Fabrication method and application of one-dimensional MOF@ZIF core-shell structure

A technology of core-shell structure and ethanol, which is applied in the field of synthesis of functional nanomaterials, can solve the problems of low specific capacity and poor rate performance restricting the development of lithium-ion batteries, and achieve high porosity, less demand for raw materials and equipment types, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1. Preparation of Co-BTC, Zn / Co-BTC, Zn / Co-MOF-74 powder.

[0045] (1) Dissolve 0.43g of 1,3,5- trimesic acid in 90ml of deionized water to form solution A 1 , dissolve 0.50g of cobalt acetate tetrahydrate in 10ml of deionized water to form solution B 1 , solution A 1 When preheated to 85°C in a water bath, add solution B 1 After adding, stirring and reacting at a constant temperature for 15 minutes, the product was centrifuged, washed with ethanol, and dried in an oven at 80° C. to obtain Co-BTC powder.

[0046] (2) Dissolve 0.43g of 1,3,5- trimesic acid in 90ml of deionized water to form solution A 2 , dissolve 0.053g cobalt acetate tetrahydrate and 0.42g zinc acetate dihydrate in 10ml deionized water to form solution B 2 , solution A 2 When preheated to 100°C in an oil bath, add solution B to 2After adding, stirring and reacting at a constant temperature for 1 min, the product was centrifuged, washed with ethanol, and dried in an oven at 80° C. to obtai...

Embodiment 2

[0049] Example 2. Preparation of Co-BTC@ZIF from Co-BTC

[0050] (1) Disperse 80mg Co-BTC powder in 90ml ethanol-water mixed solution (V 醇 : V 水 =19:1), forming a homogeneous suspension C 1 , 4g 2-methylimidazole is dissolved in 10ml ethanol water mixed solution (V 醇 : V 水 =19:1), forming solution D 1 , the C 1 Placed in a water bath and preheated to 25°C, the C 1 The solution was added to 2-methylimidazole solution D 1 The reaction was stirred at a constant temperature for 90 min.

[0051] (2) The product was centrifuged, washed with ethanol, and dried in an oven at 80°C to obtain Co-BTC@ZIF powder.

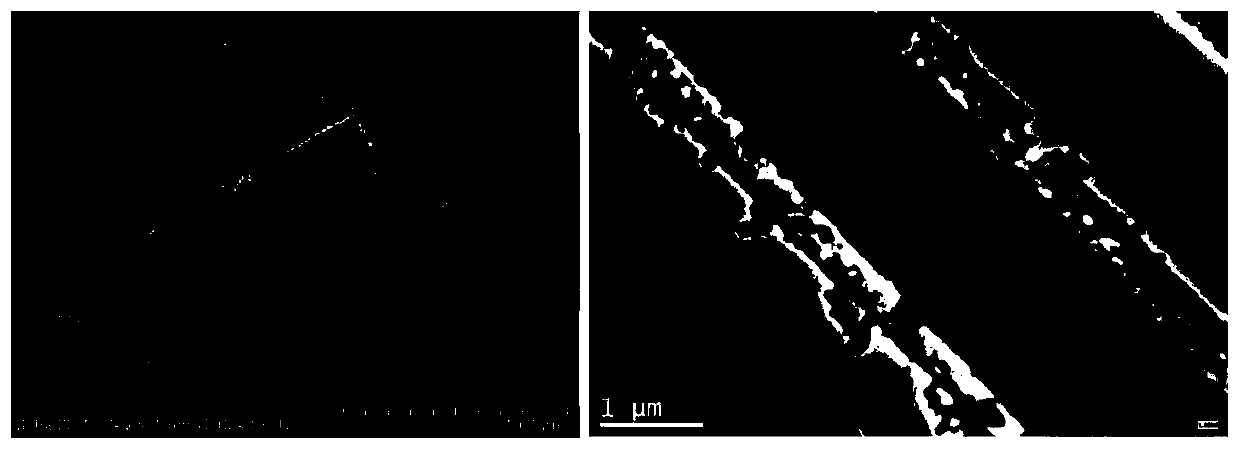

[0052] figure 2 The FESEM images and TEM images of the Co-BTC@ZIF powder prepared in this example are shown in the FESEM images. The FESEM images show that the surface of the originally smooth micro-wires has become rough, and the TEM images show a core-shell structure. Figure 5 From the XRD pattern of the Co-BTC@ZIF powder prepared in this example, it can be seen th...

Embodiment 3

[0053] Example 3. Preparation of Zn / Co-BTC@ZIF from Zn / Co-BTC

[0054] (1) Disperse 80mg Zn / Co-BTC powder in 30ml ethanol-water mixed solution (V 醇 : V 水 =9:1), forming a homogeneous suspension C 2 , 4g 2-methylimidazole is dissolved in 10ml ethanol water mixed solution (V 醇 : V 水 =9:1), forming solution D 2 , the C 2 Placed in a water bath and preheated to 45°C, the C 2 The solution was added to 2-methylimidazole solution D 2 The reaction was stirred at constant temperature for 5 min.

[0055] (2) The product was centrifuged, washed with ethanol, and dried in an oven at 80°C to obtain Zn / Co-BTC@ZIF powder.

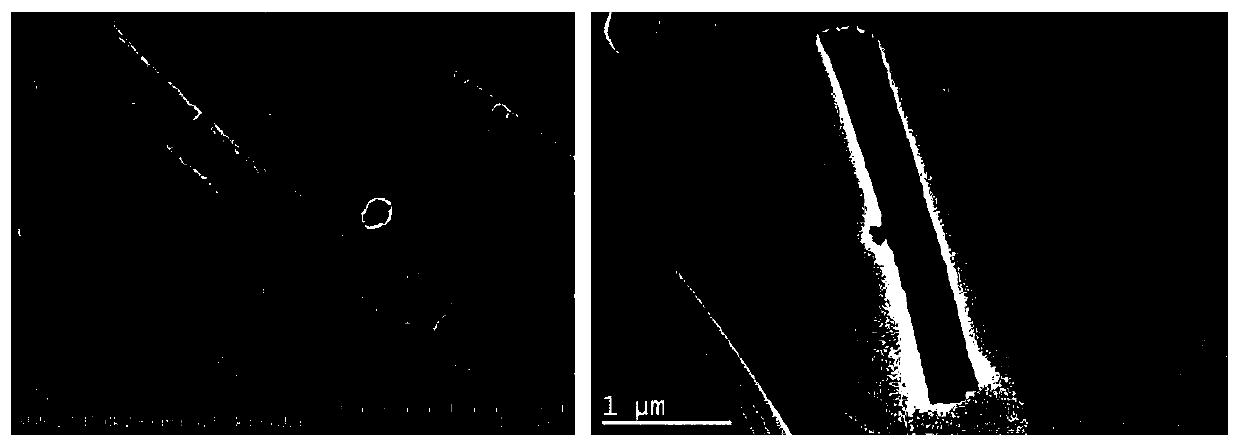

[0056] image 3 FESEM images and TEM images of the Zn / Co-BTC@ZIF powder prepared in this example. The FESEM image showed that the surface of the originally smooth nanowires became rough, and the TEM image showed a core-shell structure. Image 6 From the XRD pattern of the Zn / Co-BTC@ZIF powder prepared in this example, it can be seen that the Zn / Co-BTC diffracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com