Hollow staggered double-jacquard sandwich screen cloth and manufacturing method thereof

A jacquard sandwich and hollow technology, applied in textiles and papermaking, knitting, warp knitting and other directions, can solve the problems of insufficient and presenting of the bottom jacquard pattern, and achieve the effect of rich pattern effect and strong layering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

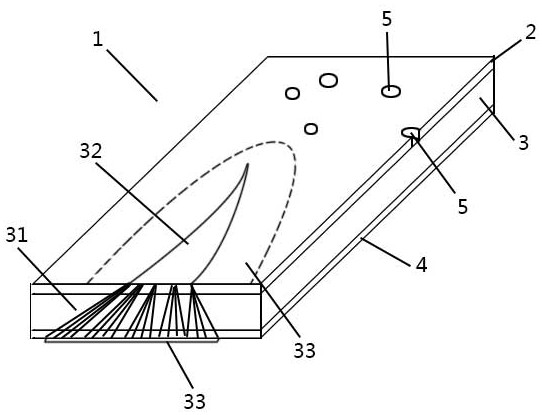

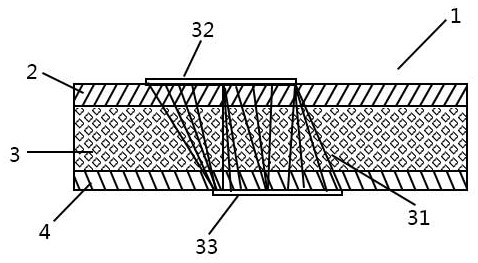

[0047] refer to Figure 1~Figure 4 , the present invention provides a hollow dislocation double jacquard sandwich mesh, and the hollow dislocation double jacquard sandwich mesh in this embodiment is woven by a double-needle bed high-speed warp knitting machine, which includes layering and integral weaving from top to bottom The formed surface base layer 2, the hollow dislocation jacquard layer 3, the subbase layer 4, the jacquard column 31 whose gaps are distributed in the hollow dislocation jacquard layer 3, and the jacquard column 31 interlaced on the surface base layer 2 and the subbase layer 4 to form loops 32 and bottom jacquard 33.

[0048] S1. Bar setting: the warp knitting machine for knitting has 6 bars, and the 6 bars are sequentially set as ground bar GB1, ground bar GB2, and ground bar GB3 from the front needle bed to the rear needle bed , Ground comb GB4, ground comb GB5, ground comb GB6;

[0049] S2. Bar threading: the ground bar GB1, ground bar GB2, ground bar...

Embodiment 2

[0062] refer to Figure 1~Figure 4 and Figure 6 , the present invention provides a hollow dislocation double jacquard sandwich mesh, and the hollow dislocation double jacquard sandwich mesh in this embodiment is woven by a jacquard creel warp knitting machine, which includes layering and integral weaving from top to bottom The formed surface base layer 2, the hollow dislocation jacquard layer 3, the subbase layer 4, the jacquard column 31 whose gaps are distributed in the hollow dislocation jacquard layer 3, and the jacquard column 31 interlaced on the surface base layer 2 and the subbase layer 4 to form loops 32 and bottom jacquard 33.

[0063] S1. Bar setting: the warp knitting machine for knitting has 6 bars, and the 6 bars are sequentially set as ground bar GB1, ground bar GB2, and Jacquard bar JK1 from the front needle bed to the rear needle bed , Jacquard bar JK2, ground bar GB5, ground bar GB6;

[0064] S2. Bar threading: the ground bar GB1, ground bar GB2, ground b...

Embodiment 3

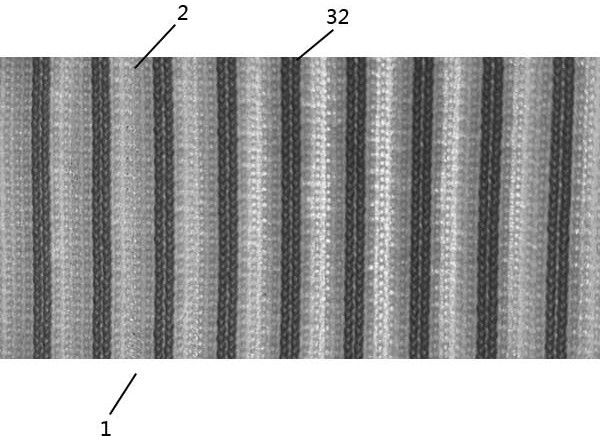

[0077] refer to Figure 7 , on the basis of embodiment 1, the ground comb GB3 walks the warp knitting basic structure 1-0 / 3-2 / 1-1 / 2-3 / / , and the ground comb GB4 walks the warp knitting basic structure 1-1 / 2-1 / 1-2 / 1-2 / / , make surface base 2 form surface jacquard 32 with 2 vertical stripes, and base 4 form bottom jacquard 33 with 3 vertical stripes.

[0078] Compared with the prior art, in this embodiment, the first F row must be shifted to the left by 2 stitches in the jacquard warp knitting machine, which breaks the limitation of the jacquard maximum shift of 1 stitch in the jacquard warp knitting machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com