Micro-foamed plylactic acid material and preparation method thereof

A polylactic acid and micro-foaming technology, which is applied in the field of polylactic acid micro-foaming materials and its preparation, can solve problems such as low melt viscosity and melt strength, small number of molecular branched chains of PLA, and easy bursting of bubbles, etc., to achieve Uniform cell size, simple foaming process, and low material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

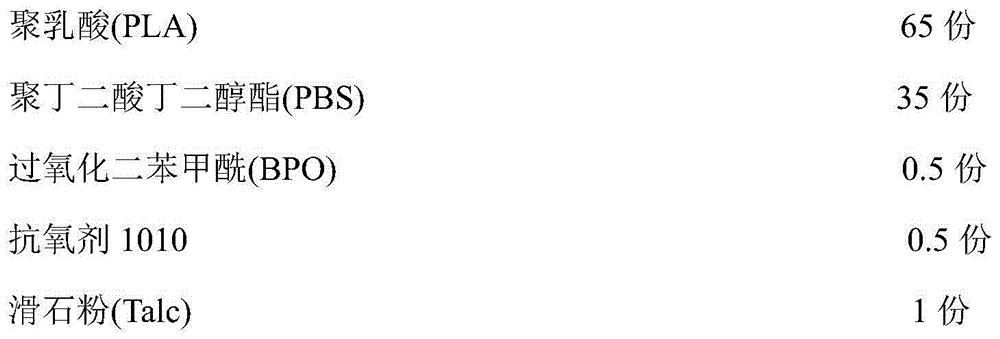

[0016] The raw material components are:

[0017]

[0018] PLA and Antioxidant 1010 were vacuum-dried at 80°C for 12h and cooled in vacuum, and the PBS particles were dried in a common blast oven at 60°C for 12h. Mix PLA, PBS, BPO and antioxidant 1010 uniformly in a high-speed blender. Then use a co-rotating twin-screw extruder to extrude and granulate. The temperature of each section of the extruder screw is: 120°C, 155°C, 160°C, 165°C, 175°C, 165°C, 160°C, and the screw speed is 160rpm. The obtained modified polylactic acid particles were vacuum dried at 50° C. for 12 h. The obtained pellets were compression-molded in a flat vulcanizer to obtain a molded sample, and the molding temperature was 160°C. Pressure 5MPa, holding time 5min. The obtained sample is swelled in a supercritical carbon dioxide foaming kettle body, the swelling temperature is controlled to be 70°C, the swelling pressure is 15Mpa, the swelling time is 80min, and the pressure is released quickly, and t...

Embodiment 2

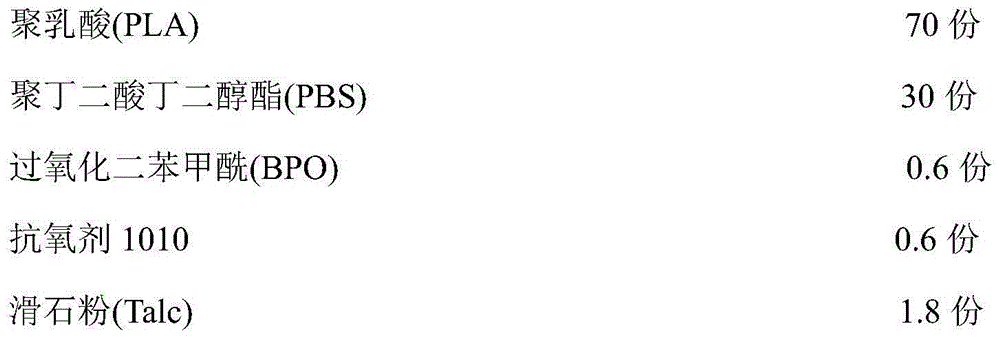

[0020] The raw material components are:

[0021]

[0022] PLA and Antioxidant 1010 were vacuum-dried at 80°C for 12h and cooled in vacuum, and the PBS particles were dried in a common blast oven at 60°C for 12h. Mix PLA, PBS, BPO and antioxidant 1010 uniformly in a high-speed blender. Then use a co-rotating twin-screw extruder to extrude and granulate. The temperature of each section of the extruder screw is: 125°C, 160°C, 165°C, 170°C, 180°C, 170°C, 165°C, and the screw speed is 170rpm. The obtained modified polylactic acid particles were vacuum dried at 50° C. for 12 h. The obtained pellets were compression-molded in a flat vulcanizer to obtain a molded sample, and the compression-molding temperature was 165°C. The pressure is 8MPa, and the holding time is 6min. Swell the obtained sample in a supercritical carbon dioxide foaming kettle body, control the swelling temperature to 80°C, the swelling pressure to 20Mpa, and the swelling time to 100min, and quickly release th...

Embodiment 3

[0024] The raw material components are:

[0025]

[0026] PLA and Antioxidant 1010 were vacuum-dried at 80°C for 12h and cooled in vacuum, and the PBS particles were dried in a common blast oven at 60°C for 12h. Mix PLA, PBS, BPO and antioxidant 1010 uniformly in a high-speed blender. Then use a co-rotating twin-screw extruder to extrude and granulate. The temperatures of each section of the extruder screw are: 120°C, 165°C, 170°C, 175°C, 185°C, 175°C, 170°C, and the screw speed is 180rpm. The obtained modified polylactic acid particles were vacuum dried at 50° C. for 12 h. The obtained pellets were compression-molded in a flat vulcanizer to obtain a molded sample, and the compression-molding temperature was 170°C. The pressure is 10MPa, and the holding time is 7min. Swell the obtained sample in a supercritical carbon dioxide foaming kettle body, control the swelling temperature to 90°C, the swelling pressure to 25Mpa, and the swelling time to 120min, and quickly release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com