Graphene bonded copper wire and preparation method thereof

A technology of bonding copper wire and graphene, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, electric solid-state devices, etc., can solve the problems of easy oxidation and hardness of copper wires, and achieve easy oxidation, increase conductivity and heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

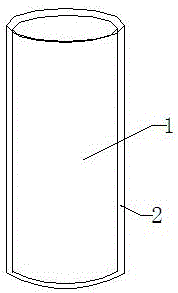

[0020] Such as figure 1 As shown, a graphene-bonded copper wire includes a copper wire 1 and a graphene layer 2 wrapped outside the copper wire 1, the wire diameter of the copper wire 1 is 0.016-0.050mm, and the thickness of the graphene layer 2 is 0.001-0.2um.

[0021] A kind of preparation method of graphene bonding copper wire of the present invention, comprises the following steps:

[0022] S1. Oxidize the graphite flakes to form a graphene oxide aqueous solution;

[0023] S2, coating the graphene oxide solution on the surface of the bonding copper wire;

[0024] S3, reducing the graphene oxide to graphene, and directly covering the surface of the bonding copper wire;

[0025] S4. Coating an annealing solution on the surface of the graphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com