Pressure-reduction, alkali-addition and ammonia-distillation system

A technology of ammonia distillation and ammonia distillation tower, which is applied in the field of deammonization of ammonia water in coal coking, can solve the problems that ammonia distillation wastewater cannot meet the water quality requirements of biological dephenolization, reduce operating pressure and temperature, and achieve simple process changes, small investment, and high efficiency. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

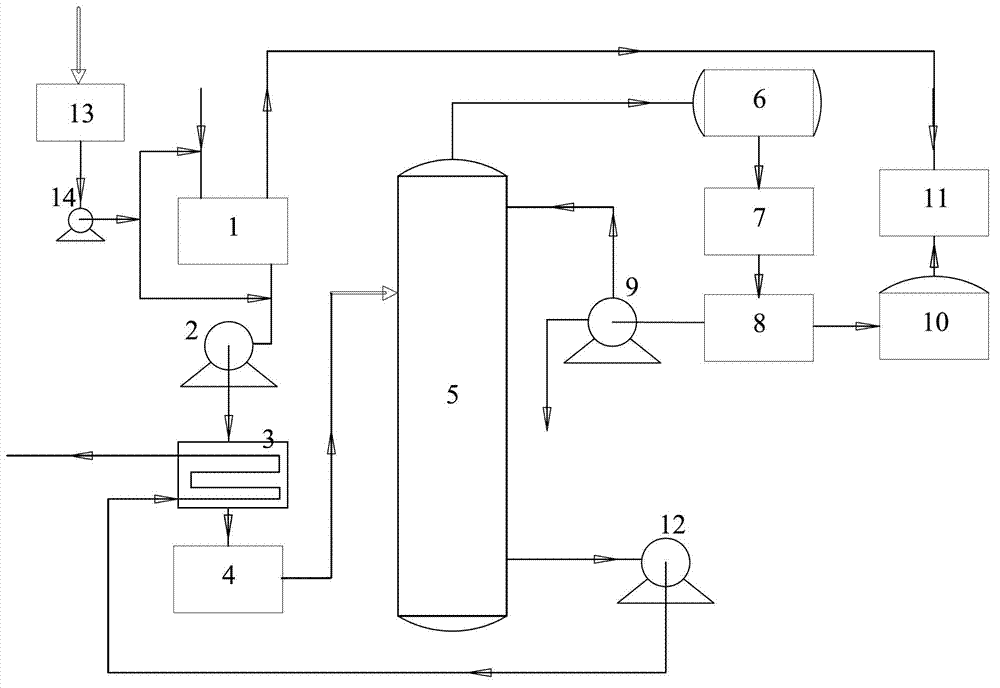

[0015] Such as figure 1 as shown,

[0016] A decompression adding alkali ammonia distillation system, including residual ammonia water tank 1, ammonia distillation tower 5, finished ammonia water tank 8, vacuum system 10, lye tank 13 and tail gas recovery device 11 several major functional parts, through several major functional equipment The effective combination forms a vacuum distillation system.

[0017] The outlet of the remaining ammonia water tank 1 is connected to the inlet of the ammonia distillation tower 5 after passing through the first pump 2, heat exchanger 3 and preheater 4 in sequence, and the inlet is located at the upper part. The gas outlet at the top of the ammonia distillation tower 5 is connected to the finished ammonia water tank 8 through the shrinker 6 and the cooler 7 in sequence, and the finished ammonia water tank is a storage container for the finished ammonia water. The finished ammonia water tank is connected to the vacuum system through pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com