Hollow plum fruit preservation method, preservative and preparation method thereof

A fresh-keeping method and a technology of a fresh-keeping agent, which are applied in the fields of fruit and vegetable preservation, food preservation, food science, etc., can solve the problems of shortening the supply period of fresh fruit, affecting market sales, and accelerating fruit rot, etc., and achieve shortening of the preservation period, good preservation effect, Enhanced antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

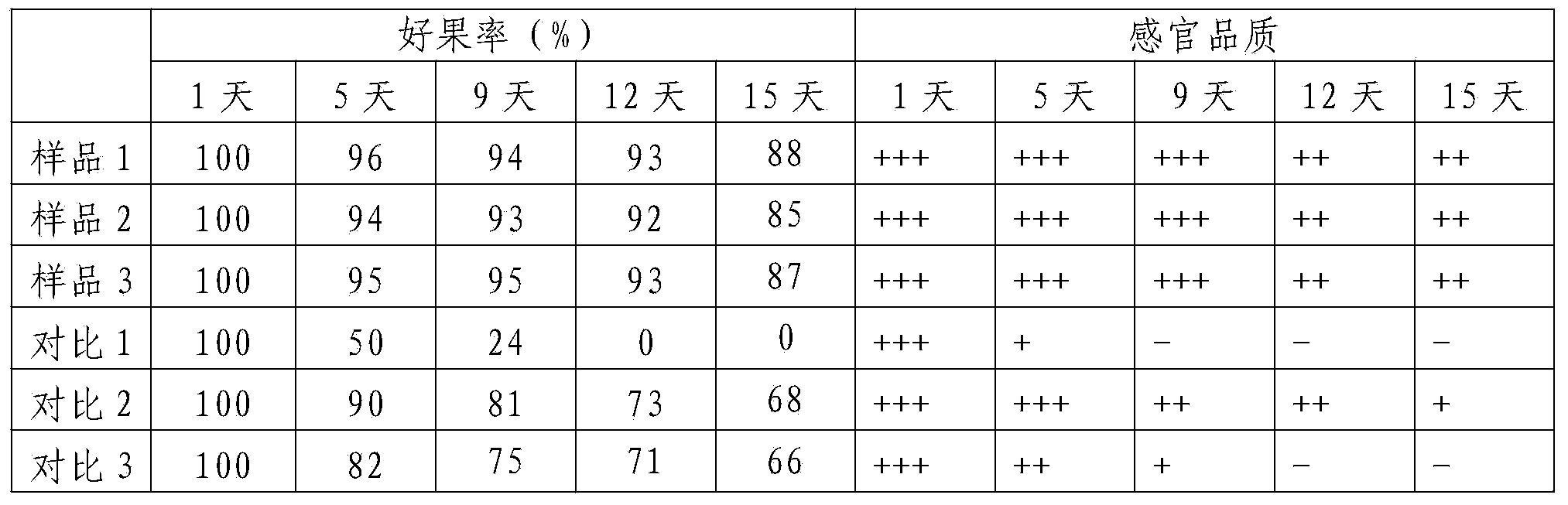

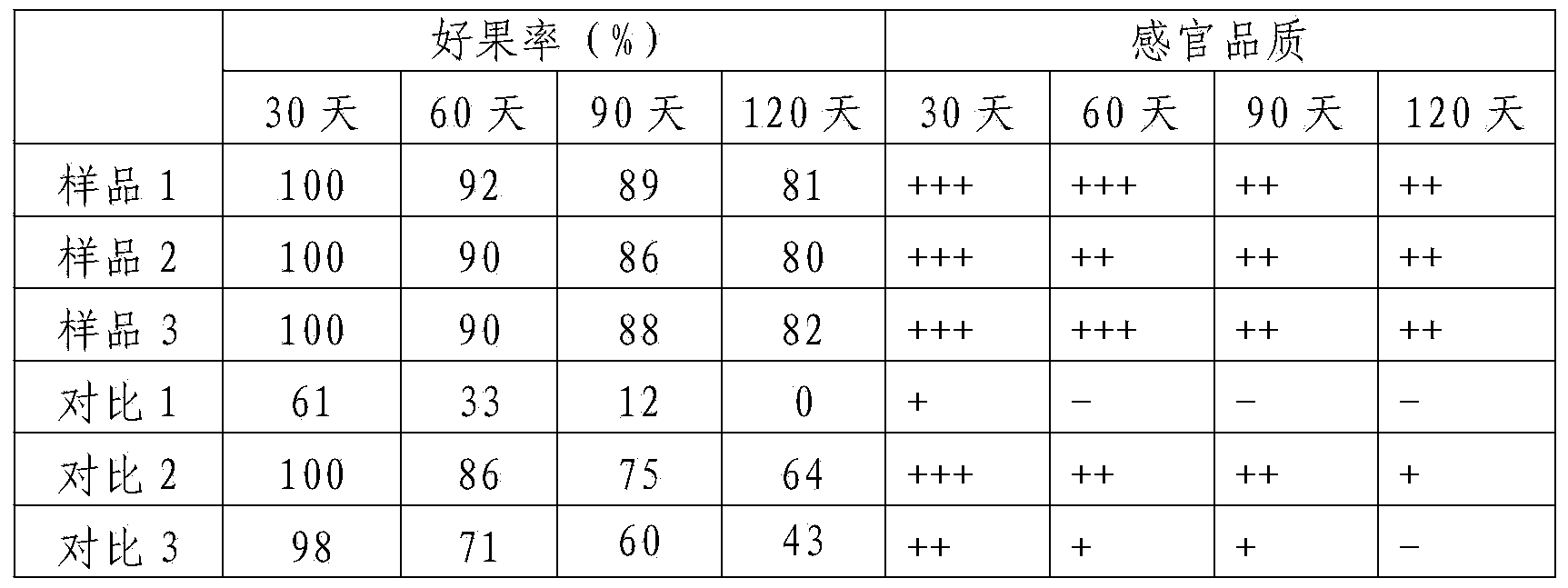

Examples

Embodiment 1

[0026] Embodiment 1 prepares plum fruit preservative according to the following steps:

[0027] Coating antistaling agent: Chitosan (containing more than 95% of deacetylation degree) 10g, citric acid 15g, vitamin C 1.0g, zinc oxide 1.0g, thiourea 200mg; measure vitamin C, zinc oxide and thiourea according to the formula, use Dissolve 70% of the total amount of pure water, then add citric acid and chitosan and stir until fully dissolved, add pure water until the total amount is 1000ml, and then configure it as a hollow plum coating preservative;

[0028] Deoxidation preservative: potassium permanganate 50g, anhydrous sodium chloride 20g, sodium hydroxide 10g, zinc oxide 15g, ferrous sulfate 20g, vitamin C 15g, calcium chloride 60g, sodium polyacrylate 15g, zeolite 500g. Measure each raw material according to the formula, put it into a rotary pulverizer, stir and mix evenly, add water according to the proportion of 2% of the mixture, and then fully stir, then dry at 100°C for 2 ...

Embodiment 2

[0033] Embodiment 2 prepares plum fruit preservative according to the following steps:

[0034] Coating antistaling agent: chitosan (containing deacetylation degree above 95%) 15g, citric acid 20g, vitamin C 2.0g, zinc oxide 2.0g, thiourea 300mg; measure vitamin C, zinc oxide and thiourea according to the formula, use Dissolve 80% of the total amount of pure water, then add citric acid and chitosan and stir until fully dissolved, add pure water until the total amount is 1000ml, and then configure it as a hollow plum coating preservative;

[0035]Deoxidation preservative: 20g potassium permanganate, 10g anhydrous sodium chloride, 5g sodium hydroxide, 8g zinc oxide, 10g ferrous sulfate, 10g vitamin C, 40g calcium chloride, 10g sodium polyacrylate, 400g zeolite. Measure each raw material according to the formula, put it into a rotary pulverizer, stir and mix evenly, add water according to the proportion of 1% of the mixture, and then fully stir, then dry at 100°C for 1 hour, and ...

Embodiment 3

[0040] Embodiment 3 prepares plum fruit preservative according to the following steps:

[0041] Coating antistaling agent: chitosan (containing more than 95% of deacetylation degree) 5g, citric acid 10g, vitamin C0.5g, zinc oxide 0.5g, thiourea 100mg; measure vitamin C, zinc oxide and thiourea according to the formula, use Dissolve 60% of the total amount of pure water, then add citric acid and chitosan and stir until fully dissolved, add pure water until the total amount is 1000ml, and then configure it as a hollow plum coating preservative;

[0042] Deoxidation preservative: 80g potassium permanganate, 30g anhydrous sodium chloride, 20g sodium hydroxide, 22g zinc oxide, 30g ferrous sulfate, 20g vitamin C, 80g calcium chloride, 20g sodium polyacrylate, 600g zeolite. Measure each raw material according to the formula, put it into a rotary pulverizer, stir and mix evenly, add water according to the proportion of 4% of the mixture, and then fully stir, then dry at 120°C for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com