A preparation method of high-purity silicon oxide/silicon carbide nano chain heterostructure

A heterostructure and nanochain technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problem of low purity of SiC/SiOx nanochain heterostructures, and achieve size distribution and morphology. effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

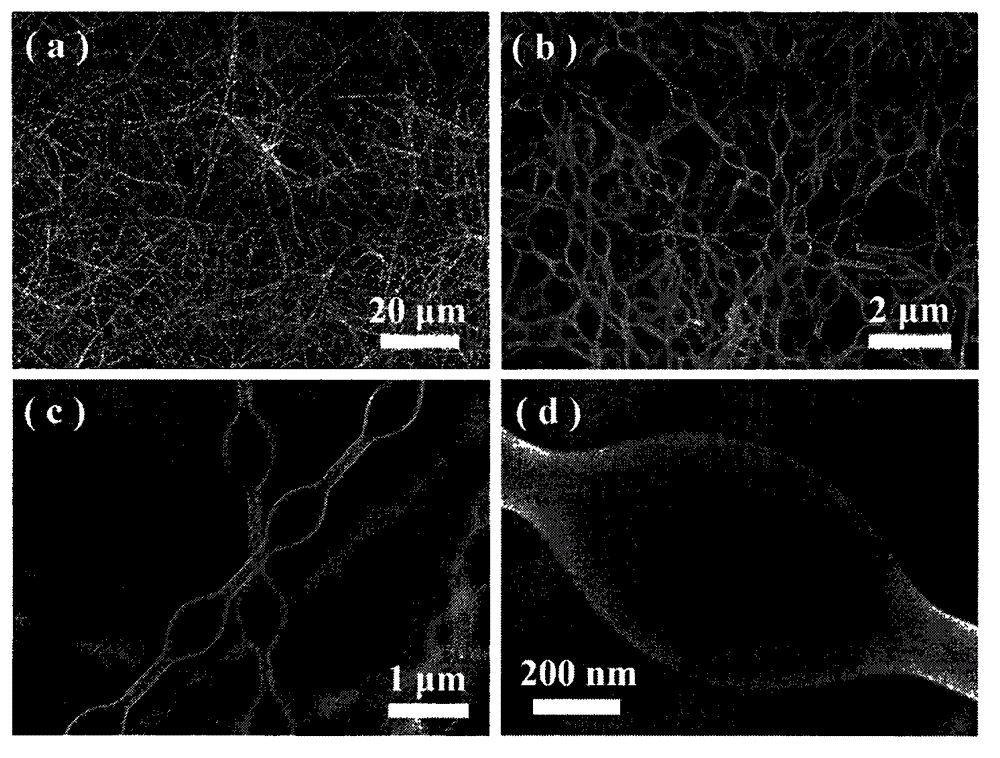

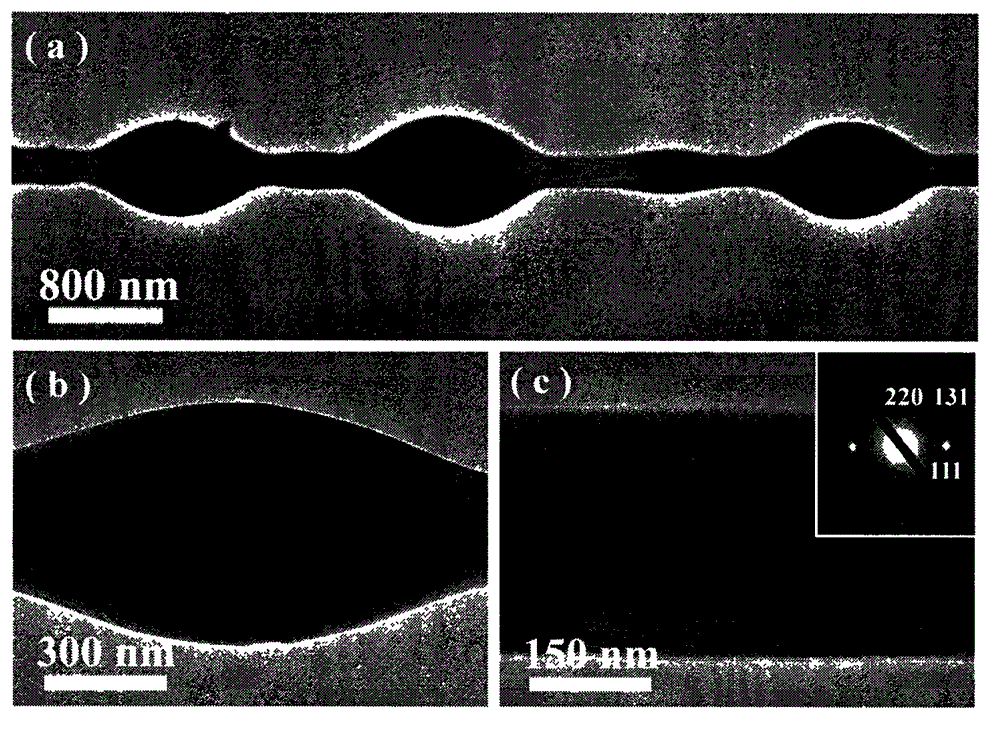

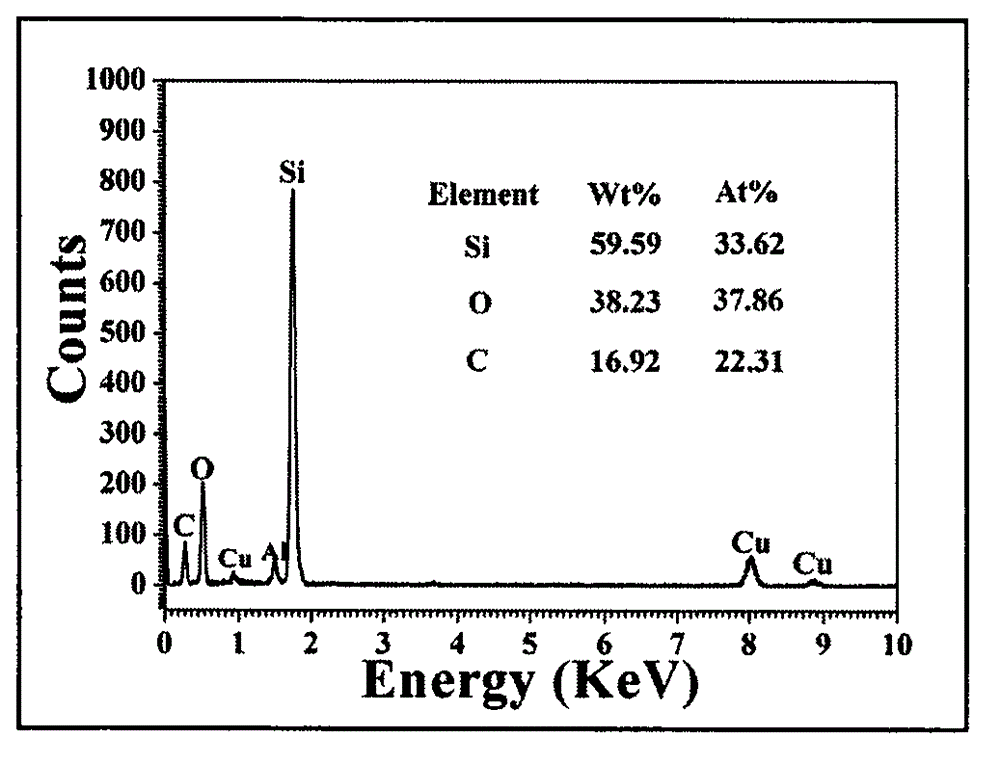

[0024] Weigh 2.0 g of polysilazane (PSN) and 3.0 g of polyvinylpyrrolidone (PVP) and dissolve in 11 g of absolute ethanol, stir and mix at room temperature for 6 hours to obtain a microemulsion with uniform composition. After the microemulsion was allowed to stand, it was incubated at 200° C. for 30 minutes under an air atmosphere to obtain a solid organic precursor. The solid organic precursor is then subjected to 99% Al 2 o 3 In the crucible, the top of the crucible is covered with a layer of carbon paper (for depositing SiC / SiOx nano-chain heterostructures) and then placed in a common tubular atmosphere sintering furnace. The temperature was raised to 1400°C at a rate of 5°C / min, and held for 2 hours for high-temperature pyrolysis, and then cooled with the furnace. Typical scanning electron microscopy (SEM) images of the as-prepared SiC / SiOx nanochain heterostructure at different magnifications are shown in figure 1 It is shown that the prepared material is a high-purity...

Embodiment 2

[0026] Weigh 2.0 g of PSN and 4.0 g of PVP and dissolve them in 10 g of absolute ethanol, stir and mix at room temperature for 6 hours to obtain a microemulsion with uniform composition. After the microemulsion was allowed to stand, it was incubated at 200° C. for 30 minutes under an air atmosphere to obtain a solid organic precursor. The solid organic precursor is then subjected to 99% Al 2 o 3 In the crucible, cover the top of the crucible with a layer of carbon paper and place it in an ordinary tubular atmosphere sintering furnace. Under the protection of a 0.1MPa 99.95% Ar atmosphere, the temperature is raised from room temperature to 1400°C at a rate of 5°C / min, and kept for 2 Hours of high temperature pyrolysis, and then cool with the furnace. Typical scanning electron microscope (SEM) images of the as-prepared SiC / SiOx nanochain heterostructure at different magnifications are shown in Figure 4 As shown, it shows that the prepared material is a high-purity SiC / SiOx n...

Embodiment 3

[0028] Weigh 2.0 g of PSN and 5.0 g of PVP and dissolve them in 9 g of absolute ethanol, stir and mix at room temperature for 6 hours to obtain a microemulsion with uniform composition. After the microemulsion was allowed to stand, it was incubated at 200° C. for 30 minutes under an air atmosphere to obtain a solid organic precursor. The solid organic precursor is then subjected to 99% Al 2 o 3 In the crucible, cover the top of the crucible with a layer of carbon paper and place it in an ordinary tubular atmosphere sintering furnace. Under the protection of a 0.1MPa 99.95% Ar atmosphere, the temperature is raised from room temperature to 1400°C at a rate of 5°C / min, and kept for 2 Hours of high temperature pyrolysis, and then cool with the furnace. A typical scanning electron microscope (SEM) of the as-prepared material at different magnifications is shown in Figure 4 As shown, it shows that the prepared material is a high-purity SiC / SiOx nano-chain heterostructure with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com