Demolding integrated mold for inner wall grid high rib barrel-shaped thin-wall part and forming method

A technology of thin-walled parts and grid ribs, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of high cost and complicated process, and reduce manufacturing costs and Effect of production cost, reduction of labor cost and raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

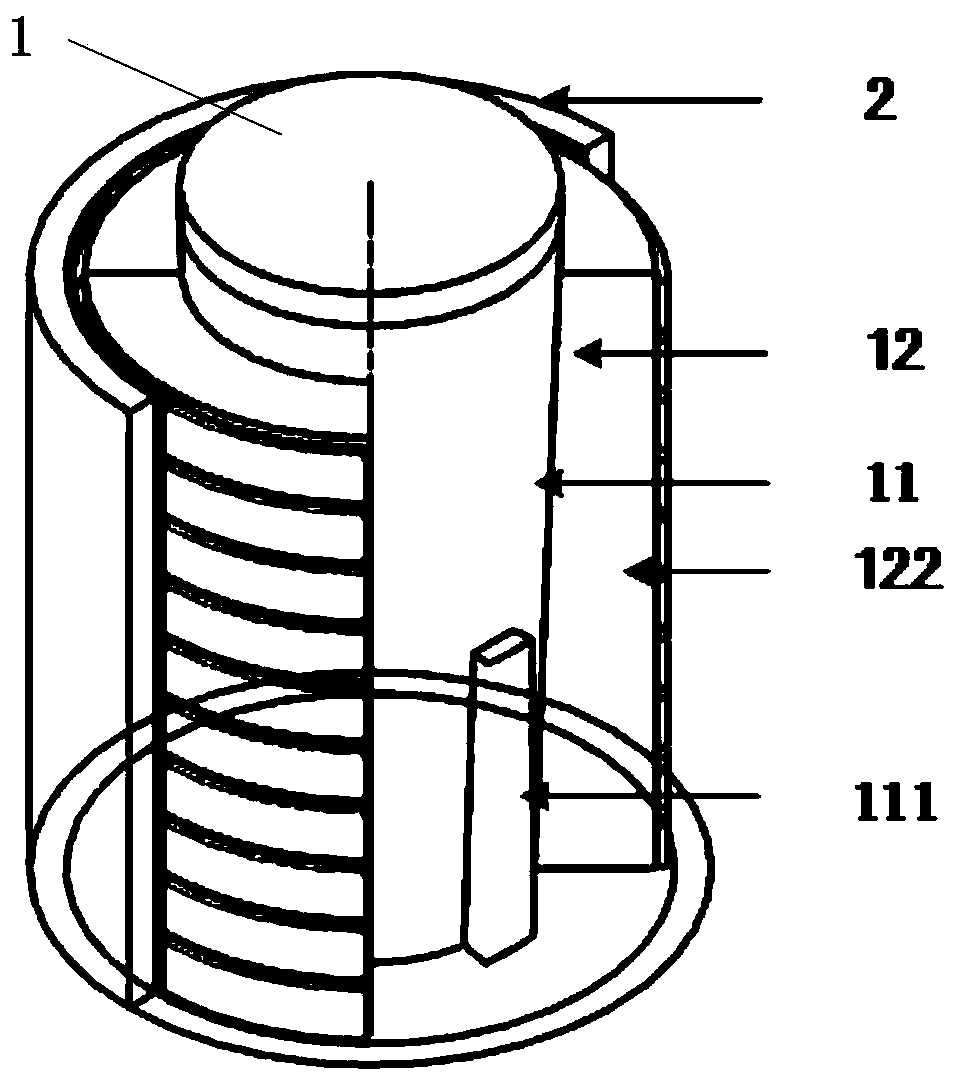

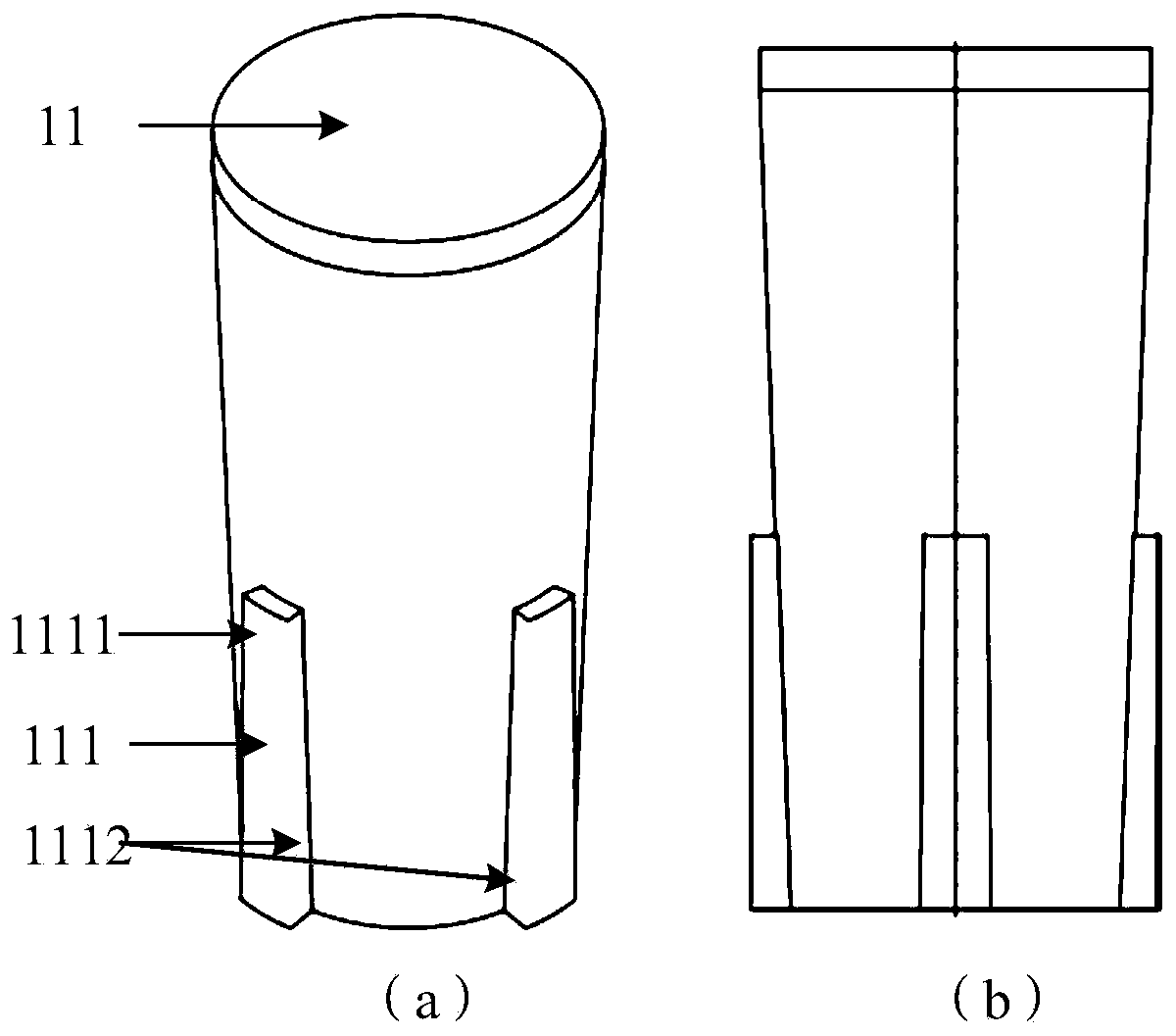

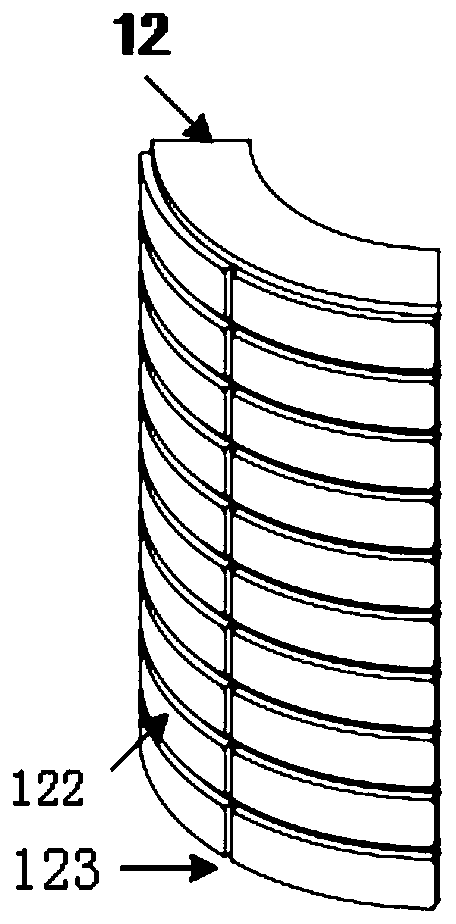

[0046] Such as Figure 1~5 As shown, the mold mainly includes a combined punch 1 (punch mandrel and multiple punch inserts), and a die 2. The material selected is low heat-resistant high-toughness steel 5CrMnMo. After heat treatment, it has sufficient strength, Hardness and wear resistance, the combined punch is divided into a punch mandrel 11 and a punch insert 12, and the upper and lower surfaces of the combined punch 1 and the die 2 are horizontal. The contact surface of the punch mandrel 11 and the punch insert 12 should be designed as a wedge mechanism, the surface has been ground and polished, the surface roughness of the punch and die is Ra0.8, the punch mandrel 11 and the punch insert 12 It should be designed as a matching relationship with a slope, and the angle is 2°-5°. The slider 111 of the punch mandrel 11 is in clearance fit with the groove 121 of the punch insert 12 , and the slider 111 and the groove 121 move without interference during extrusion. The sliders...

Embodiment 2

[0049] Such as Figure 1~5 As shown, the mold mainly includes a combined punch 1 (punch mandrel and multiple punch inserts), and a die 2. The material selected is low heat-resistant high-toughness steel 5CrMnMo. After heat treatment, it has sufficient strength, Hardness and wear resistance, the combined punch is divided into a punch mandrel 11 and a punch insert 12, and the upper and lower surfaces of the combined punch 1 and the die 2 are horizontal. The contact surface of the punch mandrel 11 and the punch insert 12 should be designed as a wedge mechanism, the surface has been ground and polished, the surface roughness of the punch and die is Ra0.8, the punch mandrel 11 and the punch insert 12 It should be designed as a matching relationship with a slope, and the angle is 2°-5°. The slider 111 of the punch mandrel 11 is in clearance fit with the groove 121 of the punch insert 12 , and the slider 111 and the groove 121 move without interference during extrusion. The sliders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com