Additive manufacturing method of metal glass lattice structure composite material part

A lattice structure, metallic glass technology, applied in the field of additive manufacturing, can solve the problems of difficult processing, warping deformation cost, poor stability, etc., and achieve the effect of improving comprehensive mechanical properties, improving hard and brittle characteristics, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for manufacturing a metal-glass composite part with a body-centered cubic lattice structure, including the following steps:

[0050] Step 1. Prefabricate Fe-based (Fe-Co-Cr-Mo-C-B-Y) metallic glass powder with a particle size of 30-50 μm;

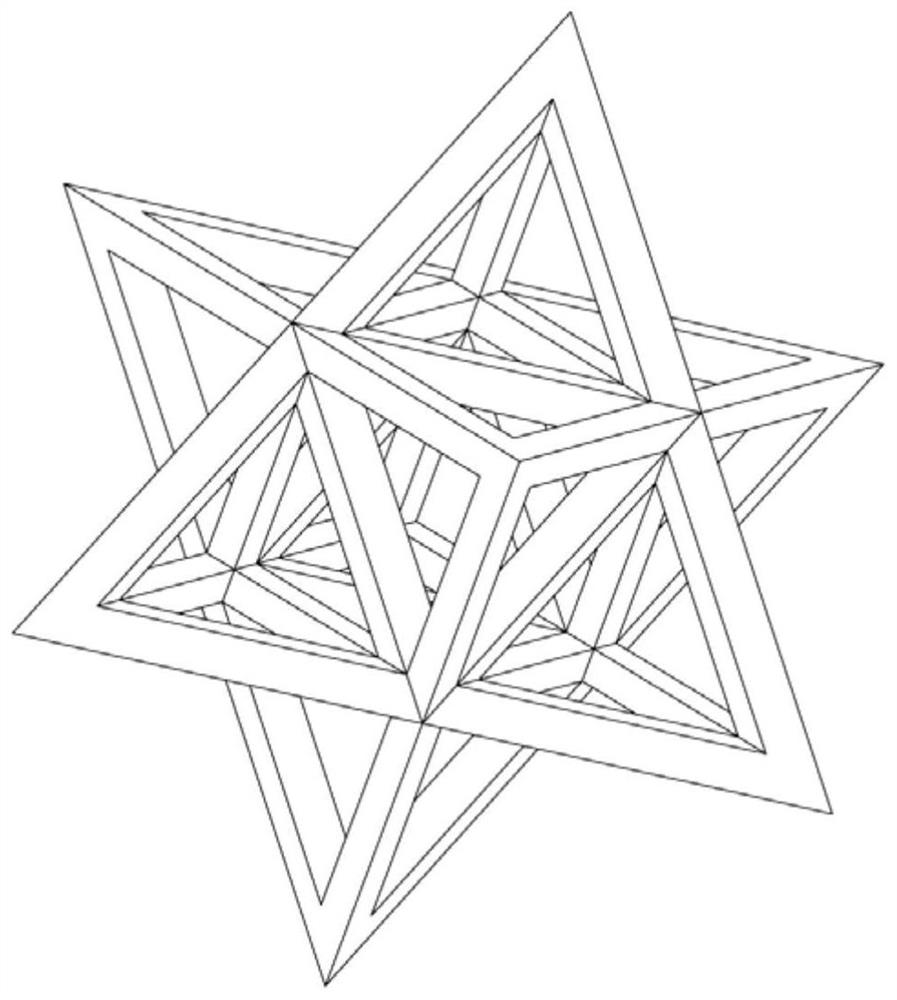

[0051] Step 2. On the premise of ensuring the strength of a given Fe-based metallic glass part, improve the plasticity of the part, and build a face-centered cubic microscopic element geometric model based on topology theory, such as figure 1 As shown, the homogenization method is used to predict the performance of the metal glass face-centered cubic lattice structure model, optimize the parameters of the microstructure unit, and determine the geometric parameters and arrangement direction of the microstructure unit;

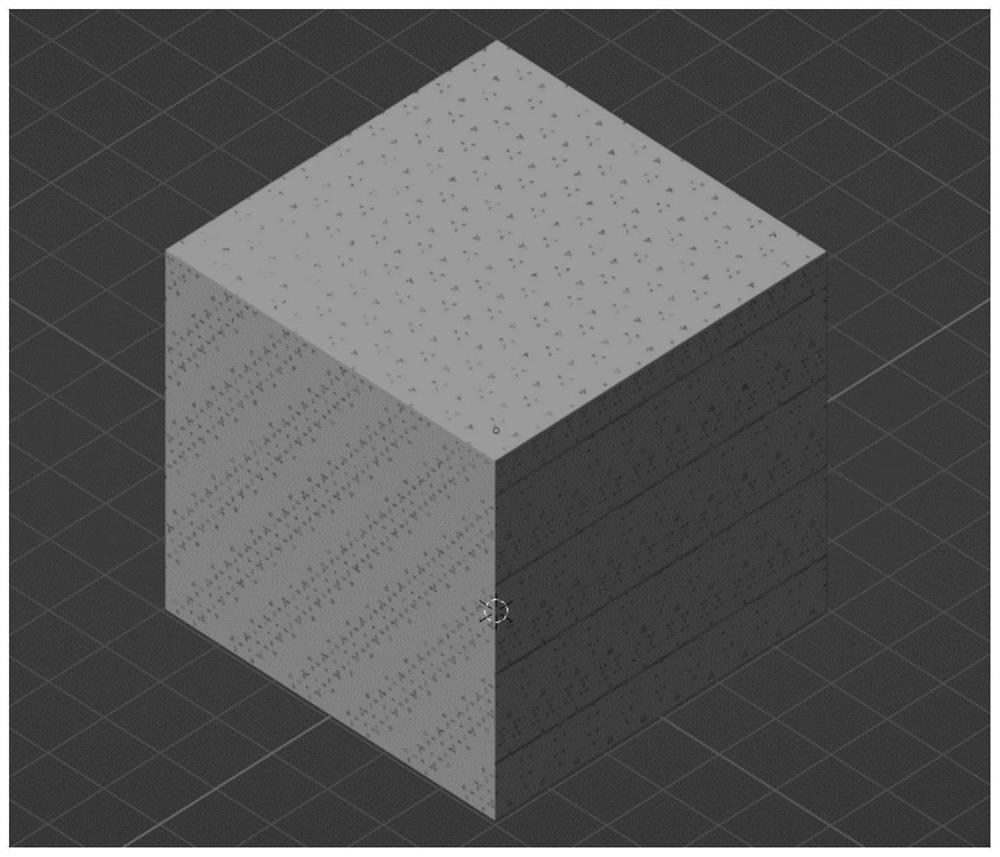

[0052] Step 3. Use Blender software to build a model of a metal glass part, in this case a square block. Then, according to the designed parameters, a face-centered cubic microscopic ...

Embodiment 2

[0058] This embodiment provides a method for manufacturing a metal-glass composite part with a face-centered cubic lattice structure:

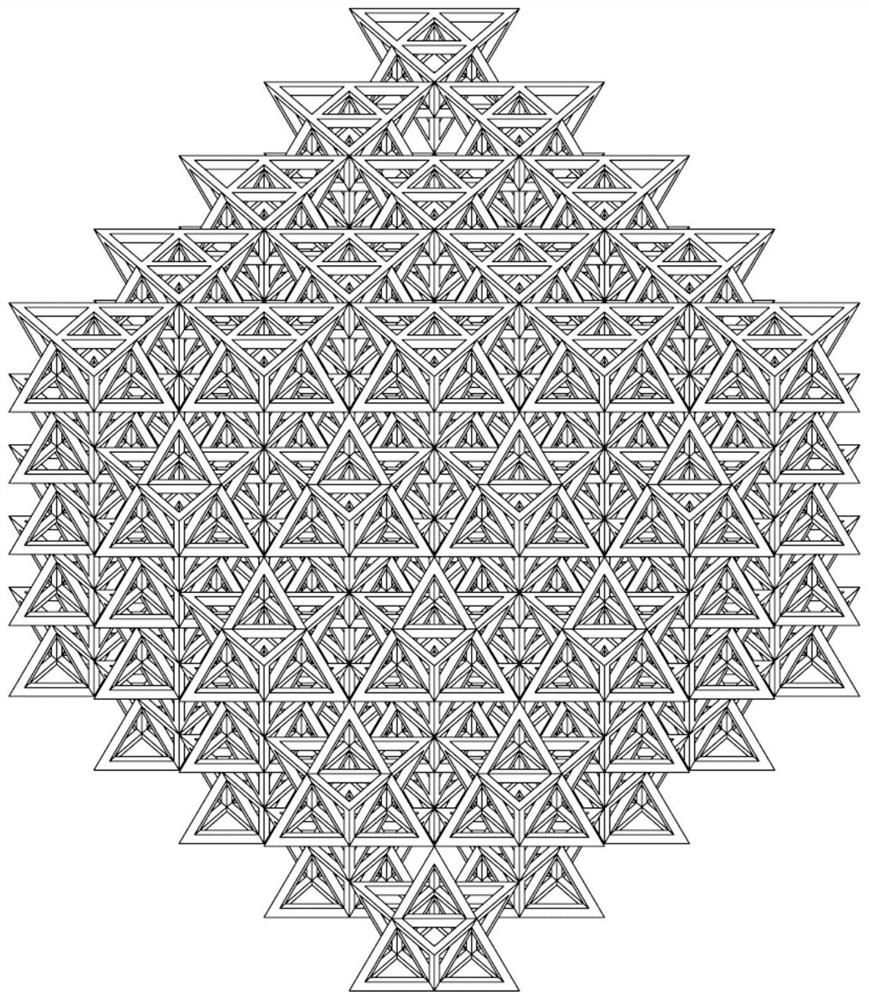

[0059] The overall process is similar to the operation steps for the manufacture of metal-glass composite parts with body-centered cubic lattice structure, the only difference is that the model of the lattice skeleton is different. For face-centered cubic lattice structure metallic glass composite parts, the lattice structure should refer to Image 6 model.

Embodiment 3

[0061] The present embodiment provides a method for manufacturing a metal-glass composite part with a random skeleton structure:

[0062] The overall process is similar to that of the body-centered cubic lattice structure metal-glass composite part fabrication, the only difference is the model of the skeleton structure. For metal-glass composite parts with random structure, the skeleton structure should be randomly generated by the program. Ideally, the skeleton structure and the shape of the formed part are as follows Figure 7 shown. It should be noted that random skeleton structures are usually not used as independent structures, and the description in this example is only to show the morphology of such structures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com