Silver ion pre-embedded manganese-oxygen-based nanowire as well as preparation method and application thereof

A nanomanganese oxide, silver manganese oxide nanotechnology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of non-environmentally friendly green production, large energy consumption, cumbersome processes, etc., and achieve excellent electrochemical performance. Performance, capacity improvement, and the effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of manganese dioxide precursor

[0055] Dissolve manganese sulfate and potassium permanganate in deionized water at a ratio of 3:2, heat in an oil bath at 80°C by magnetic stirring to obtain a precipitated product, keep it warm for 3 hours, wash it centrifugally, and dry it in vacuum to obtain manganese dioxide powder.

[0056] (2) Preparation of silver manganese oxide material

[0057] Mix the manganese dioxide precursor and silver nitrate obtained in step (1) at a ratio of 4:1, put them into a reaction kettle, and carry out hydrothermal reaction with water as the medium. The product is subjected to centrifugal washing, and vacuum-dried at 100° C. for 10 hours to obtain a silver-manganese-oxygen material, and the length of the silver-manganese-oxygen nanowires obtained under this condition is 0.1-1 micron.

Embodiment 2

[0059] (1) Preparation of manganese dioxide precursor

[0060] Dissolve manganese sulfate and potassium permanganate in deionized water at a ratio of 3:2, heat in an oil bath at 80°C by magnetic stirring to obtain a precipitated product, keep it warm for 3 hours, wash it centrifugally, and dry it in vacuum to obtain manganese dioxide powder.

[0061] (2) Preparation of silver manganese oxide material

[0062] Mix the manganese dioxide precursor and silver nitrate obtained in step (1) at a ratio of 4:1, put them into a reaction kettle, and carry out hydrothermal reaction with water as the medium. The product is washed by centrifugation and vacuum-dried at 100° C. for 10 hours to obtain a silver manganese oxide material, and the length of the silver manganese oxide nanowire obtained under this condition is 1-5 microns.

Embodiment 3

[0064] (1) Preparation of manganese dioxide precursor

[0065] Dissolve manganese sulfate and potassium permanganate in deionized water at a ratio of 3:2, heat in an oil bath at 80°C by magnetic stirring to obtain a precipitated product, keep it warm for 3 hours, wash it centrifugally, and dry it in vacuum to obtain manganese dioxide powder.

[0066] (2) Preparation of silver manganese oxide material

[0067] Mix the manganese dioxide precursor and silver nitrate obtained in step (1) at a ratio of 2:1, put them into a reaction kettle, and carry out hydrothermal reaction with water as the medium. The product is subjected to centrifugal washing, and vacuum-dried at 100° C. for 10 hours to obtain a silver-manganese-oxygen material, and the length of the silver-manganese-oxygen nanowires obtained under this condition is 1-10 microns.

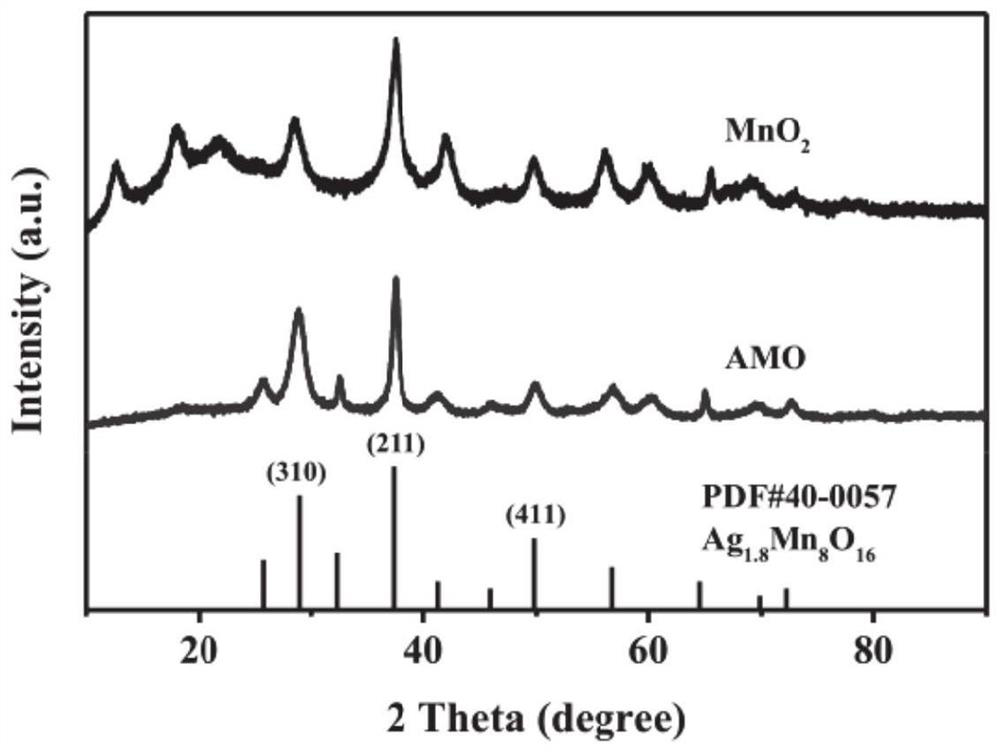

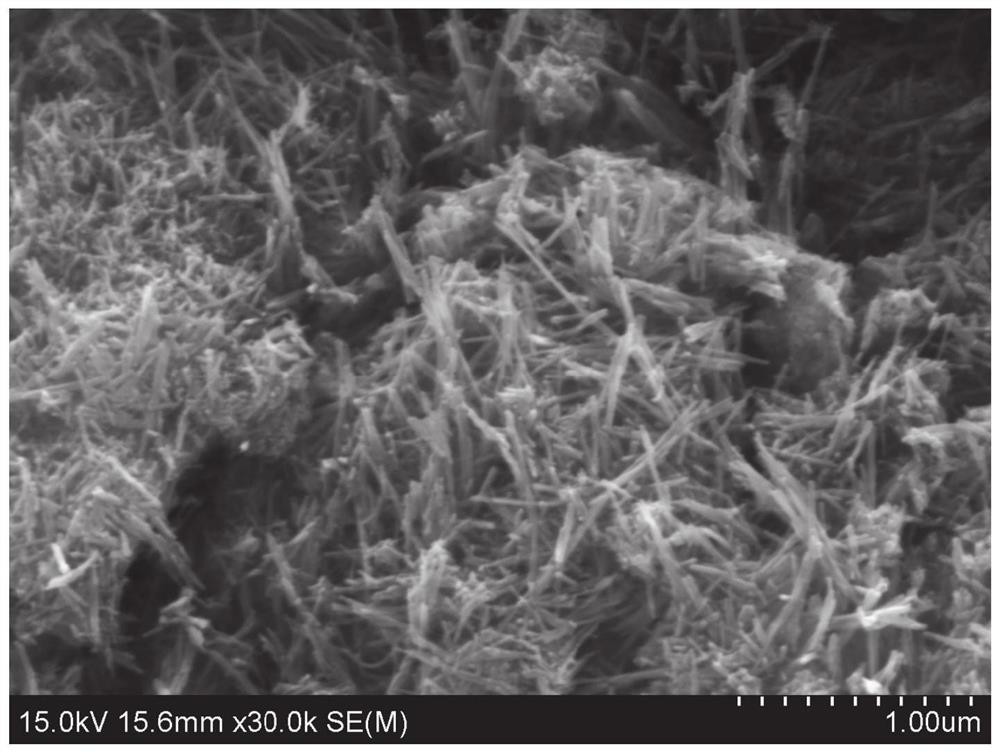

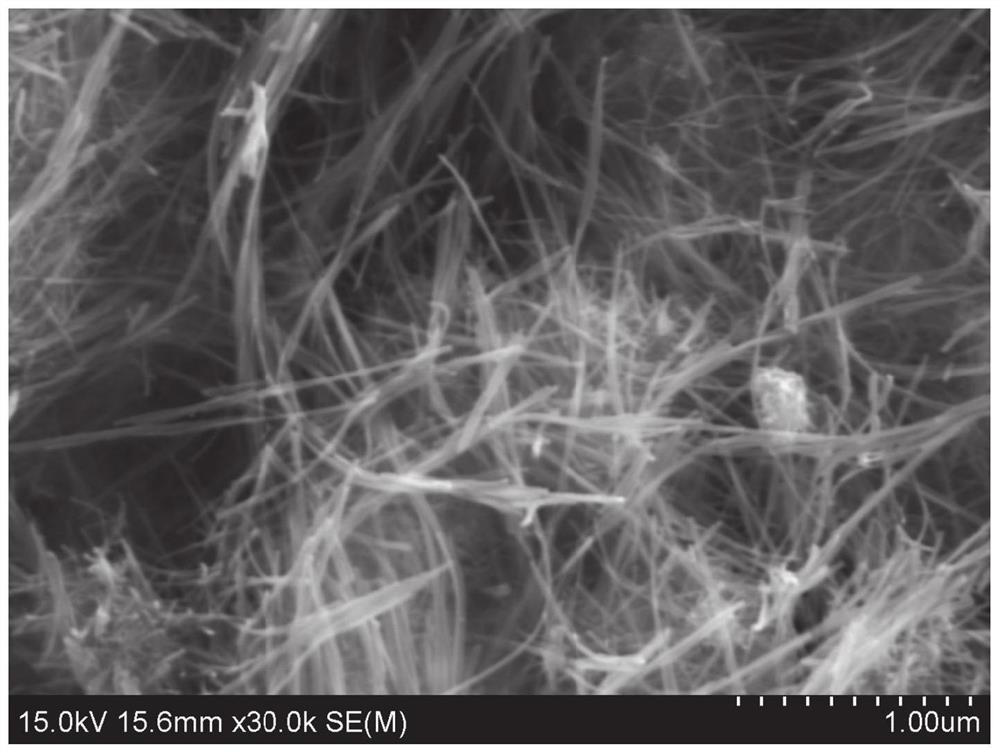

[0068] figure 1 It is the XRD comparison chart of the manganese dioxide prepared in embodiment 3 and the silver manganese oxide material after si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com