Preparation method of titanium dioxide dense film for dye-sensitized solar cell

A solar cell, titanium dioxide technology, applied in photosensitive equipment, circuits, capacitors, etc., can solve the problems of unsuitable large-scale industrialization, environmental pollution, and harsh process conditions, and achieve the promotion of industrialization, low cost, and improved battery performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

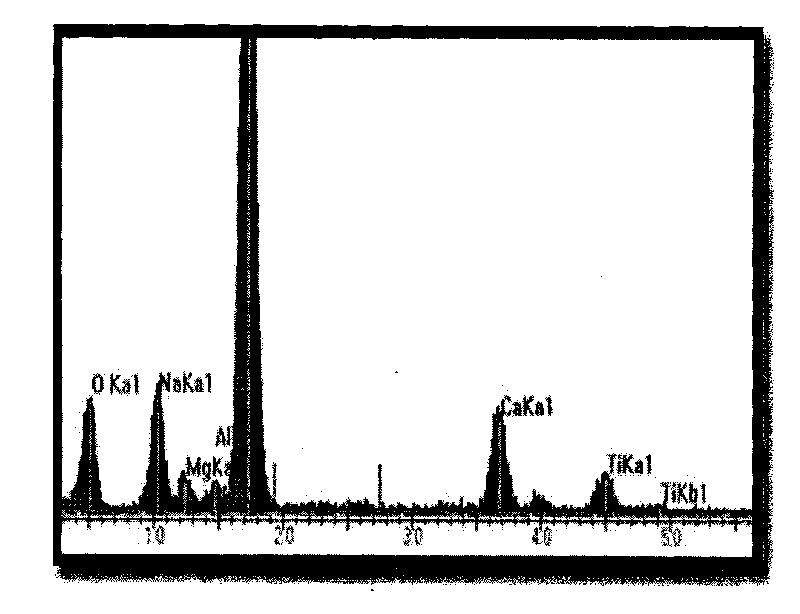

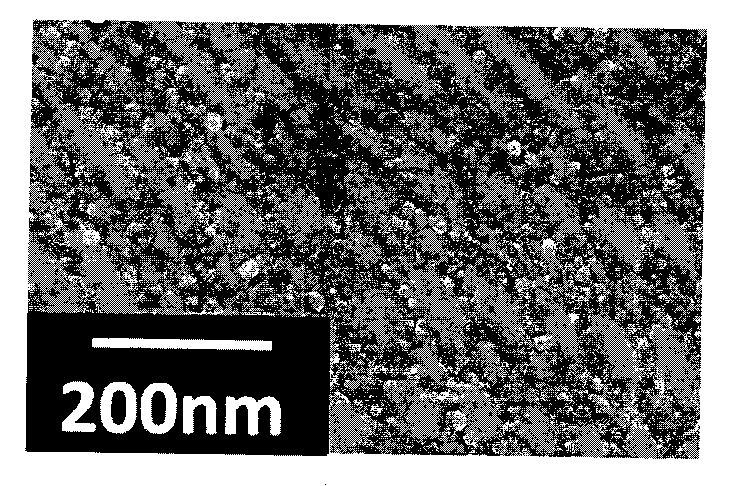

[0017] First, mix titanyl sulfate and water at 15-20°C with a titanium ion concentration of 2 mol / L, then let it stand for 14 hours to clarify, filter and co-precipitate with 1 mol / L ammonia water and titrate until the pH value is equal to 7. The resulting white precipitate was centrifuged and washed with Ba(NO 3 ) 2 The solution had no detectable residual SO 4 2- ions, then at 60°C, press Ti 4+ : organic acid: the molar ratio of hydrogen peroxide is 1: 5: 5 to dissolve, and then the pH value of this solution is adjusted to 7 with ammonia water, and after standing for 12 hours, the aqueous titanium dioxide sol suitable for coating film is obtained; Spray on the surface of FTO glass, spin coating at 3000rpm for 20 seconds to form a film; finally vacuum dry at 60°C for 30 minutes, and heat treat at 450°C for 3 hours to obtain a dense film of nano-titanium dioxide with good crystallization.

Embodiment 2

[0019] First, mix titanyl sulfate and water at 15-20°C according to the ratio of titanium ion concentration of 1mol / L, then let it stand for 12 hours to clarify, filter and co-precipitate with 1mol / L ammonia water and titrate until the pH value is equal to 7. The resulting white precipitate was centrifuged and washed with Ba(NO 3 ) 2 The solution had no detectable residual SO 4 2- ion so far, then at 30°C, press Ti 4+ : The molar ratio of organic acid: hydrogen peroxide is 1: 2: 2 to dissolve, and then the pH value of this solution is adjusted to 7.5 with ammonia water, and after standing for 14 hours, a water-based titanium dioxide sol suitable for coating is obtained; it is sprayed On the surface of FTO glass, spin-coat at 1000 rpm for 30s to form a film; then vacuum dry at 60°C for 30min, and heat treat at 300°C for 6h to obtain a dense nano-titanium dioxide film with good crystallization.

Embodiment 3

[0021] First, mix titanyl sulfate and water at 15-20°C with a ratio of titanium ion concentration of 4mol / L, then let it stand for 18 hours to clarify, filter and co-precipitate with 1mol / L ammonia water and titrate until the pH value is equal to 7. The resulting white precipitate was centrifuged and washed with Ba(NO 3 ) 2 The solution had no detectable residual SO 4 2- ions, then at 80°C, press Ti 4+ : The molar ratio of organic acid: hydrogen peroxide is 1: 10: 10 to dissolve, and then the pH value of this solution is adjusted to 8 with ammonia water, and after standing for 16 hours, the aqueous titanium dioxide sol suitable for coating is obtained; it is sprayed On the surface of FTO glass, spin-coat at 4000 rpm for 10s to form a film; then vacuum dry at 60°C for 30min, and heat treat at 500°C for 2h to obtain a dense nano-titanium dioxide film with good crystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com