the same as that of a conventional bag.

[0042] The bagging and harvesting periods are consistent with the general production period, and the bagging and harvesting periods of Jingyan are 8 / 4 and 9 / 11 respectively. Jingyan is out of the bag at 9 / 1. (See Figure 2, Figure 3)

[0043] As shown in Figure 2 and Figure 3, the hardness of the sulfuric acid paper bag is significantly higher than that of the conventional bag. There was no significant difference in soluble solids among the treatments.

Embodiment 3

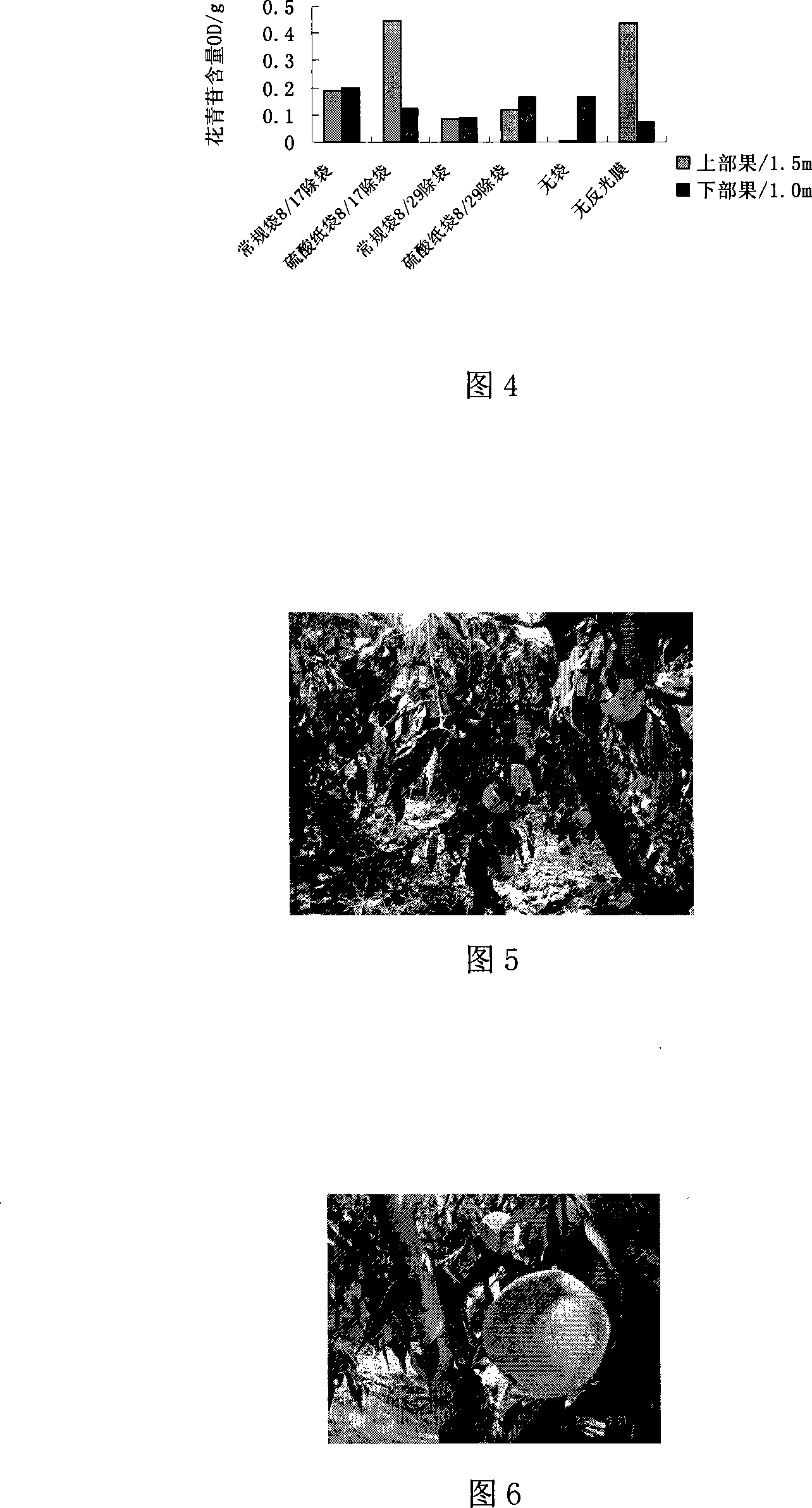

[0044] Embodiment 3: the influence of paving reflective film on the color and luster formation of face fruit

[0045] In this experiment, Huayu (grafted from Pantao Gao last year) was used as the test material. Paper bag specifications are as above, with no bag (CK) as a control. The bagging and harvesting periods are consistent with the general production period, 7 / 13 and 9 / 5 respectively. The bag was removed twice on 8 / 17 and 8 / 29 respectively, and the reflective film was laid at the same time as the bag was removed for the first time. The fruit in the conventional bag without reflective film was used as the control. (see Fig. 4, Fig. 5, Fig. 6) the fruit gets the fruit of 1.5 meters (surrounding the tree crown) and 1.0 meters (the inner chamber of the tree crown) from the ground.

[0046] As shown in Figure 4, the anthocyanin synthesis of the backlit surface of the fruit of each treatment of the Huayu variety, whether it is the fruit on the upper part of the tree crown o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com