Continuous coating system and coating method

A technology of coating and coating liquid, which is applied to the device and coating of the surface coating liquid, can solve the problems of solution waste, disordered molecular stacking in organic films, low utilization rate of printing technology materials, etc., to achieve optimization. The effect of long-range order, large-area controllable preparation, and optimization of short-range molecular orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

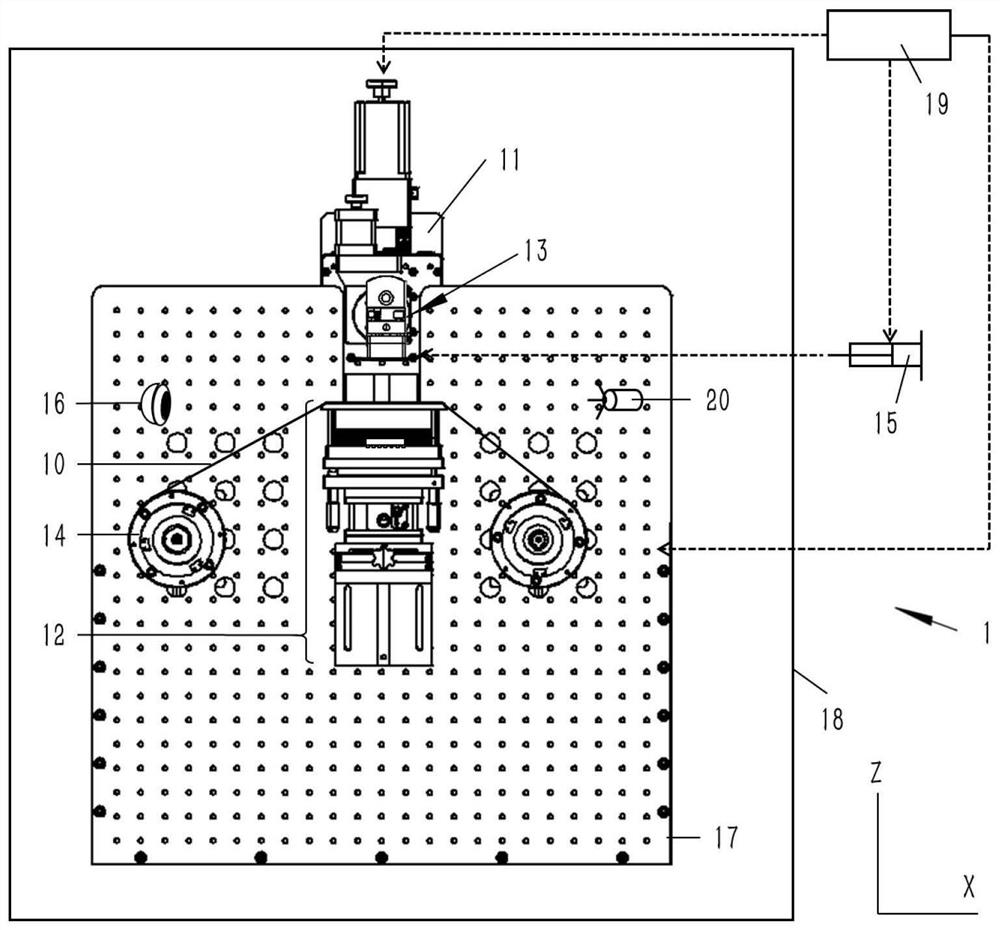

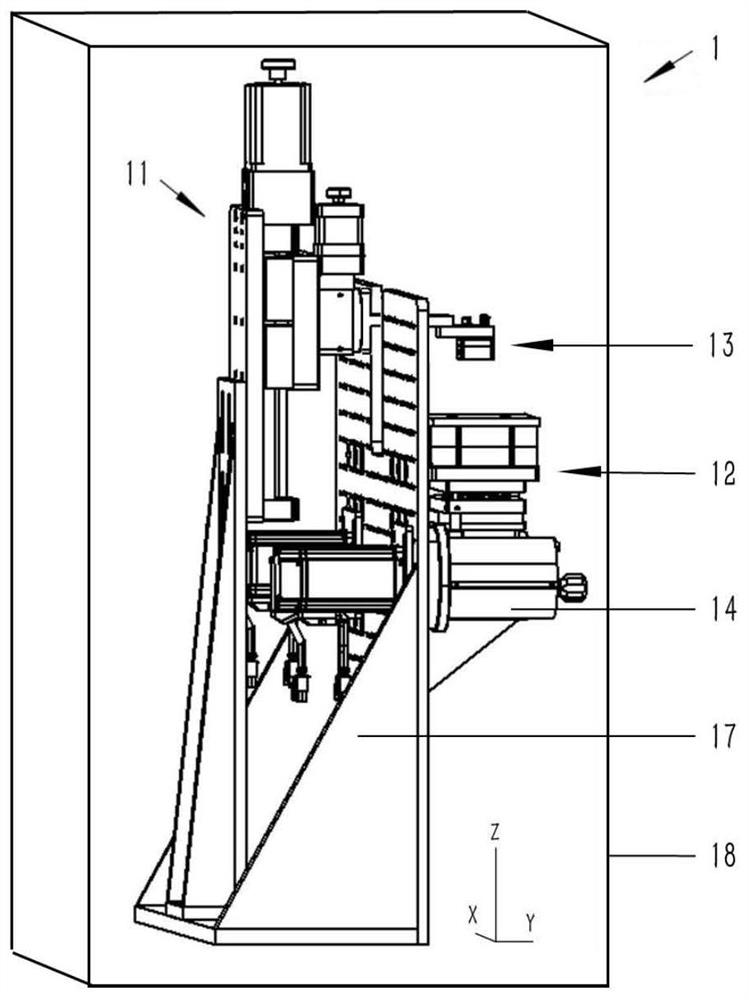

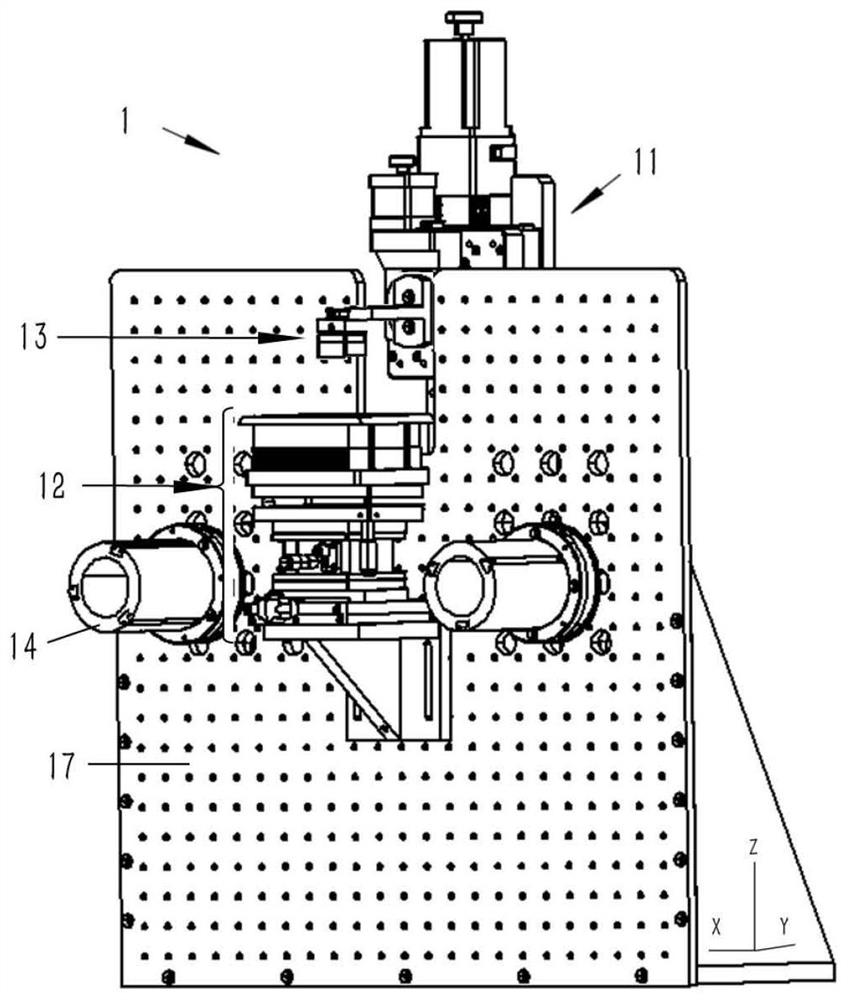

[0046] A continuous coating system will be further described in detail below in conjunction with specific examples, these examples are only for the purpose of comparison and explanation, and the present invention is not limited to these examples.

[0047] It should be noted that in the present invention, words such as "up, down, left, right, front, back, inside, outside, vertical, vertical, horizontal, top, bottom, middle" etc. are used to indicate orientation or positional relationship The description is only for the purpose of describing and understanding the present invention, and does not indicate or imply that the device or element must have a specific orientation, be constructed or operate in a specific orientation, especially when it is described that a certain part or device is "fixed" or "connected to" When using another device or component, the device or component may be directly fixed or connected to another component, or may be indirectly fixed or connected to anoth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com