Microcapsule food sweetener and preparation method thereof

A sweetener and microcapsule technology, applied in the field of preparation of microcapsule food sweeteners, can solve the problems of easily causing obesity, dental caries and other diseases, reducing calorie intake, poor storage stability, etc., and achieving good palatability and durability. Long, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

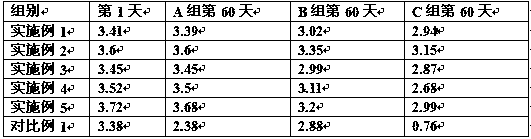

Examples

Embodiment 1

[0027] Preparation of microencapsulated food sweetener:

[0028] (1) Mix 10g of stevioside and 15g of Miraculin-type sweet protein into 100g of deionized water, then add 20g of sodium citrate and 2g of chitosan, and keep warm in a water bath at 75°C for 2 hours to obtain a viscous transparent liquid. Cool down to 60°C to obtain stevioside adhesive body;

[0029] (2) Add 20g of xylitol, 1g of emulsifier (sodium stearoyl lactylate), 0.2g of antioxidant (propyl gallate), 3.5g of filler (food grade sodium chloride) into 80g of deionized water, and add Under the condition of 50°C, stir at a high speed of 1500rpm, and the stirring process is accompanied by ultrasonic oscillation for 2 hours to obtain a uniform emulsion;

[0030] (3) Mix the emulsion prepared in step (2) with the adhesive prepared in step (1) at a volume ratio of 10:1 at 40°C, stir thoroughly for 1 hour, then raise the temperature to 80°C, and continue the reaction for 2 hours , to obtain a mixture;

[0031] (4) S...

Embodiment 2

[0033] Preparation of microencapsulated food sweetener:

[0034] (1) Mix 12g of stevioside and 12g of Thaumatin-type sweet protein into 100g of deionized water, then add 15g of sodium citrate and 1.5g of chitosan, and keep it in a water bath at 80°C for 2 hours to obtain a viscous transparent liquid. The water bath was cooled to 60°C to obtain the stevioside adhesive body;

[0035] (2) Add 18g of xylitol, 1g of emulsifier (glyceryl monostearate), 0.2g of antioxidant (propyl gallate), 3.5g of filler (tricalcium phosphate) into 82g of deionized water, and add Under the condition of 50°C, stir at a high speed of 1500rpm, and the stirring process is accompanied by ultrasonic oscillation for 2 hours to obtain a uniform emulsion;

[0036] (3) Mix the emulsion prepared in step (2) with the adhesive prepared in step (1) at a volume ratio of 10:2 at 40°C, stir thoroughly for 1 hour, then raise the temperature to 65°C, and continue the reaction for 2 hours , to obtain a mixture;

[0...

Embodiment 3

[0039] Preparation of microencapsulated food sweetener:

[0040] (1) Mix 15g of stevioside and 15g of Monellin-type sweet protein into 100g of deionized water, then add 18g of sodium citrate and 2g of chitosan, and keep it in a water bath at 75°C for 2 hours to obtain a viscous transparent liquid. The temperature was lowered to 60°C to obtain stevioside glue.

[0041] (2) Add 23g of xylitol, 1g of emulsifier (sodium stearoyl lactylate), 0.2g of antioxidant (propyl gallate), and 2.5g of filler (sodium aluminosilicate) into 82g of deionized water, at 50 Under the condition of ℃, stir at a high speed of 1500rpm, the stirring process is accompanied by ultrasonic oscillation for 2 hours, and a uniform emulsion is obtained.

[0042] (3) Mix the emulsion prepared in step (2) with the adhesive prepared in step (1) at a volume ratio of 10:2 at 40°C, stir thoroughly for 1 hour, then raise the temperature to 80°C, and continue the reaction for 2 hours , to obtain a mixture;

[0043] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com