Lithium ion battery negative electrode and pre-lithiation method and application thereof

A lithium-ion battery, pre-lithiation technology, applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of low efficiency in the first week, achieve short reaction time, promote energy density and cycle stability Improvement and controllable effect of lithiation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Under the protection of an inert atmosphere, mix biphenyl and lithium in an equimolar ratio, and disperse them in a DME solvent. After stirring, a DME (ethylene glycol dimethyl ether) solution of biphenyl lithium is obtained, and the hard carbon electrode (the loading is about 2 mg, containing 90% hard carbon) immersed in 1 mL of 0.25 mol / L DME solution of lithium biphenyl, and reacted for 1 h. After the reaction was complete, it was washed three times with DME and dried for later use.

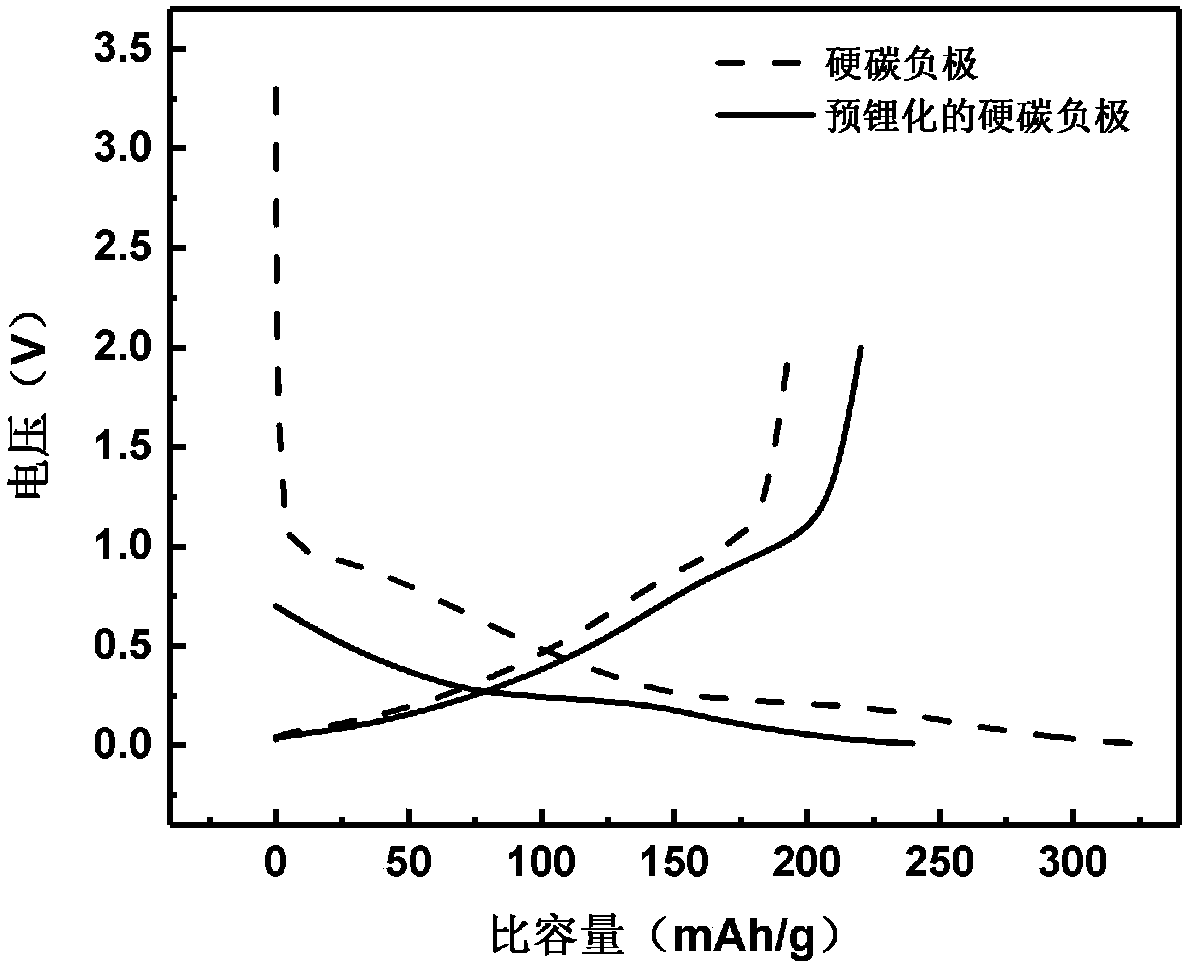

[0026] (2) The hard carbon electrode before and after pre-lithiation is used as the positive electrode, and the lithium metal is used as the negative electrode, and the ternary electrolyte (1MLiPF 6 EC / DEC / DMC (v:v:v=1:1:1)) Assemble the half-cell, and conduct a charge-discharge test. The charge and discharge curve of the first week is as follows:

[0027] Depend on figure 1 It can be seen that after pre-lithiation, the open-circuit voltage of the half-cell is reduced from 3.301V...

Embodiment 2

[0029] (1) Under the protection of an inert atmosphere, mix naphthalene and lithium in an equimolar ratio, and disperse them in a DME solvent. After stirring, a DME solution of naphthalene lithium is prepared. 70%) was immersed in 1 mL of 0.125 mol / L DME solution of lithium naphthalene and reacted for 4 h. After the reaction was complete, it was washed three times with DME and dried for later use.

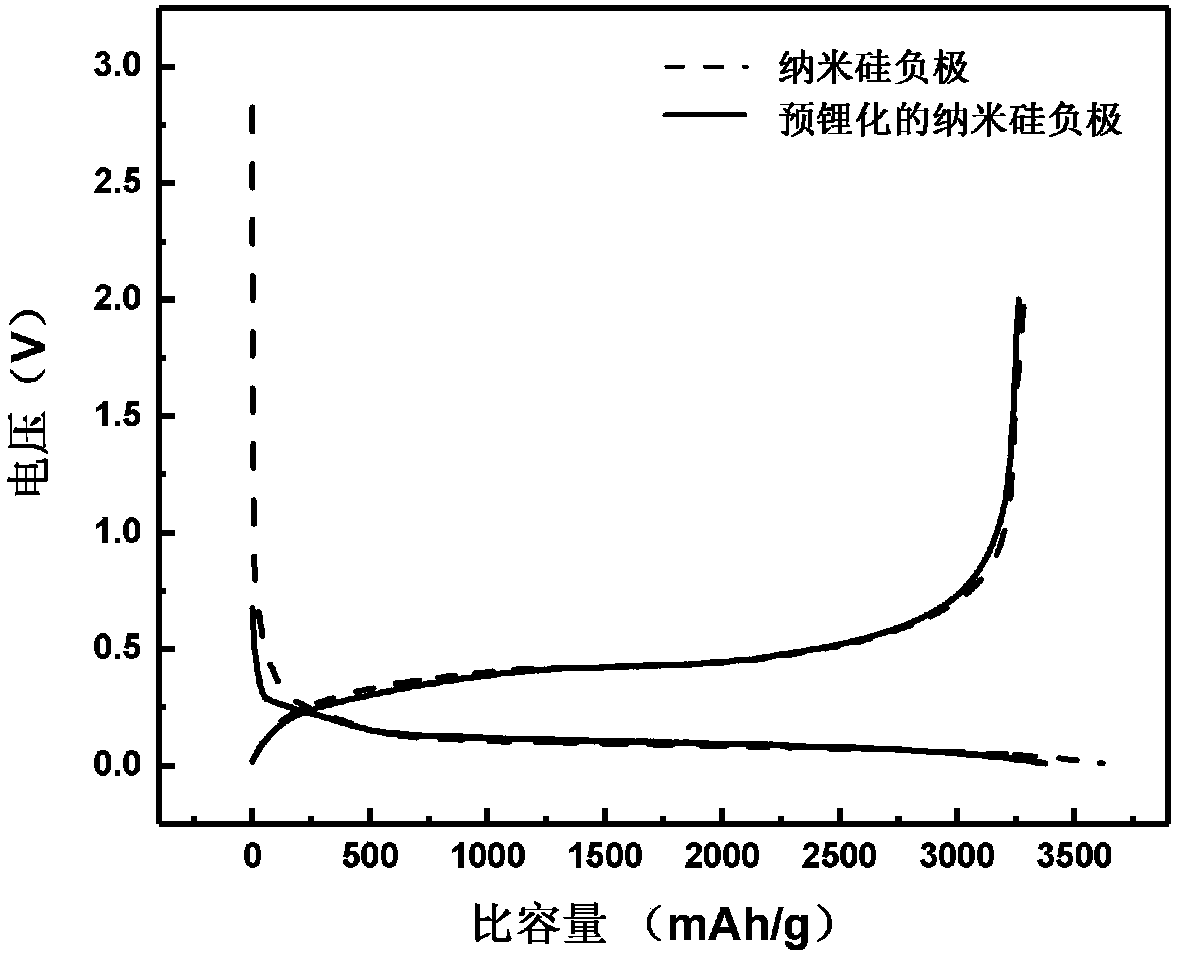

[0030] (2) With the nano-silicon electrode before and after pre-lithiation as the positive electrode and the lithium metal as the negative electrode, use a ternary electrolyte (1MLiPF 6 EC / DEC / DMC (v:v:v=1:1:1)) Assemble the half-cell, and conduct a charge-discharge test. The charge and discharge curve of the first week is as follows:

[0031] Depend on figure 2 It can be seen that after pre-lithiation, the open-circuit voltage of the half-cell decreased from 2.824V to 0.677V, and the efficiency increased from 86.67% to 96.66% in the first week.

[0032] (3) The nano-silicon e...

Embodiment 3

[0035] (1) Under the protection of an inert atmosphere, mix naphthalene and lithium in an equimolar ratio, and disperse them in a DME solvent. The cloth is placed on an antimony electrode (loading capacity is about 2.8mg, containing 80% antimony) and reacted for 0.5h. After the reaction was complete, it was washed three times with DME and dried for later use.

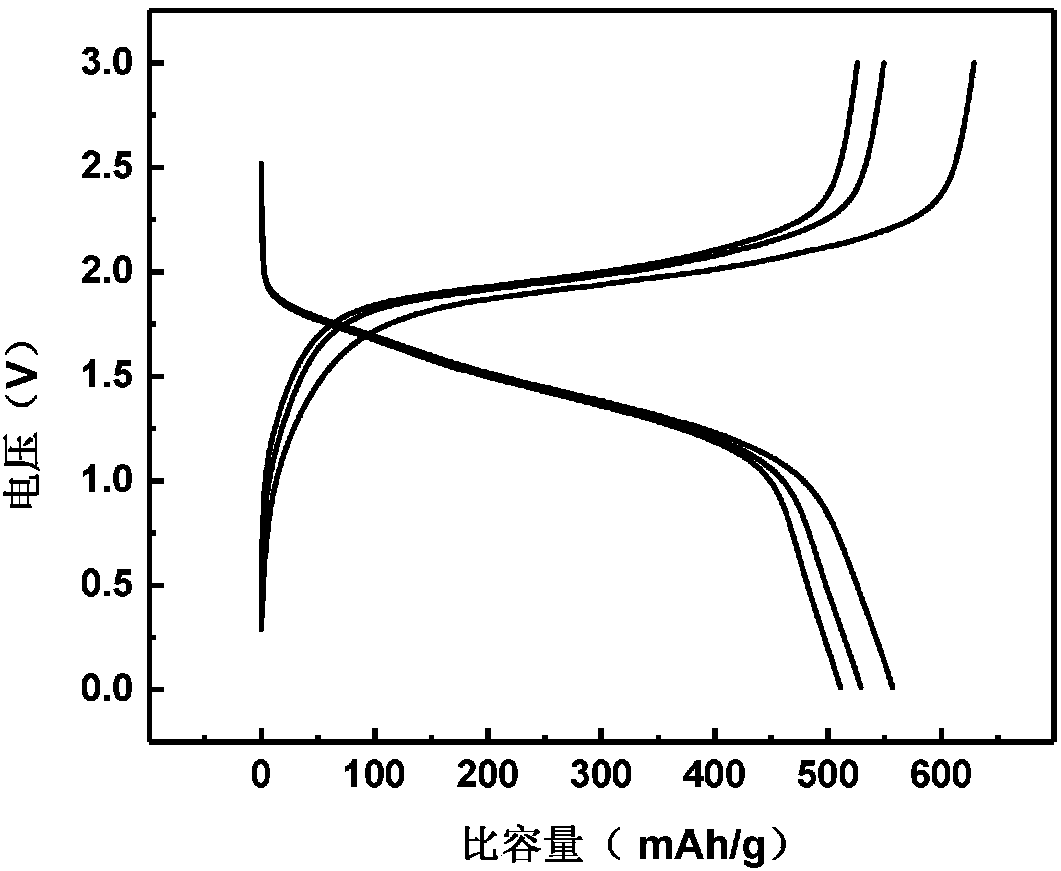

[0036] (2) Using the antimony electrode before and after pre-lithiation as the positive electrode and the lithium metal as the negative electrode, use a ternary electrolyte (1MLiPF 6 EC / DEC / DMC (v:v:v=1:1:1)) Assemble the half-cell, and conduct charge-discharge test. The charge and discharge curve of the first week is as follows:

[0037] Depend on Figure 4 It can be seen that after pre-lithiation, the open-circuit voltage of the half-cell decreased from 3.13V to 1.76V, and the efficiency increased from 69.73% to 91.69% in the first week.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com