Porous spherical tungsten rhenium alloy powder and preparation method thereof

A porous spherical, tungsten alloy technology, applied in the field of alloy powder, can solve the problems that the overall performance of the cathode is difficult to meet, affect the emission performance of the hot cathode, and it is difficult to prepare a good shape, etc., to achieve good industrial application prospects, good dispersion, The effect of avoiding the introduction of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

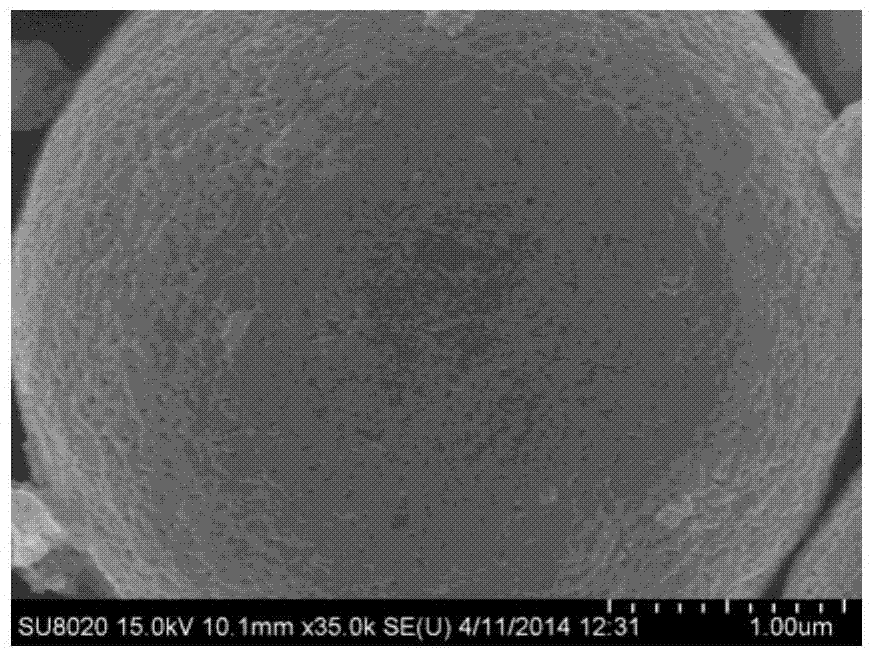

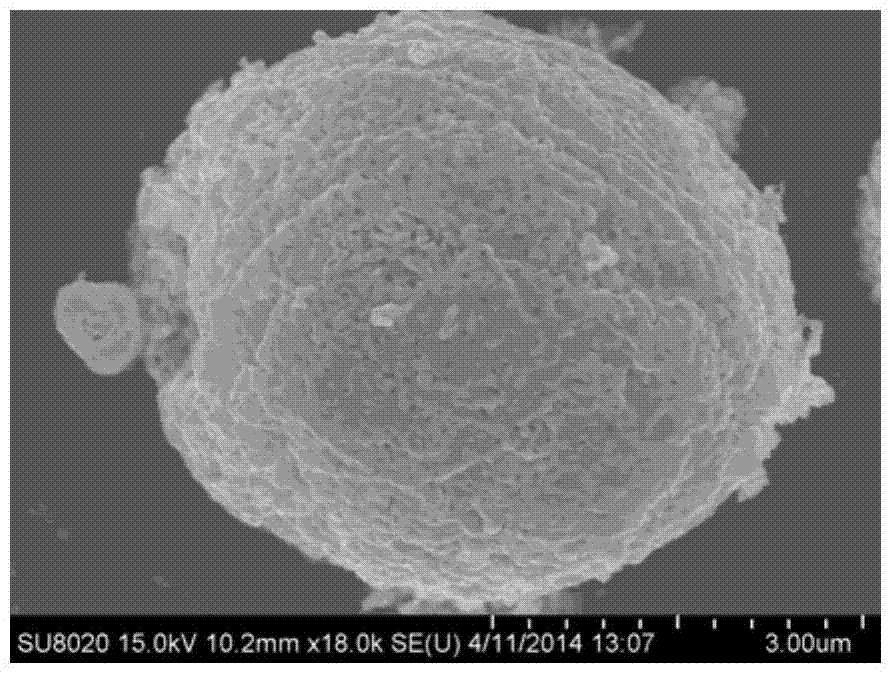

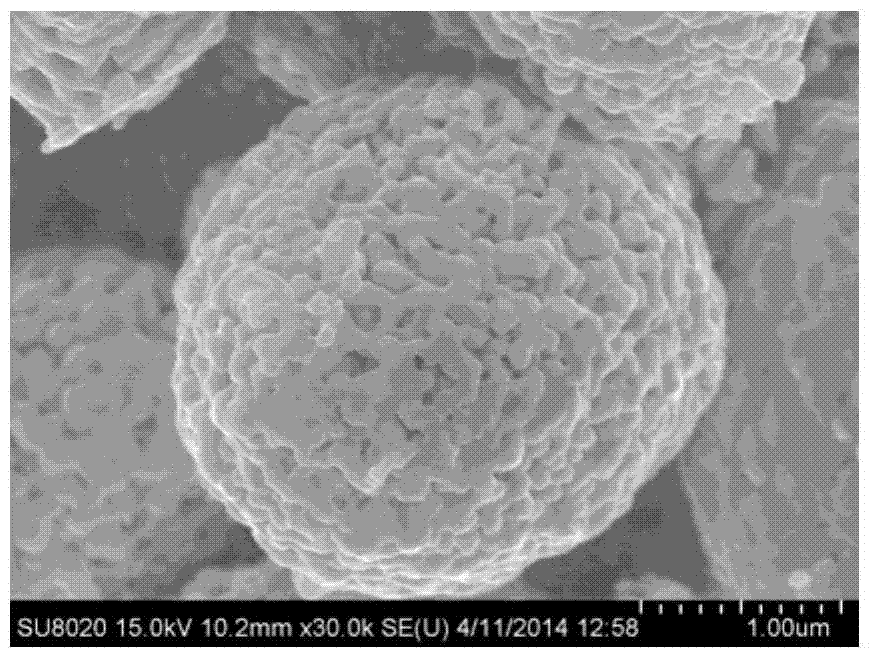

[0019] Example 1: Dissolve 14.41g of ammonium perrhenate and 128.98g of ammonium metatungstate in water to form a solution, mix the above two solutions and stir evenly, and prepare the precursor powder by spray drying method. The obtained precursor powder was decomposed and reduced in a hydrogen atmosphere: the first reduction temperature was 450°C, and the holding time was 1h; the second reduction temperature was 900°C, and the holding time was 2h, and a porous material with a rhenium content of 25% was obtained. Spherical rhenium-tungsten alloy powder. The process parameters are detailed in Table 1.

Embodiment 2

[0020] Example 2: Dissolve 50.42g of ammonium perrhenate and 93.15g of ammonium metatungstate in water respectively to form a solution, mix the above two solutions and stir evenly, and prepare the precursor powder by spray drying method. Decompose and reduce the obtained precursor powder in a hydrogen atmosphere: the first reduction temperature is 500°C, the holding time is 1.5h; the second step reduction temperature is 950°C, the holding time is 2.5h, and the rhenium content is 35%. Porous spherical rhenium-tungsten alloy powder. The process parameters are detailed in Table 1.

Embodiment 3

[0021] Example 3: Dissolve 72.03g of ammonium perrhenate and 71.65g of ammonium metatungstate in water respectively to form a solution, mix the above two solutions and stir evenly, and prepare the precursor powder by spray drying method. Decompose and reduce the obtained precursor powder in a hydrogen atmosphere: the first reduction temperature is 450°C, and the holding time is 2h; Spherical rhenium-tungsten alloy powder. The process parameters are detailed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com