Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

A lithium metal battery and surface modification technology, which is applied to the surface modification of lithium metal negative electrodes of lithium metal batteries, in the field of lithium metal batteries, can solve problems such as low Coulombic efficiency, lithium dendrite growth, safety issues, etc., and achieve good repeatability, Higher discharge capacity and lower side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The surface modification modification of metal lithium negative electrode comprises the following steps:

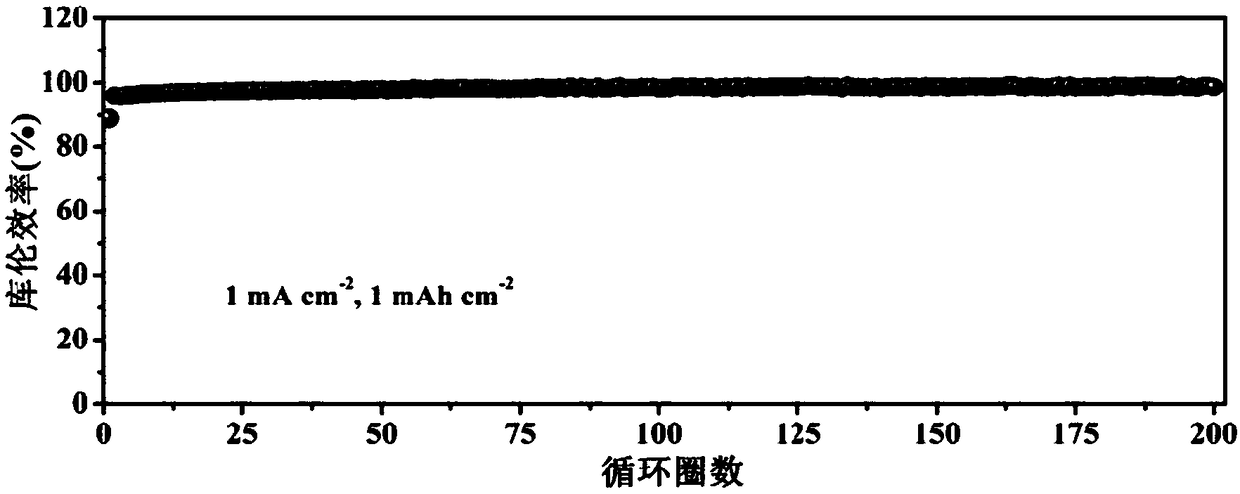

[0032] Under the protection of dry argon gas, the polished and polished lithium metal sheet was immersed in the ionic liquid 1-butyl-2,3-dimethylimidazolium tetrafluoroborate ([BMIm]BF 4 ), take it out after 60 minutes of fluorination reaction, wipe off the residual liquid with non-stick wool wipe paper, and form a protective layer rich in lithium fluoride on the surface of the lithium metal sheet, the thickness of the protective layer is 200nm, and the fluorinated Lithium-coated lithium metal anode.

[0033] The SEM picture of the surface of the metal lithium sheet without fluorination treatment is as follows Figure 1a shown by Figure 1a As can be seen, there are obvious cracks and unevenness on the surface of the metal lithium sheet before the fluorination treatment; and the metal lithium sheet (such as Figure 1b Shown) the surface is free of cracks and smoot...

Embodiment 2

[0036] Under the protection of dry high-purity argon gas, the polished and polished lithium metal sheet was immersed in the ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate ([EMIm]BF 4 ), take it out after 10 minutes of fluorination reaction, wipe off the residual liquid with non-stick wool wipe paper, and form a layer of protective layer rich in lithium fluoride on the surface of the lithium metal sheet, the thickness of the protective layer is 30nm, and the fluorinated Lithium-coated lithium metal anode.

[0037] The prepared lithium fluoride-coated metal lithium negative electrode is assembled into a symmetrical battery, the separator is a PP film, and the electrolyte is lithium bistrifluoromethanesulfonylimide (concentration in the electrolyte is 1M) dissolved in a volume ratio of 1 : 1 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME) with the addition of 2 wt% LiNO 3 mixed solution. At a current density of 2mA / cm 2 , The deposition capacity is 1mAh / cm...

Embodiment 3

[0039] Under the protection of dry argon gas, the polished and polished lithium metal sheet was immersed in the ionic liquid 1-hexyl-3-methylimidazolium tetrafluoroborate ([HMIm]BF 4 ), take it out after 2 minutes of fluorination reaction, wipe off the residual liquid with non-stick wool wipe paper, and form a layer of protective layer rich in lithium fluoride on the surface of the lithium metal sheet, the thickness of the protective layer is 5nm, and the fluorinated Lithium-coated lithium metal anode.

[0040] The lithium fluoride-coated metal lithium negative electrode is assembled into a full battery as a negative electrode matched with the lithium cobalt oxide positive electrode material; the separator of the full battery is a PP / PE film, and the electrolyte is lithium bistrifluoromethanesulfonylimide ( 1 M in the electrolyte) was dissolved in 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME) at a volume ratio of 1:1 and added 8 wt% LiNO 3 mixed solution. The test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com