Perovskite film preparation method based on anti-solution bath, and solar cell

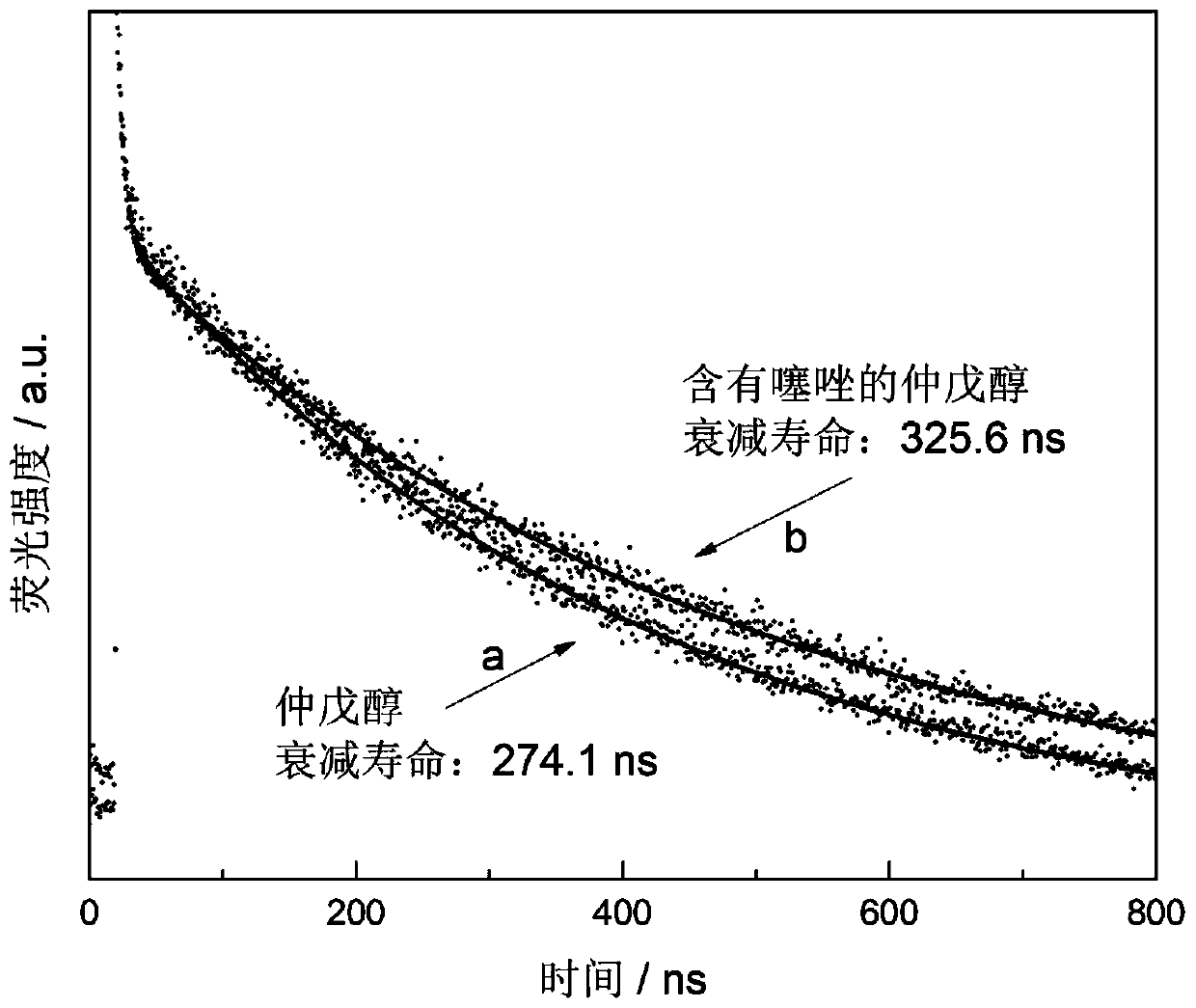

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult to prepare large area, large human factors, complex process, etc., to improve carrier concentration and extraction efficiency, optimize Crystal growth and physicochemical properties, the effect of reducing the concentration of surface defect states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the first step, use deionized water, acetone, optical glass cleaner, deionized water, and isopropanol to ultrasonically clean the ITO glass substrate (15Ω / □). After drying in an oven at 60°C for 6 hours, spin-coated SnO with a concentration of 5wt% on the ITO surface 2 Nanoparticle dispersion, wherein the solvent used is distilled water. The spin coating speed is 3000rpm, and the spin coating time is 20s. Subsequently, the substrate was transferred to a heating table and annealed at 150°C for 30 minutes.

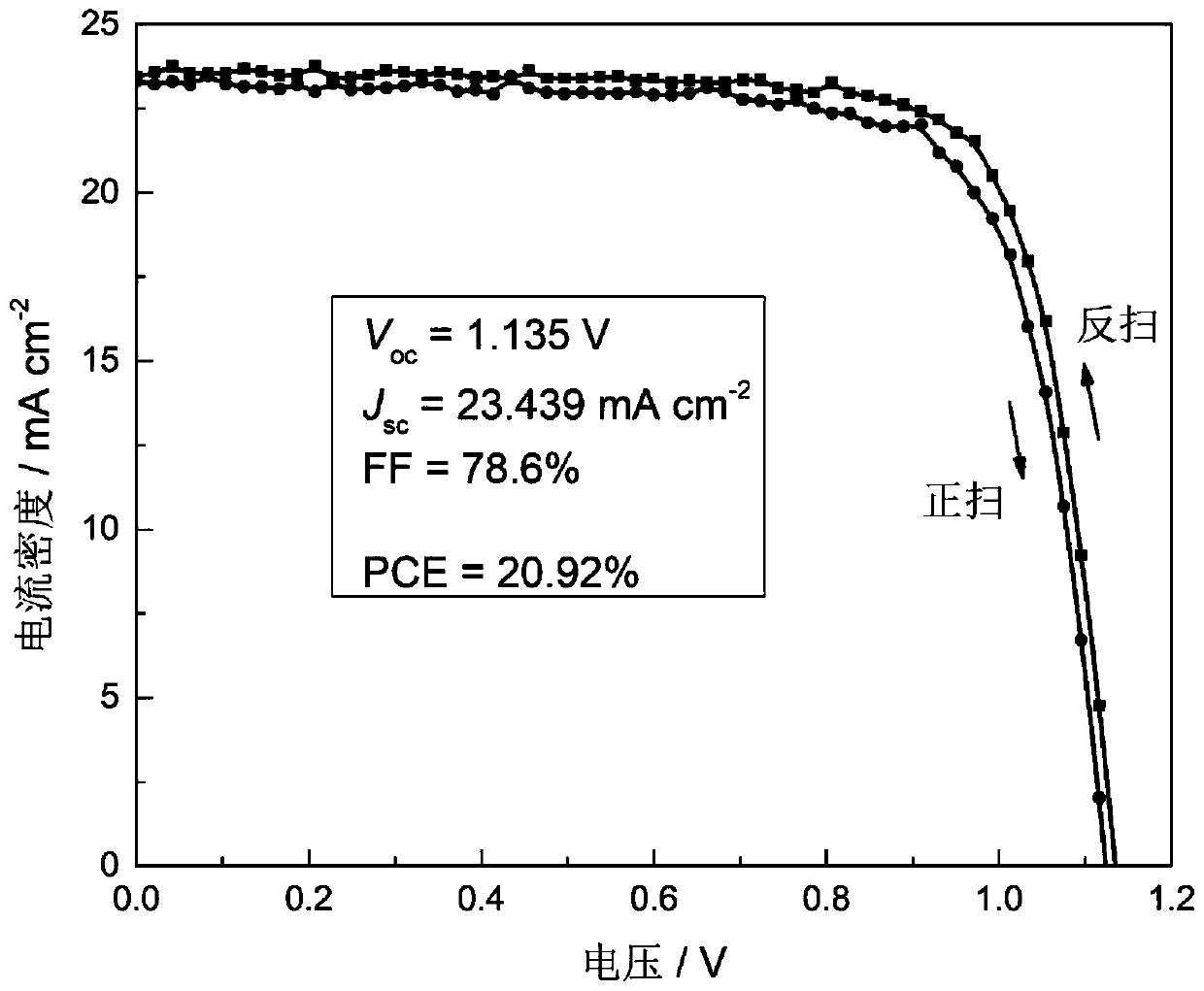

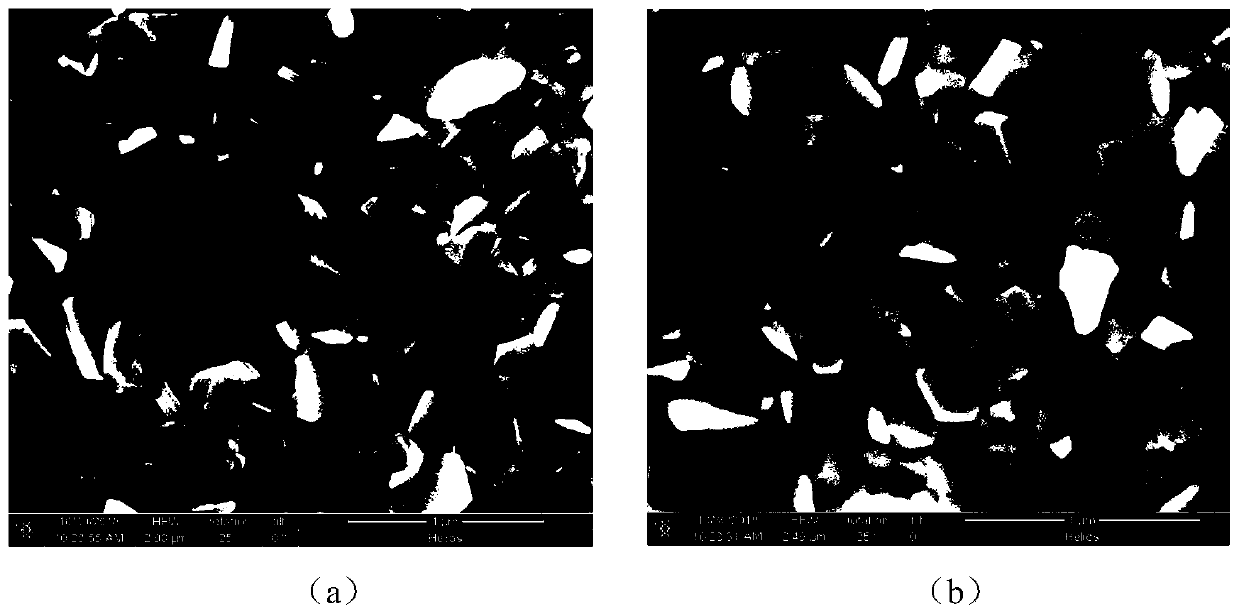

[0033] The second step is to add SnO 2 Film substrate transfer to N 2 Atmosphere glove box, and load 1.3mol / L perovskite precursor liquid on SnO 2 On the film, the spin coating speed is 6000 rpm, and the spin coating time is 10 s. The formula of the perovskite precursor fluid is: the chemical composition is FA 0.81 MA 0.10 Cs 0.04 PbI 2.55 Br 0.40 The perovskite is dissolved in a mixed solvent of DMF, DMSO and NMP (V / V / V=15:4:1). After the spin coating is finished, ...

Embodiment 2

[0037] In the second step, the solute of the counter solution was replaced with pyrazine, and the optimal concentration was 2-10 mmol / L. The preparation method of the remaining steps was the same as in Example 1. The energy conversion efficiency of such perovskite solar cells can reach -20%.

Embodiment 3

[0039] In the second step, the solute of the counter solution is replaced with formamidine hydrochloride, the optimal concentration is 4-12 mmol / L, and the preparation method of the remaining steps is the same as in Example 1. The energy conversion efficiency of such perovskite solar cells can reach -20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com