Shape correction and heat treatment method of low-plasticity and low-deformation material plates

A heat treatment method and a difficult-to-deform technology, applied in the field of processing and forming of difficult-to-deform materials, to achieve the effects of avoiding bending and warping, strong operability, and avoiding cracking and fracture problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

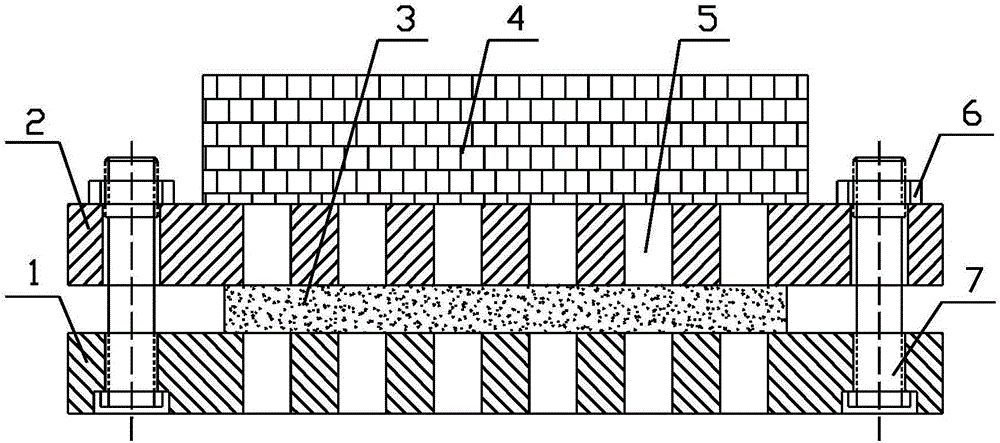

Embodiment 1

[0025] Hot rolled TiB 2 The thickness of the / QB2 copper-based composite material plate is 5mm, and the unevenness of the plate is 25-35mm / m. The unevenness of the lower supporting plate and the upper pressing plate is less than 1.5mm / m, the thickness of the lower supporting plate and the upper pressing plate is 40mm, the aperture of the uniformly distributed small holes on the lower supporting plate and the upper pressing plate is 6mm, the lower supporting plate and the upper pressing plate The material is Inconel718 nickel-based alloy; the pressure plate is No. 45 steel plate with a thickness of 80mm. The solid solution temperature is 780°C, and the temperature is kept for 2.5 hours. The aging temperature is 315°C, and the aging time is 2 hours. After leveling and heat treatment, TiB 2 The unevenness of / QB2 copper matrix composite material plate is 1~1.5mm / m.

Embodiment 2

[0027] Hot rolled TiB 2 The thickness of the / 6351 aluminum-based composite material plate is 25mm, and the unevenness of the plate is 40-50mm / m. The surface roughness of the lower supporting plate and the upper pressing plate is less than 1.5mm / m, the thickness of the lower supporting plate and the upper pressing plate is 60mm, the aperture of the uniformly distributed small holes on the lower supporting plate and the upper pressing plate is 10mm, the lower supporting plate and the upper pressing plate The material is GH13 hot work die steel; the pressure plate is No. 45 steel plate with a thickness of 120mm. The solid solution temperature is 500°C, the heat preservation is 3.5 hours, the aging temperature is 165°C, and the aging time is 12 hours. After leveling and heat treatment, TiB 2 The roughness of / 6351 aluminum matrix composite material plate is 0.9~1.2mm / m.

Embodiment 3

[0029] The thickness of the hot-rolled 7075 / 6061 layered composite sheet is 2mm, and the roughness of the sheet is 10-25mm / m. The unevenness of the lower supporting plate and the upper pressing plate is less than 1.5mm / m, the thickness of the lower supporting plate and the upper pressing plate is 25mm, the aperture of the uniformly distributed small holes on the lower supporting plate and the upper pressing plate is 4mm, the lower supporting plate and the upper pressing plate The material is GH13 hot work die steel; the pressure plate is No. 45 steel plate with a thickness of 50mm. The solid solution temperature is 470°C, heat preservation is 2 hours, the aging temperature is 120°C, and the aging time is 24 hours. After leveling and heat treatment, the unevenness of the 7075 / 6061 layered composite sheet is 1-1.5mm / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com