Poly(m-phenylenediamine) and synthesizing and applying method thereof

A technology of poly-m-phenylenediamine and m-phenylenediamine, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of low poly-m-phenylenediamine synthesis yield and limited industrial Application and high cost of use, etc., to achieve good selective adsorption, reduce application cost, and improve adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

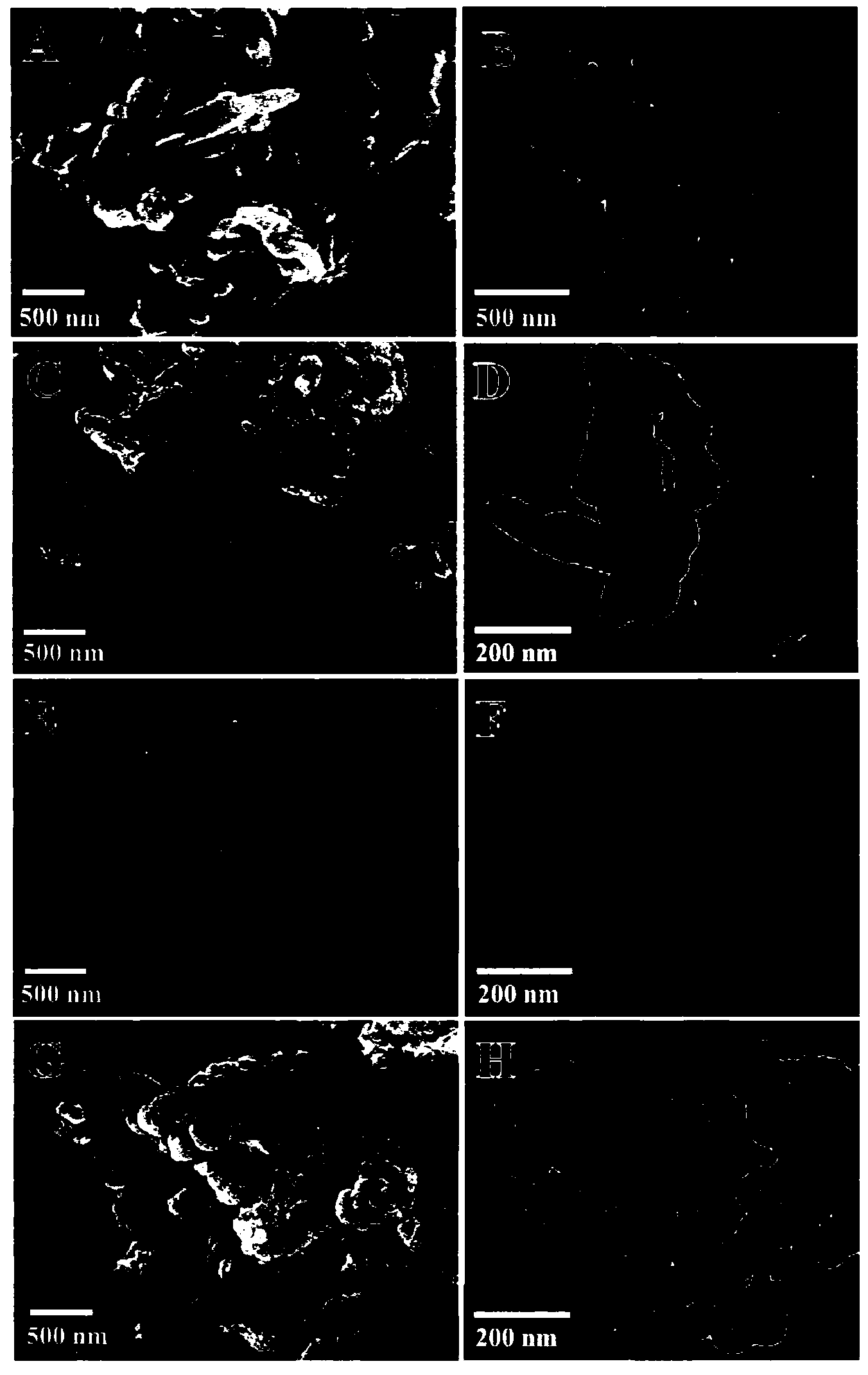

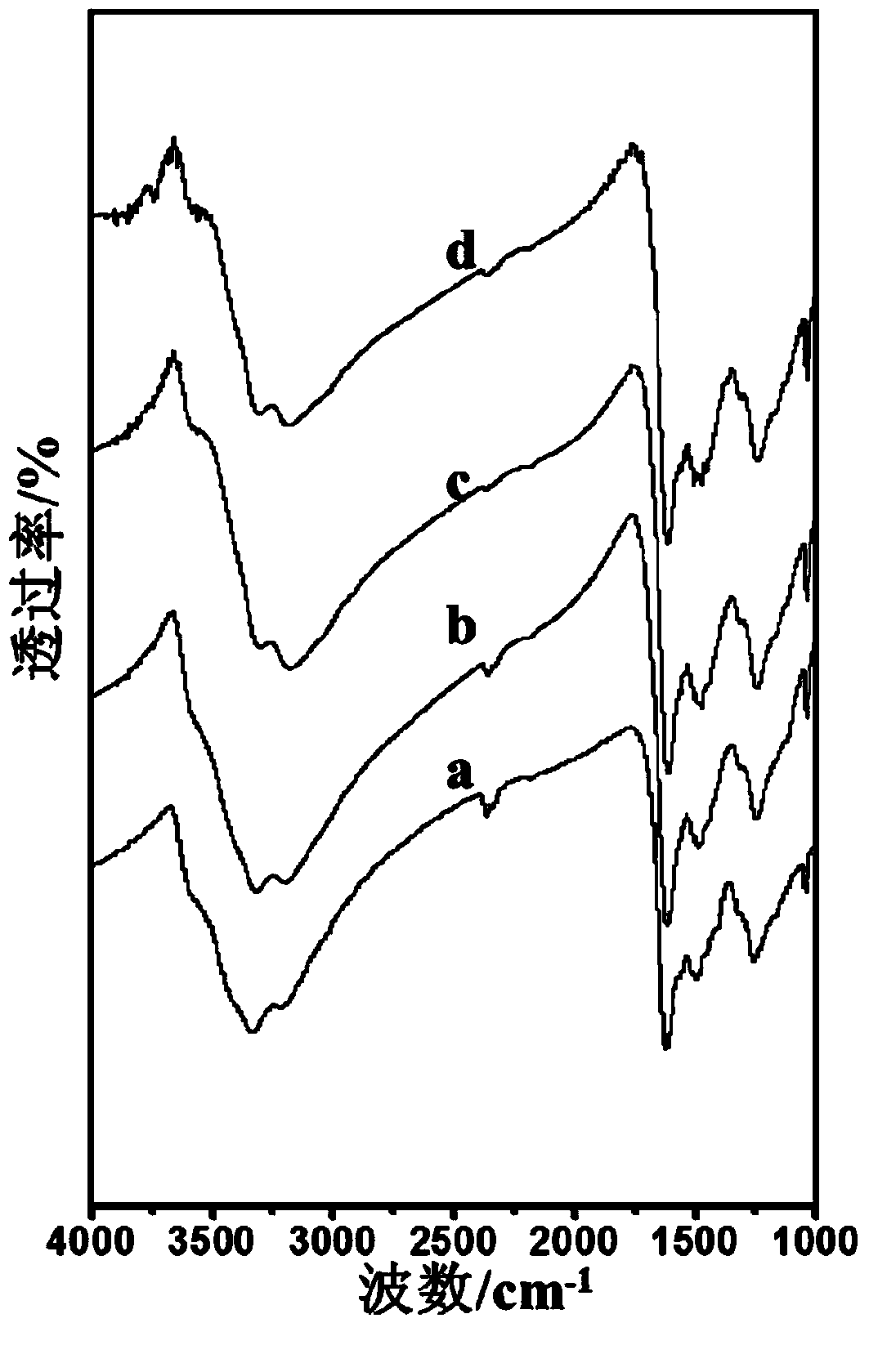

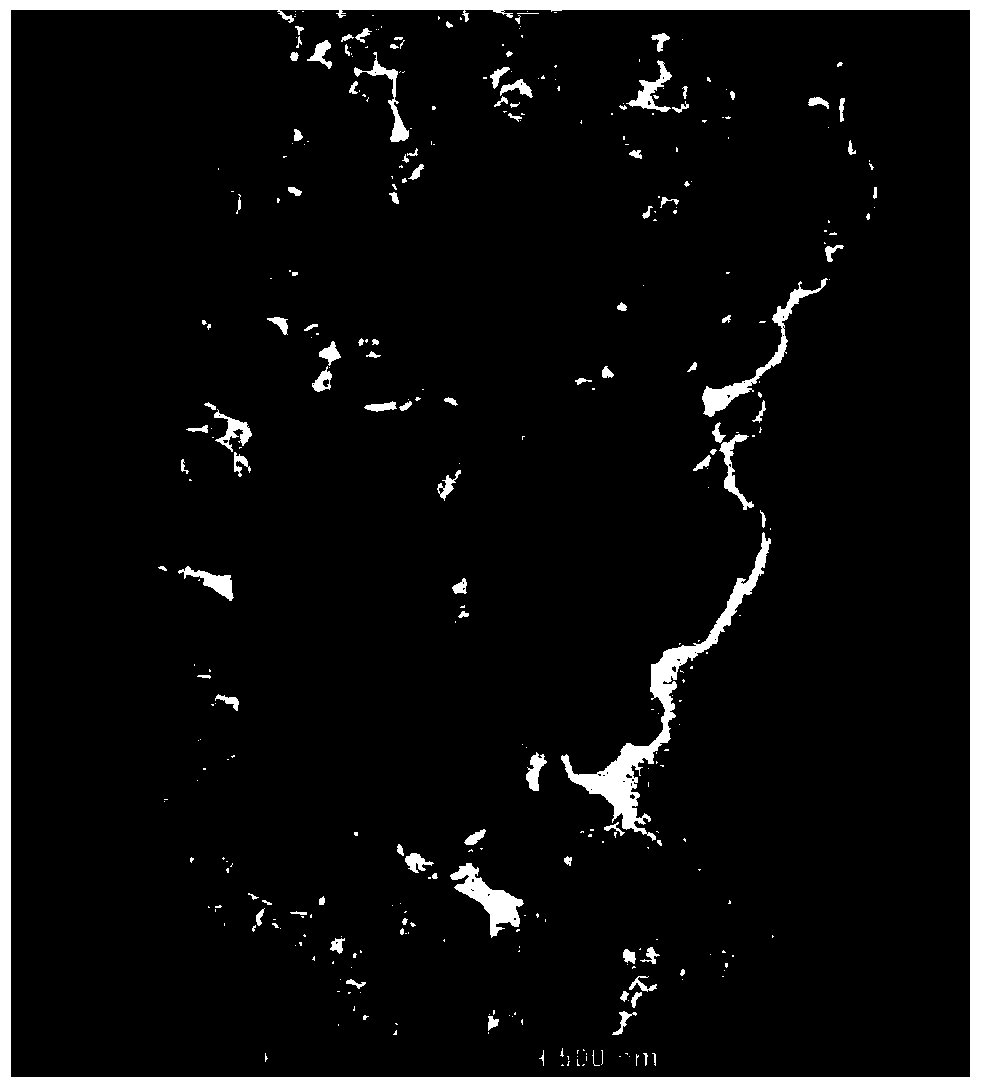

Image

Examples

Embodiment 1

[0025] Weigh 3.0g (0.0277mol) of m-phenylenediamine and dissolve it in 100mL of methanol, stir in a constant temperature water bath at 30°C for 15min, and mix the monomer solution evenly. Weigh 6.6g (0.0277mol) of sodium persulfate and dissolve it in 20mL of distilled water. The above-mentioned sodium persulfate solution and 20 mL of methanol solution with a concentration of 0.5 mol / L diethanolamine were simultaneously added dropwise to the reaction system at a rate of 2 mL / min, and the addition was completed in about 10 minutes. Then, the stirring reaction was continued for 3h. After the reaction, filter, and then wash the product with distilled water, 1:1 (volume ratio) ammonia water, absolute ethanol, and distilled water until it is colorless, and dry it in an oven at 60°C for 12 hours to constant weight to obtain black poly-m-phenylenediamine powder.

Embodiment 2~3

[0027] Adjust the concentration of added diethanolamine to 1, 1.5mol·L respectively -1 , other conditions were the same as in Example 1 to prepare poly-m-phenylenediamine.

Embodiment 4

[0033] Under the condition of a constant temperature water bath at 30°C, 25 mg of the polymers prepared in Examples 1 to 3 and Comparative Example 1 were used to absorb 20 mL of the polymer, and the initial concentration was 62 mmol L -1 Silver nitrate solution, the reaction continued for 72h. The reacted solution was filtered, and the concentration of silver ions in the filtrate was determined by Volhard titration. The polymers prepared by each embodiment are shown in Table 1 for the adsorption capacity of silver ions. It can be seen from the table that the product prepared by adding diethanolamine has better adsorption performance on silver ions than the product prepared without adding diethanolamine. It should be pointed out that an appropriate concentration of diethanolamine can maximize the product's adsorption performance on silver ions, and the concentration of diethanolamine is too high or too low to reduce its adsorption capacity. This may be closely related to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com