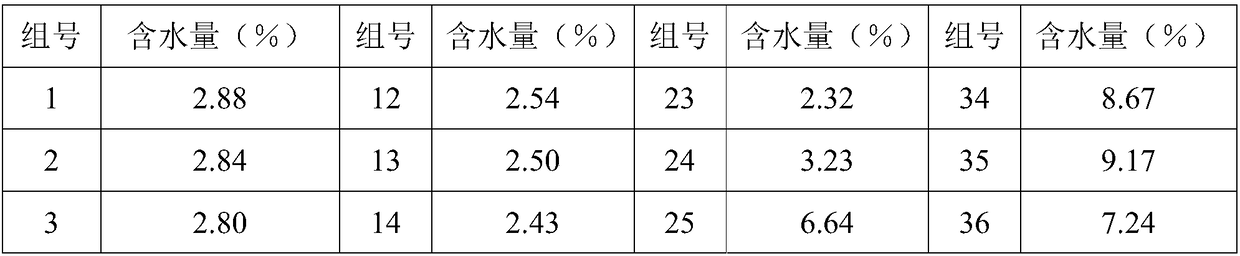

Patents

Literature

167results about How to "No browning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stachyose probiotics solid beverage

ActiveCN103653170AAntagonisticHigh purityFood ingredient functionsFood preparationBiotechnologyNutrition

The invention relates to a stachyose probiotics solid beverage which changes nutritional properties of food and comprises the following components by weight percent: 5-20 percent of stachyose, 2-10 percent of bifidobacterium powder, 2-10 percent of lactobacillus acidophilus powder, 3-8 percent of whey protein powder, 5-15 percent of milk powder, 10-40 percent of grain puffing powder, 5-15 percent of steviol glycoside, 5-15 percent of maltodextrin, 5-15 percent of citric acid and 0.5-2 percent of edible essence, wherein the sum of weight percentage of all the components is 100%. The stachyose probiotics solid beverage adopts natural raw materials, is scientific in formulation, nutritionally balanced, unique in flavor, and sweet and sour, and palatable in taste, not only is beneficial to intestinal health, but also has the health functions of improving immunity of the organisms, delaying senescence, inhibiting tumor and regulating blood lipids, and is convenient to carry and brew.

Owner:WEIHAI BAIHE BIOTECH

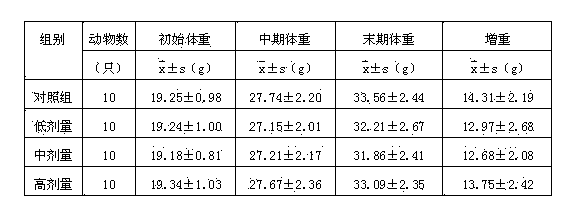

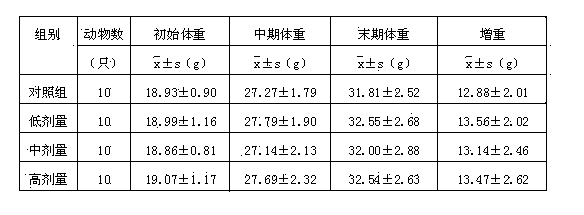

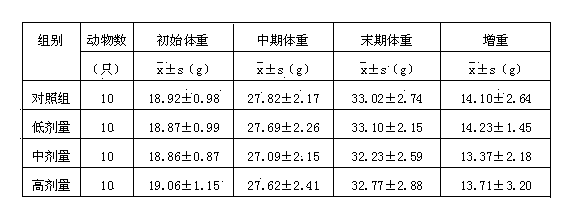

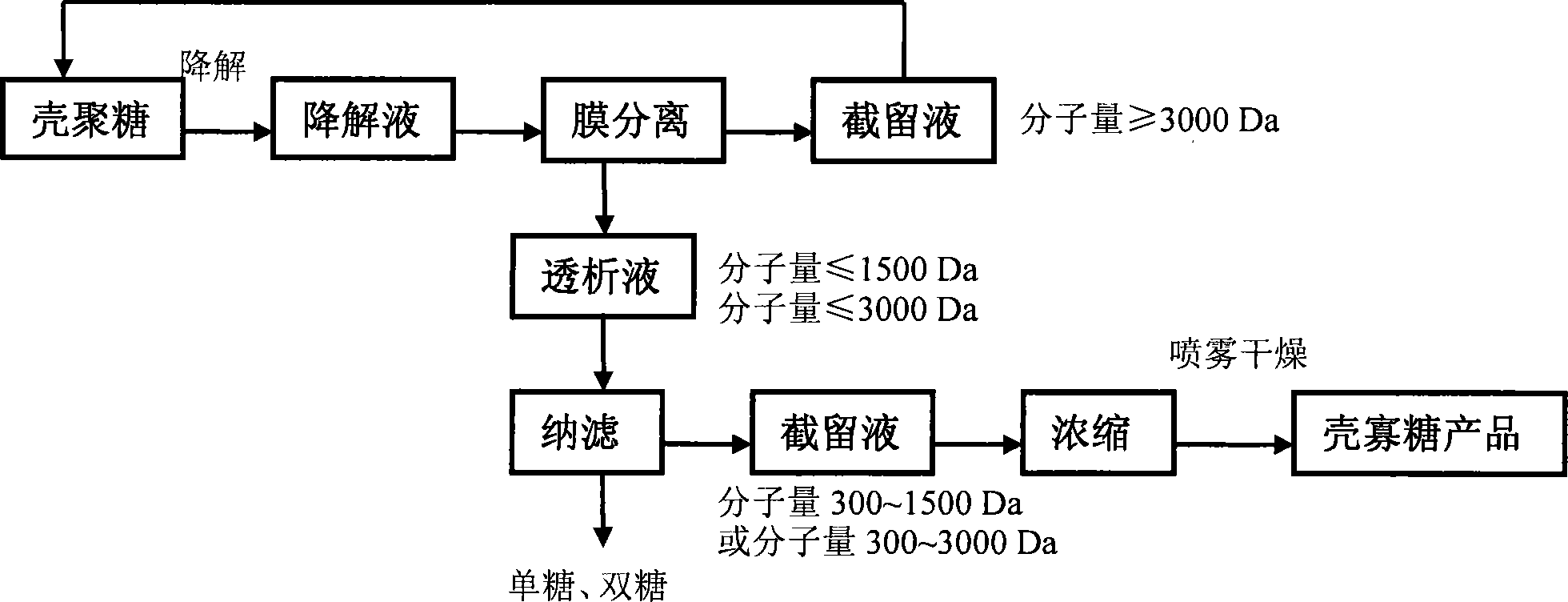

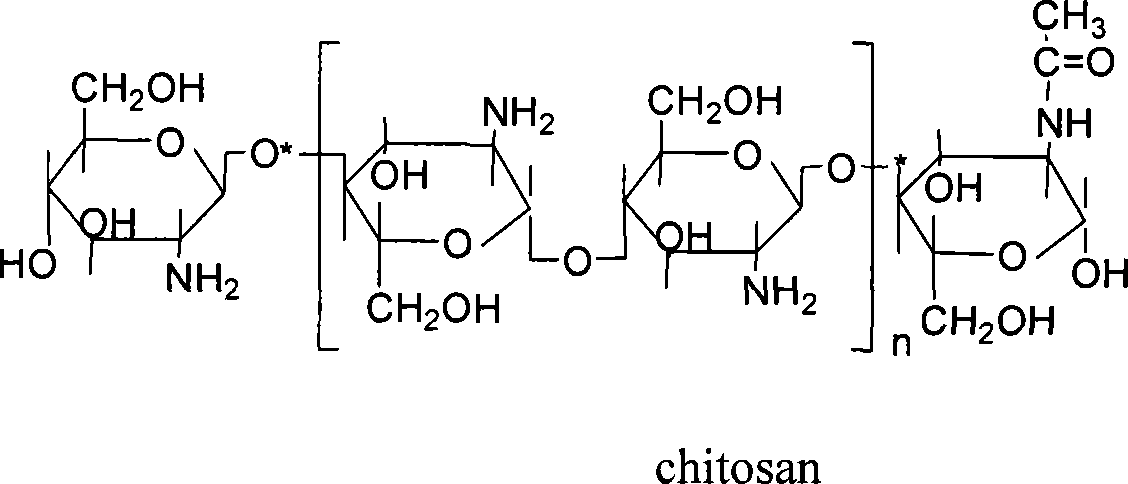

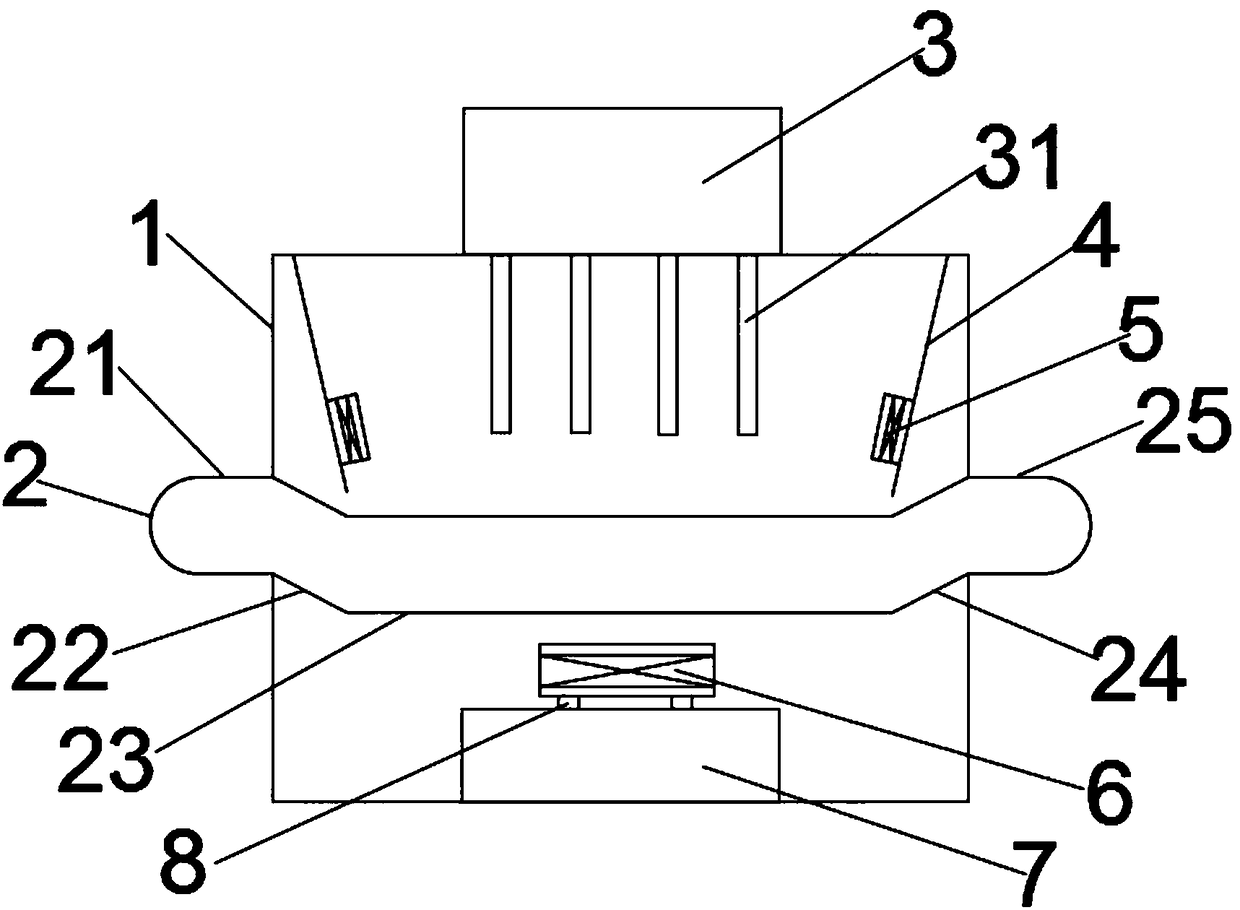

Method for preparing active chitosan oligosaccharide by using ozone to degrade chitosan

A preparation of chitosan oligosaccharide by degradating chitose with ozone, including steps of: adding acid solution of chitose into ozone degradation groove, adding ozone catalyst, insufflating ozone, reacting for 30-80 min at temperature of 10-100 DEG C. under agitation of high speed and irradiation of ultraviolet to get degradation solution, intercepting degradating product of chitose with degree of polymerization between 3 to 10 or 3 to 20 by membrane separation, concentrating and spray drying to obtain active chitosan oligosaccharide. The invention has advantages of simple operation, faster degradation speed, dramaticly reduced reaction cycle, and production cost is obviously reduced. Ozone is degradated while being decolored, so that no browning of chitosan oligosaccharide occurs. The content of active chitosan oligosaccharide (with degree of polymerization between 3 to 10 or 3 to 20) in the invention is not less than 90%.

Owner:GUANGXI UNIV

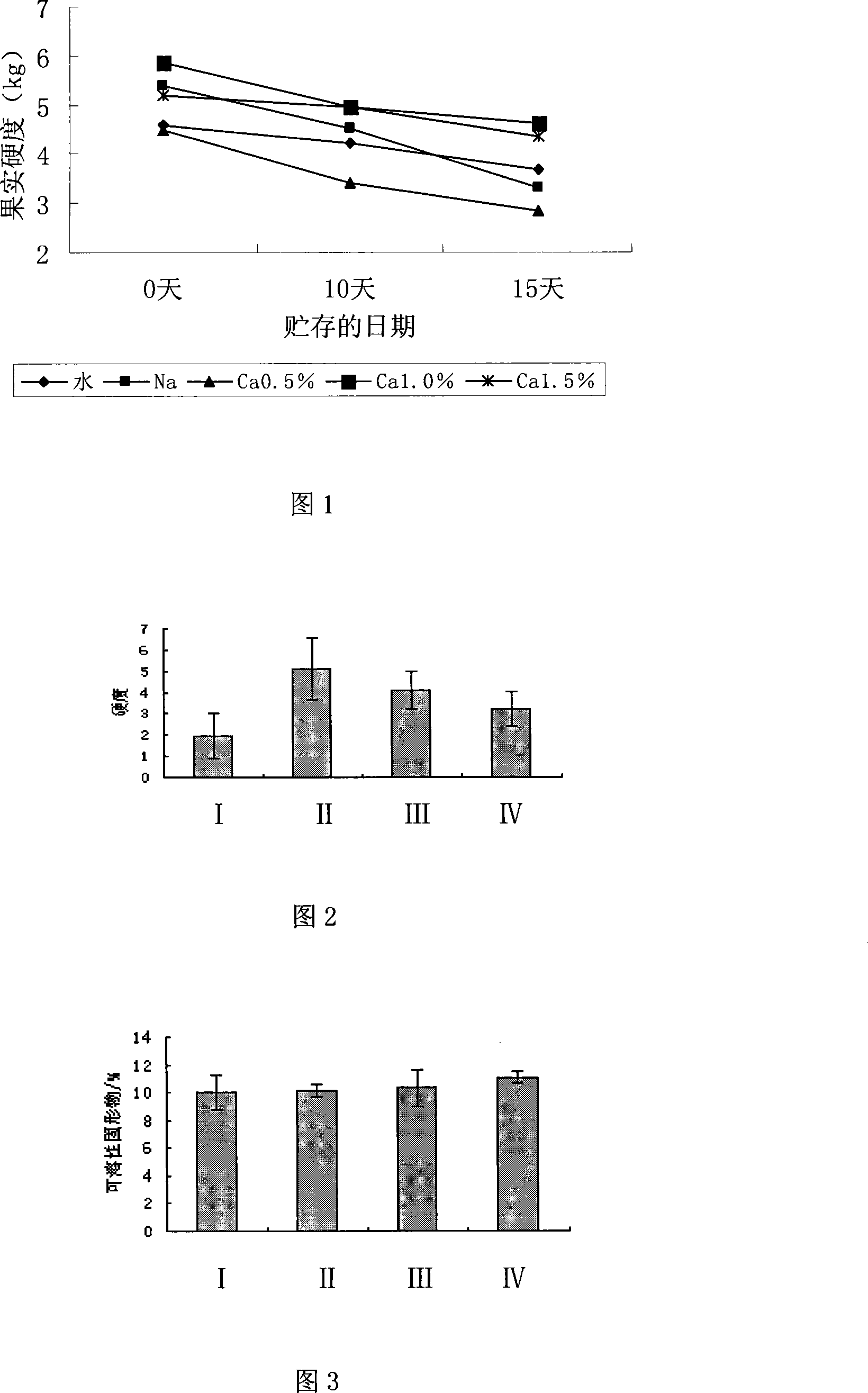

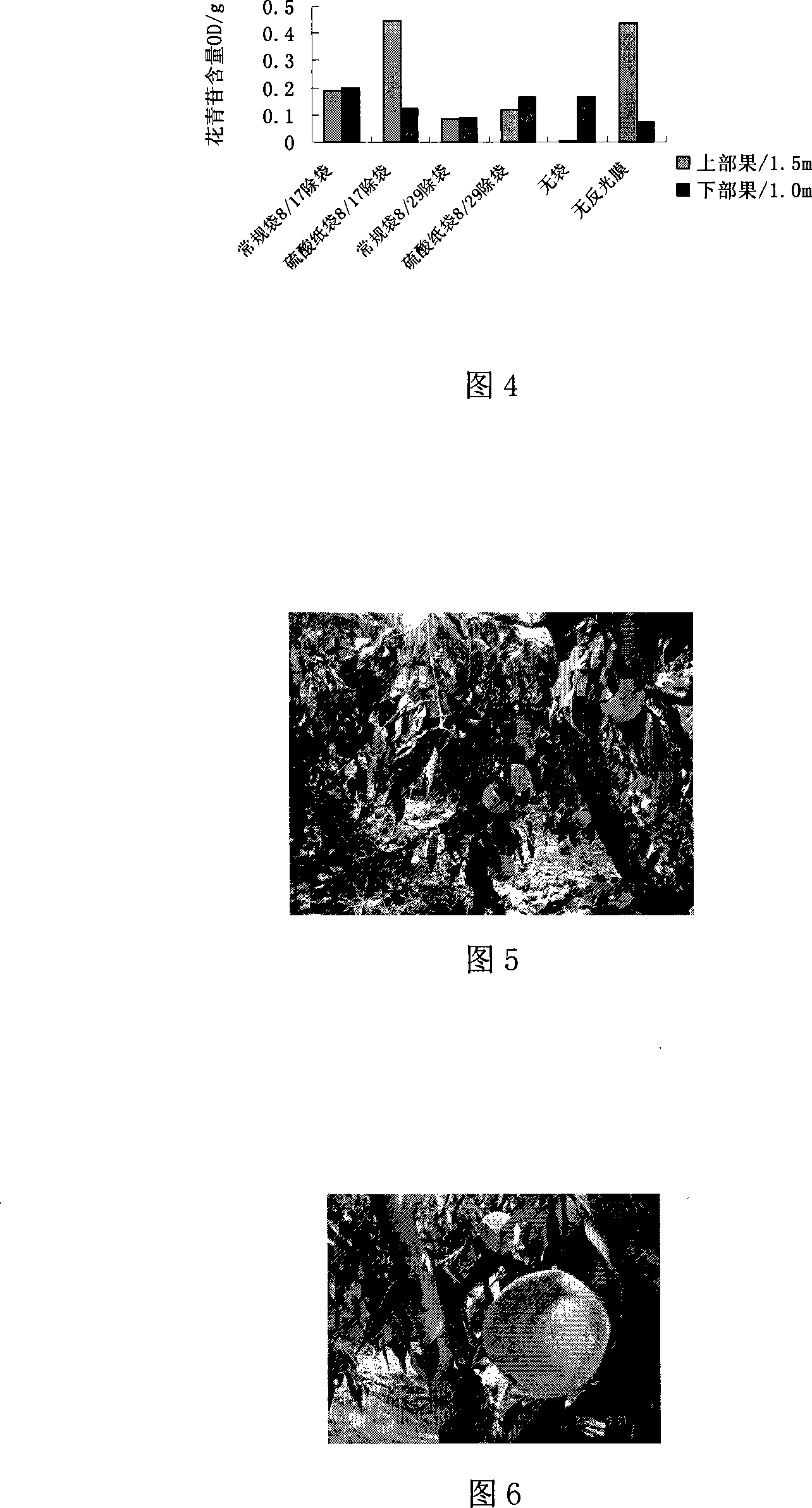

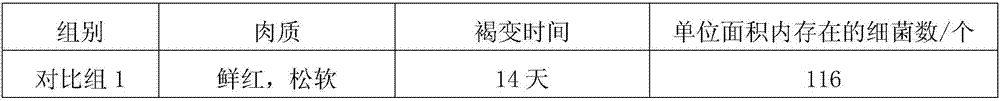

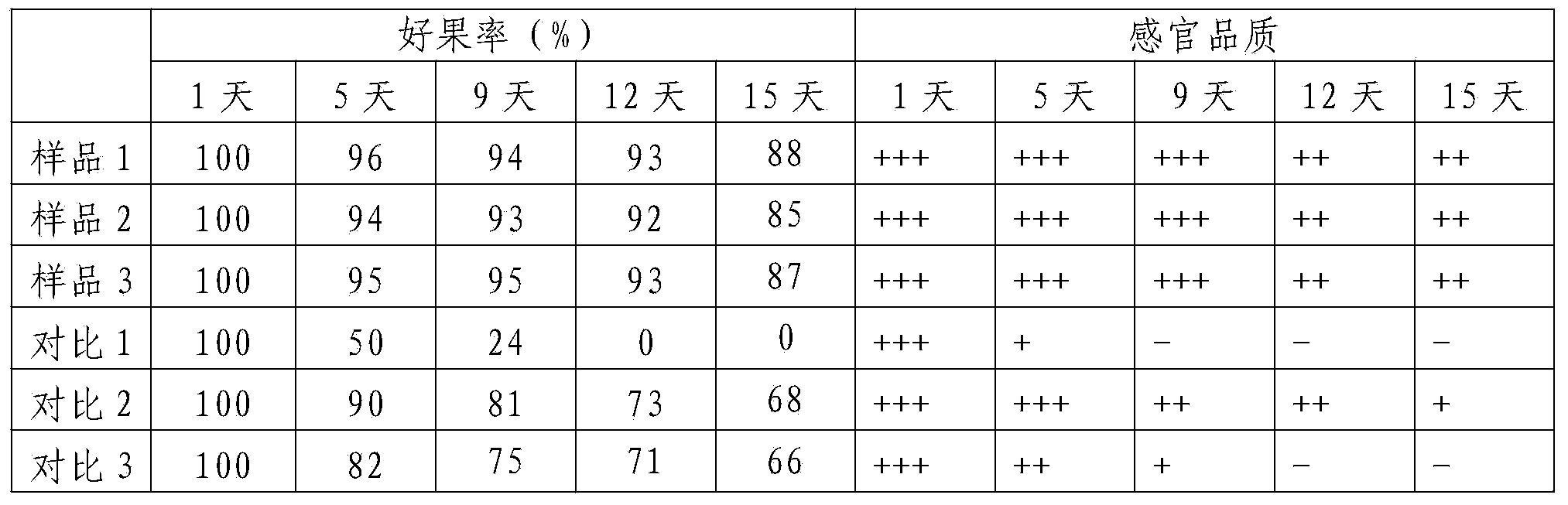

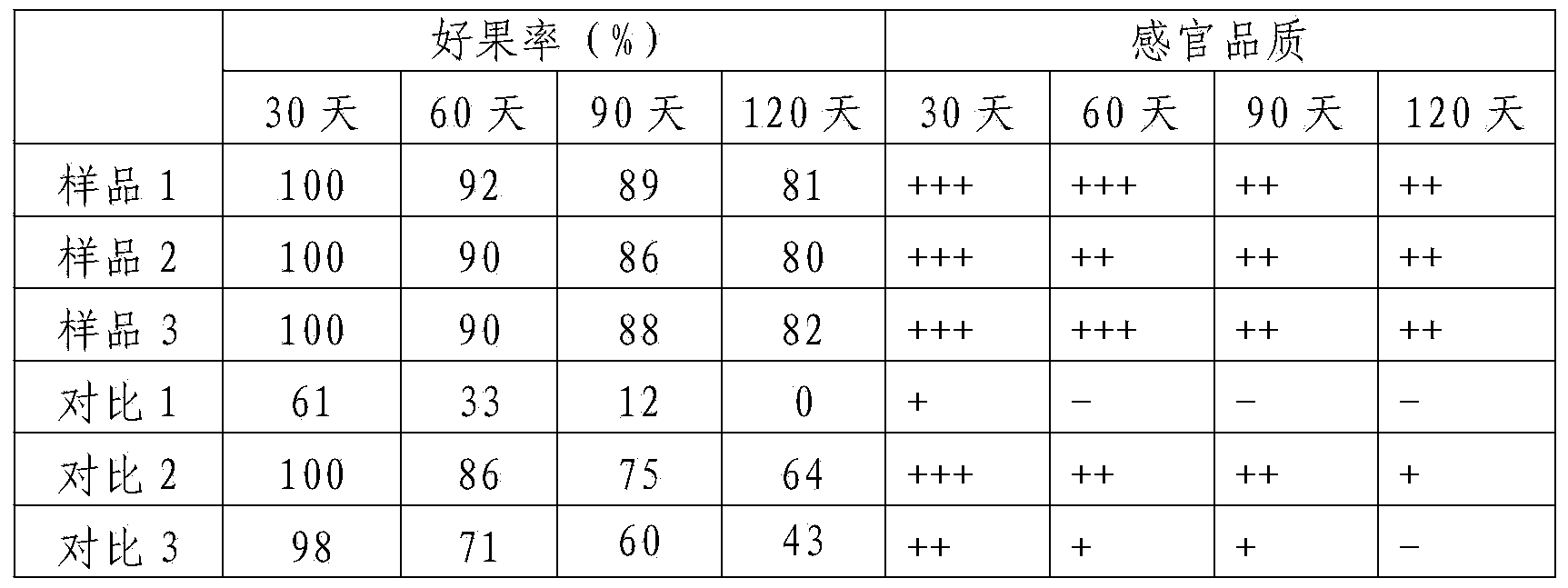

Method for fruits biological freezing point preservation and the storehouse

InactiveCN101204173AGuaranteed storage qualityEasy to combineFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingPre coolingProduct processing

The invention relates to a fresh-keeping method and a fresh-keeping storehouse of a biological freezing point for fruits belonging to an agricultural products processing field. The fresh-keeping method of the biological freezing point for the fruits includes the steps: spraying calcium salt in the process of cultivating, sleeving a transparent bag or spreading a reflecting film to improve hardness and sugar degree of the fruits; carrying out rapid cooling before putting in the fresh-keeping storehouse in a pre-cooling room; after putting in the fresh-keeping storehouse, processing with a preservative; then regulating the temperature to a critical point of the freezing point with humidity of over 90%; adopting stage heating after leaving the fresh-keeping storehouse. Preservation period of late maturing peach is prolonged to 3 months; the fruits processed by the steps are fresh as before and the phenomenon such as browning, softening and rotting do not exist. The cost of the supporting fresh-keeping storehouse constructed based on the invention is about 1.2 times of that of a low temperature cold storage and 1 / 2-2 / 3 times of that of an air conditioned storehouse with the same volume; fresh-keeping effect is remarkably superior to the low temperature cold storage and the air conditioned storehouse; the invention can promote the creativity and development of relevant industries such as a transport case and a transport vehicle of the biological freezing point as well as the relevant culture of the biological freezing point; the invention is a technology with a wide prospect and favorable economic benefits.

Owner:CHINA AGRI UNIV

Large-scale breeding method of Borneol Cinnamomum camphora

ActiveCN102630459AGood repeatabilityReduce vitrificationHorticulture methodsPlant tissue cultureDisease damageBiology

The invention relates to a large- scale breeding method of Borneol Cinnamomum camphora. The method comprises the following steps of: breeding a plantlet obtained through unique cuttage treatment by utilizing a current-growth lignified branch of strongly disease-resistant, no pest and disease damage and grown-up seed tree for about one year, acclimatizing, subculturing and propagating a sterile material after obtaining the sterile material with the current germinal sprout as an explant, secondly carrying out strong seeding rootage cultivation, and finally cultivating seeding in a greenhouse. According to the method disclosed by the invention, induced, propagated, strengthened and rooting culture mediums are optimized and improved, the stable growth of the sterile material can be effectively ensured, the sizes of sprouts are uniform, vitrification or defoliation of a tissue culture seedling can be avoided, the strong tissue culture seedlings can be obtained for sure, the repeatability is strong, an acclimation period and a subculture period are stable, a browning situation is reduced, a propagation coefficient is improved, the survival rate of planting in a greenhouse is improved, asubculture block mass cutting method determines the growth and the propagation coefficient of later-stage materials and can meet requirements of large-scale production.

Owner:SUNSHINE HORTICULTURE

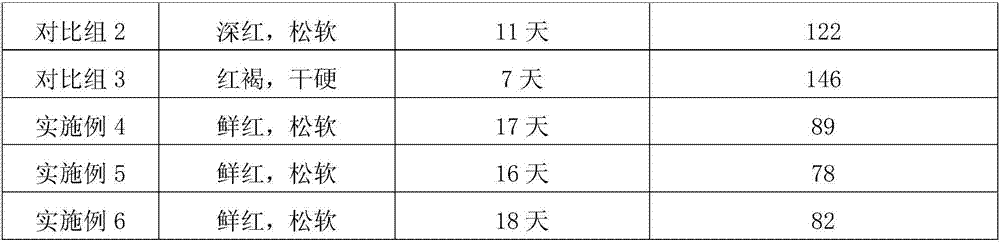

Freshness preservation method of Luchuan pork

InactiveCN106942342AImprove the preservation effectImprove permeabilityMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingBiotechnologyPork meat

The invention relates to the technical filed of food processing, and specifically relates to a freshness preservation method of Luchuan pork. The freshness preservation method of the Luchuan pork comprises the following steps: (1), carrying out pretreatment; (2), carrying out freezing; (3), carrying out marinating; (4), carrying out spraying; and (5), carrying out freshness preservation. According to the freshness preservation method of the Luchuan pork, the pork is marinated with preserving agents, and an edible fresh keeping film is sprayed onto the surface of the pork, so that the pork is under double freshness preservation effects; moreover, the preserving agents and the fresh keeping film are capable of sterilizing the pork so as to enhance the freshness preservation capacity of the pork. Thus, the pork has better freshness preservation effect, and is not liable to produce brown stains. The freshness preservation method of the Luchuan pork is suitable for promotion in the field.

Owner:广西神龙王农牧食品集团有限公司

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

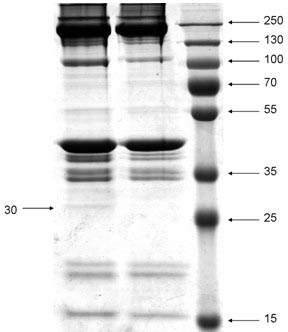

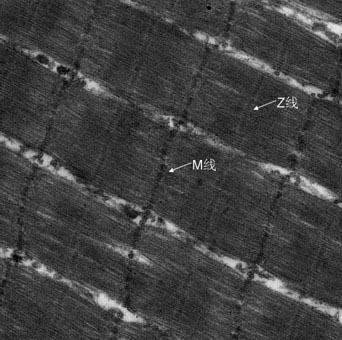

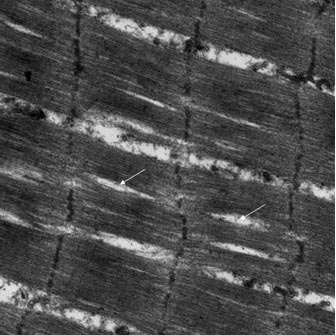

Method for tenderizing beef

InactiveCN102429242AImprove tendernessEvenly distributed flesh colorFood preparationChlorideHigh pressure

The invention discloses a method for tenderizing beef, which belongs to the field of food science, comprising the following steps of: pre-cooling the cattle carcass, cutting, injecting 200 mmol / L of calcium chloride liquor; packaging in vacuum; and processing at 250 MPa to obtain the tenderized beef. The method organically combines calcium salt injection with high-pressure process, so that the tenderness of the beef is obviously improved, and the production cost is effectively reduced at the same time. The high-pressure process can control the bacterial growth so as to prolong the shelf life.

Owner:NANJING AGRICULTURAL UNIVERSITY

Tissue culture reproduction method for liquidambar styraciflua

InactiveCN102715087AImprove survival rateNo browningHorticulture methodsPlant tissue cultureTime ratioBud

The invention discloses a tissue culture reproduction method for liquidambar styraciflua. The method comprises the following steps: taking a tender stem of liquidambar styraciflua provided with 3-6 buds as an explants, sterilizing, segmenting, inoculating into an MS+BA+NAA culture medium, performing tissue induction culture under suitable conditions, and ensuring that the time ratio of radiation to dark is 3:1. The scientific culture medium is established and assisted with a reasonable technical means, and tissue culture reproduction with good multiplication effect and high quality is realized. When the culture medium is used for culturing the explants, the browning of the explants is avoided, so that the survival rate of tissues is improved.

Owner:吴昌海

Hydrolyzed sericin peptide preparation method

ActiveCN107937460AReduce manufacturing costEasy to operatePeptide preparation methodsFermentationChemical industryPeptide

The invention relates to a hydrolyzed sericin peptide preparation method, and belongs to the technical field of protein separation and purification. According to the present invention, tasar silkwormcocoon shell or waste mulberry silk is used as a raw material, the tasar silkworm cocoon shell is washed, a sericin solution is prepared, a hydrolyzed sericin peptide solution is prepared, an activated macroporous resin decolorization system is assembled, a hydrolyzed sericin peptide decolorization solution is prepared, an activated MCI GEL resin system is assembled, a hydrolyzed sericin peptide grading separation solution is prepared, a hydrolyzed sericin peptide grading separation concentration solution is prepared, a hydrolyzed sericin peptide grading separation ethanol removing concentration solution is prepared, and hydrolyzed sericin peptide freeze-drying powder is prepared so as to obtain the product; by using multi-enzyme combined hydrolysis, ultra-filtration, nano-filtration separation, macroporous resin decolorization, MCI GEL resin grading separation, low-temperature concentration, freeze drying, and other modern chemical industry technologies and equipment, such that the preparation method has characteristics of convenient operation, mild condition, high efficiency, energy saving, low production cost and the like; and the product prepared by using the preparation methodcan be widely used in the fields of nutritious daily chemicals, fiber modification, and the like.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

Chinese chestnut rice wine and preparation method thereof

ActiveCN105296281ASweet and mellow tasteWith promoting blood circulation and removing blood stasisAlcoholic beverage preparationRed yeast riceDistillation

The invention relates to the technical field of nutritious and healthy wine processing, and especially relates to a Chinese chestnut rice wine and a preparation method thereof. The Chinese chestnut rice wine comprises the following raw materials in parts by weight: 30-50 parts of Chinese chestnut, 30-50 parts of glutinous rice, 8-14 parts of monocrystal rock sugar, 8-10 parts of red yeast rice, 1-5 parts of rice koji, and 1-5 parts of saccharomyces cerevisiae. The steps of crushing, saccharification, fermentation and distillation are carried out on raw materials of the provided Chinese chestnut rice wine, the Chinese chestnut rice wine is characterized in that the Chinese chestnut rice wine has crystal bright color, the color is orange red or bright red, nutrient composition is high, local flavor is unique, taste is sweet, obvious Chinese chestnut flavor and special ethyl caproate fragrance of the rice wine are provided; and the Chinese chestnut rice wine has the health caring functions of promoting blood circulation to remove blood stasis, invigorating spleen and promoting digestion, nourishing stomach and invigorating spleen, nourishing liver and tonifying kidney, delaying aging, treating beauty and skin, effectively adjusting human body, and reducing blood pressure and blood fat. The Chinese chestnut rice wine enables long-term preservation in a porcelain pot.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

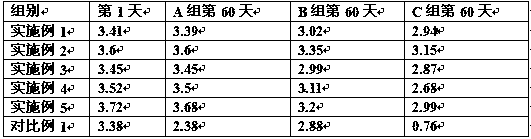

Rapid fermentation process for preparing fermented soybeans by pure strains

ActiveCN101984853AControllable formationShorten fermentation timeFood preparationVegetable oilSoybean product

The invention provides a rapid fermentation process for preparing fermented soybeans by pure strains, which comprises the following steps: cooking and curing the soaked soybeans with a water level higher than the soaked beans; inoculating the pure mucor strains after intermediate culture; fermenting at constant temperature and humidity for 48-72 hours to obtain mucor blank; adding salt and slicedginger; compacting, sealing and fermenting in the case of voidage being less than 5%; dehydrating with circulating hot air; frying with vegetable oil at the temperature of 170-190 DEG C for 30-50 seconds; mixing with blending materials timely; hot-filling at 85-90 DEG C; pressing tightly so that the oil level is 1-1.5cm higher than the surface of the beans; and carrying out vacuum sealing to finally obtain the instant fermented soybeans after being cooled. The process provided by the invention has the advantages of scientific process design, short process cycle, good color stability, continuous industrial production, controllable process, stable quality and no addition of preservative and anti-staling agent and color fixative, and can obtain the fermented soybeans which are significantly different from the products of other types, thus providing a feasible method for safely and conveniently producing fermented soybean products.

Owner:HUNAN AGRICULTURAL UNIV

Method for protecting color and keeping shape of China loropetal leaves

InactiveCN102187857AHigh economic valueImprove flexibilityDead plant preservationSucroseMicrowave oven

The invention provides a method for protecting color and keeping shape of China loropetal leaves, and relates to a method for protecting color and keeping shape of plant leaves. The method comprises the following steps: 1. preparing a color protective reagent from citric acid, sodium hydrate, hydrochloric acid, sodium dodecyl sulfate and sucrose; 2. selecting mature and undamaged red China loropetal leaves, and soaking the leaves in the prepared color protective reagent for 30-40 hours; 3. taking out the soaked leaves, then rinsing the red China loropetal leaves with clear water, and sopping up the water on the surfaces of the leaves; 4. clamping the leaves with splints and then drying the processed leaves for 40-60 seconds in a microwave oven; and 5. pressing the dried leaves for 18-30 hours by a repressing drying method so that the leaves are fully dried. The method provided by the invention has the following beneficial effects: dried red China loropetal leaves formed by the method have the advantages of good flexibility, good flatness, beautiful appearance, no browning phenomenon and brighter color compared with that of fresh leaves, thus having higher ornamental value and higher economic value.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Wild mushroom soup and making method thereof

The invention belongs to the field of foods, and relates to wild mushroom soup and a making method thereof. The soup is prepared from the following raw materials in percentage by weight: 8 to 10 percent of wild mushroom, 8 to 15 percent of meat, 8 to 15 percent of vegetable food and 60 to 70 percent of soup-stock. The making method comprises the following steps of: preprocessing the raw materials; preparing the soup; filling; curing; sterilizing; cooling; and preserving. The soup ensures the original pure flavor of the wild mushroom, is added with a great amount of food, has richer nutrition, more delicious taste and more attractive color, and better accords with the diet habits of people. The method is simple and feasible, and is suitable for industrial production.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

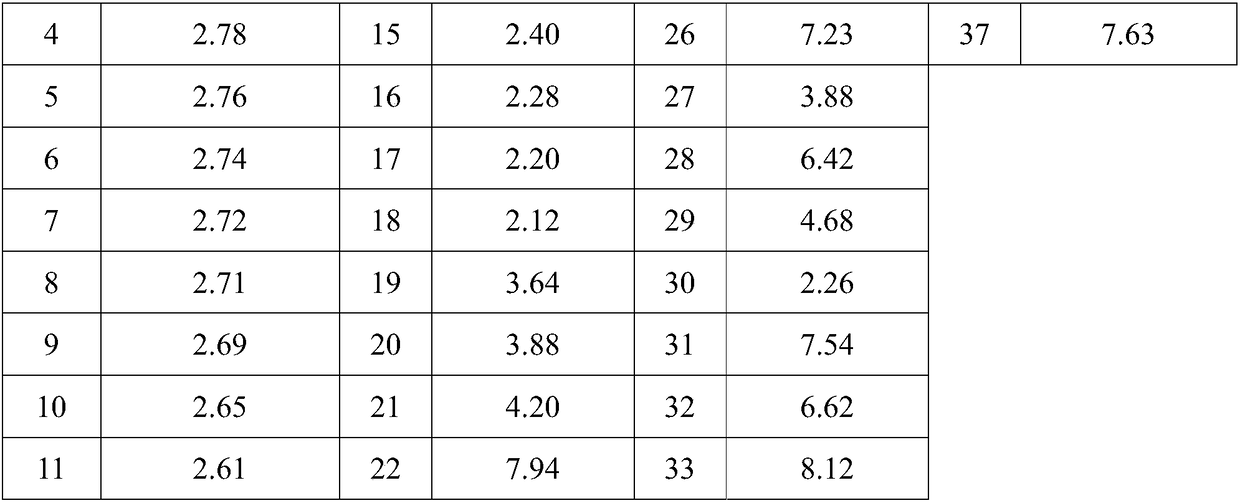

Method for processing fresh castanea mollissima packaged products

InactiveCN103876202AInhibition of respirationSolve the common addition of harmful chemical additivesFood freezingStrepto/lacto-coccusWater contentChemistry

The invention provides a method for processing fresh castanea mollissima packaged products. The method comprises the following steps: taking fresh deburred castanea mollissima, shearing notches on castanea mollissima shells by using scissors, drying the castanea mollissima through hot air for 30-60 minutes at temperature of 40-50 DEG C, shelling and peeling manually, soaking the castanea mollissima in 1-3ppm ozone water for 30-45 minutes; then blanching the castanea mollissima in a freshness retaining and color protecting liquid for 5-10 seconds at temperature of 80-90 DEG C, then instantly putting the castanea mollissima into the freshness retaining and color protecting liquid at temperature of 5-10 DEG C for carrying out ultrasonic treatment for 30-45 minutes, then refrigerating the castanea mollissima for 10-16 hours at temperature of 2-8 DEG C, then pre-freezing the castanea mollissima for 10-16 hours at temperature of -18 DEG C to -48 DEG C, and finally, drying the castanea mollissima for 48-72 hours till the content of water is 10-18%, and packing in vacuum under a clean environment and thus obtaining the fresh castanea mollissima packaged products. The products have good color, fragrance, taste and shape, can be stored and transported for 2 months at room temperature and sold by bulks in common farmers markets; the products are applicable to cooking and preparation in houses and commercial catering and secondary processing and sales of castanea mollissima food factories; by trial marketing, the fresh castanea mollissima packaged products are deeply favored by all consumers.

Owner:ZHEJIANG UNIV OF TECH +1

Method for preparing high-branch low-aromatic oligopeptides

ActiveCN106566858AReduce manufacturing costEasy to operateChemical industryFermentationFreeze-dryingHydrolysate

A method for preparing high-branch low-aromatic oligopeptides belongs to the technical field of separation and purification. The preparation method adopting dry vegetable protein powder as a raw material comprises the following steps: preparing a vegetable protein alkaline protease hydrolysate, preparing an aromatic amino acid hydrolysate with a C end, preparing a C end-removed aromatic amino acid hydrolysate, preparing an ultrafiltration separation liquid, preparing an aromatic amino acid-removed oligopeptide solution, preparing high-branch low-aromatic oligopeptide freeze-dried powder, and preparing a regenerated macro-porous adsorption resin column to prepare the high-branch low-aromatic oligopeptides with the F value reaching up to 21-26. Macro-porous adsorption resin of a styrene-based skeleton substitutes active carbon to separate aromatic amino acids and the aromatic amino acid-containing oligopeptides, so the method has the advantages of high separation efficiency, high precision and repeated use; the method adopting various modern chemical technologies and devices has the characteristics of convenience in operation, mild conditions, energy saving and low production cost; and the method realizes full utilization of the raw material, does not generate three wastes, is a typical green production process, and is convenient for being promoted and applied.

Owner:CHONGQING UNIV

Lily freeze-dried piece and preparation process thereof

ActiveCN108112995AShape retentionRetain nutritionFood freezingFood preservationFreeze-dryingWater cooling

The invention belongs to the technical field of food processing and provides a lily freeze-dried piece and a preparation process thereof. The lily freeze-dried piece mainly comprises the following steps: (1) pretreatment: including (a) blanching, (b) first-stage water cooling, (c) second-stage water cooling and (e) disc stacking; and (2) freeze drying: including (a) pre-freezing, (b) first-stage drying and (c) second-stage drying. The preparation process is scientific in design, the large-scale industrial production can be realized, the prepared lily freeze-dried piece can furthest preserve original shapes, nutrients and colors of lilies, has good reconstitution property and is convenient to eat, crispy in taste, instant and easy to store and transport.

Owner:四川鸿润佳禾食品开发有限公司

Preparation method of pucker-free non-cleaning dried jujubes

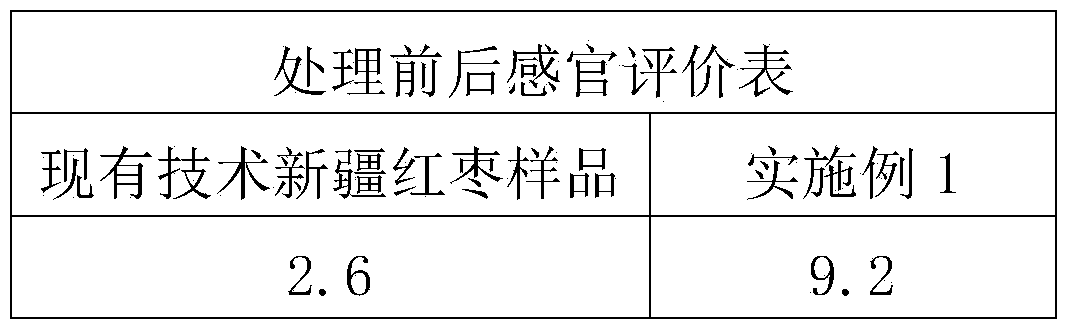

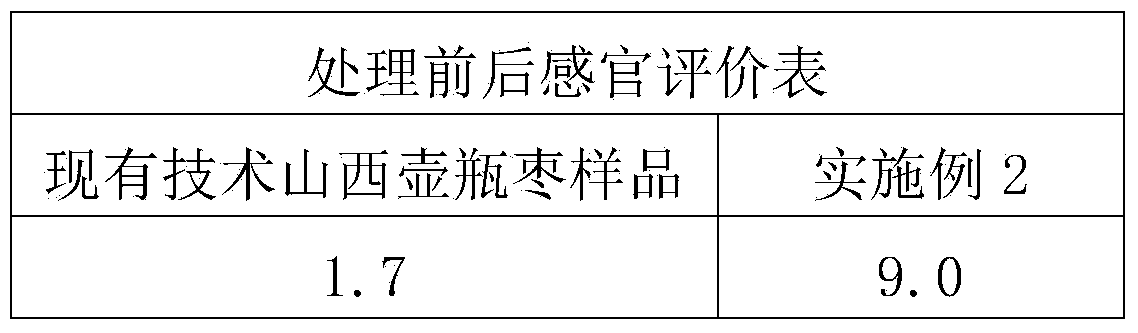

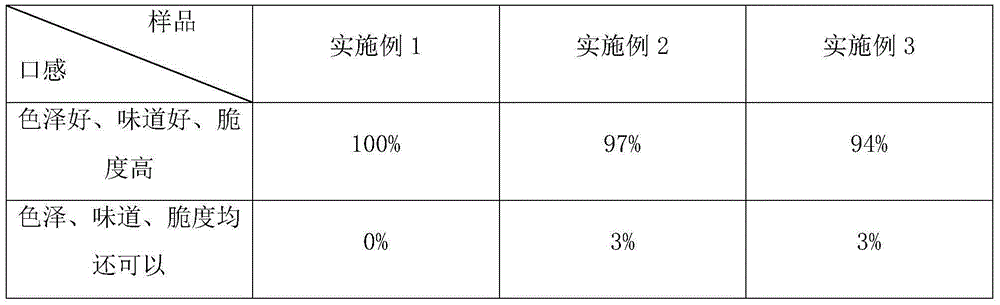

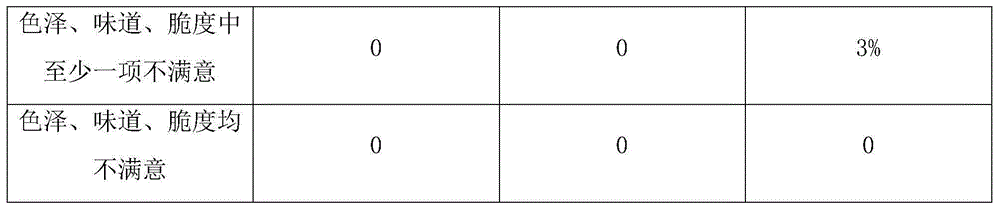

ActiveCN103843875AImprove qualitySolve the darkening of jujube skinFruits/vegetable preservation by dehydrationCold airPhysical chemistry

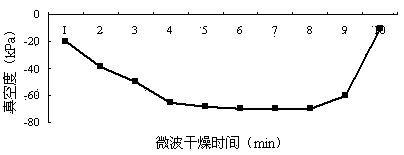

The invention discloses a preparation method of pucker-free non-cleaning dried jujubes, belongs to the technical field of food drying processing, and relates to a method of carrying out microwave vacuum puffing drying on red dates, aiming at solving the technical problems that jujube skin pucker, surface color darkening, nutritional ingredient loss, and the like appearing in a drying process of the red dates. According to the adopted technical scheme, the preparation method of the pucker-free non-cleaning dried jujubes comprises the following steps: pickling jujubes, grading the jujubes, rejecting defective fruits and impurities in materials; cleaning jujubes; drying water on the surfaces of the red dates by an air knife after cleaning the red dates; pre-drying for 3 hours-6 hours by cold air, regulating moisture of the red dates, and keeping the moisture of the red dates uniform, so that moisture content of the red dates reaches 35%-38%; carrying out microwave vacuum puffing drying on the red dates; spreading materials which are pre-dried by the cold air in a tray of a microwave vacuum unit, exhausting and then reducing pressure, wherein the conditions for carrying out the microwave vacuum puffing drying are as follows: vacuum degree is 65kPa-75kPa, microwave power is 6W / g-10W / g, drying time is 5 minutes-10 minutes, and final moisture content is controlled at 20%-25%.

Owner:交城天娇红农业科技有限公司

Preservation method for freshly-cut root vegetables

InactiveCN104542940AReduce breathing intensityAnti agingFruit and vegetables preservationSteudneraWater Chestnuts

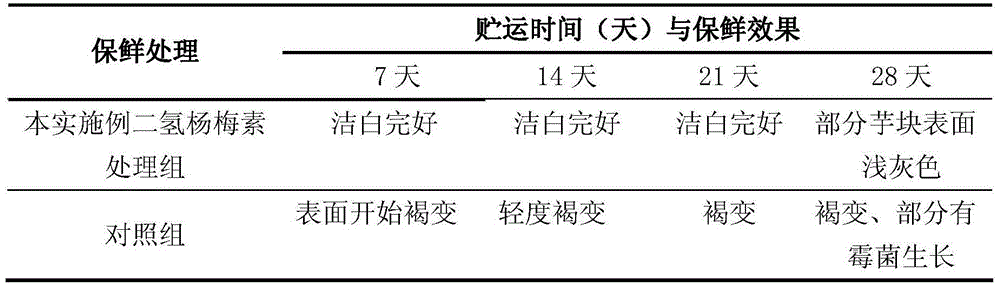

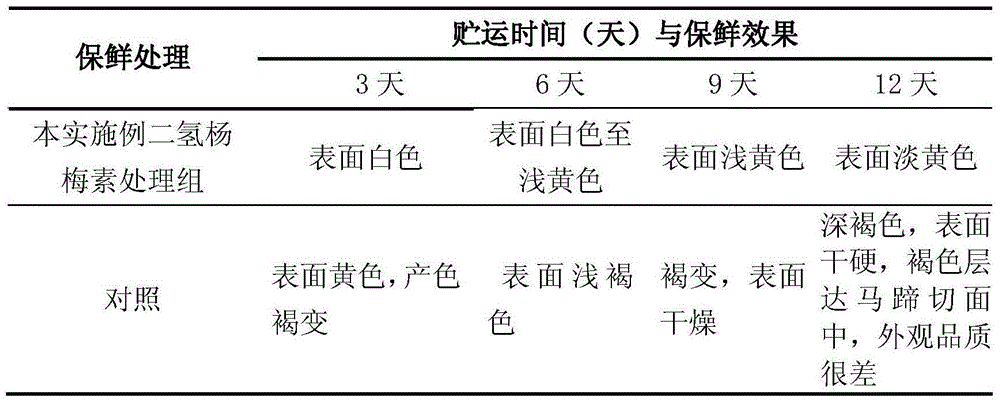

The invention discloses a preservation method for freshly-cut root vegetables. The preservation method comprises the following steps: cleaning the root vegetables with clean water, shelling and cutting the shelled vegetables into pieces or blocks; fully mixing 0.01-0.5 part by weight of dihydromyricetin and 99.5-99.99 parts by weight of water evenly to prepare a preservation liquid; soaking the freshly-cut pieces or blocks into the preservation liquid for 0.1-5 minutes, fishing out and draining off; or spraying the preservation liquid on the surfaces of the cut blocks, and draining off until the surfaces are soaked; and sub-packaging and sealing and preserving at minus 2 DEG C to 8 DEG C. According to the preservation method, the freshness time and the shelf life of the root vegetables and tuber vegetables such as freshly-cut henry steudnera tuber, water chestnuts and Chinese yam can be effectively prolonged.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for processing frozen fruit

InactiveCN1775083APleasant appearanceFast natural thawing speedFruits/vegetable preservation by freezing/coolingFood treatmentManufacturing technologyCold storage

The present invention relates to a processing method of frozen fruit. Said method includes the following steps: cleaning fresh fruit, removing pedicel, stoning, dicing, quick protecting color, wet-drying, press-moulding, quickly-freezing below-32deg.C, quickly demoulding by utilizing hot air, packaging, checking and cold storage so as to obtain the frozen food made of fresh fruit.

Owner:SHANGHAI JIAO TONG UNIV

Partially-freezing fresh-keeping method for fresh jujubes

ActiveCN104106624AKeep the flavorMaintain colorFruits/vegetable preservation by freezing/coolingFruits/vegetable preservation by dehydrationFlavorVitamin C

A partially-freezing fresh-keeping method for fresh jujubes is disclosed. The method includes a step of fresh jujube picking and selecting, namely a step of picking fresh jujubes in a crisp ripe period and having a colored area accounting for more than one third of the total fruit area, and selecting jujubes without pests, diseases or mechanical damage; a step of dehydrating, namely a step of cleaning the fresh jujubes with clear water, and performing vacuum low-temperature drying to dehydrate 5-10%; a step of partial freezing, namely a step of putting the partially dehydrated jujubes to a refrigerator, and freezing with the refrigerator temperature ranging from -2 DEG C to -4 DEG C. By adopting the partially-freezing fresh-keeping technique combining proper dehydration, the taste, flavor, color and nutrition quality of fresh jujubes can be largely maintained after the jujubes are stored for 4 months. The jujubes are crisp and sweet in taste, the hardness is higher than 120 N / cm<2> and the content of soluble solid is more than 20%. The flesh is free of obvious brown stain, and maintains the white green color of the fresh jujubes. The jujubes maintain the good flavor of the fresh brown stain, are free of bad flavors and have a vitamin C content higher than 70 mg / 100 g.

Owner:FUTURE FOOD RES INST (NANJING) CO LTD

Nelumbo nucifera Gaertn. product and preparation method thereof

InactiveCN105211789AReduce problemsTo achieve the purpose of color protectionClimate change adaptationFood preservationMonosodium glutamateVitamin C

The invention discloses a Nelumbo nucifera Gaertn. product and its preparation method. The Nelumbo nucifera Gaertn. product is prepared from the following raw materials (by weight): 100 kg of Nelumbo nucifera Gaertn., 0.5-1 kg of additives and 17-20 parts of seasoning. The additives comprise the following ingredients (by weight): 0.1-0.2 kg of citric acid, 0.3-0.5 kg of acetic acid, 0.05-0.1 kg of sodium benzoate and 0.01-0.02 kg of flavor nucleotides disodium. The seasoning comprises the following ingredients (by weight): 2-5 kg of salt, 3-6 kg of monosodium glutamate, 5-10 kg of white vinegar and 2-5 kg of white sugar. The invention has beneficial effects as follows: storage time of the Nelumbo nucifera Gaertn. product is long, and the product can maintain good taste, color and brittleness for over 12 months; the Nelumbo nucifera Gaertn. product can reach each index of food requirements; browning of the product will not happen; and the product contains no substances harmful to human body. The Nelumbo nucifera Gaertn. product contains rich nutrients, especially has high content of vitamin C and is beneficial to body health. Besides, content of protein in each 100 g of Nelumbo nucifera Gaertn. can reach 1.3 g and above.

Owner:WUHAN NEWSTAR FOOD

Making method of smokeless smoked black areca catechu seeds

The invention relates to a making method of smokeless smoked black areca catechu seeds. The making method comprises the steps of selecting seeds, performing microwave pretreatment, cooking seeds, performing corruption steam explosion treatment, performing seed cooking, performing seed fermenting, performing seed roasting, performing seed steaming, performing seed pressing, applying gum, simmeringgum, performing seed cutting, removing kernels, performing marinating, performing packaging and performing sterilization. A part of raw materials and auxiliary materials conforming to the food additive safety standards GB2760-2014 are added, the condition of seed fermenting temperature and time and the like is controlled, and qualified black areca catechu seeds are made. To sum up, the making of the smokeless smoked black areca catechu seeds is completed through combination of three respects of qualified food technology raw materials, a technology method and a technology condition; and the prepared areca catechu seeds are white in sections and black in surfaces, have rich smoky flavor, do not have peculiar smell, have juice sense of green areca catechu seeds and hot irritating sensation ofsmoked areca catechu seeds, and have unique mouth feel between the green areca catechu seeds and the smoked areca catechu seeds, and novel areca catechu seeds having innovative and unprecedented mouth feel are provided for people eating the areca catechu seeds.

Owner:湖南胖哥鑫鸿实业有限公司

Coprinus comatus production method

InactiveCN108157059AIncrease moisture contentAppropriate distribution of moisture contentSuperphosphatesCalcareous fertilisersBiotechnologyCold storage

The invention discloses a Coprinus comatus production method, and belongs to the field of edible fungi cultivation. To solve the problems that the protein content of the Coprinus comatus is difficultto improve, the shelf-life is short, and the conventional fresh-keep methods are not healthy and are poor in effect, the Coprinus comatus production method includes: 1) inoculating; 2) spawn growth; and 3) soil covering and fruiting. The Coprinus comatus production method can effectively prolong the service life of mushroom shelves, and can significantly improve the protein content; in the acquired Coprinus comatus, 30.2 g of protein is contained in each 100 g of dried Coprinus comatus; in cold storage shelves at the temperature of 5-10 DEG C, the shelf-life can reach 8-10 days; and the Coprinus comatus will not brown and water will not run off significantly within 8-10 days.

Owner:SHANDONG CHANGSHENGYUAN MUSHROOM IND +2

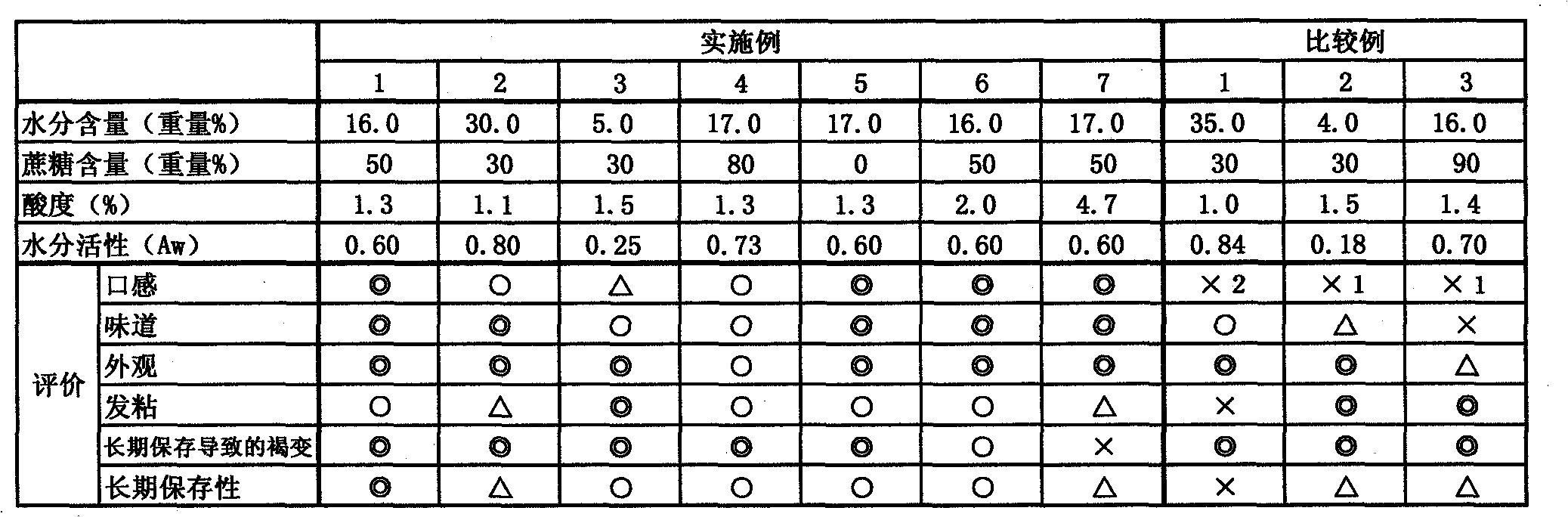

Dried cut citrus fruit and manufacturing process therefor

InactiveCN102325457AEasy to chewRound and soft tasteFood preparationFruits/vegetable preservation by dehydrationFlavorSaccharum

Provided is a dried cut citrus fruit, such that the pericarp (flavedo and albedo) and sarcocarp (segments and pulp) can be consumed without being separated and the quality thereof can be maintained over an extended period. The dried cut citrus fruit has an attractive appearance and can be eaten whole, because the sarcocarp has been preserved and the sarcocarp and the pericarp are not separated; has a superior texture, because the pericarp is appropriately softened; has an excellent flavor that is neither bitter nor too sweet; and does not brown even when stored for extended periods. Also provided is a manufacturing process therefor. The dried cut citrus fruit is characterized by a 5-30 wt.% water content, and 80 wt.% or less of the saccharides are sucrose.

Owner:KRACIE FOODS

Hollow plum fruit preservation method, preservative and preparation method thereof

InactiveCN104286148AImprove freshnessIncreased durabilityFruit and vegetables preservationVitamin CThiourea

The invention discloses a hollow plum fruit preservation method, a preservative and a preparation method thereof. The preservation method realizes preservation mainly by combining coating and deoxidization. The invention further provides a fruit preservative for treating picked hollow plum fruits. The preservative is divided into a coating preservative and a deoxidization preservative, wherein the coating preservative contains 10g of chitosan, 15g of citric acid, 1.0g of vitamin C, 1g of zinc oxide and 200mg of thiourea; and the deoxidization preservative contains 50g of potassium permanganate, 20g of anhydrous sodium chloride, 10g of sodium hydroxide, 15g of zinc oxide, 20g of ferrous sulfate, 15g of vitamin C, 60g of calcium chloride, 15g of sodium polyacrylate and 500g of zeolites. The preservation method comprises the steps of picking fresh hollow plum fruits, treating with the coating preservative, spreading and drying in air for 3-4h, then packing in storage bags in a separating manner, adding a part of deoxidization preservative into each bag, and preserving in a cool environment with the temperature being less than 25 DEG C. According to the preservation method, safety, efficiency and convenience are realized, the quality of hollow plums can be kept, and the rotting rate of the hollow plums can be effectively reduced at the same time.

Owner:GUIZHOU YANHE WUJIANG BIOTECH DEV

Microcapsule food sweetener and preparation method thereof

ActiveCN108112954AGood acid and alkali resistanceImprove salt toleranceFood ingredient as antioxidantFood preservationFood sweetenersStevioside

The present invention discloses a microcapsule food sweetener. The microcapsule food sweetener is characterized by comprising microcapsule wall materials and core materials wrapped inside the microcapsule wall materials. The core materials are xylitol and the wall materials consist of stevioside, sodium citrate, sweet proteins and chitosan. The microcapsules are formed by solidification of stevioside and emulsification of xylitol, and spray drying. Good characteristics of acid resistance, alkali resistance, salt resistance, etc. of the stevioside are utilized, the microcapsule food sweetener can be stored for a long time without mildew and deterioration, and browning phenomena, the sodium citrate itself is good in stability, the sweet proteins have excellent antibacterial effects, so thatthe microcapsule sweetener is greatly improved in stability, long in shelf life and wide in application ranges, and can be applied to most common food.

Owner:GUANGZHOU HENGYU SPICES CO LTD

Lotus root slices with jujubes and glutinous rice and preparation method of lotus root slices

InactiveCN104872576ARuddy colorPleasant fragranceFood ingredient as antioxidantFood preparationHorticultureLotus root

The invention discloses lotus root slices with jujubes and glutinous rice and a preparation method of the lotus root slices. The preparation method of the lotus root slices comprises the following steps: washing and peeling fresh lotus roots, removing lotus root knots, cutting the lotus roots into lotus root segments, filling the glutinous rice into lotus root holes, putting the lotus root segments in boiled sugar water, and boiling the lotus root segments over high fire under the normal pressure, boiling the lotus root segments for 2-4 hours over medium fire after the sugar water is boiled, cooling and then slicing the lotus root segments, and canning the lotus root slices with the canned sugar water, then heating cans for 20-60 minutes at 90-110 DEG C, and finally vacuumizing, sealing and sterilizing to prepare canned lotus root slices with jujubes and glutinous rice. The lotus root slices with jujubes and glutinous rice is ruddy in color and luster, pleasant in fragrance and delicious in taste; the problem that the lotus root slices brown in the preservation process can be solved thoroughly.

Owner:JIANGSU HONEST FOOD

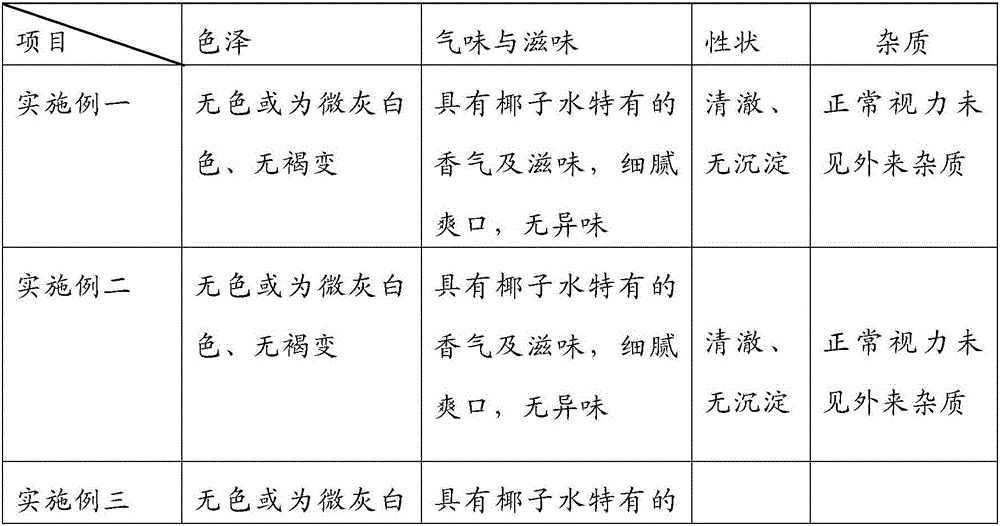

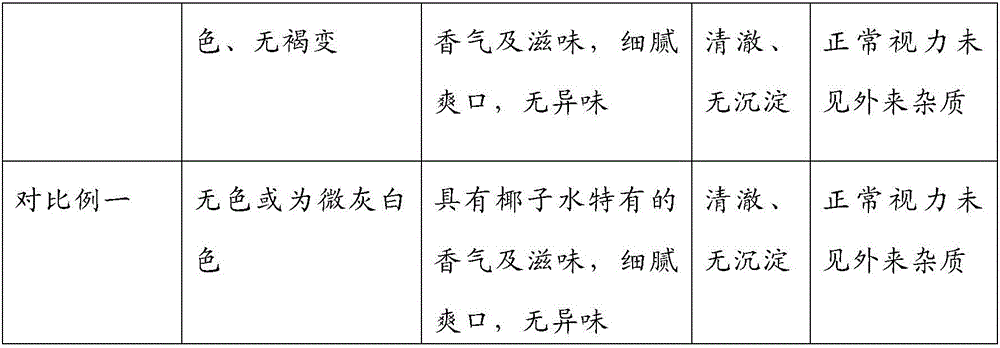

Pure coconut water beverage and preparation method thereof

The invention discloses a preparation method of pure coconut water beverage. The preparation method comprises the following steps of (1) crushing shell of fresh coconut, fetching out coconut water, performing coarse filtering, and quickly refrigerating at the temperature of 4 to 10 DEG C; (2) performing pasteurization on the refrigerated coconut water; (3) centrifuging the coconut water at the temperature of 50 to 55 DEG C; (4) performing secondary centrifuging on the coconut water at least at rotation speed of 8000r / min at the temperature of 50 to 55 DEG C; (5) degassing the coconut water at low temperature and low vacuum; (6) sterilizing in a sterilizing machine. The preparation method of the pure coconut water beverage has the advantages that the fresh coconut water is used as raw material; at the premises of not mixing water and adding food additives, by adjusting technological steps and parameters, the prepared pure coconut water beverage is fresh, and is free from brown stain, and the flavor and nutrient and functional ingredients in the coconut water are effectively remained.

Owner:COCONUT PALM GRP

Microwave vacuum freeze drying method for dendrobium officinale ginseng superfine powder

InactiveCN109394975AAvoid heat transfer resistance and heat lossShorten freeze-drying timePowder deliveryMetabolism disorderChemistryFreeze dry

The invention discloses a microwave vacuum freeze drying method for dendrobium officinale ginseng superfine powder. The microwave vacuum freeze drying method comprises the following steps: 1) pretreating: using water for washing off silt from freshly harvested dendrobium officinale and ginseng, and draining water; 2) pulping: pulping the pretreated dendrobium officinale and ginseng with water; 3)concentrating: adopting a reverse osmosis device for concentrating pulp; 4) pre-freezing: using a high speed stirrer for stirring the concentrated solution which is concentrated by the reverse osmosisdevice, and then post-freezing; 5) freeze-drying: putting the pre-frozen concentrated solution into a dry cabin, performing vacuum freeze drying, releasing pressure after the ending of drying, and taking out from the dry cabin; 6) smashing: using a jet mill for smashing, thereby acquiring dendrobium officinale ginseng superfine powder. According to the method disclosed by the invention, freeze-drying time is effectively reduced, freeze-drying energy consumption is reduced, active ingredients and effective constituents are kept and excellent rehydration property of products is maintained.

Owner:胡爱娣

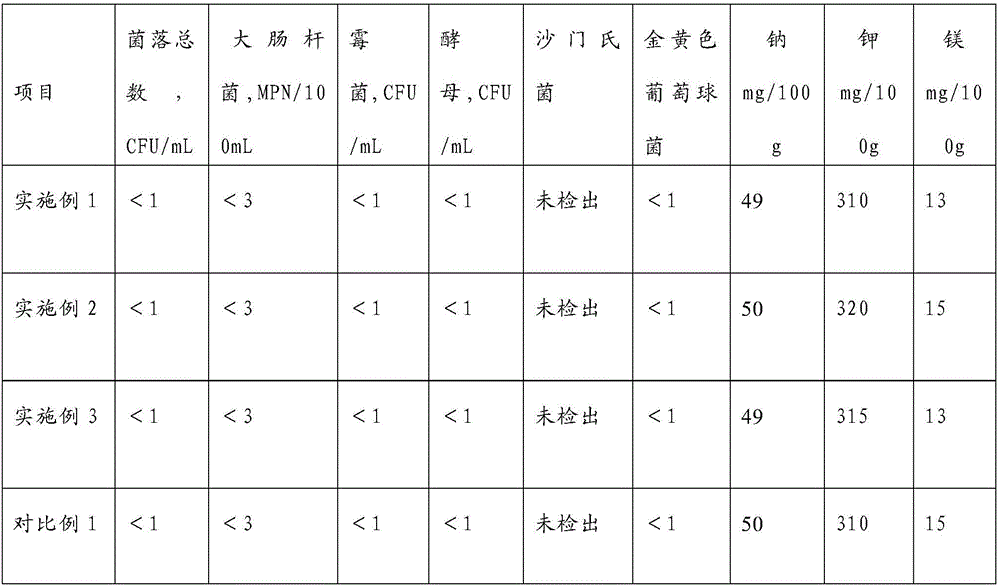

Fast-frozen flour and rice food and making method thereof

InactiveCN108185291AHas a conformal effectImprove water retentionFood freezingFood preservationFood flavorMoisture

The invention belongs to the technical field of fast-frozen flour and rice foods, in particularly relates to fast-frozen flour and rice food and a making method thereof. According to the fast-frozen flour and rice food disclosed by the invention, hydroxypropyl methylcellulose ether is added into dough, so that the water retention property, the frost resistance and the mouth feel of the dough are improved, and the breakage rate of the dough is reduced, and made fast-frozen dumplings are more three-dimensional in shape; licorice powder in fast-frozen oil is used for improving the sweetness of fillings, and has the characteristics of adjusting and protecting activity of a digestive system, a respiratory system, a nervous system, an endocrine system and the like; citrus dietary fibers are usedfor effectively preventing moisture from translocating, so that the water retention property, the chewiness and the mouth feel are improved; through adoption of nutrient substances and Chinese yam flour, the nutrients are strengthened, the flavor and the mouth feel of the fillings are improved, and the stability of the fast-frozen oil and the uniformity and the fineness of texture of the fast-frozen oil are improved, so that the conditions that the fast-frozen oil of the fast-frozen food is high in hardness, poor in flavor, and low in nutrition, and the fast-frozen food is liable to crack areobviously reduced; and the nutrient substances conform to the theory of monarch, minister, assistant and guide in traditional Chinese medical science, the components in a formula complement with eachother, the effect of easing mental anxiety is jointly achieved, and the sleep quality is improved.

Owner:太仓鼎膳食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com