Lily freeze-dried piece and preparation process thereof

A preparation process and technology of freeze-dried tablets, applied in the field of lily freeze-dried tablets and its preparation, can solve the problems of shape, color, property damage, bioactive substance inactivation, nutrient loss, etc., and achieve good rehydration and recovery , high nutritional value, crunchy and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A kind of preparation technology of lily freeze-dried sheet, comprises the following steps:

[0016] (1) Pretreatment: including a blanching, b first-stage water cooling, c second-stage water cooling, d air cooling, and e code disc in sequence.

[0017] It should be noted that, in this embodiment, before blanching in a, it also includes: peeling, grading and cleaning; wherein, the peeling and grading includes: after removing the roots and mud of the lily scales, peeling the lily scales from the outside to the inside. In order to facilitate the arrangement and packaging of the final product, the individual pieces are graded according to size; due to the heat generation and heat dissipation of the lily itself, the temperature of the lily itself is relatively high, especially in spring, when the lily has a strong metabolism and is prone to deterioration and rot. The scales are cooled. Considering the reduction of production cost, in this embodiment, the method of cleaning ...

Embodiment 1

[0029] The present embodiment provides a kind of preparation technology of lily freeze-dried sheet, comprising:

[0030] (1) Preprocessing:

[0031] a blanching: blanching the lily scales at 70°C for 15 minutes;

[0032] b The first stage of water cooling: put the lily scales in 30°C water to cool for 10 minutes;

[0033] c The second stage of water cooling: put the lily scales in 10°C water to cool for 10 minutes;

[0034] d Air cooling: dry the lily scales until there is no flowing water on the surface;

[0035] e code plate: stack dried lilies with a thickness of 5cm;

[0036] (2) Freeze drying:

[0037] a Pre-freezing: Place the stacked lily scales in the freezing cabin, drop the temperature in the freezing cabin to -30°C at a rate of 0.1°C / min, then drop to -45°C at a rate of 0.3°C / min, When the cold hydrazine temperature reaches -45°C, keep the cold hydrazine temperature for 3 hours;

[0038] b The first stage of drying: the first temperature rise: control the vacu...

Embodiment 2

[0042] This example provides a preparation process for lily freeze-dried flakes, which differs from Example 1 in that: a) blanching: blanching lily scales at 90° C. for 3 minutes.

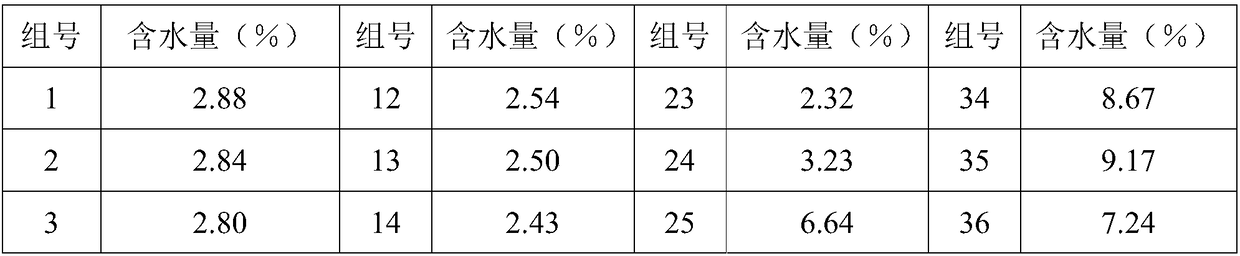

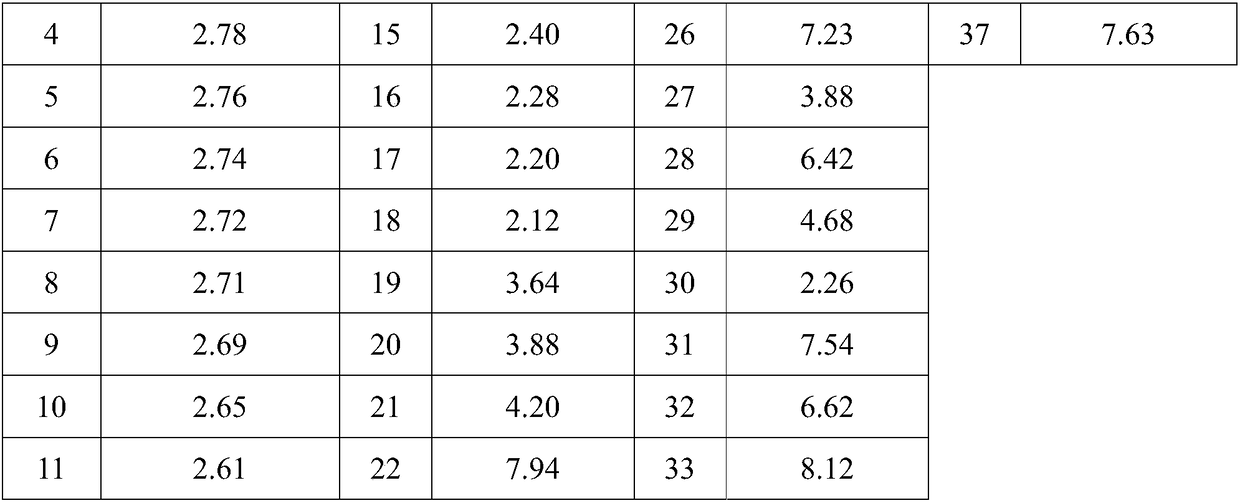

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com