Pure coconut water beverage and preparation method thereof

A coconut water and beverage technology, applied in the field of pure coconut water beverage and its preparation, can solve the problems of unsatisfactory green, safe and healthy drinks, and achieve the effect of retaining flavor and nutrition without browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

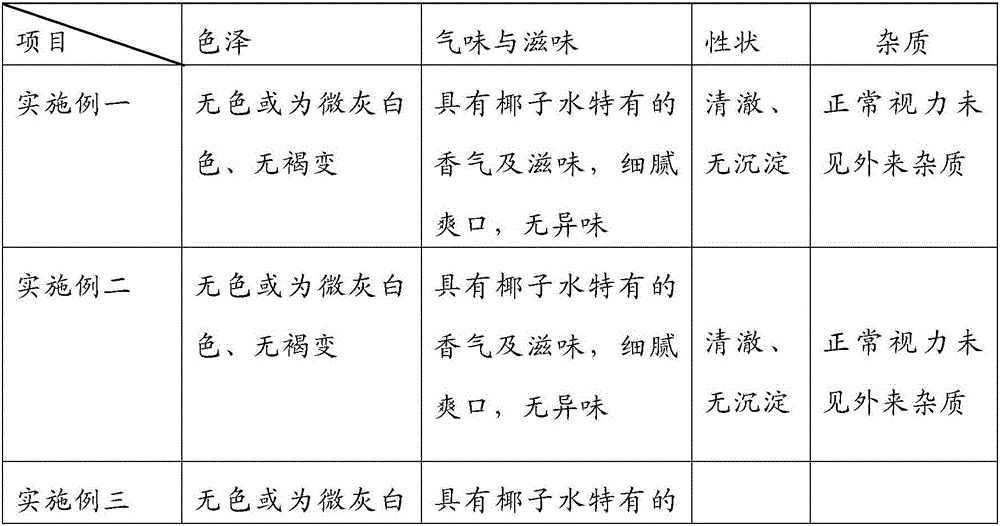

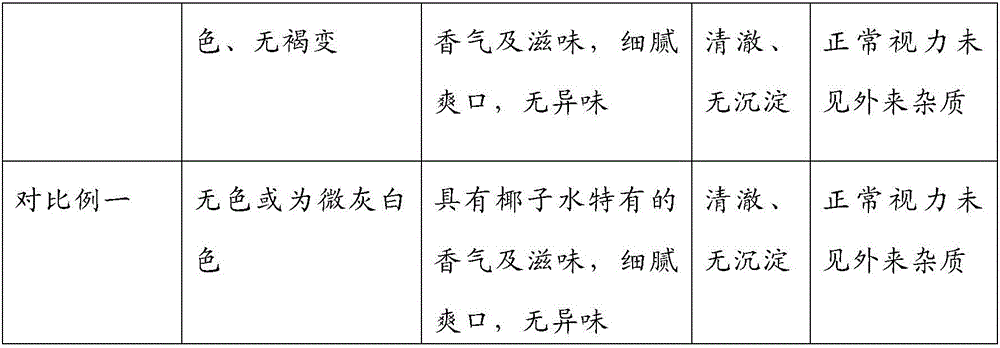

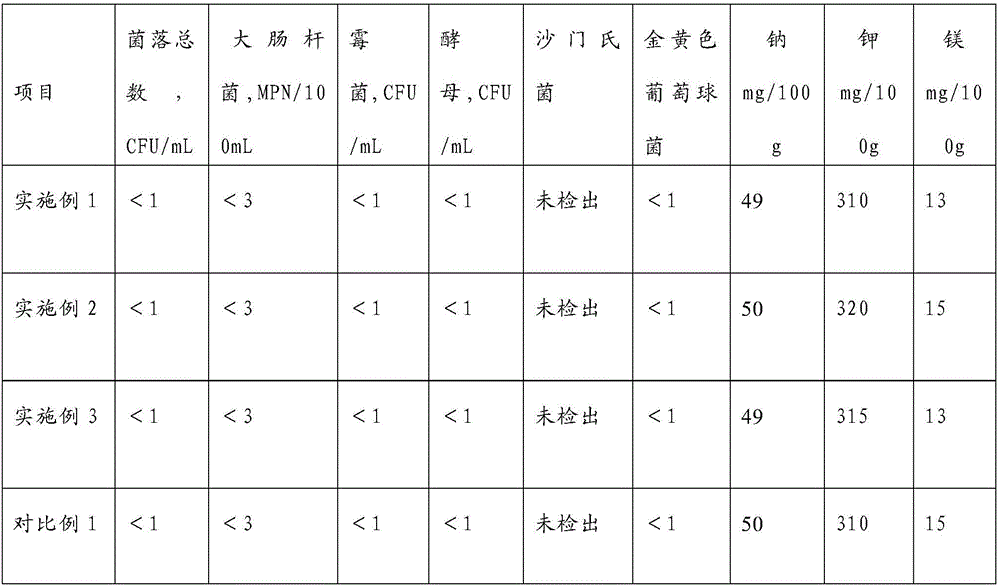

Examples

Embodiment 1

[0020] Example 1: The mature and intact coconut shells are broken to get water, collected and filtered with a 200-mesh sieve, and quickly sent to a refrigerated bucket at 4°C for refrigeration, and then the refrigerated coconut water is sent to a pasteurization machine for pasteurization, sterilization The temperature is 85°C, and the time is 32s. Pasteurization is to sterilize the raw materials; centrifuge for 80s at a speed of 6000r / min and a temperature of 50°C to remove impurities and odors; then use 8000r / min, Centrifuge at a temperature of 50°C for 80s to remove bacteria and spores; then degas the coconut water at a vacuum of 0.085MPa and a temperature of 40°C for 80s, and sterilize it at 130°C for 16s in a high-temperature sterilizer. The finished product is processed and sent to the filling machine for aseptic packaging.

Embodiment 2

[0021] Embodiment 2: The mature and intact coconut shells are broken to get water, collected and filtered with a 200-mesh sieve, quickly sent to refrigerated barrels at 6°C for refrigeration, and then the refrigerated coconut water is sent to a pasteurization machine for pasteurization, sterilization The temperature is 88°C, the time is 20s, and then centrifuged at 7000r / min and 52°C for 70s to remove impurities and odors; then centrifuged at 9000r / min and 52°C for 70s to remove Bacteria and spores are removed; then the coconut water is degassed for 60s at a vacuum of 0.09MPa and a temperature of 60°C, preferably to remove oxygen and water vapor. Sterilize at 140°C for 10s in a high-temperature sterilizer, and then send to a filling machine for aseptic packaging.

Embodiment 3

[0022] Embodiment 3: The ripe and intact coconut shells are broken to get water, filtered with a 200-mesh sieve after collection, and quickly sent to refrigerated barrels at 10°C for refrigeration, and then the refrigerated coconut water is sent to a pasteurization machine for pasteurization, sterilization The temperature is 95°C, the time is 32s, and then centrifuged at 7000r / min and 55°C for 40s to remove impurities and odors; then centrifuged at 9000r / min and 55°C for 40s to remove Bacteria and spores are removed; then the coconut water is degassed for 40s at a vacuum of 0.095MPa and a temperature of 80°C. Sterilize at 140°C for 8 seconds in a high-temperature sterilizer, and then send to a filling machine for aseptic packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com