Silicon boride-enhanced laser additive manufacturing niti micro-nano powder core wire material and preparation method thereof

A technology of powder core wire material and laser additive material, which is applied in the field of materials for laser additive manufacturing and its preparation, silicon boride-enhanced NiTi micro-nano powder core wire material for laser additive manufacturing and its preparation, which can solve the problem of shape Loss of memory function and other problems, to achieve the effect of enhancing shape memory function, refining grains, and reducing burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Taking the preparation of 1000g of silicon boride-enhanced NiTi micro-nano powder core wire for laser additive manufacturing as an example, the specific steps are as follows:

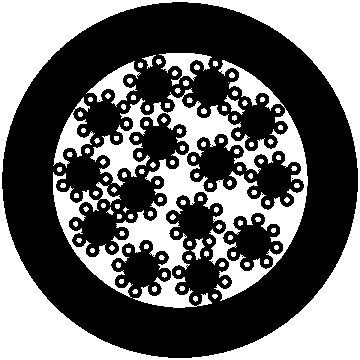

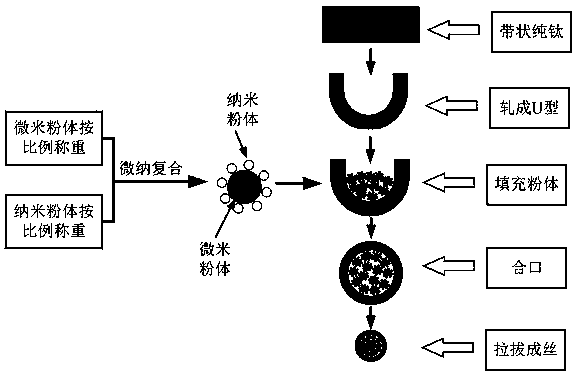

[0031] Prepare 540g of nickel powder (particle size 50-75 microns) according to the required ratio, and then disperse 10g of silicon boride nano-powder (powder size 30-80 nanometers) in ethanol to prepare a nano-suspension, and put the two together Put into the ball mill and compound by ball milling to obtain 550g of micro-nano powder with micron nickel powder as the core and nano-silicon boride as the shell. Select 450g of pure titanium strip with a width of 10mm and a thickness of 0.3mm, first roll it into a U shape, add the aforementioned micro-nano powder into the U-shaped groove and then close it, and pull it into a finished product with a diameter of 1.5mm by a drawing device Powder core wire.

[0032] Under the same laser process conditions, NiTi alloy powder, NiTi solid wire, and NiTi mi...

example 2

[0036] Taking the preparation of 1000g of silicon boride-enhanced NiTi micro-nano powder core wire for laser additive manufacturing as an example, the specific steps are as follows:

[0037] Prepare 560g of nickel powder (particle size 50-75 microns) according to the required ratio, and then disperse 20g of silicon boride nano-powder (powder diameter 30-80 nanometers) in ethanol to prepare a nano-suspension, put the two together Enter the ball mill into the ball mill and compound to obtain 580g of micro-nano powder with micron nickel powder as the core and nano-silicon boride as the shell. Select 420g of pure titanium strip with a width of 10mm and a thickness of 0.3mm, first roll it into a U shape, add the aforementioned micro-nano powder into the U-shaped groove and then close it, and pull it into a finished product with a diameter of 0.5mm by a drawing device Powder core wire.

[0038] Under the same laser process conditions, NiTi alloy powder, NiTi solid wire, and NiTi mi...

example 3

[0040] Taking the preparation of 1000g of silicon boride-enhanced NiTi micro-nano powder core wire for laser additive manufacturing as an example, the specific steps are as follows:

[0041]Prepare 550g of nickel powder (particle size 50-75 microns) according to the required ratio, and then disperse 15g of silicon boride nano-powder (powder size 30-80 nm) in ethanol to prepare a nano-suspension, put the two together Put into the ball mill and compound by ball milling to obtain 565g micro-nano powder with micron nickel powder as core and nano-silicon boride as shell. Select 435g of pure titanium strip with a width of 10mm and a thickness of 0.3mm, first roll it into a U shape, add the aforementioned micro-nano powder into the U-shaped groove and then close the mouth, and pull it into a finished powder with a diameter of 2mm by a drawing device Core wire.

[0042] Under the same laser process conditions, NiTi alloy powder, NiTi solid wire, and NiTi micro-nano powder core wire a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com