Patents

Literature

35results about How to "Realize shape control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabrication method and application of one-dimensional MOF@ZIF core-shell structure

ActiveCN110212194ALarge specific surface areaHigh porosityCell electrodesSecondary cellsElectrochemical energy storageChemistry

The invention provides fabrication method and application of a one-dimensional MOF@ZIF core-shell structure. The fabrication method comprises the following steps of (1) dispersing different MOF materials in an ethanol water mixed solution to form a uniform suspension liquid C; (2) dissolving 2-methylimidazole in the ethanol water mixed solution to form a solution D; and (3) placing the suspensionliquid C in water bath for preheating to a reaction temperature, pouring a solution D, performing constant-temperature stirring so that conversion among different crystal-structure MOFs can be generated during the process, centrifugally separating a product, sequentially washing the product with ethyl alcohol and deionized water, and finally placing the product in a drying oven for drying to obtain MOF@ZIF core-shell structure powder. The morphology can be maintained after high-temperature carbonization and pickling of the one-dimensional core-shell structure MOF@ZIF core-shell structure, andthe obtained porous carbon@nitrogen doping porous carbon shows excellent electrochemical storage performance due to unique core-shell structure and in-situ nitrogen atom doping. The fabrication methodis simple to operate and is low in cost, the process is easy to control and observe, the conversion among the MOFs material and morphology control are successfully achieved, the prepared MOF@ZIF core-shell structure can have wide application prospect and can be used for storing electrochemical energy.

Owner:HEFEI UNIV OF TECH

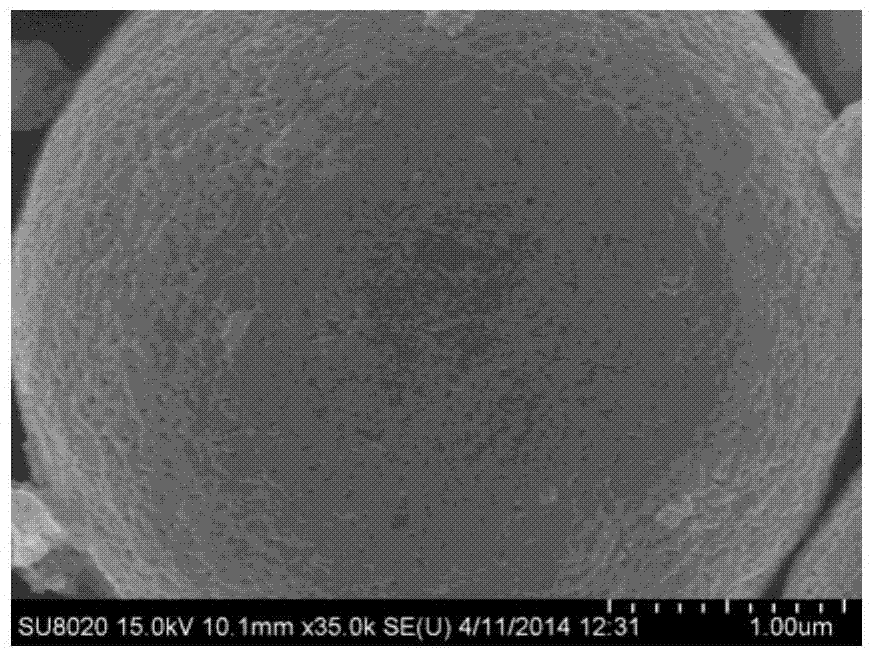

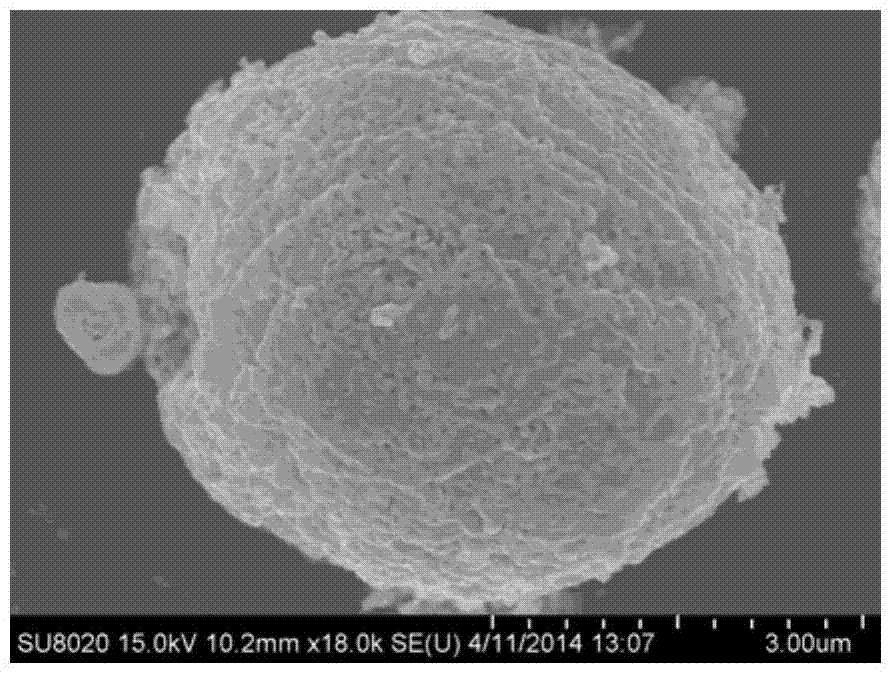

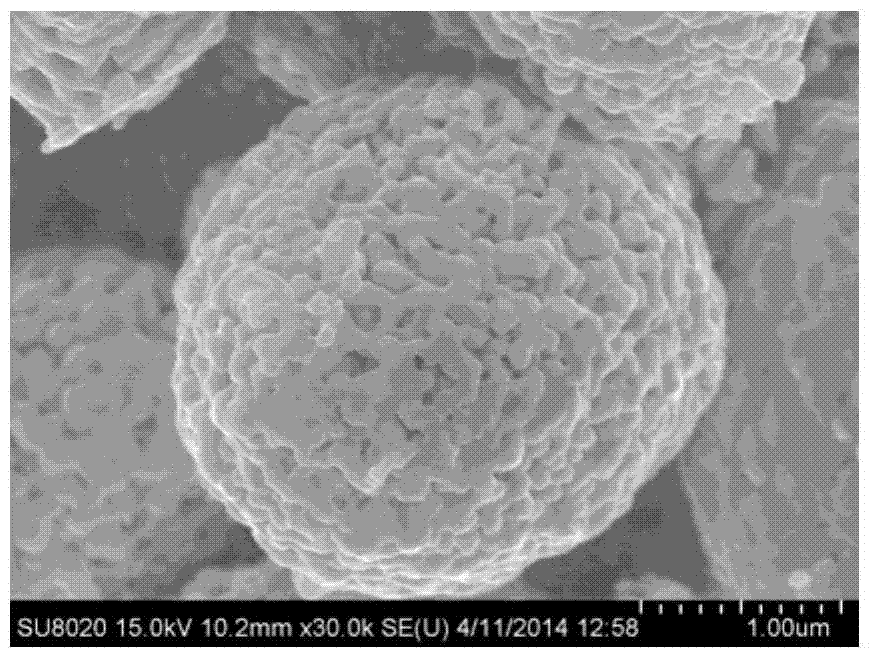

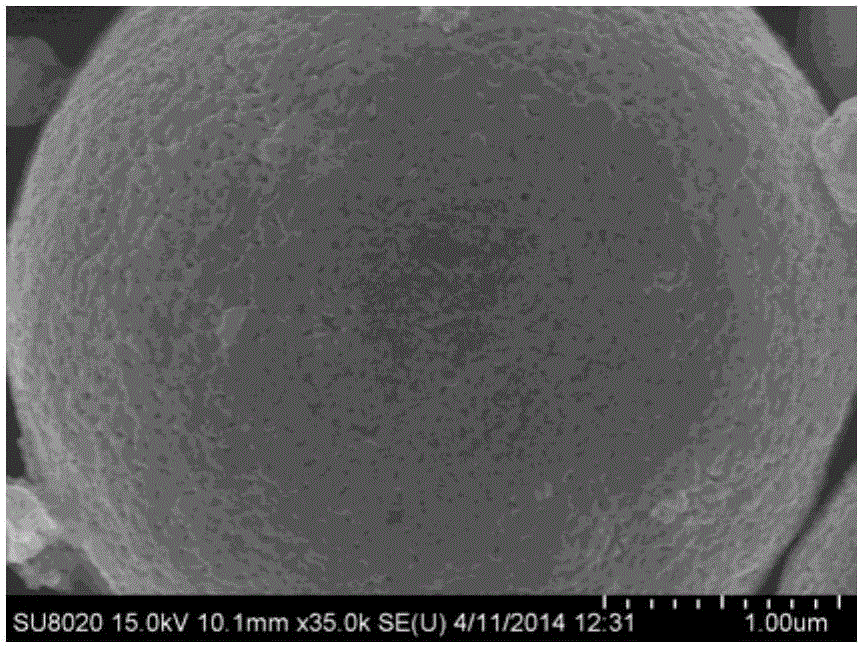

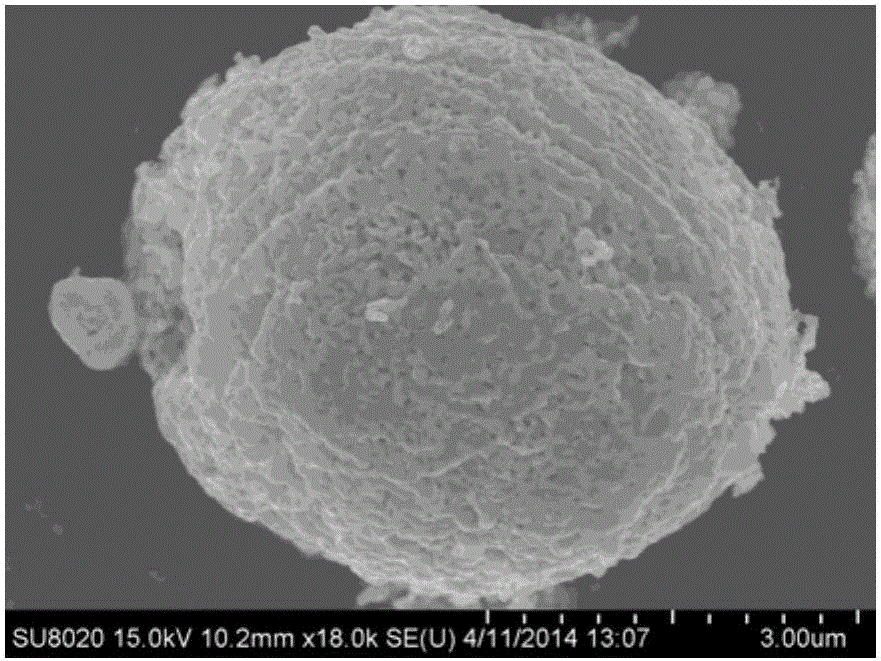

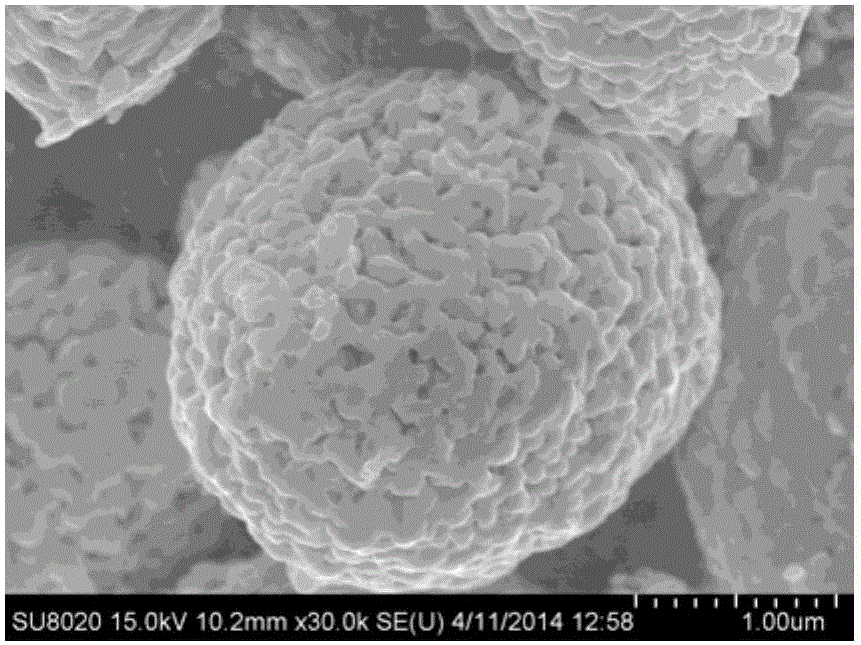

Porous spherical tungsten rhenium alloy powder and preparation method thereof

The invention relates to a porous spherical tungsten rhenium alloy powder and a preparation method thereof, and belongs to the technical field of alloy powder. The mixture of tungsten and rhenium is in the atomic level, the content of the tungsten in proportion by weight ranges from 25% to 90%, and the content of the rhenium in proportion by weight ranges from 10% to 75%. The method includes adopting ammonium perrhenate and ammonium metatungstate as raw materials, configuring into solution, and preparing precursor powder by the spray drying method; depositing and reducing in the atmosphere of hydrogen gas in two steps, namely in the first step,allowing the temperature to be 450 to 550 DEG C and insulating heat for 1 to 2 hours, in the second step, allowing the reducing temperature to be 850 to 950 DEG C, and insulating heat for 2 to 3 hours; and obtaining the porous spherical tungsten rhenium alloy powder. According to the method, process is simple, repeatability and operability are high, the introduction of impurity elements in the preparation process is avoided, the purity of prepared samples is high, and appearance control of a porous spherical tungsten rhenium alloy ball can be implemented by controlling the content of the tungsten, the reducing temperature and heat insulating time.

Owner:韶关元泰资源科技有限公司

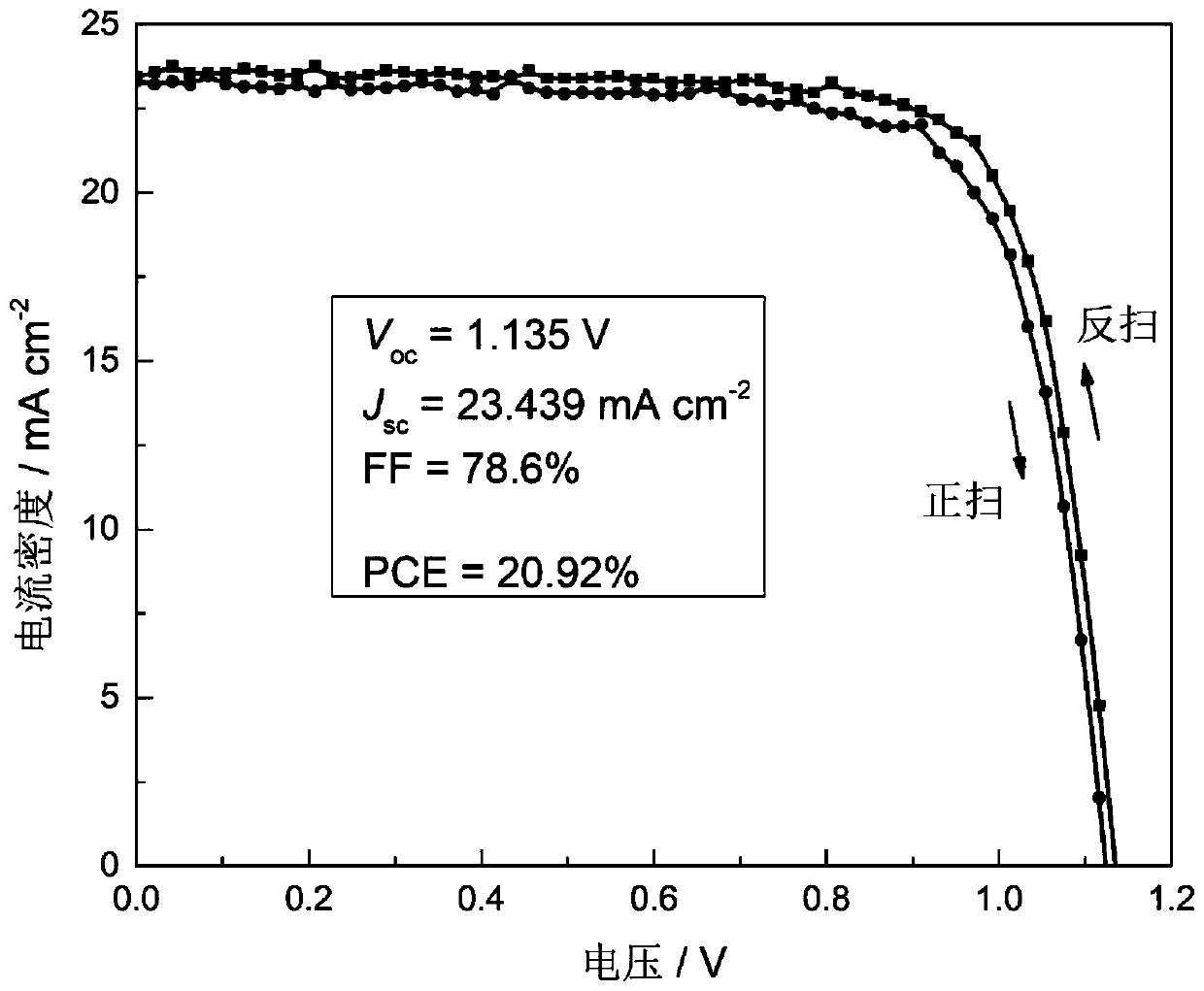

Perovskite film preparation method based on anti-solution bath, and solar cell

ActiveCN109904318AAchieve crystallization controlRealize shape controlFinal product manufactureSolid-state devicesPerovskite solar cellAnti solvent

The invention discloses a perovskite film preparation method based on an anti-solution bath, and a solar cell. A proper solute is added into an anti-solvent to prepare anti-solutions with different functions; crystallization control and morphology regulation of a perovskite film are realized; and meanwhile, an interface between the perovskite film and a carrier transmission layer is passivated, sothat the surface defect state and the interface recombination are reduced, the carrier concentration and the extraction efficiency at the interface are improved, and the carrier transmission is better facilitated. The perovskite solar cell prepared with the anti-solution bath method has relatively high photoelectric conversion efficiency and high stability. The preparation method is simple and convenient, relatively short in production period and high in controllability and repeatability, and has a wide application prospect in the production and preparation of large-area and large-scale perovskite solar cells.

Owner:PEKING UNIV

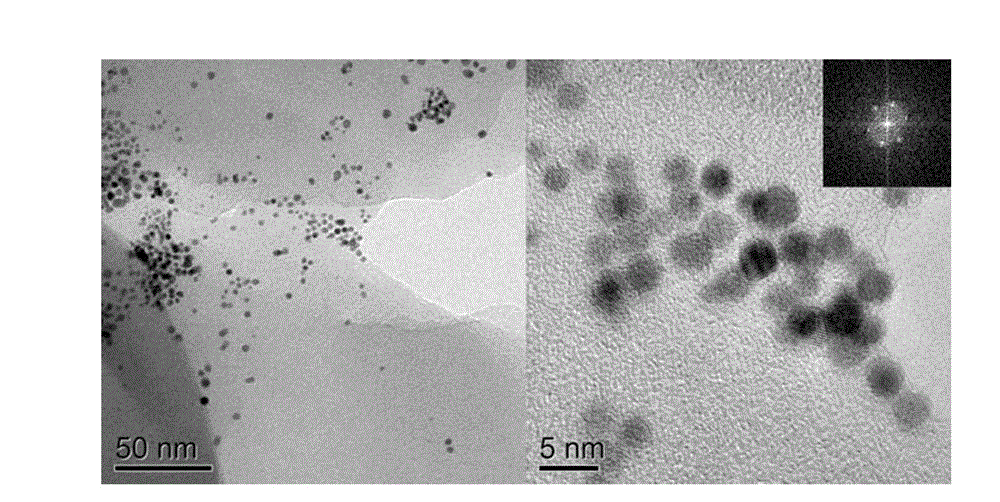

Direct-methanol fuel cell anode catalyst and preparation method

InactiveCN102723503ARealize shape controlHigh catalytic activityCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsHigh energyCrystal plane

The present invention discloses a direct-methanol fuel cell anode catalyst and a preparation method, which belongs to the field of the fuel cell catalyst. According to the invention, a stabilizer and a carrier of the catalyst is cucurbit [6] uril, an active substance of the catalyst is platinum nanoparticles, the regulation and control of growth of different crystal planes are realized by regulating the types of the reducing agents, so that the control of shape of the catalyst can be realized. The diameter of nanoparticles is less than 10nm, and the catalyst has the advantages of uniform diameter of nanoparticles, high energy plane enrichment, uniform distribution, high catalytic activity, excellent ability of carbon monoxide poisoning resistance and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

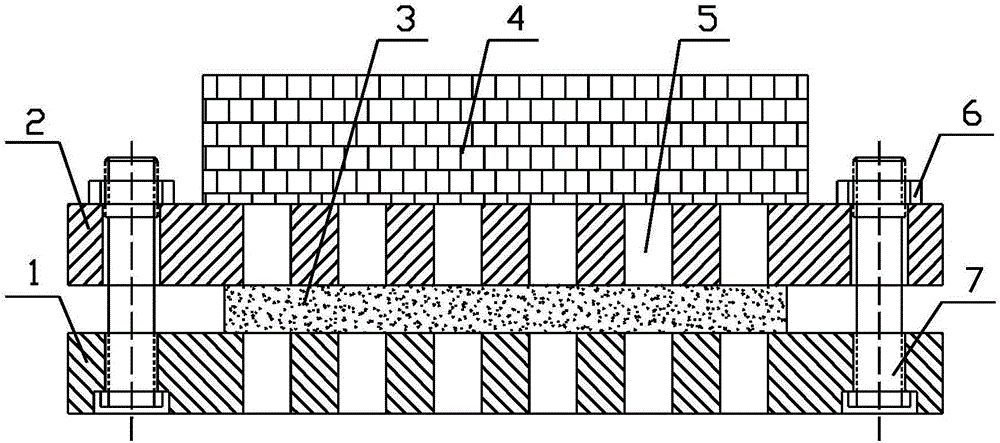

Shape correction and heat treatment method of low-plasticity and low-deformation material plates

The invention relates to a shape correction and heat treatment method of low-plasticity and low-deformation material plates and belongs to the technical field of processing and forming of low-deformation materials. The method comprises the following steps: flattening the low-plasticity and low-deformation material plates under the action of high temperature and pressure, putting upper plate surfaces and low plate surfaces of the plates into water under the constraint action, rapidly cooling and carrying out solution treatment, then carrying out aging treatment to obtain plates with unevenness being less than 1.5mm / m. The method is capable of controlling shape and property of the low-plasticity and low-deformation material plates; the problem of the shape of the low-plasticity and low-deformation material plates is solved; the quality and the yield of the plates are ensured; the application of the low-plasticity and low-deformation material plates can be promoted and broadened; the low-plasticity and low-deformation material plates has good economic values and application prospects.

Owner:有研金属复材技术有限公司

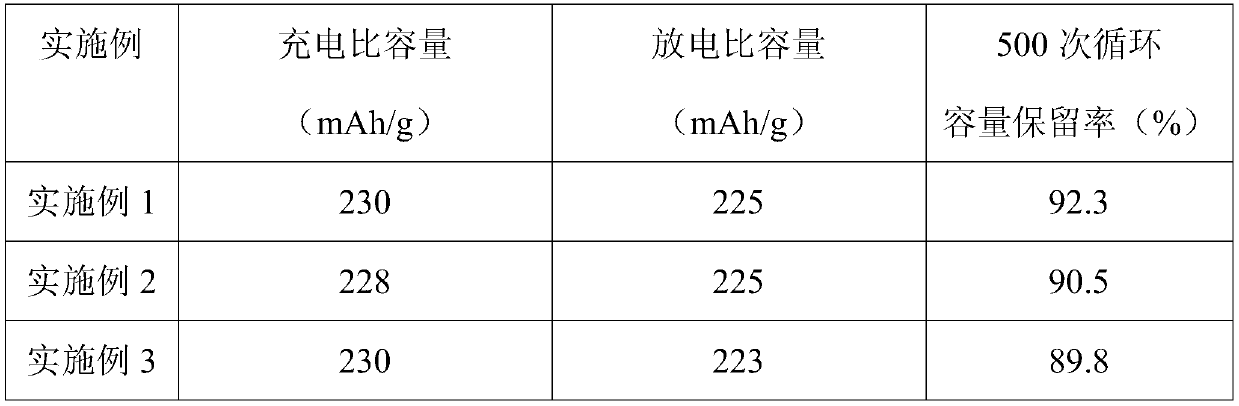

Magnesium ion battery cathode material of composite core-shell structure and preparation method thereof, and application of magnesium ion battery cathode material of composite core-shell structure

ActiveCN109860533AGood electrical propertiesHigh charge and discharge capacityCell electrodesSecondary cellsCharge dischargeSolvent

The present invention relates to a magnesium ion battery cathode material of a composite core-shell structure and a preparation method thereof, and an application of a magnesium ion battery cathode material of composite core-shell structure. The magnesium ion battery cathode material comprises a magnesium ion battery cathode material as a core and coating used for coating the surface of the core.The coating comprises a composite oxide. The preparation method comprises the steps of: dispersing the magnesium ion battery cathode material into a solvent to obtain a solution A; dispersing the composite oxide into the solution A to obtain a solution B; and finally, performing spraying and drying the solution B to obtain the magnesium ion battery cathode material. The preparation method is simple in process, mild in reaction condition, can achieve morphological control of materials, and is suitable for industrialized production, the prepared magnesium ion battery cathode material has a core-shell structure to greatly improve the structure stability of the material, and the battery prepared by employing the cathode material is excellent in electrical properties, and has high charge-discharge specific capacity and a capacity retention ratio.

Owner:LANGFANG GREEN IND TECH CENT +1

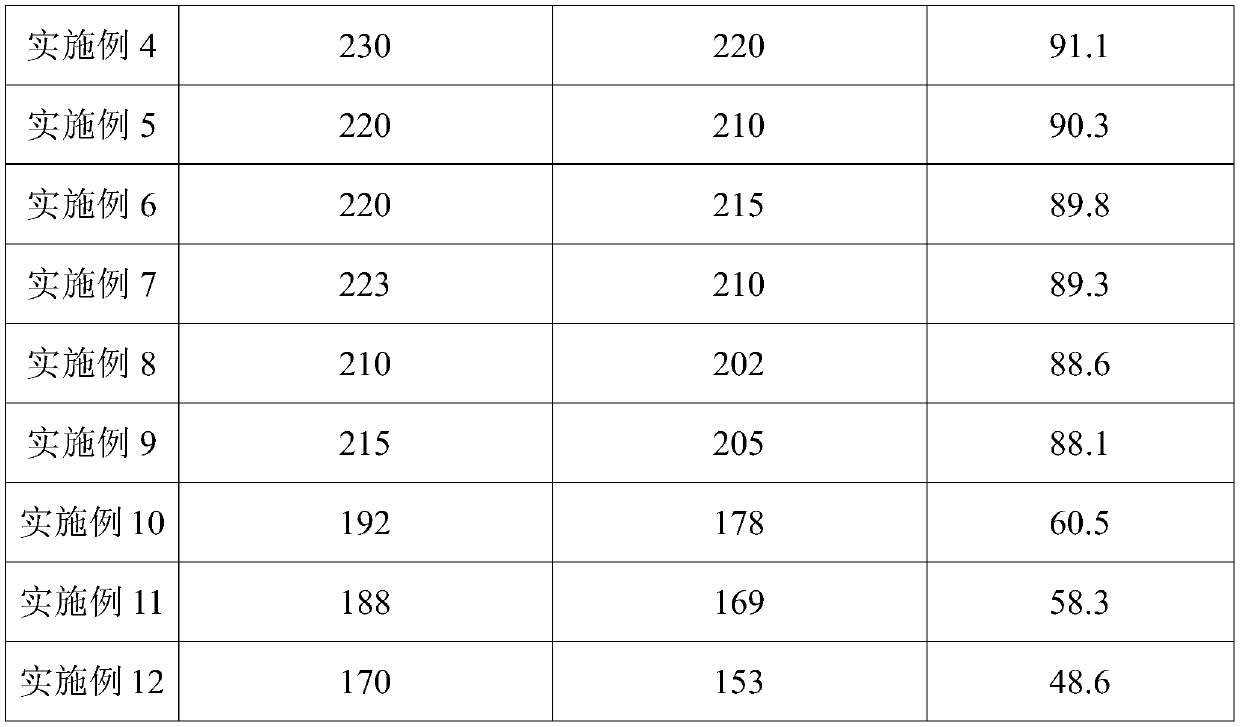

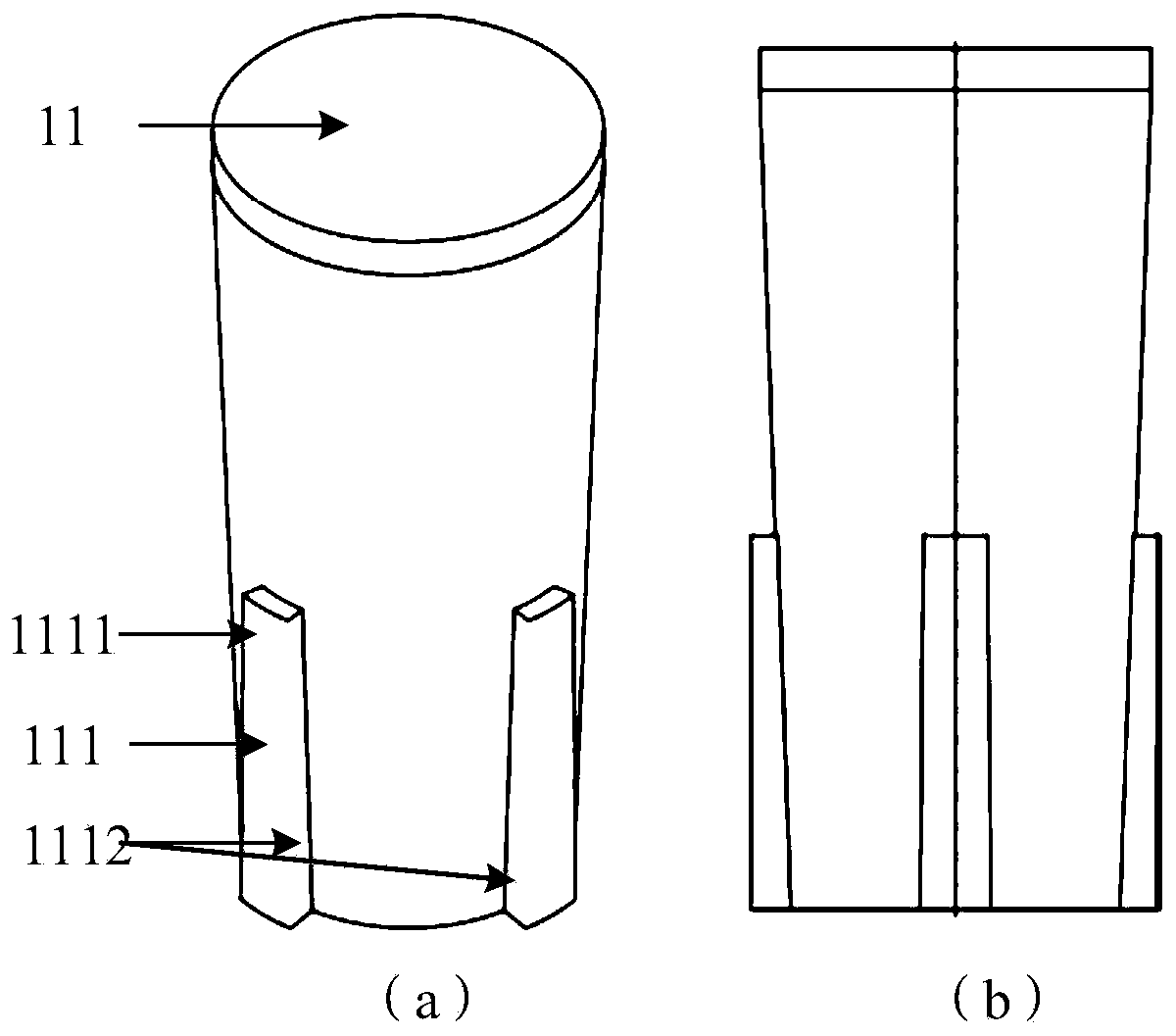

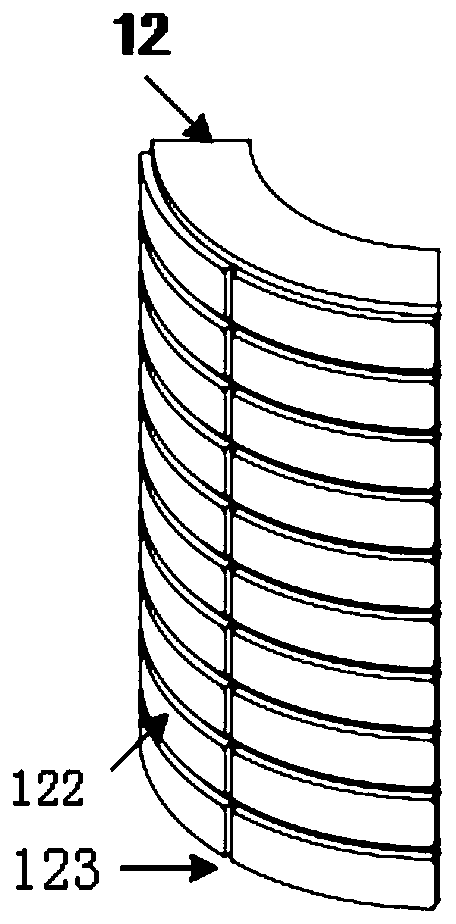

Demolding integrated mold for inner wall grid high rib barrel-shaped thin-wall part and forming method

InactiveCN109894562ARealize shape controlImprove fatigue resistanceForging/hammering/pressing machinesBarrel ShapedThick wall

The invention discloses a demolding integrated mold for an inner wall grid high rib barrel-shaped thin-wall part and a forming method. The mold comprises a convex mold and a concave mold, wherein theconvex mold comprises a convex mold mandrel and a plurality of convex mold inserts. The diameter of the periphery of the convex mold mandrel is gradually decreased from the top end to the bottom end.The convex mold inserts form a cylinder arranged on the periphery of the convex mold mandrel in a sleeving manner. A plurality of toroidal rib grooves and a plurality of vertical rib grooves are formed in the outer surface of each convex mold insert, and the toroidal rib grooves and the vertical rib grooves are arranged in a staggered manner to form a plurality of mesh blocks. The concave mold isarranged on the periphery of the convex mold in a sleeving manner. The forming method solves the problems of high cost, complex steps and the like of an existing forming method (for example, machininghigh ribs on a thick-wall barrel and fixing the high ribs to a panel by way of welding or riveting) of a metal barrel-shaped structural part, so that a large inner wall grid high rib barrel-shaped member is formed integrally.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

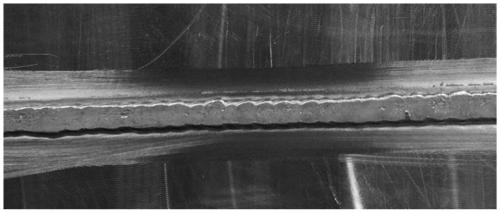

Welding method suitable for thick plate type aluminum alloy

ActiveCN111069745AIncrease dull edge thicknessImprove welding efficiencyArc welding apparatusWelding/soldering/cutting articlesThick plateWeld seam

The invention provides a welding method suitable for a thick plate type aluminum alloy. The welding method comprises the following steps that S1, welding grooves are formed in the adjacent to-be-welded end faces of two to-be-welded workpieces correspondingly, the two welding grooves form a U-shaped groove, and the U-shaped groove is arranged in an axial symmetric mode by taking a center line of agap between the two to-be-welded workpieces as an axis; and S2, backing welding of a first layer, cosmetic welding of a second layer and cosmetic welding of a third layer are sequentially performed inthe U-shaped groove from bottom to top. According to the welding method suitable for the thick plate type aluminum alloy, the technical problem that in a traditional thick plate welding process, theamount of deposit metal required for filling is relatively large, and a weld joint is non-uniformly contracted in thickness direction, so that generated welding deformation is relatively large is solved.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO

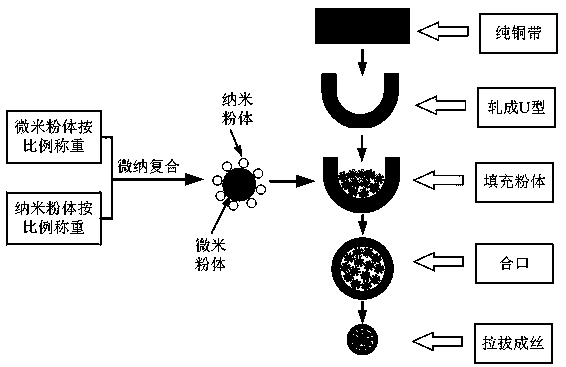

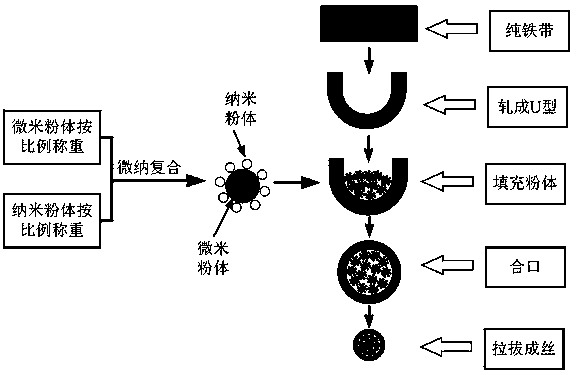

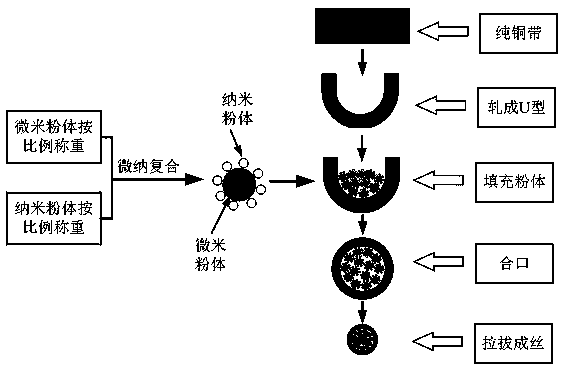

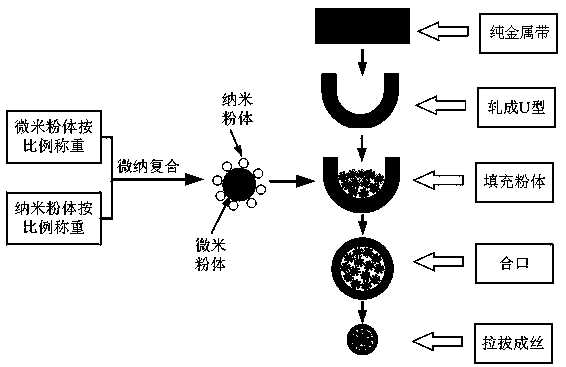

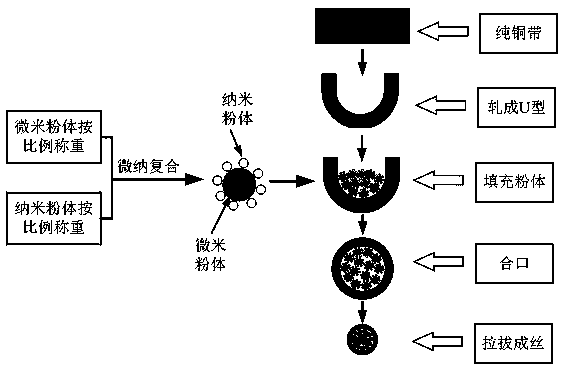

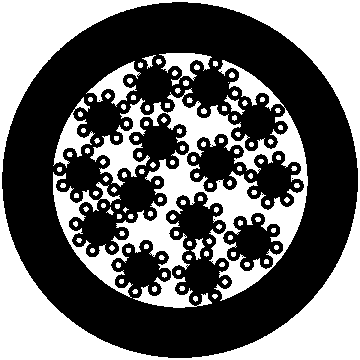

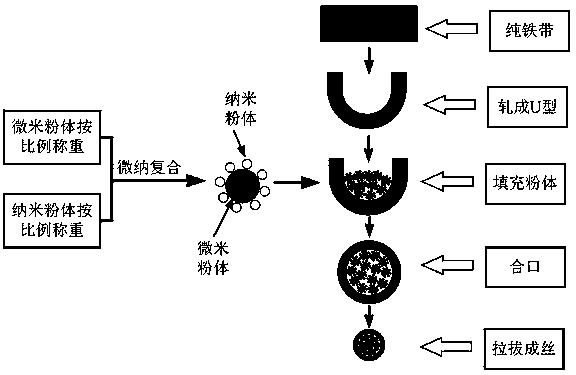

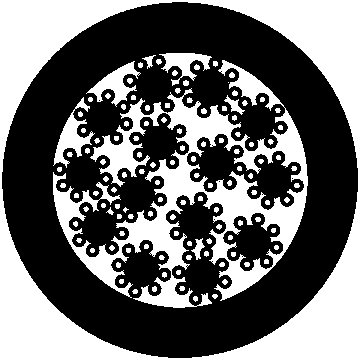

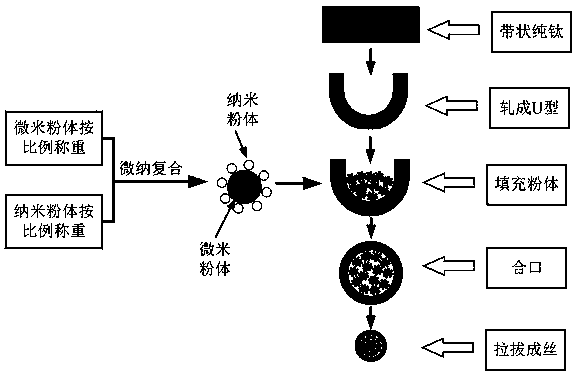

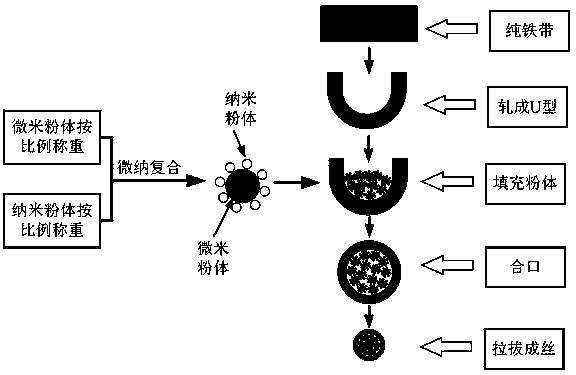

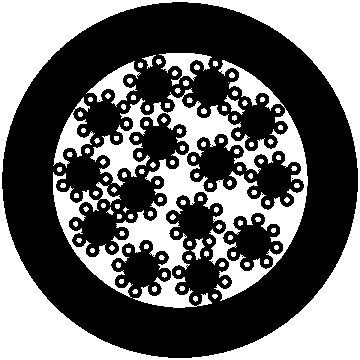

Functional low-loss shape memory alloy micro-nano powder core filament for laser additive manufacturing

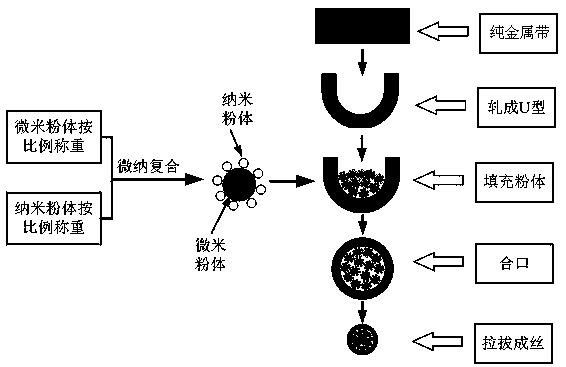

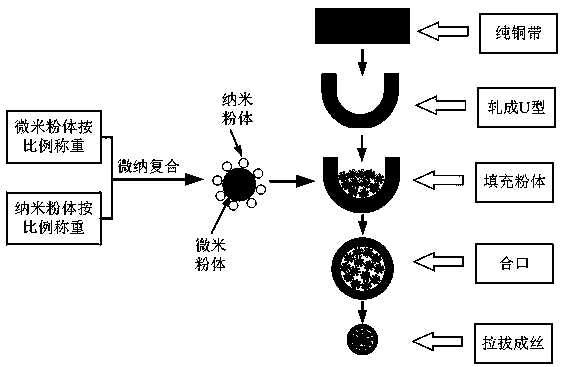

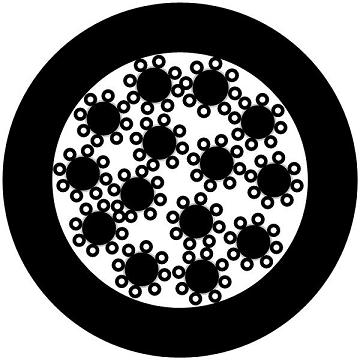

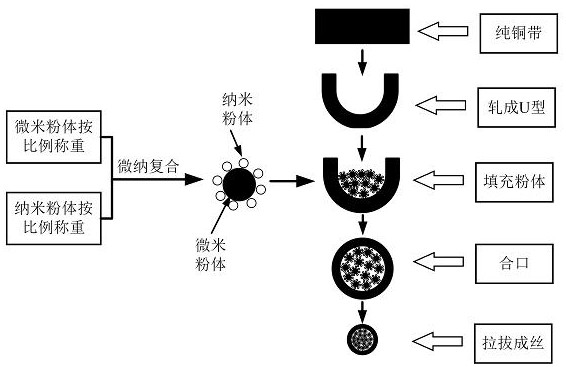

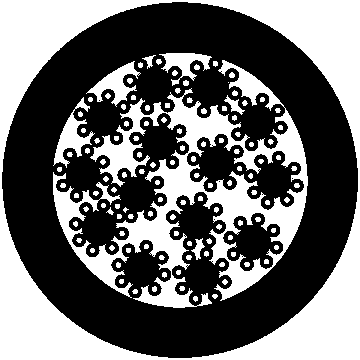

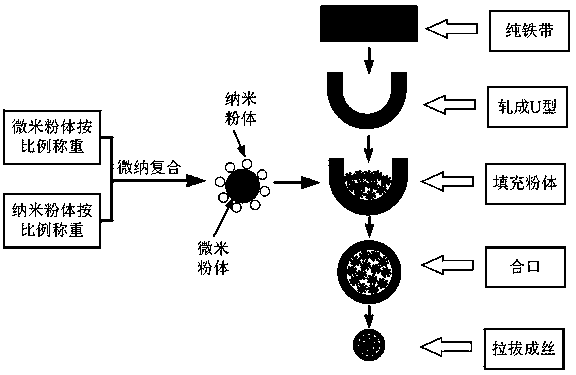

ActiveCN108746586AAvoid problems such as low utilizationSolve the problem that higher laser energy is more likely to cause functional lossAdditive manufacturing apparatusTransportation and packagingBoiling pointMicrometer

The invention discloses a functional low-loss shape memory alloy micro-nano powder core filament for laser additive manufacturing and a preparing method thereof. The functional low-loss shape memory alloy micro-nano powder core filament is characterized in that the outer skin of the powder core filament is the pure metal of one element, with the highest boiling point, in all elements constitutingthe shape memory alloy, the powder core of the powder core filament is a mixture consisting of the elementary substance metal micrometer powders of the other elements, except the element with the highest boiling point, constituting the shape memory alloy, or the micro-nano powder consisting of the alloy micrometer powder of other elements and the nano powder with the reinforcing function, wherein,the nano powder in the micro-nano powder accounts for 0.5-4% of the mass of the whole powder core filament; and the preparing method mainly includes the preparation of micro-nano powder, skin formingand powder filling, opening closing and drawing filament forming. The shape memory alloy micro-nano powder core filament is used as the material for the laser additive manufacturing, and the characteristics of being low in loss of shape memory function, high in forming precision and the like are achieved.

Owner:JIANGSU UNIV

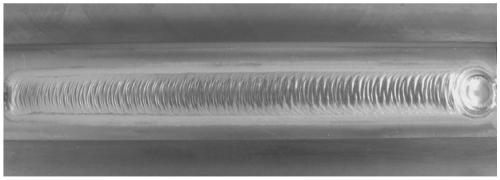

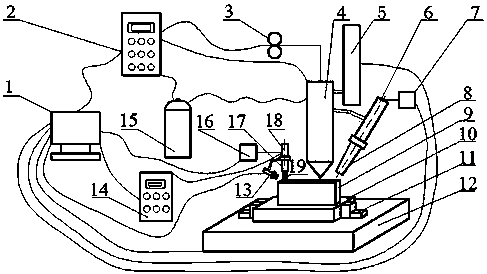

A method for shape control of ultrasonic vibration assisted arc additive manufacturing

InactiveCN106735967BImprove mechanical propertiesExtended service periodArc welding apparatusIncreasing energy efficiencyMelting tankManufacturing technology

The invention discloses a method of shape and property control of electric arc additive manufacturing through assistance of ultrasonic vibration. In the process of electric arc additive manufacturing, non-contact ultrasonic vibration is applied to molten baths synchronously, grains in the molten baths are crushed, growth of the grains is restrained, and refinement of the grains is achieved. Meanwhile, by effectively utilizing residual heat of a formed part, the effect that a material in the position where a tool bit makes contact with the surface of a cladding layer is in a softened state is guaranteed, by applying ultrasonic vibration to the tool bit, the tool bit impacts the surface of the cladding layer at a high frequency, and finishing processing and surface reinforcing treatment are conducted on the surface, so that the dimension precision of the cladding layer is improved, the residual stress of the cladding layer is reduced, the surface grains are refined, and accordingly the purpose of shape and property control of electric arc additive manufacturing is achieved. According to the method, the roughening effect of the residual heat accumulation amount to the part grains and severe influences of warping deformation are reduced and even avoided, the service cycle of the tool bit is prolonged, and subsequent machining treatment of parts is reduced. The effective method is provided for shape and property control of the electric arc additive manufacturing technology.

Owner:XIANGTAN UNIV

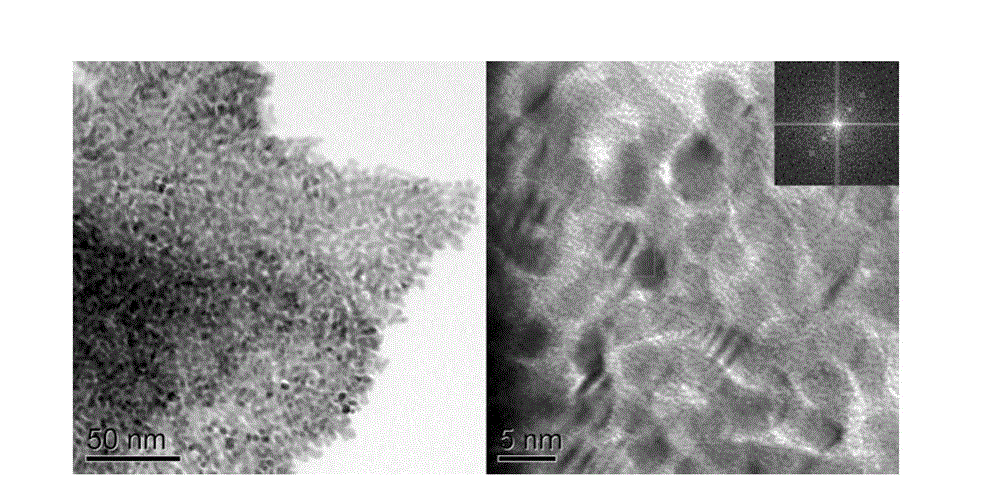

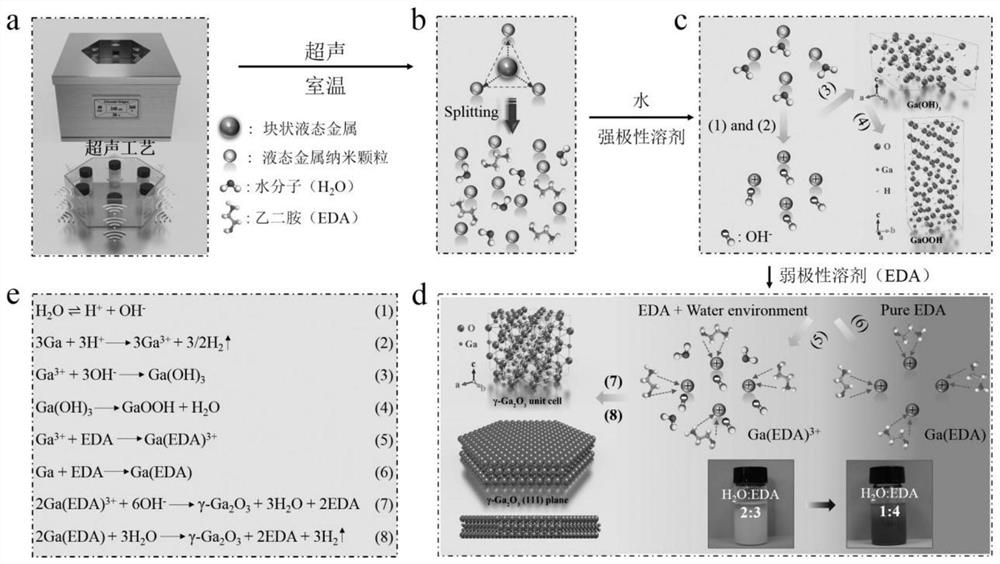

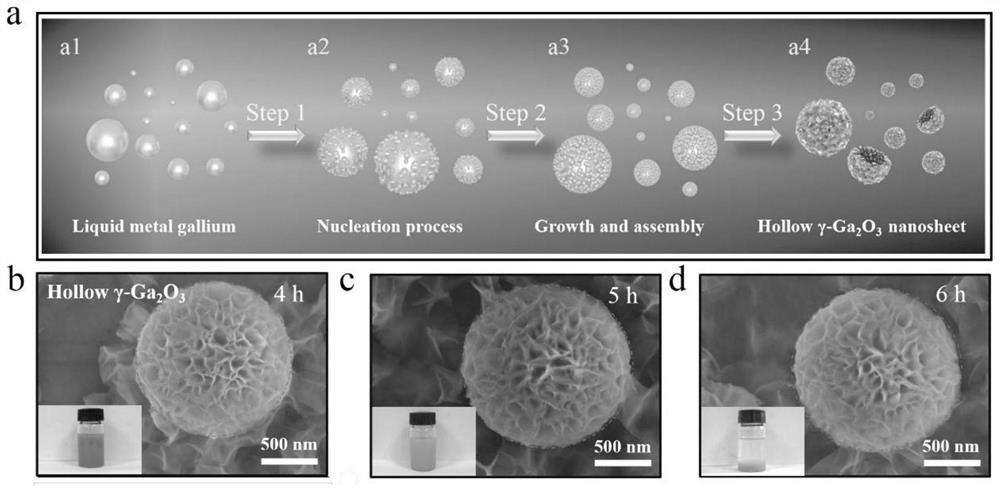

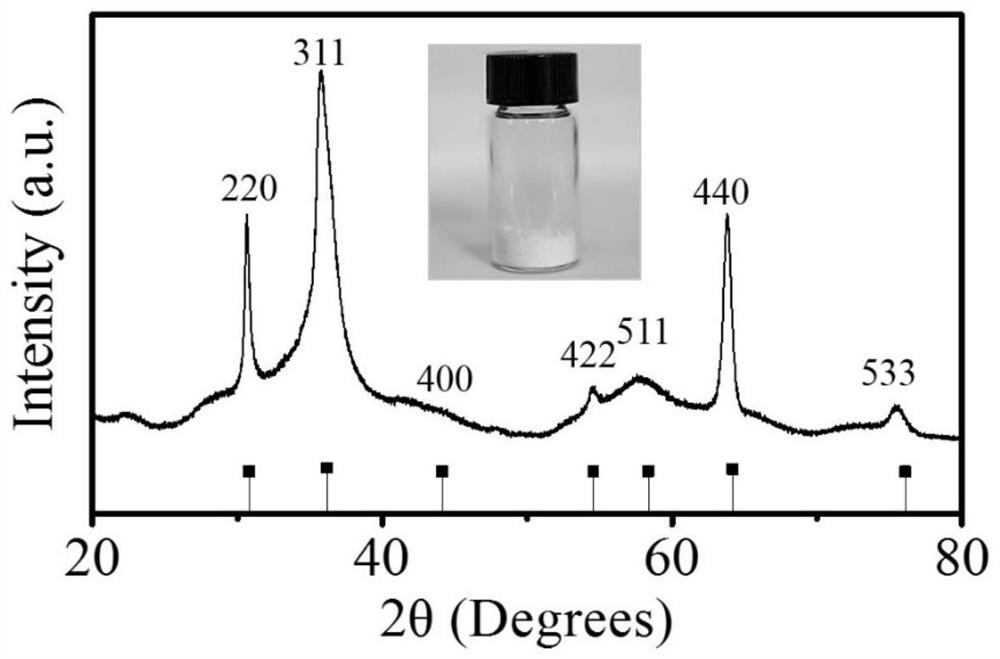

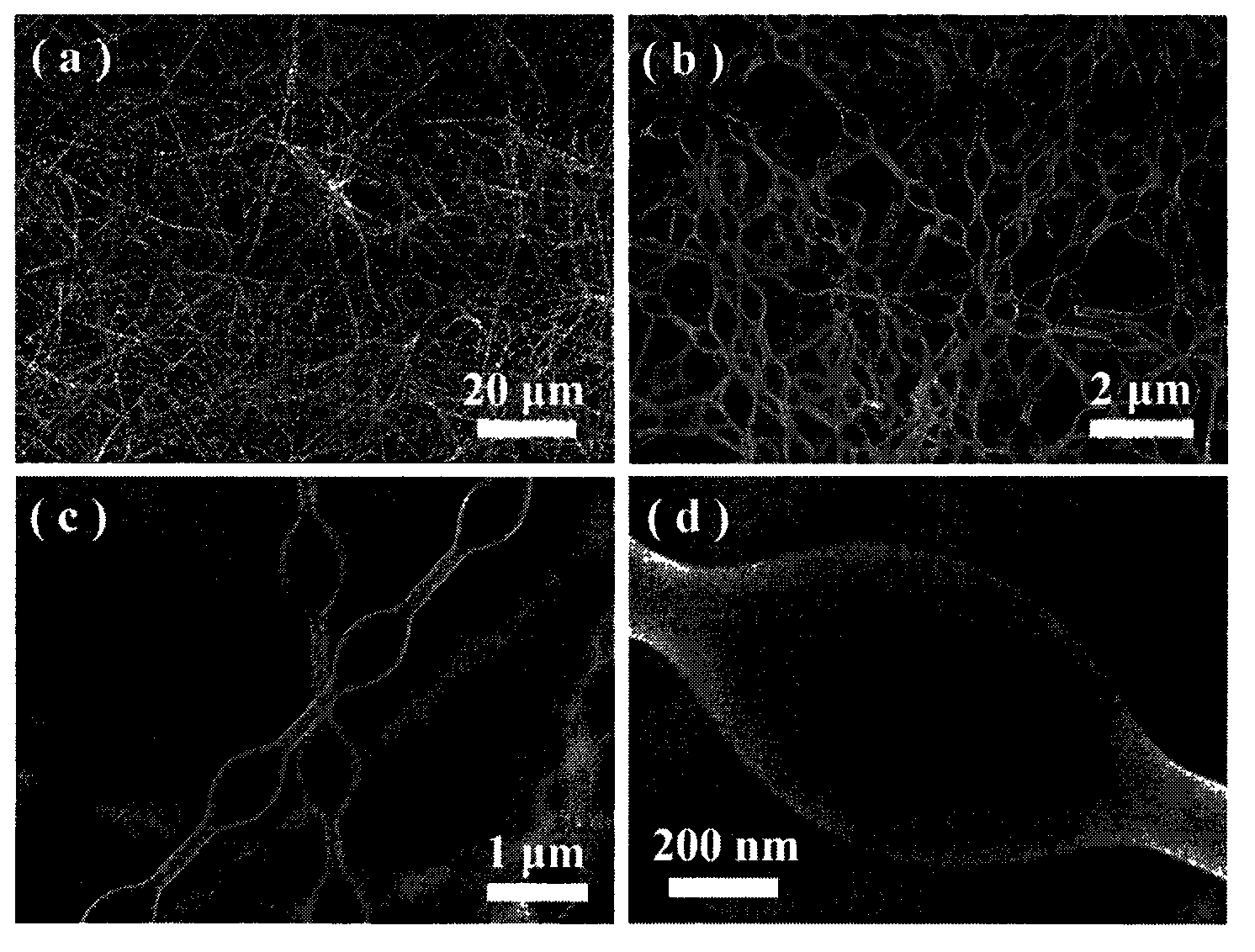

Preparation method of nano metal oxide

PendingCN114057219AFast preparationHigh purityMaterial nanotechnologyOxide/hydroxide preparationOrganic solventPhysical chemistry

The invention provides a preparation method of a novel nano metal oxide. The preparation method comprises the step of treating a mixture comprising a metal simple substance, water and an organic solvent by using ultrasonic waves. The preparation process and equipment requirements are simple, the material cost is low, experimental parameters are few, experimental conditions are mild, a heat source and / or pressure do not need to be additionally applied, the nano-scale metal oxide of the kilogram level or above can be rapidly prepared at the environment temperature and the environment pressure, and the preparation method is suitable for industrial large-scale production.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

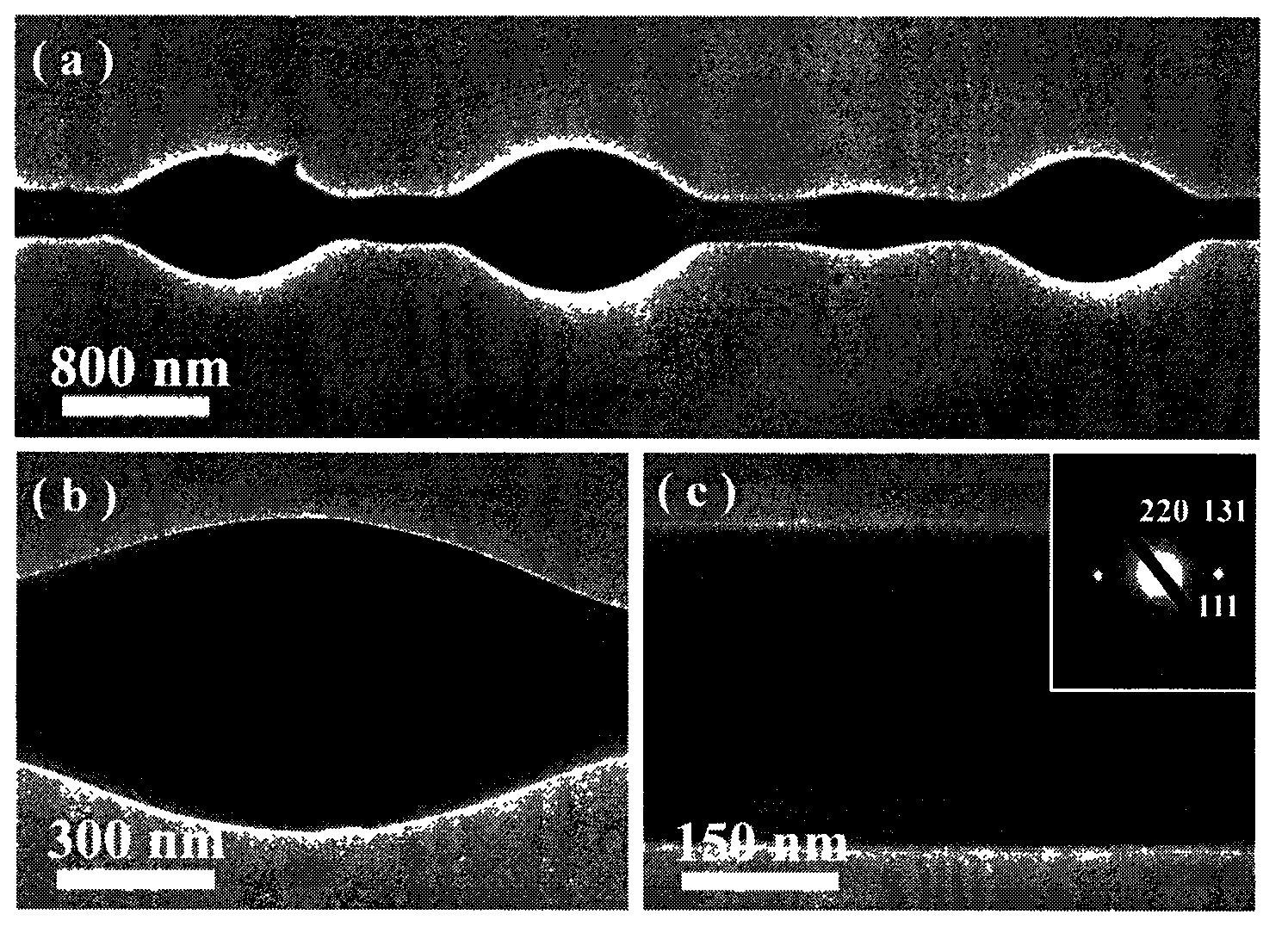

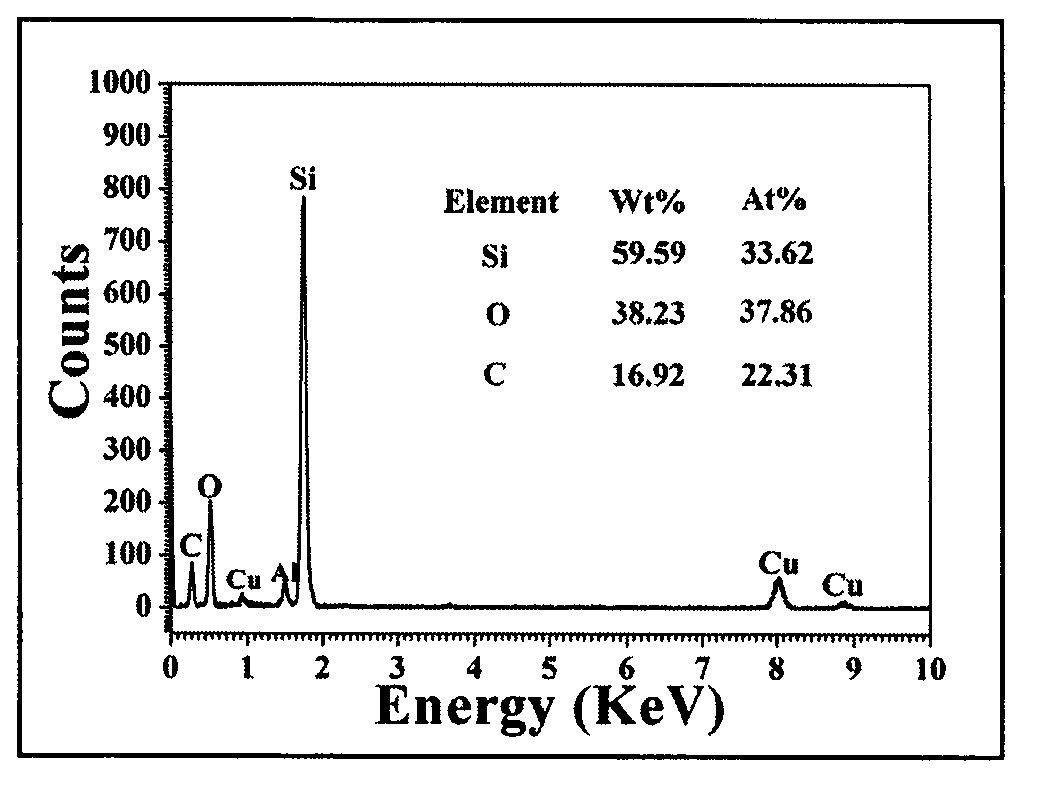

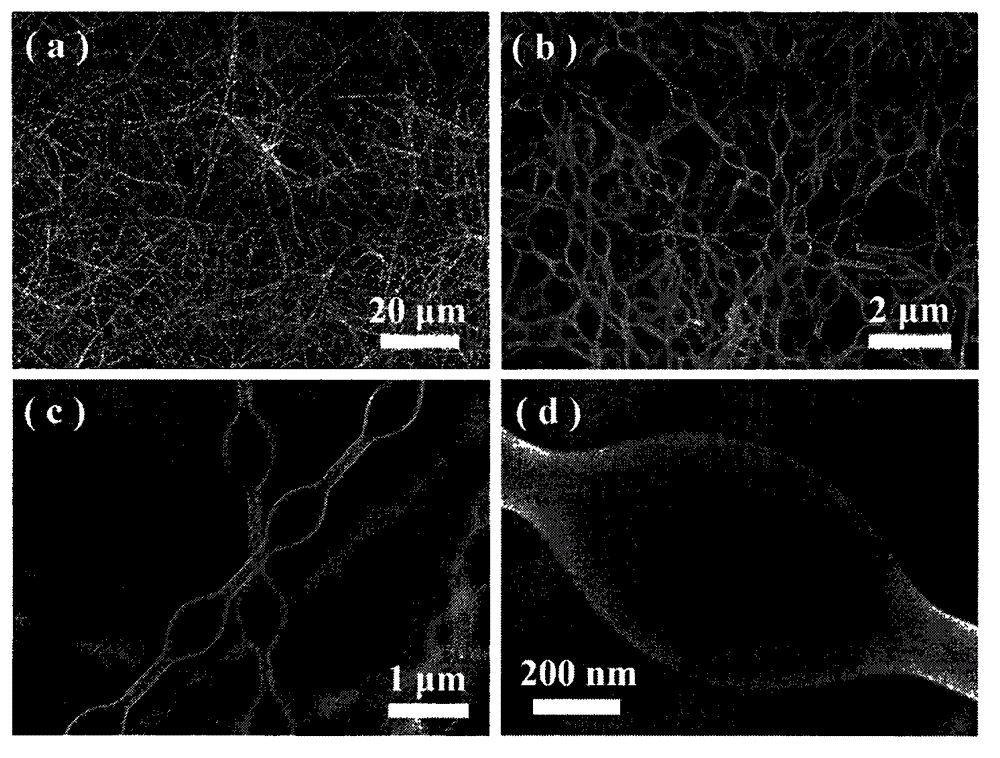

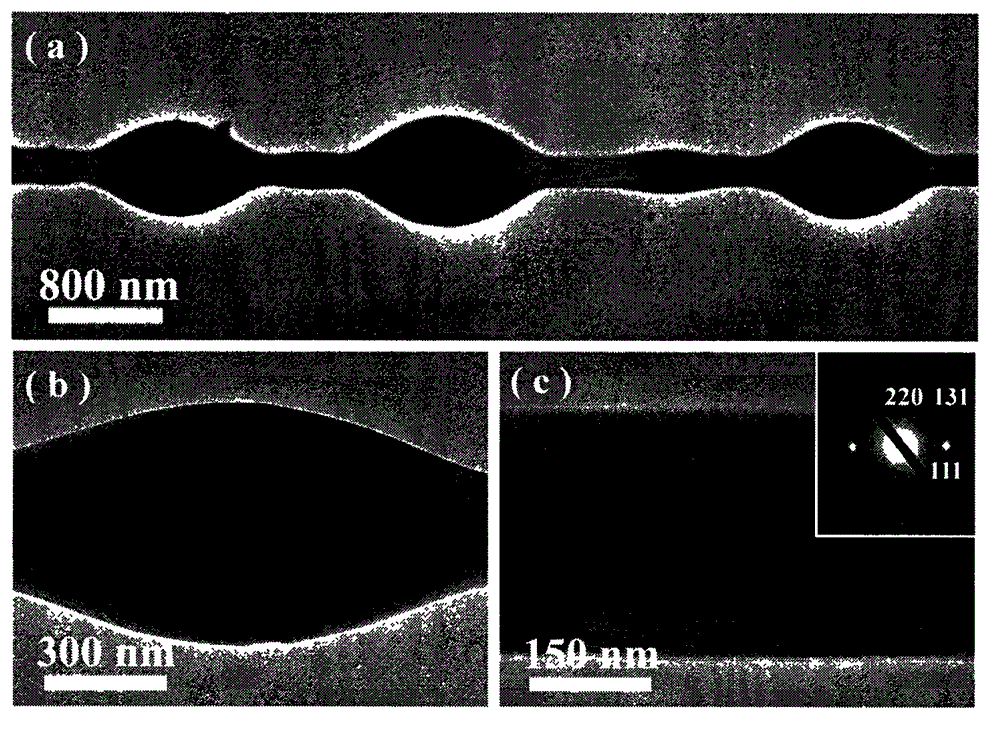

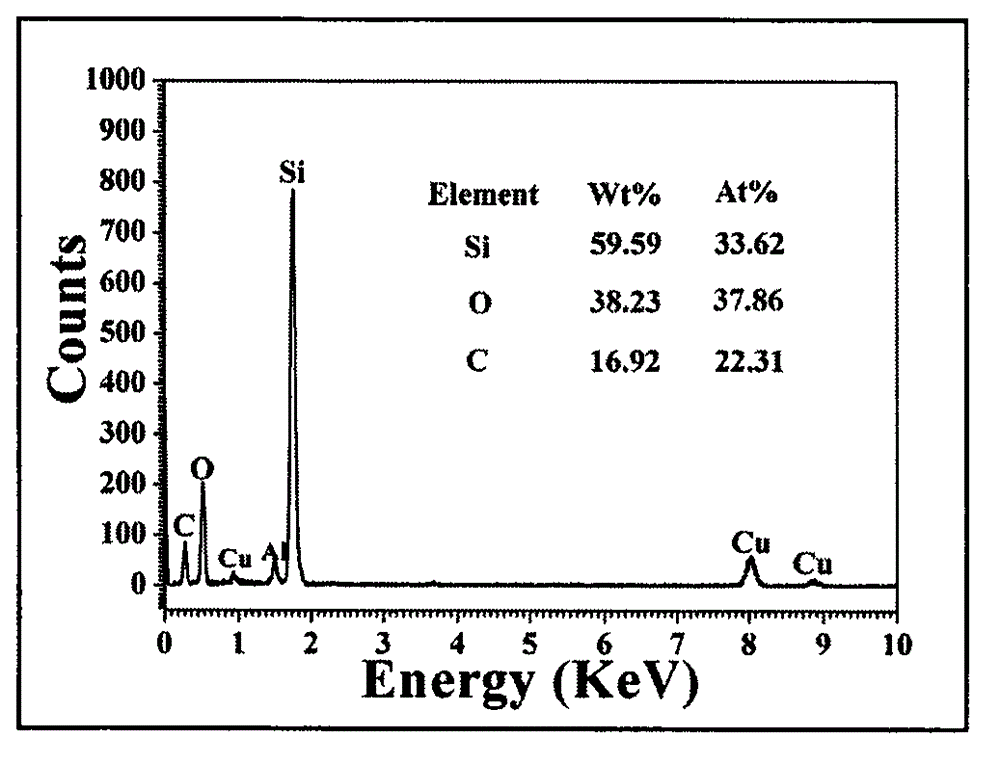

High purity silicon oxide/silicon carbide nanometer chain-like heterostructure preparation method

InactiveCN103255468AHigh purityAchieve sizePolycrystalline material growthFrom solid stateAir atmosphereThermal insulation

The invention relates to a high purity SiC / SiOx nanometer chain-like heterostructure preparation method, which comprises the following specific steps: (1) organic precursor preparing: dissolving polysilazane (PSN) and polyethylene (PVP) in dehydrated alcohol according to a certain ratio, and carrying out stirring mixing at a room temperature to form a micro-emulsion; (2) organic precursor curing: carrying out thermal insulation on the micro-emulsion for 30 min at a temperature of 200 DEG C in an air atmosphere to obtain a solid state organic precursor; and (3) high temperature pyrolysis: placing the solid state organic precursor in a common tube type atmosphere sintering furnace to carry out high temperature pyrolysis for a certain time at a certain pyrolysis temperature under a protection atmosphere to obtain a SiC / SiOx nanometer chain-like heterostructure. With the present invention, preparation of the high purity SiC / SiOx nanometer chain-like heterostructure having a perfect structure, regulation and control of morphology and size distribution can be achieved, and potential application prospects are provided in the field of optoelectronic nanometer devices and the like.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

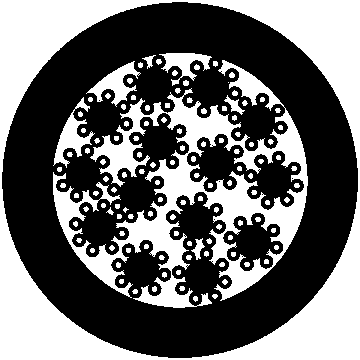

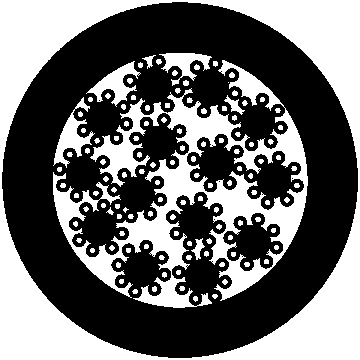

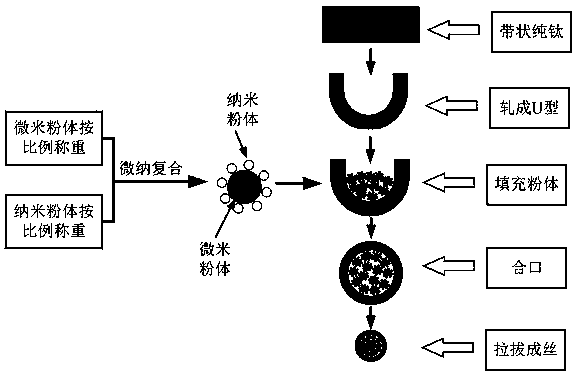

Functional low loss type CuZnAl micro-nano powder cored wire for laser additive manufacturing and preparation method thereof

ActiveCN108746583AAvoid problems such as low utilizationSolve the problem that higher laser energy is more likely to cause functional lossAdditive manufacturing apparatusIncreasing energy efficiencyMicro nanoCopper

The invention discloses a functional low loss type CuZnAl micro-nano powder cored wire for laser additive manufacturing and a preparation method thereof. The functional low loss type CuZnAl micro-nanopowder cored wire is characterized by being composed of, by mass, 24.5%-26% of micron zinc powder, 3.5%-4% of nano aluminum powder and 70%-72% of a copper sheet, and the sum of the components is 100%. The preparation method mainly includes the steps of micro-nano powder preparation, skin forming and powder filling, closing and drawing into the wire. The CuZnAl micro-nano powder cored wire is usedas a laser additive manufacturing material, has the characteristics of small loss of shape memory function, high forming precision and the like, the problem of the low utilization rate of powder whenpowder is used as additive manufacturing materials is avoided, and the problem that high laser energy is more likely to cause functional loss when solid wire materials are used as the additive manufacturing materials is also solved.

Owner:JIANGSU UNIV

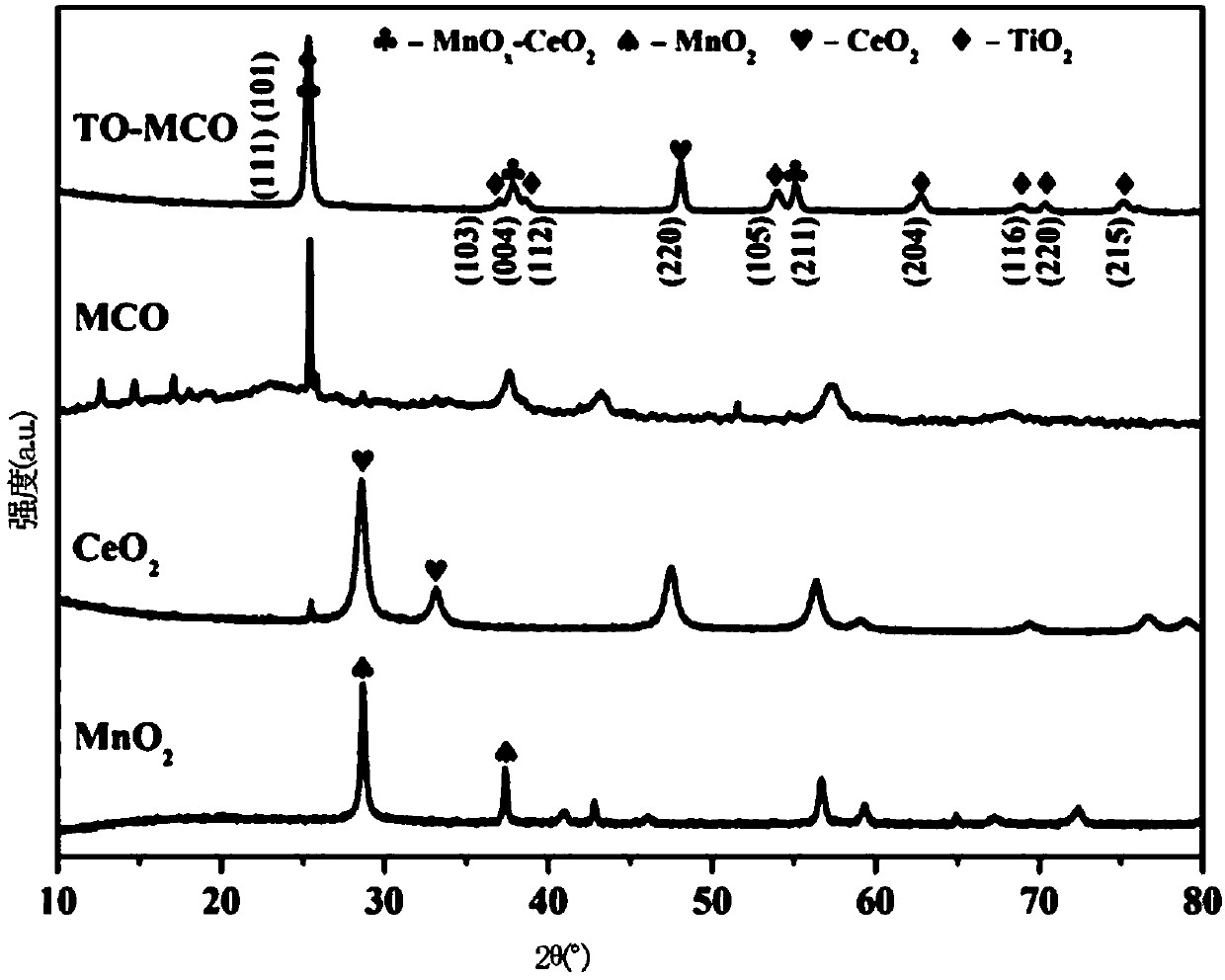

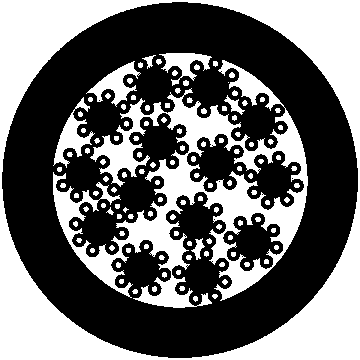

Catalyst to catalytically degrade formaldehyde at normal temperature and preparation method and application thereof

InactiveCN110314680AEfficient degradationImprove adsorption capacityHeterogenous catalyst chemical elementsDispersed particle separationNanocrystalChemistry

The invention relates to the technical field of catalyst materials to purify formaldehyde and particularly discloses a catalyst to catalytically degrade formaldehyde at a normal temperature and a preparation method thereof. The catalyst herein is a composite which employs MnOx-CeO2 as a carrier; TiO2 is carried on the surface of the carrier; the composite is spherical nano crystal. The catalyst ofthe invention is capable of efficiently and quickly degrading formaldehyde stably attracted to the surface of the catalyst, and can degrade formaldehyde having the low concentration of 500 ppb and below at a degrading rate of 60% and above within 3 hours.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST +1

Silicon boride-enhanced laser additive manufacturing femnsi micro-nano powder core wire material and preparation method thereof

ActiveCN108746584BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyPhysical chemistryManganese

Owner:湖南麓邵技术服务有限公司

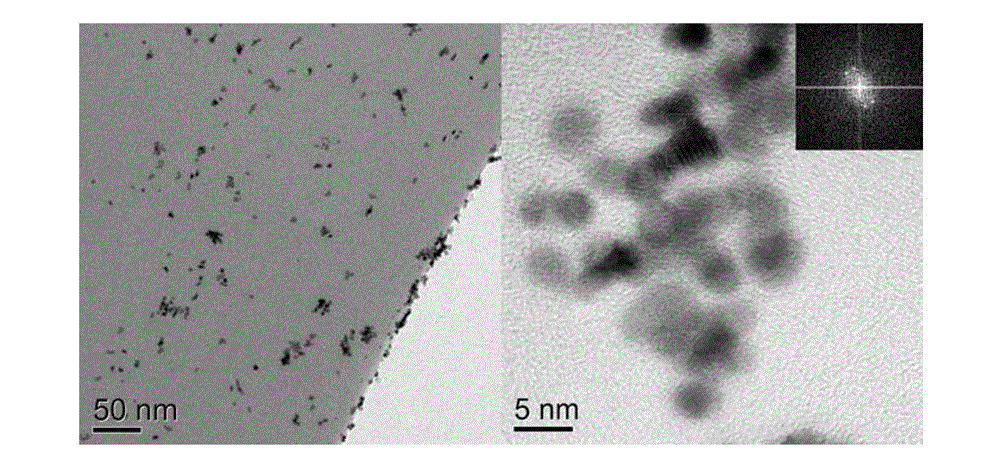

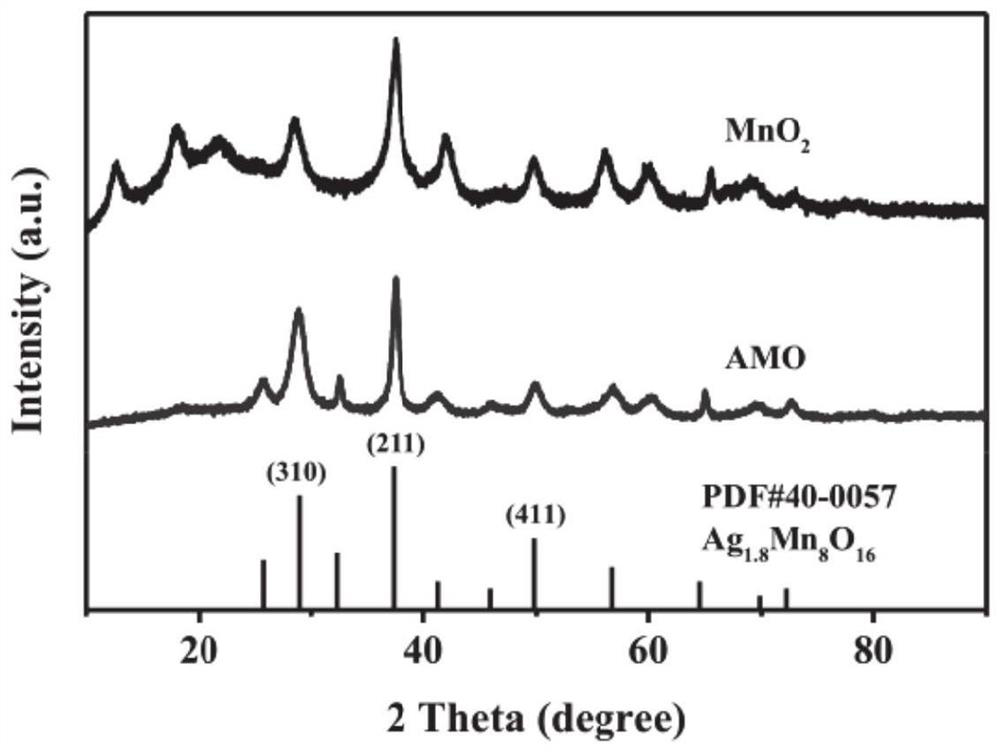

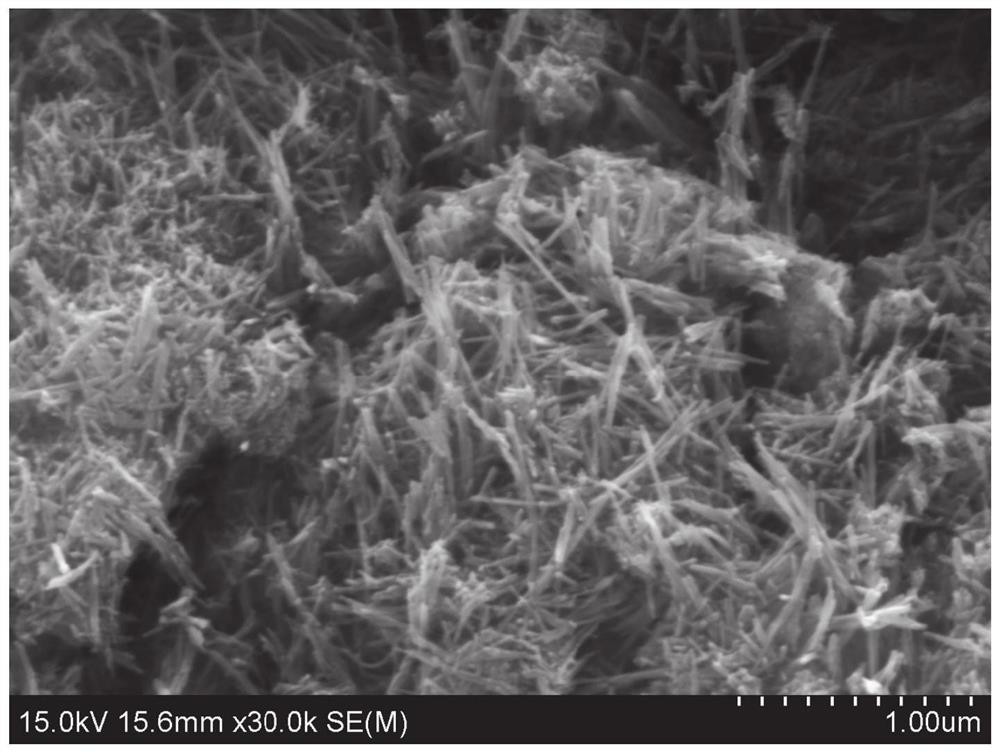

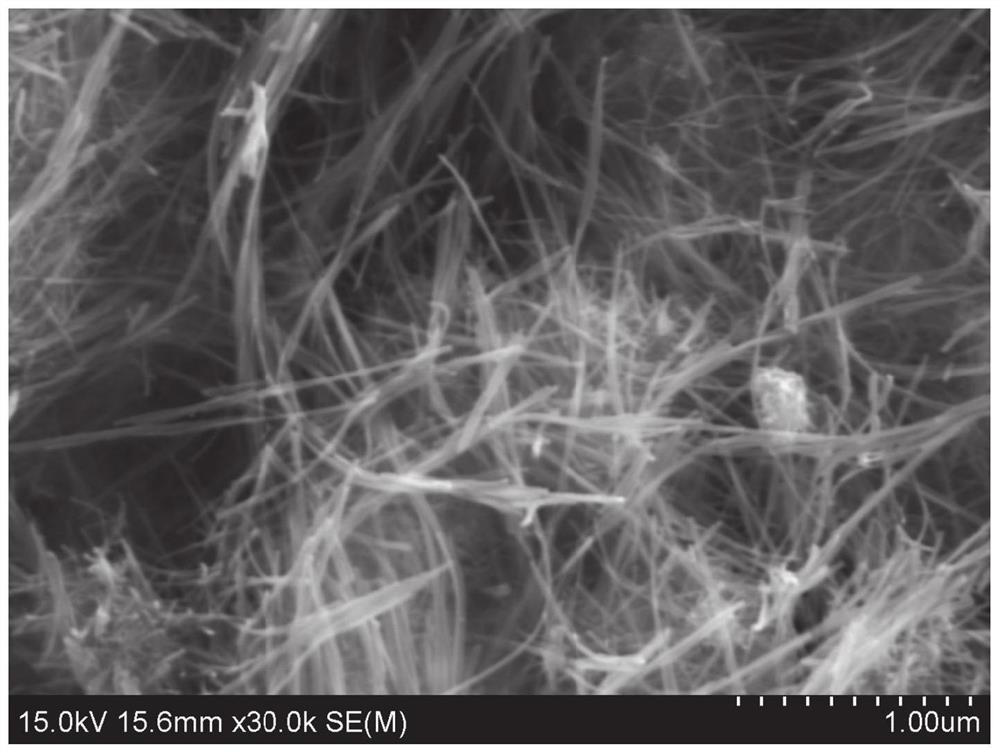

Silver ion pre-embedded manganese-oxygen-based nanowire as well as preparation method and application thereof

PendingCN111943271AImprove electrochemical performanceRealize shape controlMaterial nanotechnologyCell electrodesManganese sulphateNanowire

The invention belongs to the field of nano material preparation, and relates to a silver ion pre-embedded manganese-oxygen-based nanowire as well as a preparation method and application thereof. The preparation method comprises the following steps that firstly, a proper manganese dioxide material is prepared as a precursor, manganese sulfate and potassium permanganate are selected as raw materials, and a manganese dioxide nanorod-like material is prepared as a precursor of subsequent hydrothermal reaction by adopting a precipitation method; a hydrothermal synthesis method is adopted to synthesize and prepare the silver ion pre-embedded manganese-oxygen-based material, the hydrothermal synthesis method has the advantages of simplicity in operation, controllable reaction conditions, uniformparticle size of the obtained nano material and the like, morphology regulation and control are performed by reasonably controlling reaction time and reaction temperature, and finally, expected morphology is obtained.

Owner:SHANDONG UNIV

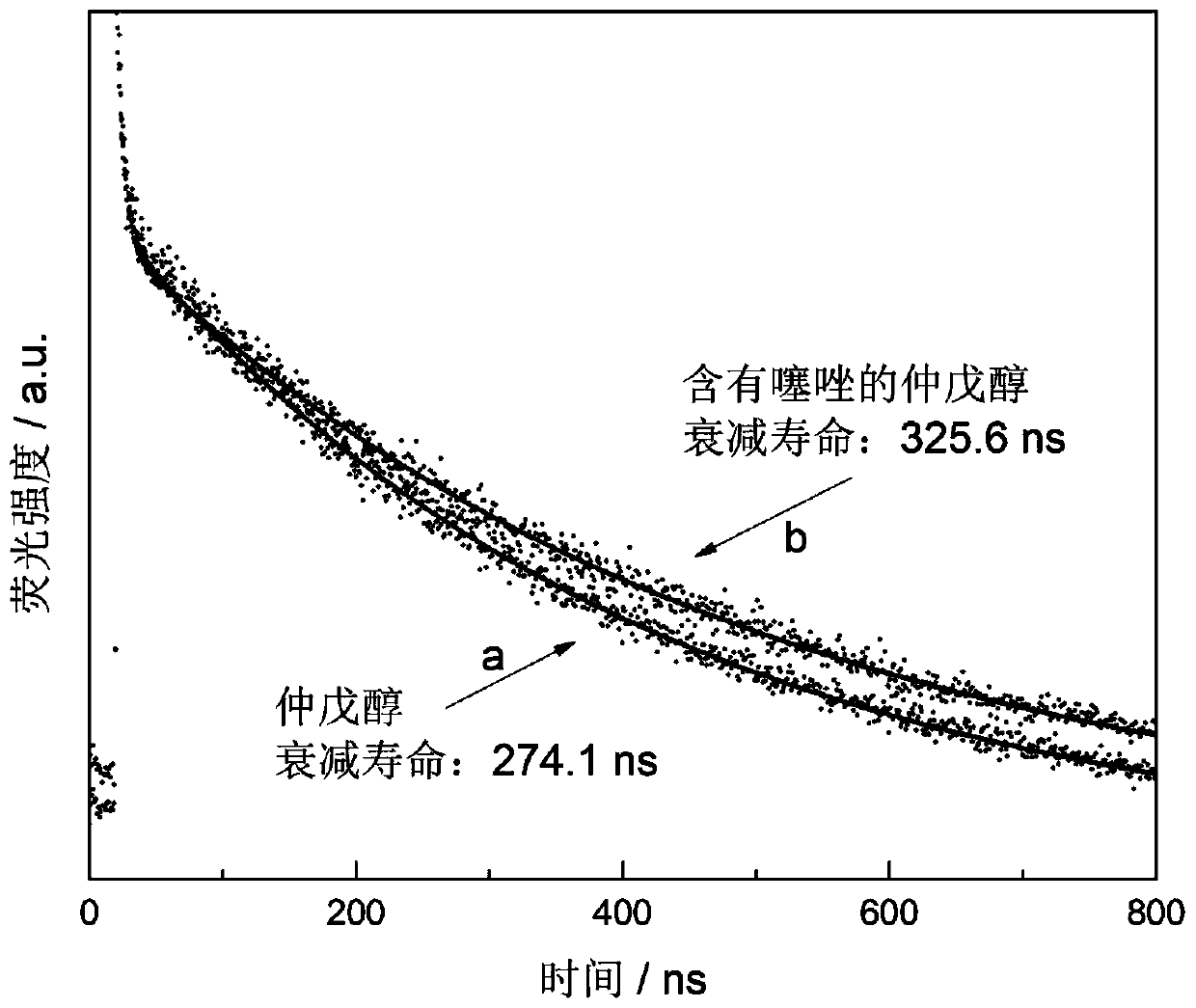

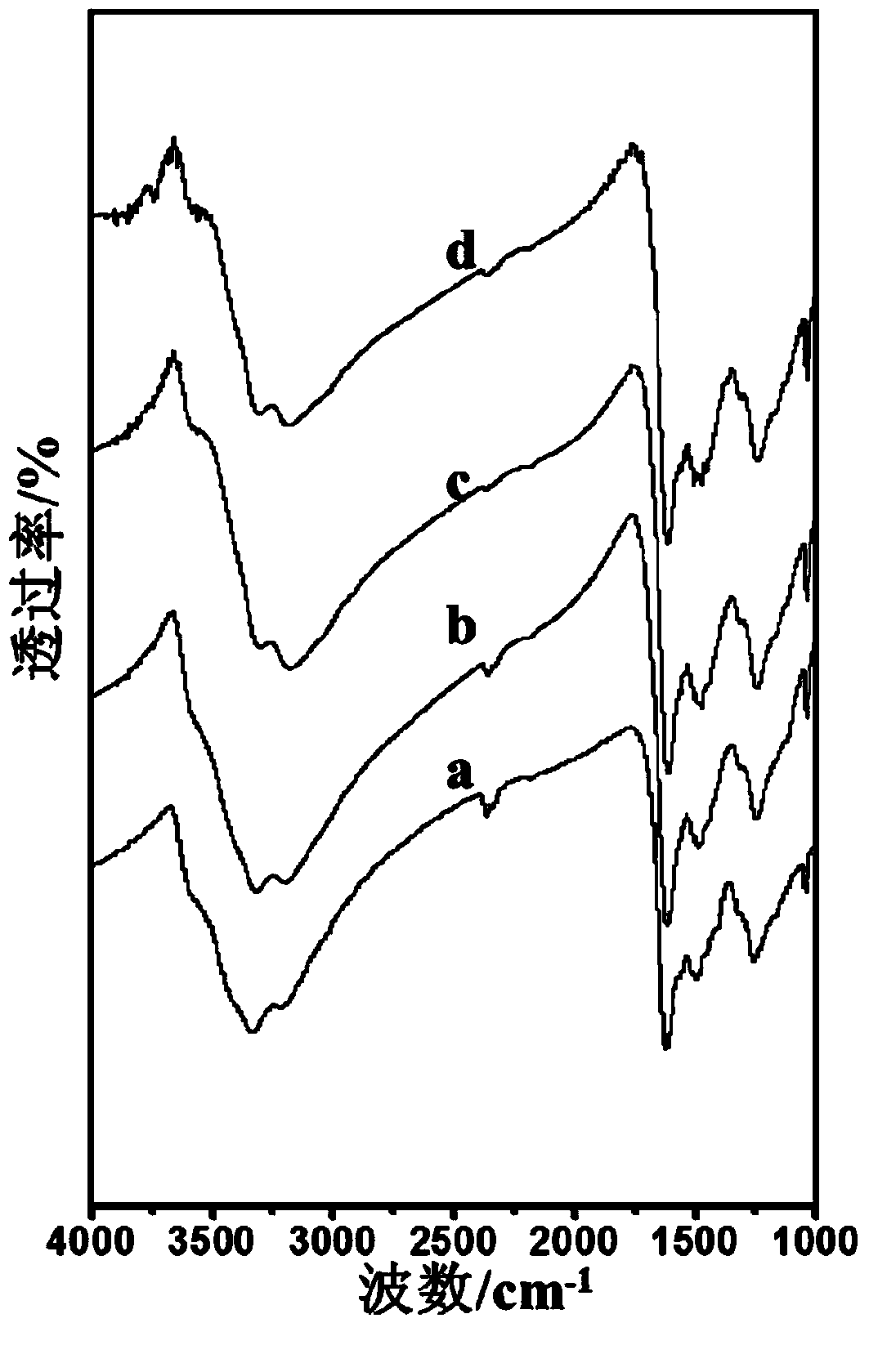

Poly(m-phenylenediamine) and synthesizing and applying method thereof

ActiveCN103724619AHigh synthetic yieldRealize shape controlOther chemical processesWater/sewage treatment by sorptionAlcoholVolumetric Mass Density

The invention discloses poly(m-phenylenediamine) and a synthesizing and applying method thereof. The poly(m-phenylenediamine) is prepared by using m-phenylenediamine as a raw material, adding an oxidant into an alcohol solvent and a certain amount of diethanolamine solution, so that the morphological structure of poly(m-phenylenediamine) can be regulated, and the yield can be 87.5 percent; the maximum adsorption amount of the poly(m-phenylenediamine) product to silver ions in a water body can be over 2,318.5mg.g<-1>, the poly(m-phenylenediamine) product has excellent selective adsorbability; regarding as a low-density silver ion-containing water body, the density of the treated silver ions is far lower than 0.005ppm which is the safety value of silver to a human body in the specification of WHO (World Health Organization).

Owner:CENT SOUTH UNIV

A kind of porous spherical rhenium-tungsten alloy powder and its preparation method

The invention relates to a porous spherical tungsten rhenium alloy powder and a preparation method thereof, and belongs to the technical field of alloy powder. The mixture of tungsten and rhenium is in the atomic level, the content of the tungsten in proportion by weight ranges from 25% to 90%, and the content of the rhenium in proportion by weight ranges from 10% to 75%. The method includes adopting ammonium perrhenate and ammonium metatungstate as raw materials, configuring into solution, and preparing precursor powder by the spray drying method; depositing and reducing in the atmosphere of hydrogen gas in two steps, namely in the first step,allowing the temperature to be 450 to 550 DEG C and insulating heat for 1 to 2 hours, in the second step, allowing the reducing temperature to be 850 to 950 DEG C, and insulating heat for 2 to 3 hours; and obtaining the porous spherical tungsten rhenium alloy powder. According to the method, process is simple, repeatability and operability are high, the introduction of impurity elements in the preparation process is avoided, the purity of prepared samples is high, and appearance control of a porous spherical tungsten rhenium alloy ball can be implemented by controlling the content of the tungsten, the reducing temperature and heat insulating time.

Owner:韶关元泰资源科技有限公司

Rare earth-enhanced cuznal micro-nano powder core wire material for laser additive manufacturing and preparation method thereof

ActiveCN108746581BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyMicro nanoRare earth

A rare-earth enhanced CuZnAl micro-nano powder core wire material for laser additive manufacturing and its preparation method, characterized in that the powder core wire material accounts for 28% to 30% of the entire powder core wire material by mass and is composed of zinc and aluminum Rare earth reinforced micro-nano powder core composed of rare earth micron powder and rare earth nano powder whose mass accounts for 2%~4% of the entire powder core wire material and copper skin whose mass accounts for 66%~70% of the entire powder core wire material. The sum is 100%, and its preparation method mainly includes micro-nano powder preparation, skin forming and powder filling, mouth closing and drawing into filaments. Using the CuZnAl micro-nano powder core wire material described in the present invention as a material for laser additive manufacturing has the characteristics of small loss of shape memory function and high forming accuracy, and avoids the low powder utilization rate that exists in the current powder as additive manufacturing materials. At the same time, it also solves the problem of using solid wire as an additive manufacturing material, which requires higher laser energy and is more likely to cause functional loss.

Owner:JIANGSU UNIV

Additive manufacturing method of metal glass lattice structure composite material part

ActiveCN114653967AImprove plasticityImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMicro structure

The invention relates to an additive manufacturing method of a metal glass lattice structure composite material part, and belongs to the technical field of additive manufacturing. A selective laser melting technology is adopted, laser process parameters are regulated and controlled, metal of different microscopic structures is formed at different positions, a lattice structure framework for regulating and controlling mechanical properties is embedded in a metal glass part, and forming of the metal glass and lattice framework integrated composite material part based on the same material is achieved. The lattice structure is applied to metal glass forming, microstructure units of a lattice structure model are established based on the topology theory, performance prediction is conducted on the lattice structure model through a homogenization method, and lattice structure parameters are optimized; by means of the method, large metal glass parts in any shape and with lattice structures can be directly formed in a near-net mode, the plasticity of the metal glass parts can be remarkably improved, the comprehensive mechanical property of the formed parts is improved, and the stability of the metal glass parts is enhanced.

Owner:JILIN UNIV

Functional low-loss shape memory alloy micro-nano powder core wire for laser additive manufacturing

ActiveCN108746586BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusTransportation and packagingMicro nanoBoiling point

A functional low-loss shape memory alloy micro-nano powder core wire material for laser additive manufacturing and its preparation method, characterized in that the skin of the powder core wire material is a pure metal with the highest boiling point among the elements constituting the shape memory alloy, The powder core of the powder core wire is a mixture of elemental metal micropowders of other elements except the element with the highest boiling point that constitute the shape memory alloy, or a micronano powder composed of alloy micropowders of other elements and nanopowders that play a reinforcing role. , wherein the nano-powder in the micro-nano powder accounts for 0.5%-4% of the mass of the whole powder core wire material, and its preparation method mainly includes micro-nano powder preparation, skin forming and powder filling, jointing and drawing into wire. The use of the shape memory alloy powder core wire material of the present invention as a material for laser additive manufacturing has the characteristics of small loss of shape memory function and high forming precision.

Owner:JIANGSU UNIV

Rare earth enhanced FeMnSi micro-nano powder cored wire for laser additive manufacturing and preparation method thereof

ActiveCN108705076AAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyMicro nanoManganese

The invention provides a rare earth enhanced FeMnSi micro-nano powder cored wire for laser additive manufacturing and a preparation method thereof. The rare earth enhanced FeMnSi micro-nano powder cored wire is characterized by consisting of micro powder of which the mass accounts for 28-36% of the whole powder cored wire and which comprises manganese and silicon, a rare earth enhanced micro-nanopowder core consisting of rare earth nano-powder of which the mass accounts for 2-4% of the whole powder cored wire, and iron sheets of which the mass accounts for 60-70% of the whole powder cored wire, and the total percent of all the components is 100%. The preparation method mainly comprises micro-nano powder preparation, scarfskin shaping, powder filling, closing and wire pulling. When used for laser additive manufacturing, the rare earth enhanced FeMnSi micro-nano powder cored wire has the characteristics of small loss of a shape memory function, high shaping precision and the like; the current problem of low powder utilization ratio caused when powder is taken as a material for additive manufacturing is solved; and meanwhile, the problems of functional loss and the like caused by thereason that high laser energy is required when a solid wire serves as the material for additive manufacturing are solved.

Owner:JIANGSU UNIV

Niti micro-nano powder core wire for rare earth-enhanced laser additive manufacturing and preparation method thereof

ActiveCN108746582BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyMicro nanoFilamentation

A rare earth-enhanced NiTi micro-nano powder core wire material for laser additive manufacturing and a preparation method thereof, characterized in that the powder core wire material is composed of micron nickel powder and a mass accounting for 54% to 56% of the entire powder core wire material. The rare earth reinforced micro-nano powder core composed of 0.5%~1.5% rare earth nanopowder of the whole powder core wire material and the titanium skin whose mass accounts for 42.5%~45.5% of the whole powder core wire material are composed, and the sum of each component is 100%. The preparation method mainly includes micro-nano powder preparation, skin forming and powder filling, mouth closing and drawing into filaments. Using the NiTi micro-nano powder core wire material according to the present invention as a material for laser additive manufacturing has the characteristics of small loss of shape memory function and high forming accuracy, and avoids the low powder utilization rate of current powder as additive manufacturing materials. At the same time, it also solves the problem of using solid wire as an additive manufacturing material, which requires higher laser energy and is more likely to cause functional loss.

Owner:JIANGSU UNIV

A preparation method of high-purity silicon oxide/silicon carbide nano chain heterostructure

InactiveCN103255468BHigh purityAchieve sizePolycrystalline material growthFrom solid stateAir atmosphereThermal insulation

The invention relates to a high purity SiC / SiOx nanometer chain-like heterostructure preparation method, which comprises the following specific steps: (1) organic precursor preparing: dissolving polysilazane (PSN) and polyethylene (PVP) in dehydrated alcohol according to a certain ratio, and carrying out stirring mixing at a room temperature to form a micro-emulsion; (2) organic precursor curing: carrying out thermal insulation on the micro-emulsion for 30 min at a temperature of 200 DEG C in an air atmosphere to obtain a solid state organic precursor; and (3) high temperature pyrolysis: placing the solid state organic precursor in a common tube type atmosphere sintering furnace to carry out high temperature pyrolysis for a certain time at a certain pyrolysis temperature under a protection atmosphere to obtain a SiC / SiOx nanometer chain-like heterostructure. With the present invention, preparation of the high purity SiC / SiOx nanometer chain-like heterostructure having a perfect structure, regulation and control of morphology and size distribution can be achieved, and potential application prospects are provided in the field of optoelectronic nanometer devices and the like.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of biomolecule microarray based on cellular porous membrane

The invention discloses a method for preparing a biomolecular microarray based on a honeycomb porous membrane, and relates to multiple fields such as biotechnology, material chemistry, and nanoscience. The present invention is based on the honeycomb porous film prepared by patterned template, combining the patterning of the honeycomb porous film with the surface functionalization of the film, through the combination of the amino group or sulfhydryl group contained in the biomolecules and the polydopamine modification layer on the surface of the honeycomb porous film Covalent linkage enables patterned microarrays of biomolecules. This method is not only simple to operate, low in cost, and controllable in size, it solves the problem that conventional methods usually require expensive instruments and equipment or special mask materials, and is applicable to the construction of various biomolecular microarrays, and can be used in honeycomb The three-dimensional directional arrangement of biomolecules is realized in the holes, and it is expected to be widely used in the fields of biochips, tissue engineering materials, and biosensors.

Owner:UNIV OF JINAN

Cuznal micro-nano powder core wire material for silicon boride-enhanced laser additive manufacturing and preparation method thereof

ActiveCN110508799BAvoid problems such as low utilizationSolve the problem that higher laser energy is more likely to cause functional lossAdditive manufacturing apparatusIncreasing energy efficiencyPhysical chemistrySilicon boride

A silicon boride-enhanced CuZnAl micro-nano powder core wire material for laser additive manufacturing and a preparation method thereof, characterized in that the powder core wire material is composed of 28% to 30% of the entire powder core wire material and its composition is zinc The micro-nano powder core composed of aluminum micron powder and silicon boride nano-powder whose mass accounts for 2% to 4% of the entire powder core wire material and copper skin whose mass accounts for 66% to 70% of the entire powder core wire material, each group The sum of the points is 100%, and its preparation method mainly includes the preparation of micro-nano powder, skin forming and powder filling, mouth closing and drawing into filaments. Using the CuZnAl micro-nano powder core wire material described in the present invention as a material for laser additive manufacturing has the characteristics of small loss of shape memory function and high forming accuracy, and avoids the low powder utilization rate that exists in the current powder as additive manufacturing materials. At the same time, it also solves the problem of using solid wire as an additive manufacturing material, which requires higher laser energy and is more likely to cause functional loss.

Owner:JIANGSU UNIV

Functional low-loss femnsi micro-nano powder core wire material for laser additive manufacturing and preparation method thereof

ActiveCN108746585BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingAdditive layer manufacturing

A functional low-loss type FeMnSi micro-nano powder core wire material for laser additive manufacturing and its preparation method, characterized in that the micro-nano powder core wire material is composed of a micro-nano composite powder core and an iron sheet, and the micro-nano powder core It is composed of micron Mn powder whose mass accounts for 14%~33% of the entire micronano powder core wire material and nanometer Si powder whose mass accounts for 1%~6% of the entire micronano powder core wire material. The mass of the iron sheet accounts for the entire micronano powder core wire material. Material 61%~80%, the sum of each component is 100%. The preparation method mainly includes micro-nano powder preparation, skin forming and powder filling, mouth closing and drawing into filaments. Using the FeMnSi micro-nano powder core wire material described in the present invention as a material for laser additive manufacturing has the characteristics of small loss of shape memory function and high forming accuracy, and avoids the low powder utilization rate that exists in the current powder as additive manufacturing materials. At the same time, it also solves the problem of using solid wire as an additive manufacturing material, which requires higher laser energy and is more likely to cause functional loss.

Owner:JIANGSU UNIV

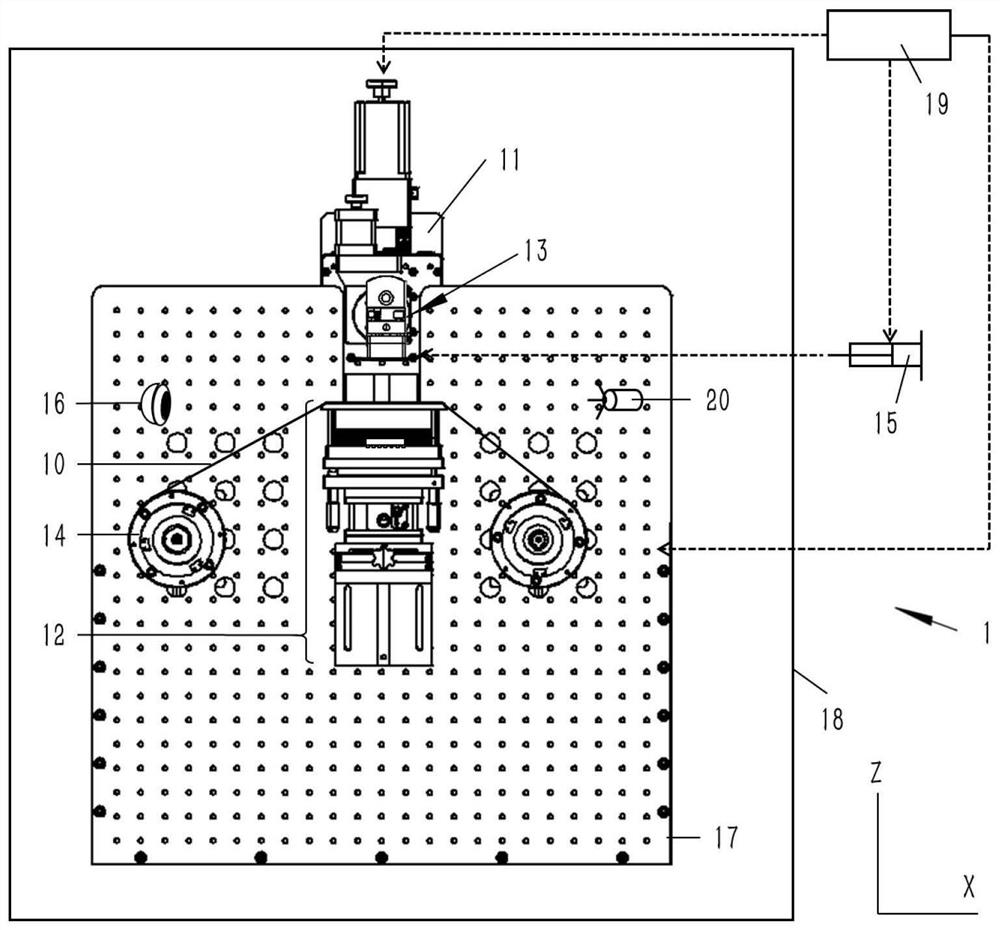

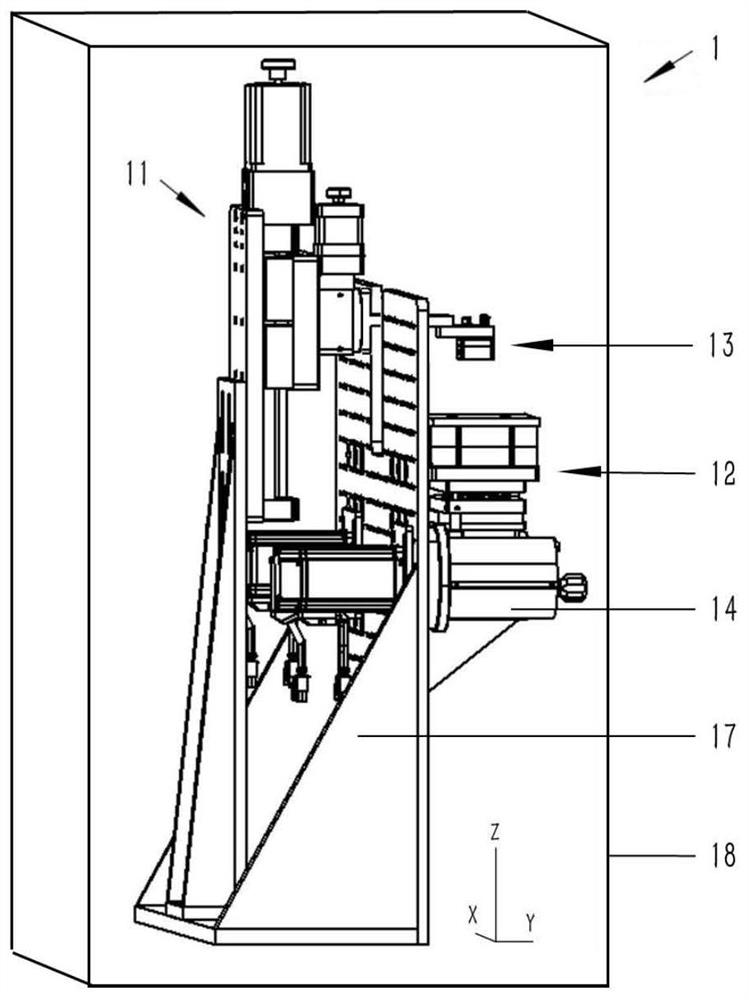

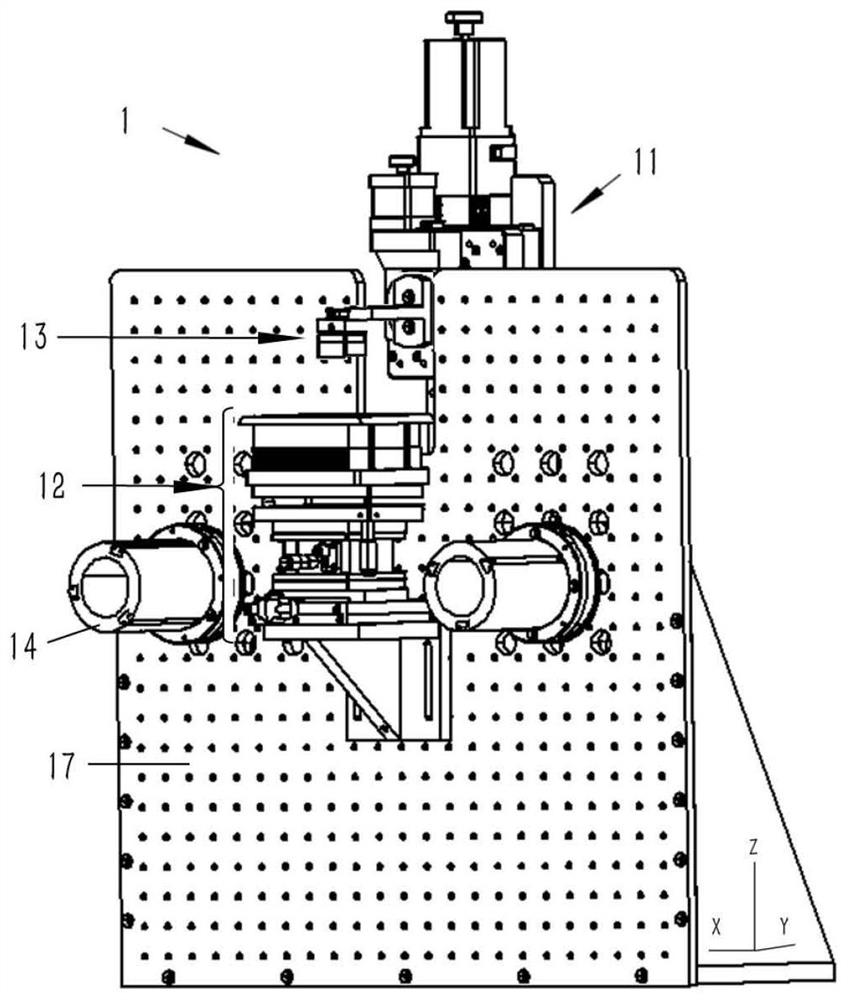

Continuous coating system and coating method

ActiveCN113828492ARapid large-area controllable preparationEfficient and large-area controllable preparationLiquid surface applicatorsCoatingsOrganic filmCoating system

The invention discloses a continuous coating system and a coating method, belongs to the technical field of coating devices, and solves the problem that in the prior art, an organic semiconductor material cannot be used for accurately controlling the shape and a stacking structure of a film while being used for rapidly and efficiently preparing a film in a large area. The continuous coating system comprises a frame, a coating unit, a liquid supply device, a coating unit moving device, a temperature control base station unit and a base material conveying device, wherein the coating unit moving device, the temperature control base station unit and the base material conveying device are arranged on the frame, the base material conveying device is used for conveying a base material, the liquid supply device provides coating liquid for the base material, the coating unit is arranged on the coating unit moving device, and the coating unit moving device is used for controlling the distance and the angle between the coating unit and the base material, the coating unit is used for controlling the thickness and the appearance of a coating film by applying a shearing force to the coating liquid, the coating unit comprises a horizontal adjusting disc and a traction piece, and the horizontal adjusting disc is used for adjusting the pitch angle so as to ensure that the initial position of the traction piece is horizontal. According to the continuous coating system and a coating method, the preparation of the large-area orderly-arranged organic thin film is realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Rare earth-enhanced laser additive manufacturing femnsi micro-nano powder core wire material and preparation method thereof

ActiveCN108705076BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyPhysical chemistryManganese

Owner:JIANGSU UNIV

Silicon boride-enhanced laser additive manufacturing niti micro-nano powder core wire material and preparation method thereof

ActiveCN108971478BAvoid problems such as low utilizationRealize shape controlAdditive manufacturing apparatusIncreasing energy efficiencyMicro nanoTitanium

A silicon boride-enhanced NiTi micro-nano powder core wire material for laser additive manufacturing and a preparation method thereof, characterized in that the powder core wire material is composed of micron nickel powder and nickel powder whose mass accounts for 54% to 56% of the entire powder core wire material. The micro-nano powder core composed of silicon boride nanopowder whose mass accounts for 1% to 2% of the entire powder core wire material and titanium skin whose mass accounts for 42% to 45% of the entire powder core wire material, the sum of each component is 100% , the preparation method mainly includes the preparation of micro-nano powder, skin forming and powder filling, mouth closing and drawing into filaments. Using the NiTi micro-nano powder core wire material according to the present invention as a material for laser additive manufacturing has the characteristics of small loss of shape memory function and high forming accuracy, and avoids the low powder utilization rate of current powder as additive manufacturing materials. At the same time, it also solves the problem of using solid wire as an additive manufacturing material, which requires higher laser energy and is more likely to cause functional loss.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com