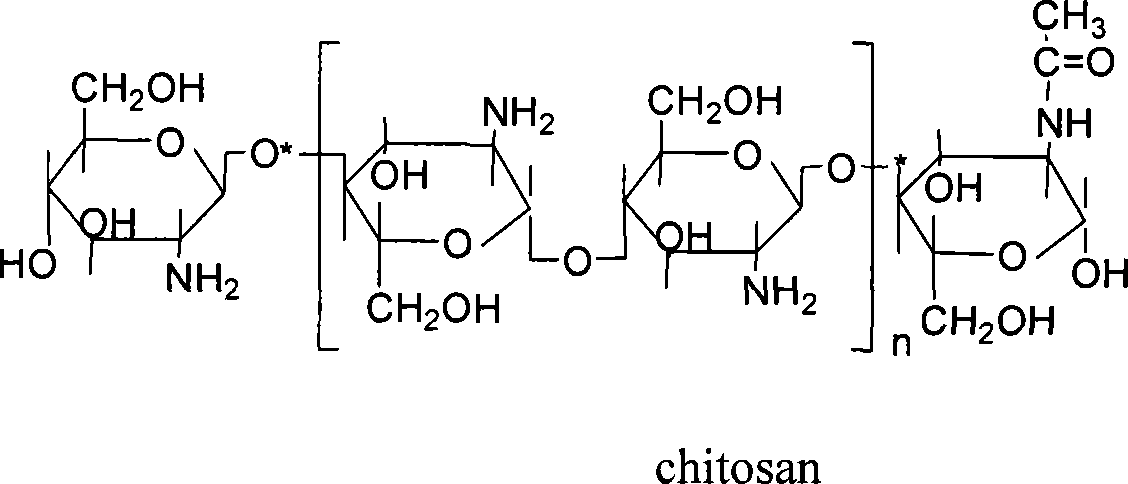

Method for preparing active chitosan oligosaccharide by using ozone to degrade chitosan

A technology of ozone degradation and chitosan, which is applied in the field of preparation of active chitosan oligosaccharides, can solve the problems of long production cycle, limited degradation degree, and decreased amino group content, and achieve the effects of reduced production cost, shortened reaction cycle, and fast degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

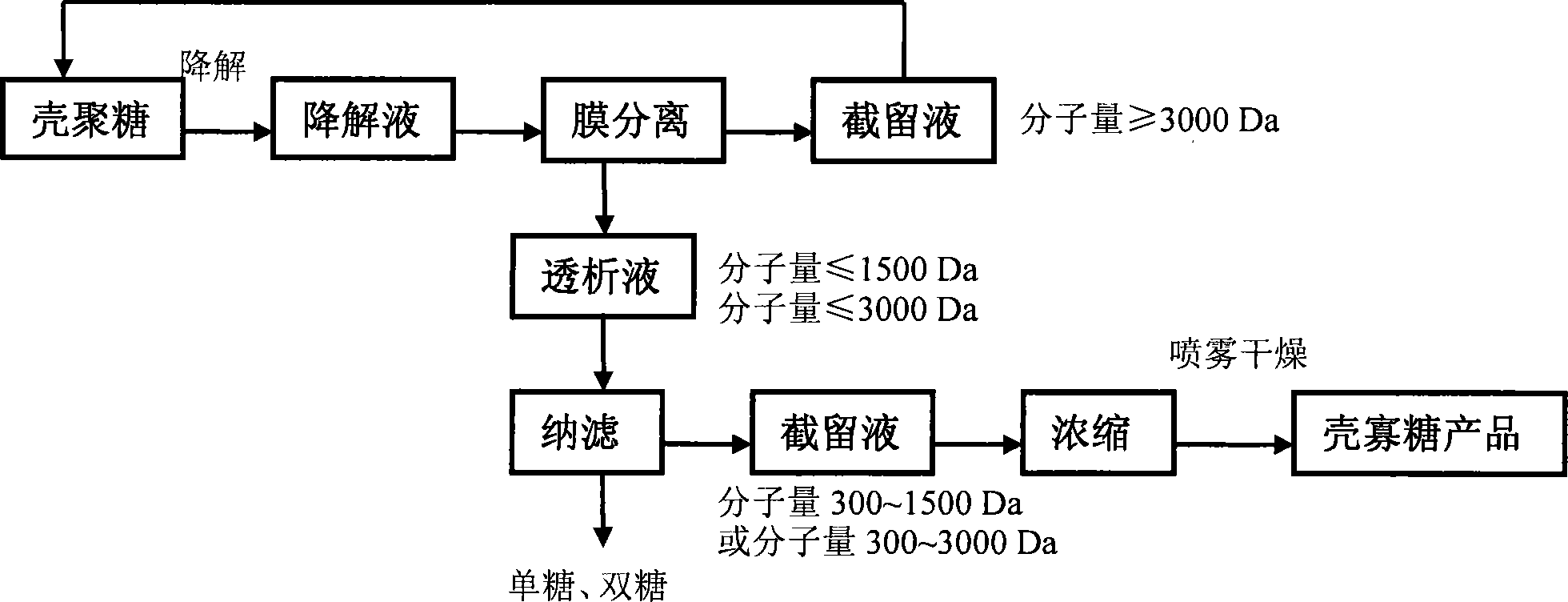

[0026] Specific embodiment one: present embodiment prepares active chitosan oligosaccharide according to the following steps: a. the concentration that 20g chitosan (Mw=560kDa, DD=78.5%) is dissolved in 480ml is the acetic acid solution of 2% (mass percentage) , adjust the pH to about 3.0 with hydrochloric acid. b. Place the chitosan solution in a 500ml Erlenmeyer flask, add 5mg Ag / Al 2 o 3 , and then placed in a water bath in an ultrasonic oscillator. c. Open the valve of the compressed oxygen cylinder, open the ozone generator, import the ozone into the chitosan solution by the gas distributor at a speed of 65ml / min, and simultaneously run the agitator to stir at a speed of 750r / min. After reacting for 1 hour, the viscosity of the measured solution had dropped to 10% of the initial value, and the ozone generator was turned off to stop the reaction. d. After microfiltration, the degradation liquid is pumped into an ultrafiltration device with a molecular weight cut-off of ...

specific Embodiment 2

[0027] Specific embodiment two: present embodiment prepares active chitosan oligosaccharide according to the following steps: a. 25g chitosan (Mw=250kDa, DD=90%) is dissolved in the concentration of 475ml and is in the hydrochloric acid solution of 2%. b. Place the chitosan solution in a 500ml Erlenmeyer flask, add 5mg Ni / SiO 2 , and then placed in a water bath in an ultrasonic oscillator. c. Open the valve of the compressed oxygen cylinder, open the ozone generator, import the ozone into the chitosan solution by the gas distributor at a speed of 100ml / min, and simultaneously run the stirrer to stir at a speed of 650r / min. After reacting for 1.5 h, the viscosity of the measured solution had dropped to 8% of the initial value, and the ozone generator was turned off to stop the reaction. d. After microfiltration, the degradation liquid is pumped into an ultrafiltration device with a molecular weight cut-off of 1500 Da, and the degradation products greater than 1500 Da are retur...

specific Embodiment 3

[0028] Specific embodiment three: present embodiment prepares active chitosan oligosaccharide according to the following steps: a. 45g chitosan (Mw=250kDa, DD=85%) is dissolved in the concentration of 955ml and is in the hydrochloric acid solution of 2.5%. b. Put chitosan solution in 1500ml ozone degradation tank, add 10mg Ni / Al 2 o 3, react at room temperature 20°C. c. Open the ultrasonic oscillator of the ozone degradation tank, open the compressed oxygen cylinder valve, open the ozone generator, import the ozone into the chitosan solution by the gas distributor at a speed of 150ml / min, and run the stirrer at the same time at 800r / min stirring speed. After reacting for 1.5 h, the viscosity of the measured solution had dropped to 6% of the initial value, and the ozone generator was turned off to stop the reaction. d. After microfiltration, the degradation liquid is pumped into an ultrafiltration device with a molecular weight cut-off of 2000Da, and the degradation products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com