Poly (carbonate-ether)tetrahydric alcohol, preparation method of poly (carbonate-ether)tetrahydric alcohol and carbon dioxide based shape memory polyurethane

A carbon dioxide and carbonate technology, applied in the field of organic synthesis, can solve the problems of difficult molecular structure, high cost, long synthesis cycle, etc., and achieve the effects of adjustable shape recovery performance, reduced production cost, and excellent shape memory performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

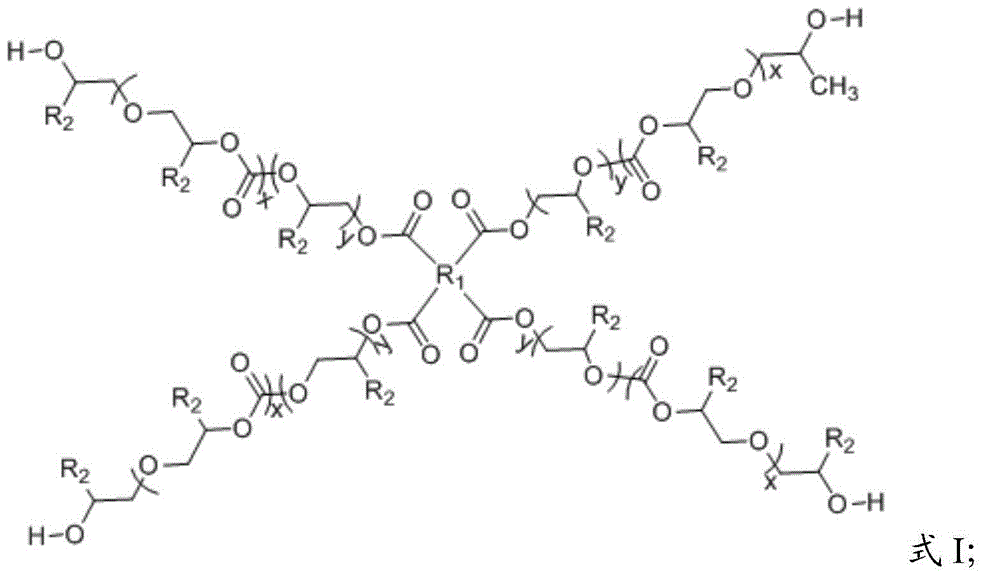

[0050] The invention provides a kind of preparation method of poly(carbonate-ether) tetrahydric alcohol, comprises the following steps:

[0051] Zn based on rare earth doping 3 [Co(CN) 6 ] 2 In the presence of a double metal cyanide catalyst, a tetravalent carboxylic acid compound is used as a chain transfer agent, and carbon dioxide and an epoxy compound are polymerized to obtain the above-mentioned poly(carbonate-ether) tetraol.

[0052] In the present invention, there is no special limitation on the carbon dioxide, and carbon dioxide well known to those skilled in the art can be used. In the present invention, the pressure of the carbon dioxide is preferably 2MPa-10MPa, more preferably 3MPa-7MPa.

[0053] In the present invention, the epoxy compound preferably includes one or more of ethylene oxide, propylene oxide, butylene oxide, cyclohexane oxide and epichlorohydrin, more preferably includes ethylene oxide One or more of alkanes, propylene oxide and epichlorohydrin. ...

Embodiment 1

[0090] Embodiment 1 (preparation of the Y-DMC doped with rare earth)

[0091] 0.78g (0.004mol) YCl3 and 11.42g (0.084mol) ZnCl 2 Dissolve in the mixed solution formed by 60mL deionized water and 30mL tert-butanol, heat the formed solution to 50°C and keep the temperature for 20min, then add 1.32g (0.004 mol) analytically pure K 3 [Co(CN) 6 ] and 20mL of deionized water, dropwise added for 45min, kept the reaction constant at 50°C, stirred for 1h to obtain a suspension; centrifuged the resulting suspension for 10min with a centrifuge (5000rpm), poured out the separated clear liquid , the sediment was washed with 60mL 50°C mixed solution of TBA and H2O for 5 times, and finally with TBA for 1 time, TBA and H 2 TBA and H in the mixed solution of O 2 The volume ratio of O was 30 / 30, 40 / 20, 50 / 10, 60 / 0 respectively, the stirring speed during the washing process was 5000 rpm, the centrifugation time was 10 min, and then the obtained sediment was vacuum dried at 50 °C for 10 h , ...

Embodiment 2

[0092] Embodiment 2 (preparation of Nd-DMC doped with rare earth)

[0093] 0.1g (0.004mol) Nd(NO 3 ) 3 and 11.42g (0.084mol) ZnCl 2 Dissolve in the mixed solution formed by 60mL deionized water and 30mL tert-butanol, heat the formed solution to 50°C and keep the temperature for 20min, then add 1.32g (0.004 mol) analytically pure K 3 [Co(CN) 6 ] and 20mL of deionized water, dropwise added for 45min, kept the reaction constant at 50°C, stirred for 1h to obtain a suspension; centrifuged the resulting suspension for 10min with a centrifuge (5000rpm), poured out the separated clear liquid , the sediment was successively washed with 60mL 50℃ TBA and H 2 The mixed solution of O was pulped and washed 5 times, and finally washed once with TBA pulp, TBA and H 2 TBA and H in the mixed solution of O 2 The volume ratio of O was 30 / 30, 40 / 20, 50 / 10, 60 / 0 respectively, the stirring speed during the washing process was 5000 rpm, the centrifugation time was 10 min, and then the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com